Texlabel SPB User manual

User Guide

V. 20.0316

SPB

2

Summary

OVERVIEW............................................................................................................................................3

INSTALLING PRINTER............................................................................................................................5

INSTALLING DRIVER FOR WINDOWS USERS ........................................................................................5

INSTALLING CUTTER / STACKER (Optional)..........................................................................................6

LOADING RIBBONS AND FOILS.............................................................................................................8

LOADING LABELS ON CONTINUOUS MODULE...................................................................................12

HOW TO USE Cablabel S3 Lite SOFTWARE ........................................................................................13

MAINTENANCE...................................................................................................................................21

CLEAR ERROR MESSAGES...................................................................................................................22

PARAMETERS FOR WHITE AND COLORED STICKERS .........................................................................24

PARAMETERS FOR TRANSPARENT STICKERS .....................................................................................26

PARAMETERS FOR COMPOSITION LABELS.........................................................................................28

PRINCIPAL REQUIREMENTS FOR INTERNATIONAL CARE LABELS ......................................................33

3

OVERVIEW

Please keep the original packaging in case the printer must be returned.

Box Content:

SPA Printer

DVD including software and printer driver for Windows

One empty cylinder core for rewinding the foil

USB Cable

AC Adapter

Power Adapter

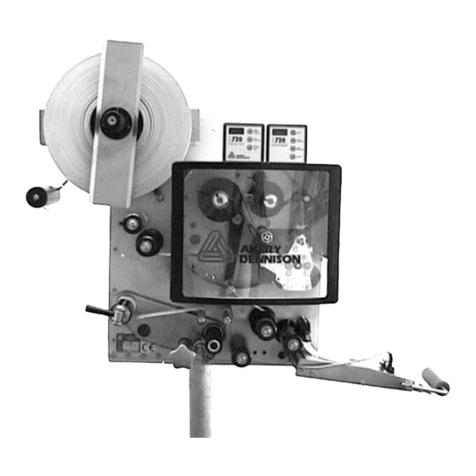

Printer View:

1. Cover

2. Ribbon regulator tabs

3. Ribbon supply wheel

4. Foil supply wheel

5. Foil rewind wheel

6. Print mechanism

7. Touchscreen Display

4

8. Foil guide roll

9. Pressure wheel

10. Extractable allen key for regulating

11. printhead lever secure

12. Advancement wheel

13. Ribbon guide roll

14. Photoelectric label barrier

15. Ribbon lateral guide regulator

16. Pressure wheel pin lock

17. Anti-static brush

18. ON/OFF Switch

19. AC Power Port

20. Slot for SD Memory Card

21. USB Port

22. Usb 2.0 port pc connection

23. Ethernet 10/100 base-t

24. Serial interface RS-232C

5

INSTALLING PRINTER

1. Place printer onto flat and regular surface

2. Make sure ON/OFF switch is set to OFF

3. Install the cutter / stacker (See page 6)

4. Connect printer to the computer with USB cable or Ethernet cable

5. Connect AC cable to the AC Power port on the back of the printer, and then connect the Power

Adapter to a grounded socket

6. Install drivers (link below)

7. The printer will run a test upon power up. If connected properly, the display should show the

writing “Ready”.

INSTALLING DRIVER FOR WINDOWS USERS

1. Option 1.

a. Connect to the following link for instructions on how to download the Windows driver for

the printer

www.texlabel.eu/wp/download-it

2. Option 2.

a. Turn on printer and wait for the writing “Ready” to appear on the display

b. Run DVD as an administrator and follow the printer setup wizard

Installing Software

1. Insert the DVD in the computer.

2. Choose "Software" on the Welcome screen.

3. Press the icon "install software" to start the installation.

6

INSTALLING CUTTER / STACKER (Optional)

1) Cutter inert port

2) Cutter anchor fastening point

3) Cutter data connector

4) Cutter inert port

WARNING!!! RISK OF BEING CUT

PROCEED WITH THE PROCESS WITH THE AC CORD DISCONNECTED FROM THE PRINTER

Place the cutter onto the frontal part of the printer, making sure to align the cutter outputs with the cutter

inert ports. By doing so, also aligns the cutter data connector. After this task is complete, fasten the screw

of the cutter onto the cutter anchor fastening point.

LATERAL GUARDS FOR CUTTER AND STACKER PLATE (OPTIONAL)

1) Fastening plate bolts

2) Lateral guards screws

3) Stacker plate

4) Lateral guards

Place the stacker plate onto the cutter stacker track, inserting the fastening plate bolts into the assigned

holes. Fasten and secure the plate.

7

WARNING!!! RISK OF BEING CUT

PROCEED WITH THE PROCESS WITH THE AC CORD DISCONNECTED FROM THE PRINTER

Install the lateral guards as shown below, making sure to align the fastening points indicated by the arrows.

The lateral guards are both different from one another, one is for the left side and one is for the right side.

Be careful in positioning the guards.

In case of difficulty with these processes, contact TEXLABEL technical support.

Once the lateral guards and stacker is installed, the cutter will look as so:

8

REGULATE THE WIDTH OF THE STACKER

Adapting the width of the stacker, based on the ribbon width.

By loosening (using the allen key for regulating) the 4 screws indicated in the picture below, allows to slide

the lateral guards of the stacker to increase or decrease the width needed. To lock the width at a

determined width, use the measurement ruler placed between the bolts as a guide.

9

LOADING RIBBONS AND FOILS

LOADING RIBBONS

Rotate the regulator tab ring (5) counter-clockwise, so the arrow (6) is aligned with unlock symbol. In this

way loosening the regulator tab (4).

