Terratek TBG6 User manual

User Manual - Please read and retain for future

reference.

6”Heavy Duty Bench Grinder

TBG6

LISTED

E154499

Page 1

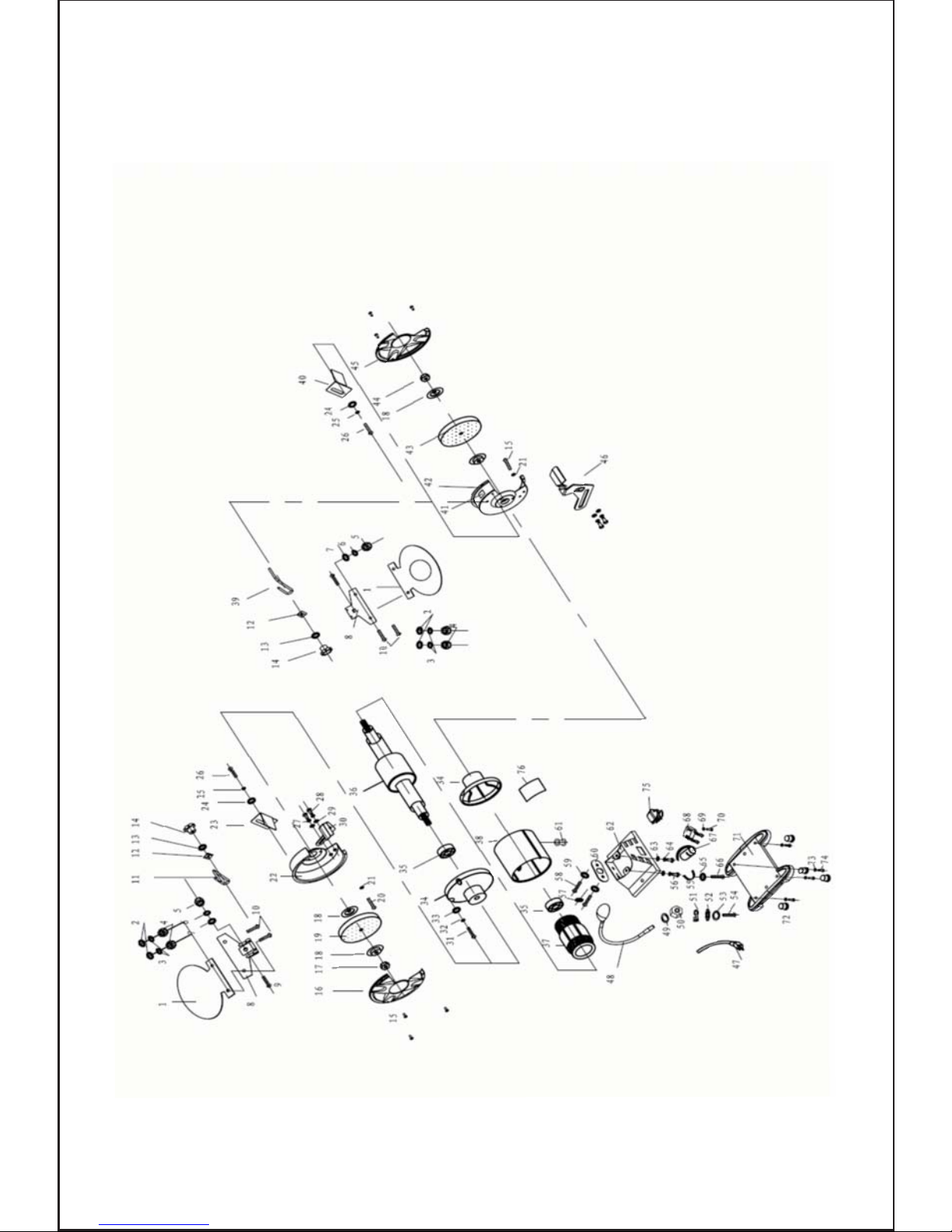

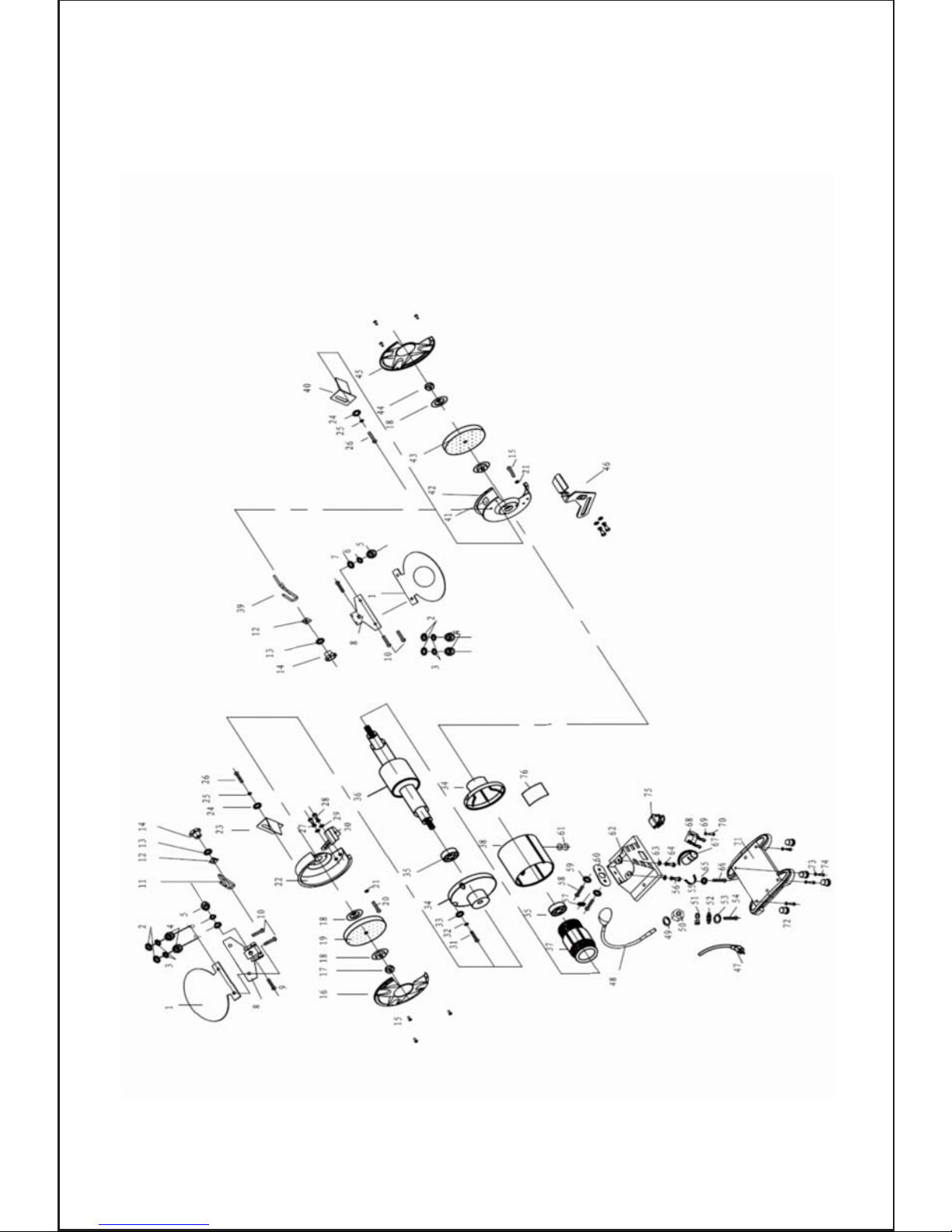

part list

Eye-shield

Washer

Washer

Nut

Nut

Washer

Washer

Eye Shield Bracket

Square Neck Screw

Screw

LEFT EYE SHIELD MOUNTING ROD

Fixing piece

Washer

Nut

Screw

Left Outer Guard

Nut

Wheel flange

Grinder Wheel

Screw

Washer

Left inner guard

Left spark guard

Washer

Washer

Bolt

Washer

Bolt

Washer

Left tool rest

Screw

Washer

Washer

End bell

Bearing

Rotor

Stator

Motor house

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

2

4

4

4

2

2

2

2

2

4

1

2

2

2

6

1

1

4

1

6

6

1

1

2

2

2

4

4

4

1

8

8

8

2

2

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

4

4

4

1

1

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

No Part list QTY.

Right eye shield mounting rod

Right spark guard

Label

Right inner guard

Grinder Wheel

Nut

Right Outer Guard

Right tool rest

Plug & cable

Lamp

Washer

Nut

Ground terminal

Washer

Washer

Screw

Capacitor clip

Bolt

Cable Clip

Screw

Washer

Cable Block

Cable Protector

Base

Washer

Washer

Washer

Screw

Capacitor

Transformer

Washer

Screw

Base plate

Rubber foot

Washer

Screw

Switch

Logo

No Part list QTY.

Contents

Parts List Page 1

Technical Spec Page 3

Safety Instructions Page 4

Using your product Page 9

Maintenance Page 9

Warranty Page 10

Exploded Assembly Diagram

Page 2

Technical Information

Copyright 2008 by ACL Group (Intl) Ltd All rights reserved. This manual or any artwork

contained herein must not be reproduced in any shape or form without the express

written consent of ACL Group (Intl) Ltd. Diagrams within this manual may not be

drawn proportionally. Due to continuing improvements. actual product may differ

slightly from the product described herein.

Read this entire manual before

using this product. Failure to do so can result

in serious injury. Save this manual for future

reference.

Voltage: 120V

Frequency: 60Hz

Power: 1.5A 1/2HP

Speed: 3550rpm

Wheel Size: 6”x1/2”

Work Light : LED

NW/GW: 23/26 lbs.

Page 3

Important SAFETY Information

This symbol is to warn you of potential personal

