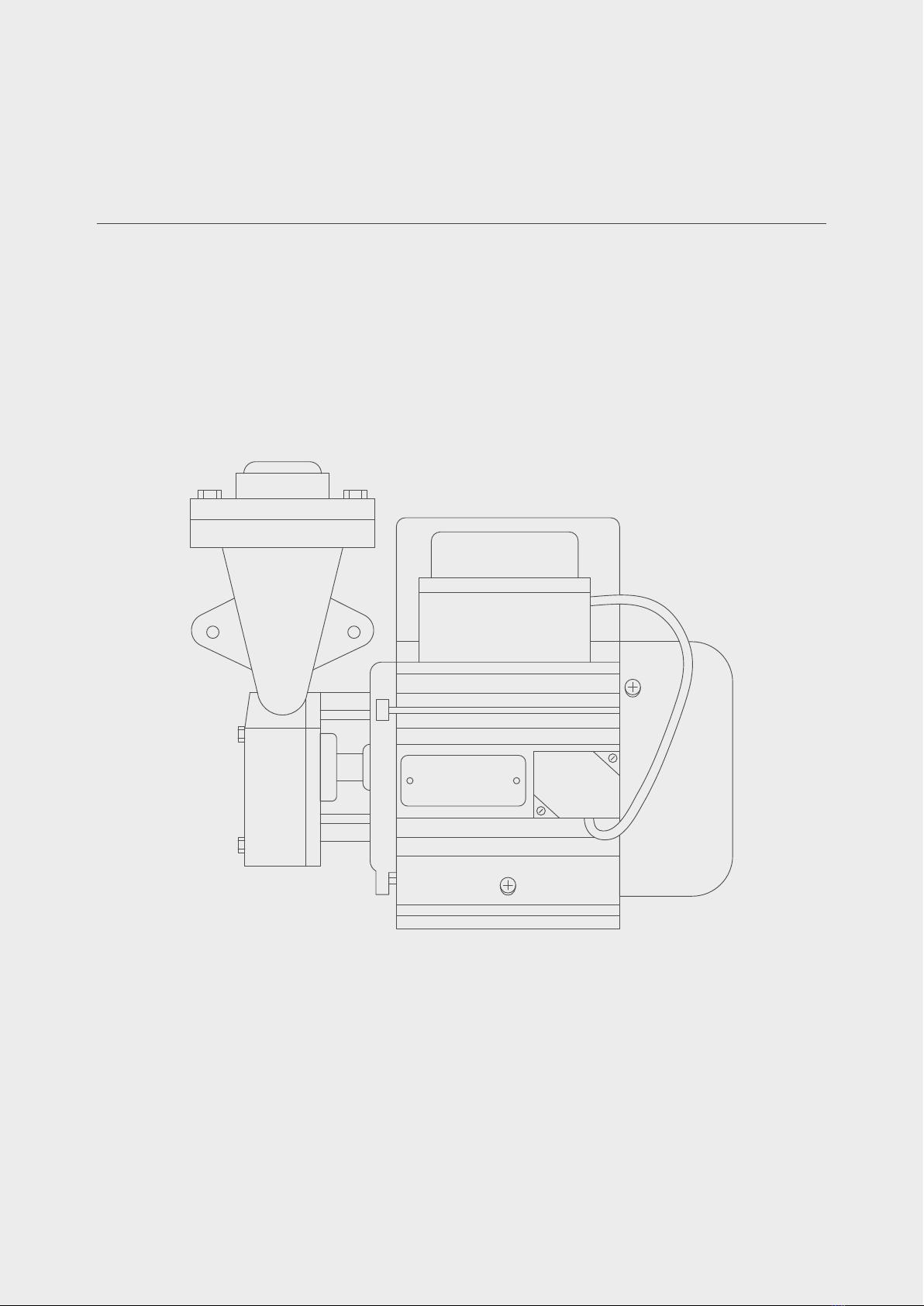