Remove the regulator tab (4) from the ribbon supply holder (3).

Insert the ribbon (2) onto the ribbon supply holder (3), so that the ribbon unwinds clockwise.

Insert the regulator tab (4) onto the ribbon supply holder (3) and slide down until the two regulator tabs (1

and 4) keep the ribbon (2) in place.

Rotate the regulator tab ring (5) clockwise, so the arrow (6) is aligned with the lock symbol. By doing so, the

regulator tab will fasten onto the ribbon supply holder.

10

Make sure the printhead is raised and that the pressure wheel is raised.

Increase the lateral guides of the ribbon using the lateral guide regulator.

Pass the ribbon through the print mechanism as shown below.

Once the ribbon is installed and guided through the print mechanisms, proceed with regulating the lateral

guides of the ribbon.

To regulate the lateral guides of the ribbon, use the lateral guide regulator indicated by the red arrow. By

rotating the regulator clockwise, the lateral ribbon guides (yellow arrows) will close, and counter-clockwise

will open them.

The lateral guides need to be regulated based on the width of the ribbon being used.

If the guides are too tight, a “belly” will form on the ribbon that will cause a bad quality of print and will

probably jam the printer.

If the guides are too wide, the ribbon will move during the printing process.

11

LOADING FOIL

Make sure the printheads are raised.

Insert the foil onto the upper foil supply wheel, making sure that the matte side is facing down in a way to

make contact with ribbon to be printed on.

Position the foil at the center of the wheel using the ruler as a guide.

Once positioned, rotate the green locking ring on the extremity of the wheel counter-clockwise until the foil

is locked in place.

Place an empty cylinder core onto the upper foil rewind wheel and lock it into place using the green locking

ring on the extremity of the wheel.

Guide the foil film through the printing mechanism as shown in the image below.

Attach the foil film extremity to the center of the empty cylinder core, using a sticker (usually found on the

foil seal).

Once the foil is attached to the foil rewind wheel, rotate the rewind wheel until reaching the beginning of

the ink strip and maintain the foil in tension.

12

LOADING LABELS ON CONTINUOUS MODULE

1. Position the label pack behind the printer (5).

2. Rotate the regulator ring (4) counter-clockwise, so that the white arrow is aligned with the

unlock symbol. In this way loosing the regulator tab (3). Leave the regulator tab onto the

supply ribbon holder (7).

3. Push the internal regulator tab (2) towards the case (1) until it is in place. At the same time,

push the external regulator tab towards the outside.

4. Guide the labels (6) through the regulator tabs (6) passing over the ribbon supply wheel (7).

Make sure the material to printed on, is facing up.

5. Push the external regulator (3) until the two regulators (2, 3) leave no space for the labels

to move, without blocking or bending the labels.

6. Rotate the regulator ring (4) clockwise, so that the white arrow is aligned with the lock

symbol. By doing so, the regulator tab will fasten onto the ribbon supply holder (3).

7. Pass the labels through the printhead.

8. Regulate the photoelectric barrier of the labels.

13

HOW TO USE Cablabel S3 Lite SOFTWARE

Click on the tab “devices”

In the list of devices, select the printer “SQUIX 4/300MT”, click on “Install selected device”, and then click

on the “OK” button.

14

Click on “New label” to open a new project

In the window that appears, select the text box “View Name” and insert the name of the format you want

to create

In “label layout”, set the size of the label

In “spacing”, set the value in mm of the space between one label and another

Click the button “Next” to confirm and proceed to the creation of the label

15

To edit the label, use the tool bar located above (as shown in image below)

To use a tool, simply click on it and then click on the center of the label.

The tool “Text” is used to insert a text box onto the label

By clicking on the blank label, after selecting the “Text” tool, the following window will open:

16

From this window, it is possible to insert the text and format it using the “Font properties”

Click on the “OK” button to confirm

The tool “Barcode” is used for inserting barcodes

17

After selecting the tool “Barcode”, click onto the center of the label, and the following window will open:

From this window, it is possible to set the size of the barcode, size of numbers, style, and type of code

(EAN13, UPC, CODE39, etc.)

18

The tool “Image” is used to insert an image onto the label

N.B. For a higher quality print, we advise to insert black and white images. In the

case that you want to insert color or greyscale images, the result in the print phase

will not be of good quality. In the print phase, there is an area for regulating the

image quality of color or greyscale images.

The following highlighted tools are used to insert lines, rows, squares, rectangles, circles and

ellipses.

19

TO INSERT THE WASH SYMBOLS ON THE LABEL,

FOR EXAMPLE: FL R W bh d Y r n

YOU MUST INSERT A TEXT BOX SELECTING THE TYPE OF FONT, E.G.:

THIS REFERS TO THE "CHARACTER MAP TEXLABEL –ISO" FOR THE FOLLOWING

TABLE (EVERY SYMBOL CORRESPONDES TO A CHARACTER).

TEXLABEL - ISO

TEXLABEL fonts can also be purchased at a later time by contacting TEXLABEL.

20

Separately purchased TEXLABEL fonts:

TEXLABEL - ISO

TEXLABEL –KR

TEXLABEL –ASTM

Table of contents

Other Texlabel Label Maker manuals

Popular Label Maker manuals by other brands

Brother

Brother RuggedJet RJ-2030 Quick setup guide

Graphic Products

Graphic Products DuraLabel PRO 300 quick start guide

Datamax

Datamax A-Class A-4212 Operator's manual

Weidmuller

Weidmuller PrintJet ADVANCED user manual

Brother

Brother PT 1950 - P-Touch 1950 B/W Thermal Transfer... user guide

Avery Dennison

Avery Dennison ALX 720 user manual