injury hazards. Please read carefully the notes along side

this warning to avoid possible injury or death.

General Safety Rules

WARNING! Read all instructions. Failure to follow all instructions listed

below may result in electric shock, fire and/or serious injury. The term

“power tool" in all of the warnings listed refers to corded or cordless po-

wer tools.

Work area safety

Read and Keep This Manual

Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control.

Please read carefully all instructions within this manual. Failure to follow all safety

warnings can result in serious personal injury. The term “Power Tool” in all of the following

warnings refers to your main operated (corded) or battery operated (cordless) power

tool

Page 4

Keep work area clean and well lit. Cluttered or dark areas invite accidents. Do not

operate power tools in explosive atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

Electrical safety

Before use. ensure that the power outlet you are using matches the plug on your

power tool and that the voltage of the outlet matches that of your power tool.

Only use grounded extension cards with power tools fitted with 3 pin plugs and if

using outdoors ensure any extension cord is suitable for outdoor use.

Always try to avoid body contact with grounded surfaces, such as radiators, cooking

ranges and any other fixed appliance with metal surfaces.

Do not expose your power tool to wet or damp conditions and NEVER use in rain.

Check regularly the power cord of your machine and any extension cord that you are

using for damage.

Do not carry or pull the machine with the power cord.

Ensure the cord is clear from hot surfaces, oil or sharp objects.

Personal safety

Never use your machine whilst under the influence of alcohol, drugs or medication.

Tiredness can often cause accidents, stay alert.

Never use your machine without the correct guards in place.

Always use ANSI approved eye protection and dust mask. Non slip safety shoes and

hearing protectors should be worn at all times when using your power tool.

Ensure any dust collecting device supplied with your machine is connected correctly

before use.

Ensure all loose clothing, long hair or jewelry is kept clear of the machine.

Before plugging your machine into the power outlet ensure the machine is in the OFF

position and that all blades and accessories being used are secure.

Check that wrenches or adjusting keys have been removed. Any wrench or key left

attached to a moving part can result in injury.

Power tool use and care.

Keep your machine clean and well serviced at all times.

Never adjust or service any power tool before disconnecting from the mains electricity

supply.

Page 5

SAFETY CHECK LIST

Before starting

1 Check that the power outlet matches your power tool plug.

2. Check voltage of power outlet, make sure it matches your power tool

3. Check that power cords are not damaged

4. Check that guards and clamps are secure and working.

5. Check that all wrenches, keys and accessories are clear.

6. Check that blades/cutting parts move freely

7. Check surrounding environment is clear.

8. Check the power tool is fixed securely to its work stand or bench

9. Check that no person under the age of 18 years old will use this tool.

10 Check all children are out of the work area.

11. Check you are working with the correct materials recommended for use with

this tool.

During Use

1. Do not reach across the machine.

2. Do not operate without the correct safety apparel.

3. Do not operate with loose clothing.

4. Keep all hands and limbs a safe distance from the wheels.

5. Ensure all clamps and guards are being used.

6. Do not grind materials not suitable for this machine.

7. Do not use in wet/damp conditions or locations.

8. Always use supports when working with long pieces of metal.

9. Always disconnect from the main power supply before making any adjustments

to this machine.

10. DO NOT LEAVE THIS MACHINE UNATTENDED WHILE CONNECTED TO THE

POWER SUPPLY

Always use the correct tool for the job.

Never force the tool to work harder than it is designed to do.

Never use your machine with broken parts such as switches, supports or leg stands.

ALWAYS keep your power tools away from children.

Keep cutting tools sharp to ensure less stress on the motor.

Replace damaged or dull wheels.

Only have your power tool serviced by a qualified repair agent using manufacturers

recommended parts.

This machine is supplied with all the relevant safety guards and features, it should be

checked before every operation. this manual should be read and kept in a safe place .

Whilst we warn of all the possible risks attached to using power tools

Page 6

any operator must have read and understood the manual and apply their own

caution and common sense when using this machine.

Following this guide will greatly reduce your risk of electric shock or injury.

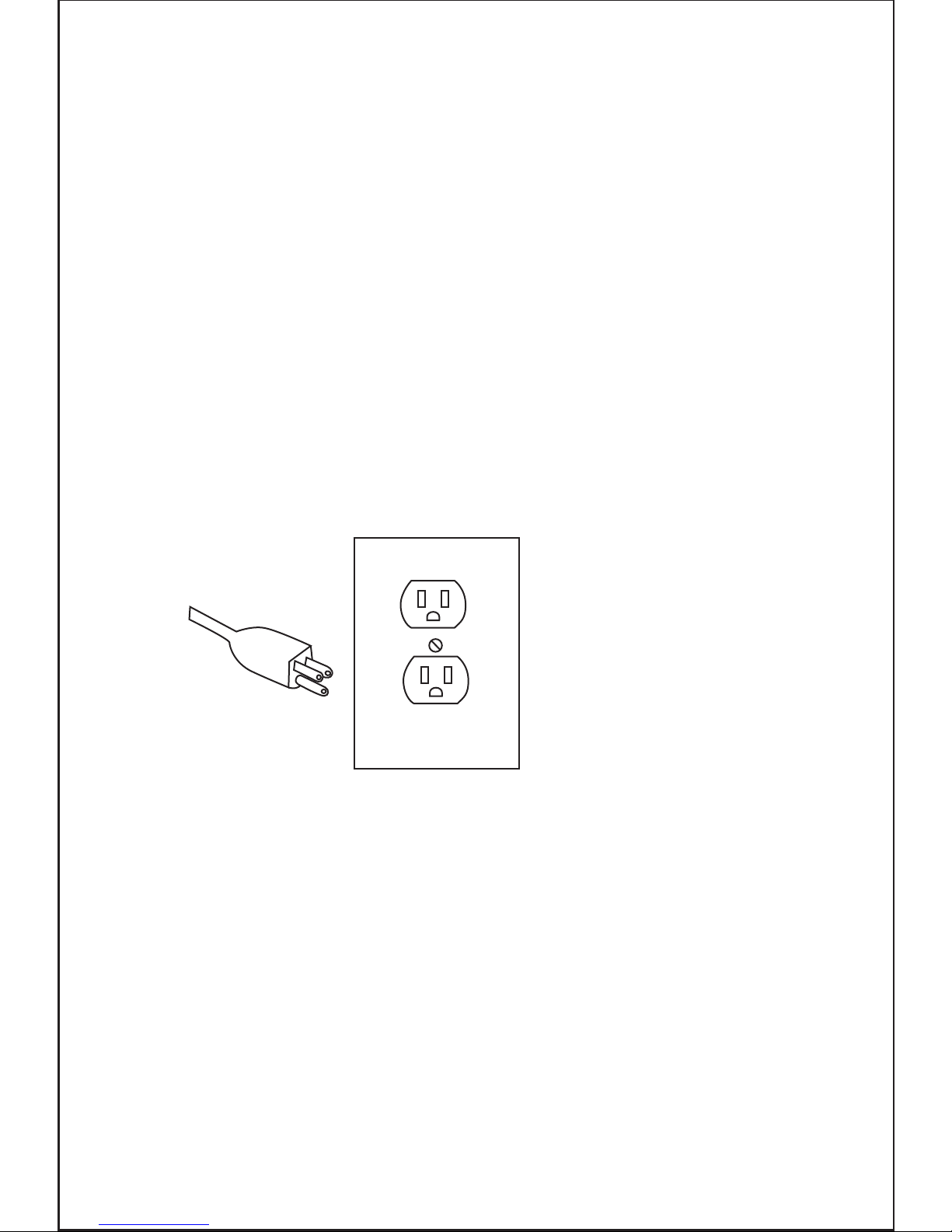

Grounding Tools

Electrical Powered Connections

3- Prong Plug and Outlet

Any electric powered tool that is marked Ground Required must have a fitted three

wired power cord. The main importance of this is the green wire within the cord, this

green wire must at all times be connected to the grounding prong of the plug. This

prong must never be removed or discarded. The green wire Must NEVER be conne-

cted to any other prong. The Three prong plug must only be connected to the power

supply through a three prong power outlet

The illustration above shows a three prong plug and outlet.

Only use qualified repair agents to service this machine.

Only use qualified electrician to repair any damaged wiring.

NEVER remove the grounding prong from the power toll or extension cord.

Page 7

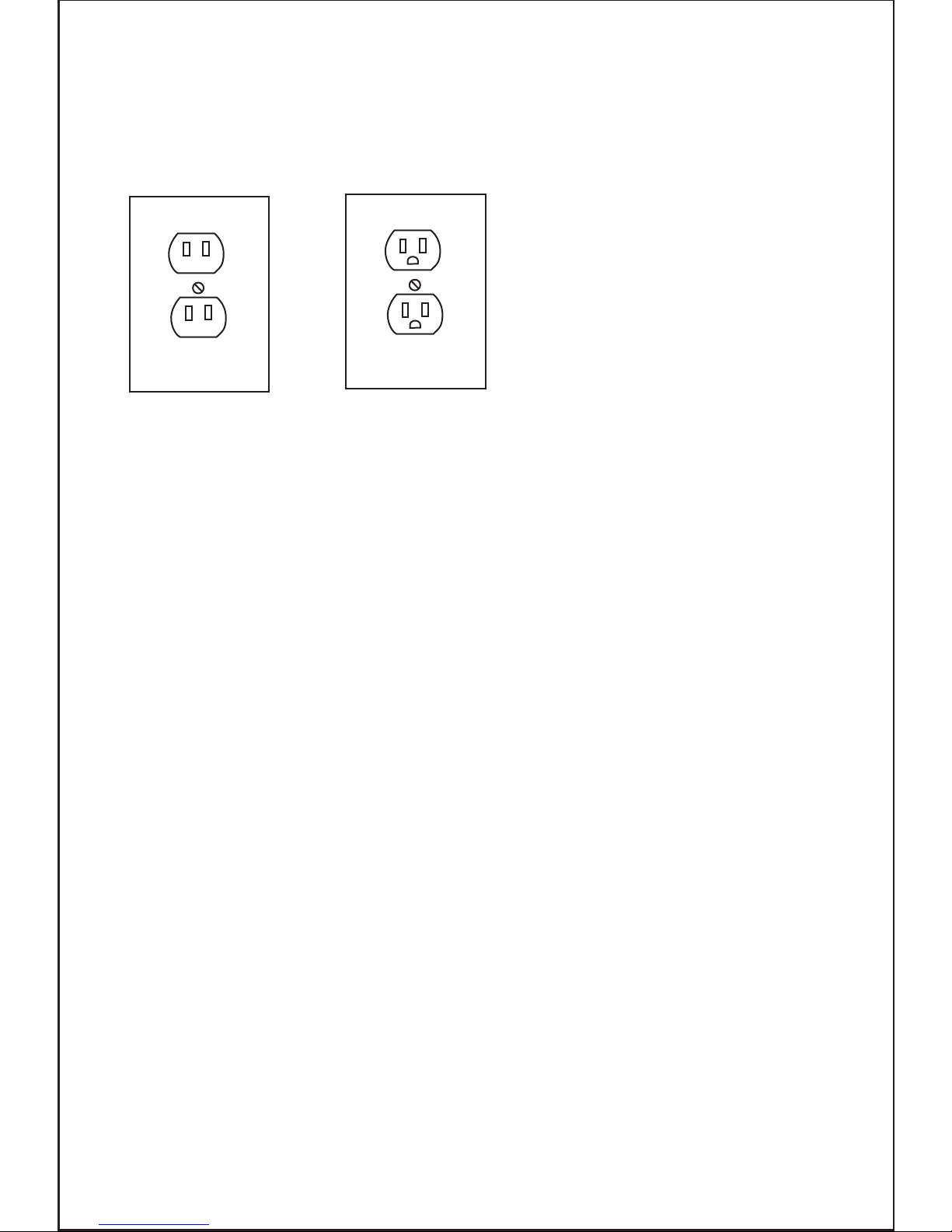

Outlets for 2-Prong Plug

Any electric powered tool that is marked “Double Insulated” only needs a two prong

connection and will be perfectly safe to operate.

These tools do not require grounding as they are fitted with an additional insulation

system internally that complies with all relevant electrical safety standards.

Unlike the three prong tools these tools CAN be connected through outlets suitable

for two prong or three prong plugs.

The illustration above shows the outlets that this type of tool can be connected to.

Any power tool marked “Grounding Required”, MUST only be connected to a three

wire extension cord. Only double insulated tools can be connected to twowire cords.

When using any extension cord the machine will suffer a power reduction due to the

drop in voltage caused by the length of the cord. This can be partially offset by sele-

cting extension cords with lower gauge wire.

Double Insulated Power Tools

Plug and Outlet, 2 prong

e.g. Cords marked 14 gauge can carry a higher current than cords marked 16 gauge,

therefore when linking extension cords make sure each cord wire gauge matches.

Note: Outdoor extension cords used in must carry the letters “W-A” (USA)) or “W”(C-

anada)

Check all extension cords for damage before use.

Avoid sharp objects.

Do not position cord where it could be subject to traffic passing over it.

Page 8

Turn on the grinder and wait until it reaches full speed before you start grinding.

Use the tool rest to keep the work piece steady. Keep a steady even pressure on the

work piece and keep moving it from side to side at even pace for smooth grinding and

to avoid uneven wheel wear. Do not push too hard because this may overheat the

motor and prematurely wear down the wheels, work slowly.

Note the original grind angle on the item you are sharpening/grindring and try to keep

the same angle. Make sure the grinding wheel always rotates down onto the object

you are grinding to avoid injury. Obtain a tray with water and place it next to the grinder

to dip your work to keep from overheating or burning as this will weaken the metal.

WARNING: For your own safety, make sure switch is OFF and unplugged from the

power source before doing any maintenance or adjustments. Replace the power cord

immediately if it is cut, worn, or damaged in any way.

Under normal use, grinding wheels may become cracked, chipped, grooved or packed

with debris from materials being cut. If a wheel cracks or chips replace it immediately.

New wheels occasionally require dressing to remedy out of round conditions.

If replacing a wheel make sure it is replaced with the same wheel and specs as the

existing wheel. Maintain the existing sequence of retaining hardware. For your own

safety make sure grinder is unplugged before attempting any repairs.

Your bench grinder can be used for polishing and buffing, you can obtain these wheels

from most hardware stores.

WARNING: The use of any other accessories is not recommended because it may

result in serious injury.

Operation

Always wear eye protection when using this or any other grinder.

Maintenance

Grinding Wheel Care

Wheel Replacement

Page 9

Thank you for purchasing a quality TERRATEK product. All TERRATEK products have

been made of high demanding quality standards and are guaranteed for domestic use

against any manufacturing faults for a period of 24 months from the date of purchase.

Normal wear and tear, including accessory wear, is not covered under this warranty.

This warranty is void if the product has been overloaded or subject to neglect, improper

use or attempted repair other than by a qualified engineer. Heavy duty, daily professional

or hire usage is not covered under this warranty. Due to continuous product develop-

ment, we reserve the right to change the product specifications without prior notice.

If the product fails due to a defect in material or workmanship during the 24 month p-

eriod, please return it to your place of purchase.

Warranty

Page 10

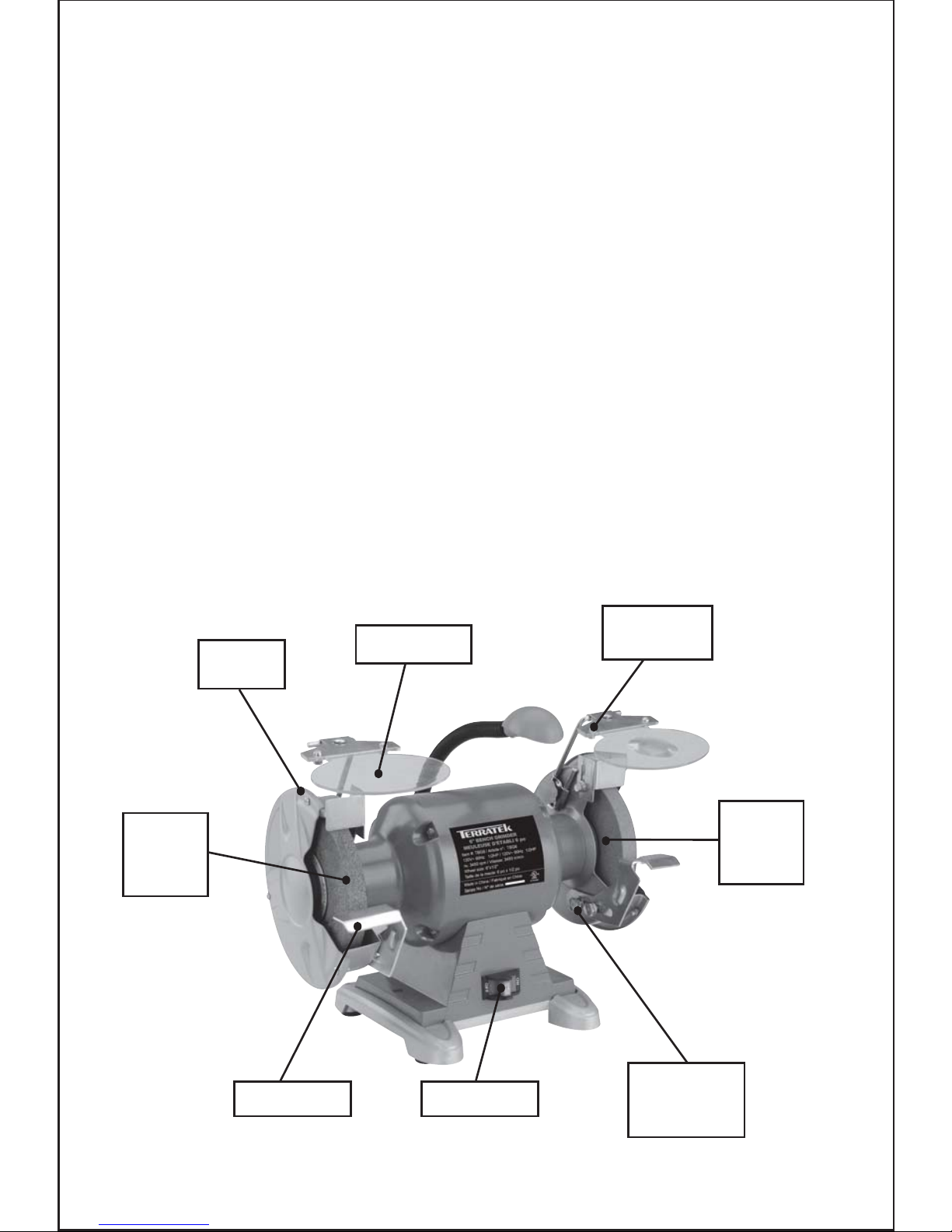

Coarse

wheel

36 grit

Fine

wheel

60 grit

Eye shield

Wheel

guard

Eye shield

bracket

Tool rest

adjustment

screw

Switch

Tool rest

Know your product:

Page 11

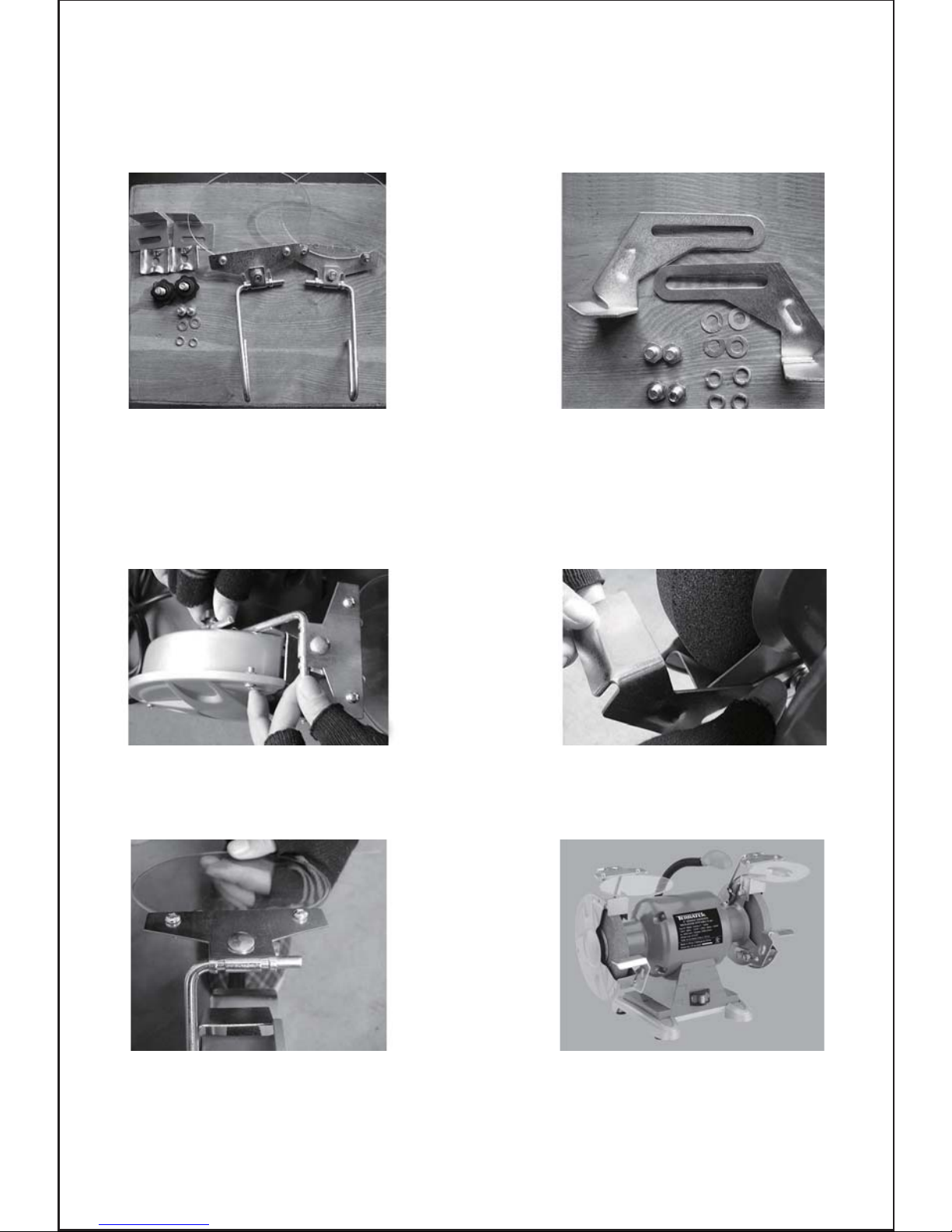

Accessories list:

Ref 5. Remove the eye shield

protective sleeve

Ref 6. Always mount on a stable /

level surface

(mounting holes provided)

How to assemble the bench grinder:

Ref 3. Assemble the eye shield Ref 4. Set up the tool rest

Ref 2. Accessories for tool rest

1. Tool rest part

2. Screw, set-screw, flat washer,

star washer, knob

Ref 1. Accessories for eye sheild

1.Screw, set-screw, flat

washer, spring washer, nut

2.Eye shield

Page 12

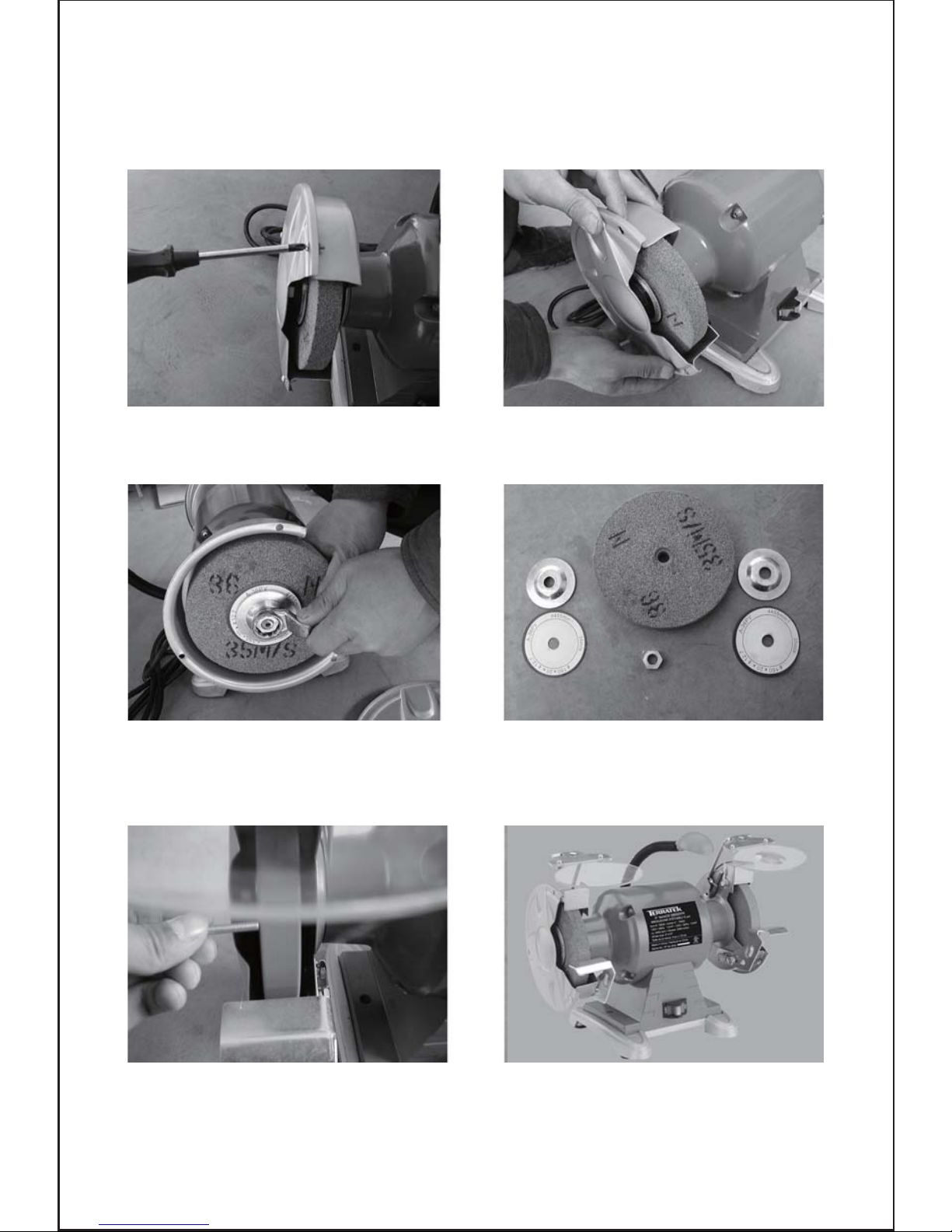

How to replace the grinding wheel

Ref 7. Take off the 3 screws on wheel guard Ref 8. Remove the wheel guard

Ref 9. Use spanner to take off the screw

nut for wheel

Ref 10. Wheel assembly parts

Ref 11.After changing a wheel make sure you

dress it to eliminate any wobble

To assemble, reverse order of disassembly

LISTED

E154499

Page 13

Manual del usuario – Por favor lea este manual y

guárdelo para referencia futura

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

4

4

4

1

1

Page 14

Lista de piezas

Protector ocular

Arandela

Arandela

Tuerca

Tuerca

Arandela

Arandela

Soporte de protector ocular

Tornillo de cuello cuadrado

Tornillo

Barra de montaje de protector ocular izquierdo

Pieza de fijación

Arandela

Tuerca

Tornillo

Guarda protectora exterior izquierda

Tuerca

Brida de muela

Muela abrasiva

Tornillo

Arandela

Guarda protectora interior izquierda

Guarda protectora contra chispas izquierda

Arandela

Arandela

Perno

Arandela

Perno

Arandela

Soporte de herramienta izquierdo

Tornillo

Arandela

Arandela

Cono extremo

Cojinete

Rotor

Estator

Alojamiento del motor

2

4

4

4

2

2

2

2

2

4

1

2

2

2

6

1

1

4

1

6

6

1

1

2

2

2

4

4

4

1

8

8

8

2

2

1

1

1

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

Barra de montaje de ojo derecho

Guarda protectora contra chispas derecha

Etiqueta

Guarda protectora interior derecha

Muela abrasiva

Tuerca

Guarda protectora exterior derecha

Soporte de herramienta derecho

Enchufe y cable

Lámpara

Arandela

Tuerca

Terminal de tierra

Arandela

Arandela

Tornillo

Abrazadera de capacitor

Perno

Grapa de cable

Tornillo

Arandela

Bloque de cables

Protector de cable

Base

Arandela

Arandela

Arandela

Tornillo

Capacitor

Transformador

Arandela

Tornillo

Placa de asiento

Patas de caucho

Arandela

Tornillo

Interruptor

Logo

Contenido

Lista de piezas Página 14

Especificaciones técnicas Página 16

Instrucciones de seguridad Página 17

Utilización de la producto Página 23

Mantenimiento Página 23

Garantía Página 24

Número

de la

pieza Nombre de la pieza Cantidad

Número

de la

pieza Nombre de la pieza Cantidad

Dibujo despiezado del conjunto

Page 15

Información técnica

Copyright© 2008 perteneciente al ACL Group (Intl) Ltd. Quedan reservados todos los

derechos. Este manual o cualquier material artístico incluido en el mismo no deberá

ser reproducido en cualquier versión o forma sin el permiso escrito expreso del ACL

Group (Intl) Ltd. Los diagramas que aparecen en este manual no podrán ser dibujados

de manera proporcional. Debido a mejoras continuas, el producto especificado puede

diferir ligeramente del producto descrito en el presente.

Este manual debe leerse por ompleto

antes de utilizar este producto.

Si no se hace así pueden sufrirse lesiones graves.

Guardar este manual para referencia futura.

Page 16

Voltaje: 120V ~ 60Hz

Potencia: 1.5A 1/2HP

Velocidad: 3550 rpm

Amaño de muela: 6”X 1/2”

Luz de trabajo: LED

Peso: 23/26 lb

Información de SEGURIDAD importante

Este símbolo sirve para advertirle sobre los po-

sibles peligros de sufrir lesiones personales. Por favor

lea detenidamente las notas incluidas en este aviso para

evitar sufrir una posible lesión o muerte.

Reglas de seguridad generales

¡AVISO! Lea todas las instrucciones. Si no se observan todas las instru-

cciones enumeradas a continuación podrán sufrirse sacudidas eléctricas,

quemaduras o lesiones graves. El término “herramienta motorizada” in-

cluido en todos los avisos enumerados se refiere a herramientas motor-

izadas con cable o sin cable.

Seguridad en el área de trabajo

Leer y guardar este manual

Por favor lea detenidamente todas las instrucciones contenidas en este manual.

Si no se observan todas as advertencias de seguridad pueden sufrirse lesiones per-

sonales graves. El término “herramienta motorizada” en todas las advertencias

siguientes se refiere a su herramienta motorizada que funciona vía la red eléctrica

(con cable) o a la que funciona vía baterías (sin cable).

Page 17

Mantenga el área de trabajo limpia y bien iluminada. Áreas de trabajo desordenadas

o mal iluminadas causan accidentes.

No utilice las herramientas motorizadas en atmósferas explosivas, tales como las que

contienen líquidos, gases o polvos inflamables. Las herramientas motorizadas crean

chispas que pueden encender el polvo o los humos.

Mantenga alejados a menores y curiosos mientras utiliza la herramienta motorizada.

Las distracciones pueden hacerle perder el control.

Seguridad eléctrica

Antes de usar, asegure que la toma de energía que utiliza coincide con el enchufe incluido

en su herramienta motorizada y que el voltaje de la toma coincide con el de la herramienta

motorizada.

Use solamente cables de extensión conectados a tierra con herramientas motorizadas

provistas de enchufes de 3 clavijas y si las usa en el exterior asegure que el cable de

extensión sea adecuado para uso externo.

Trate siempre de evitar contacto corporal con las superficies conectadas a tierra, tales

como las de radiadores, hornillas de cocinar y cualquier otro aparato fijo con superficies

metálicas.

No exponga su herramienta motorizada a condiciones mojadas o húmedas y no la use

NUNCA bajo la lluvia.

Compruebe regularmente el cable eléctrico de su máquina y cualquier cable de extensión

que esté utilizando por si muestra daños.

No transporte o tire de la máquina usando su cable eléctrico.

Asegure que el cable esté alejado de superficies calientes, aceite u objetos afilados.

No use nunca la máquina mientras está bajo la influencia de alcohol, drogas o med-

icamentos.

El cansancio con frecuencia puede causar accidentes; permanezca alerta.

No use nunca la máquina sin las cubiertas protectoras correctas en su sitio.

Use siempre protección ocular y máscara antipolvo aprobadas por ANSI. Mientras se

utiliza la herramienta motorizada deberá llevarse en todo momento calzado y auricu-

lares protectores.

Asegure que cualquier dispositivo colector de polvo suministrado con la máquina esté

conectado correctamente antes de usarla.

Asegure que todas las ropas, pelo largo o joyas se mantengan alejadas de la máquina.

Antes de enchufar la máquina en la toma eléctrica asegure que la máquina esté en la

posición OFF (apagada) y que todas las cuchillas y accesorios utilizados estén colo-

cados con seguridad.

Compruebe que hayan sido retiradas todas las llaves de tuercas o de ajuste. Cualquier

llave de tuerca o de ajuste que haya sido dejada acoplada a una pieza móvil puede

causar lesiones.

Seguridad personal

Page 18

Utilización y cuidado de la herramienta motorizada

LISTA DE COMPROBACIÓN DE SEGURIDAD

Antes de comenzar

1. Compruebe que la toma eléctrica coincide con el enchufe de la herramienta motorizada.

2. Compruebe que el voltaje de la toma eléctrica coincida con el de su herramienta

motorizada.

3. Asegure que los cables eléctricos no estén dañados.

4. Compruebe que las cubiertas protectoras y las pinzas estén seguras y en buen

estado de funcionamiento.

5. Asegure que todas las llaves de tuercas y demás accesorios esté retirados.

6. Compruebe que las cuchillas y piezas de corte funcionan libremente.

7. Compruebe que el entorno de trabajo esté despejado.

8. Asegure que la herramienta motorizada esté sujeta con seguridad a su banco o

plataforma de trabajo.

9. Asegure que ninguna persona menor de 18 años maneje esta herramienta.

10. Asegure que todos los menores estén alejados del área de trabajo.

11. Asegure que trabaja con los materiales correctos recomendados para uso con esta

herramienta.

Durante la utilización

1. No extienda el cuerpo sobre la máquina.

2. No ponga la máquina en marcha sin las ropas de seguridad correctas.

3. No ponga la máquina en marcha con las ropas sueltas.

4. Mantenga manos y extremidades alejadas de las cuchillas de la sierra.

5. Asegure que todas las abrazaderas y cubiertas protectoras estén en su sitio.

6. No corte metal o mampostería con una máquina de cortar madera.

7. No use la máquina en condiciones mojadas o húmedas.

8. Use siempre soportes cuando trabaje con piezas de madera largas.

Mantenga su máquina limpia y en buen estado de servicio en todo momento.

No efectúe nunca el ajuste o servicio de cualquier herramienta motorizada antes de

desconectarla del suministro eléctrico.

Use siempre la herramienta correcta para la herramienta.

No fuerce nunca la herramienta a trabajar con fuerza superior a la diseñada.

No use nunca la máquina con piezas rotas tales como interruptores, defensas de guía

o soportes de patas.

Mantenga SIEMPRE la herramienta motorizada alejada de los menores.

Mantenga las herramientas cortantes afiladas para asegurar que el motor se esfuerza

menos.

Sustituya las cuchillas si tienen desperfectos o están desafiladas.

Haga que el servicio de la herramienta motorizada sea realizado por un agente de

reparaciones profesional que utilice piezas recomendadas por el fabricante

Page 19

Table of contents

Languages:

Other Terratek Grinder manuals