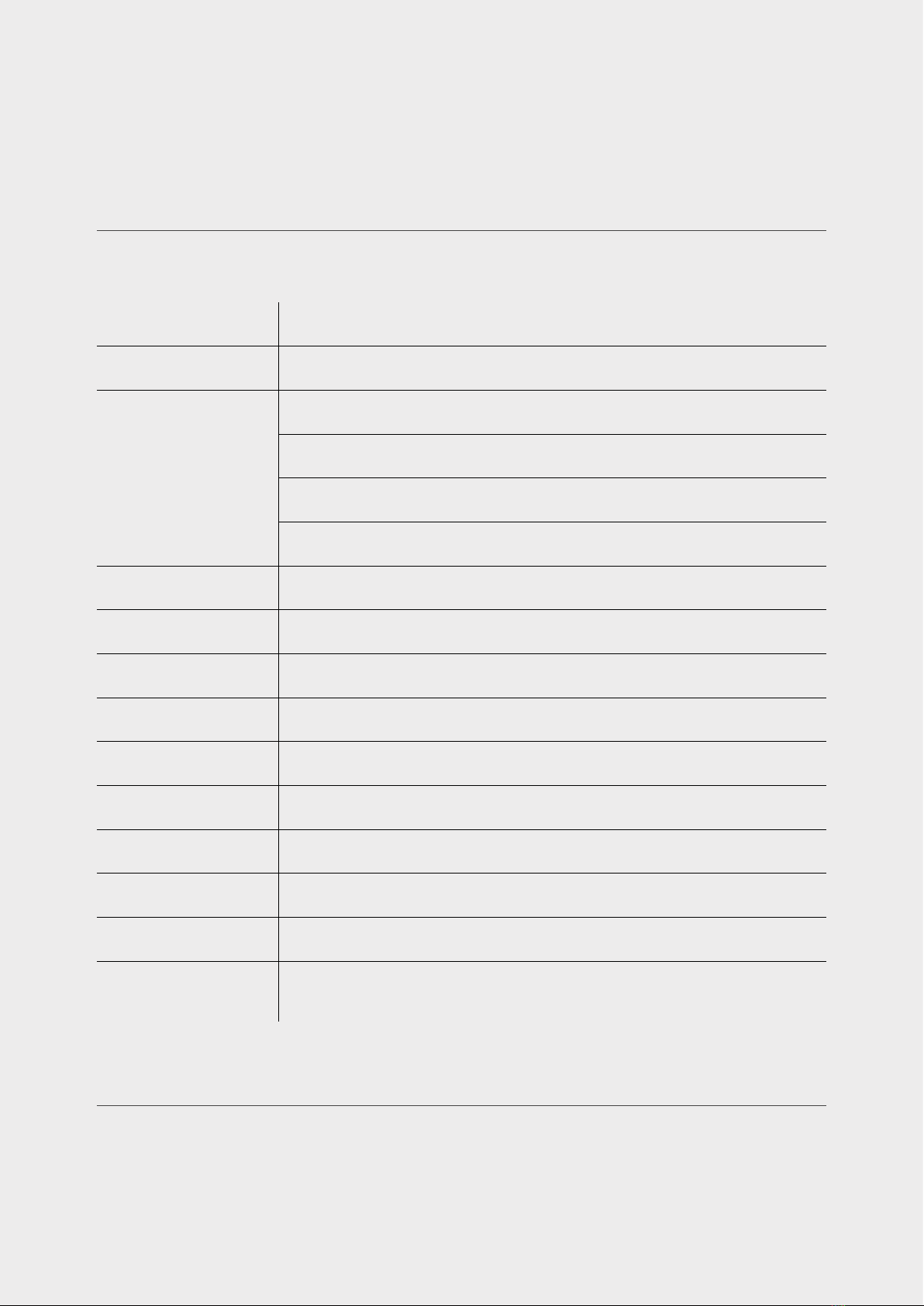

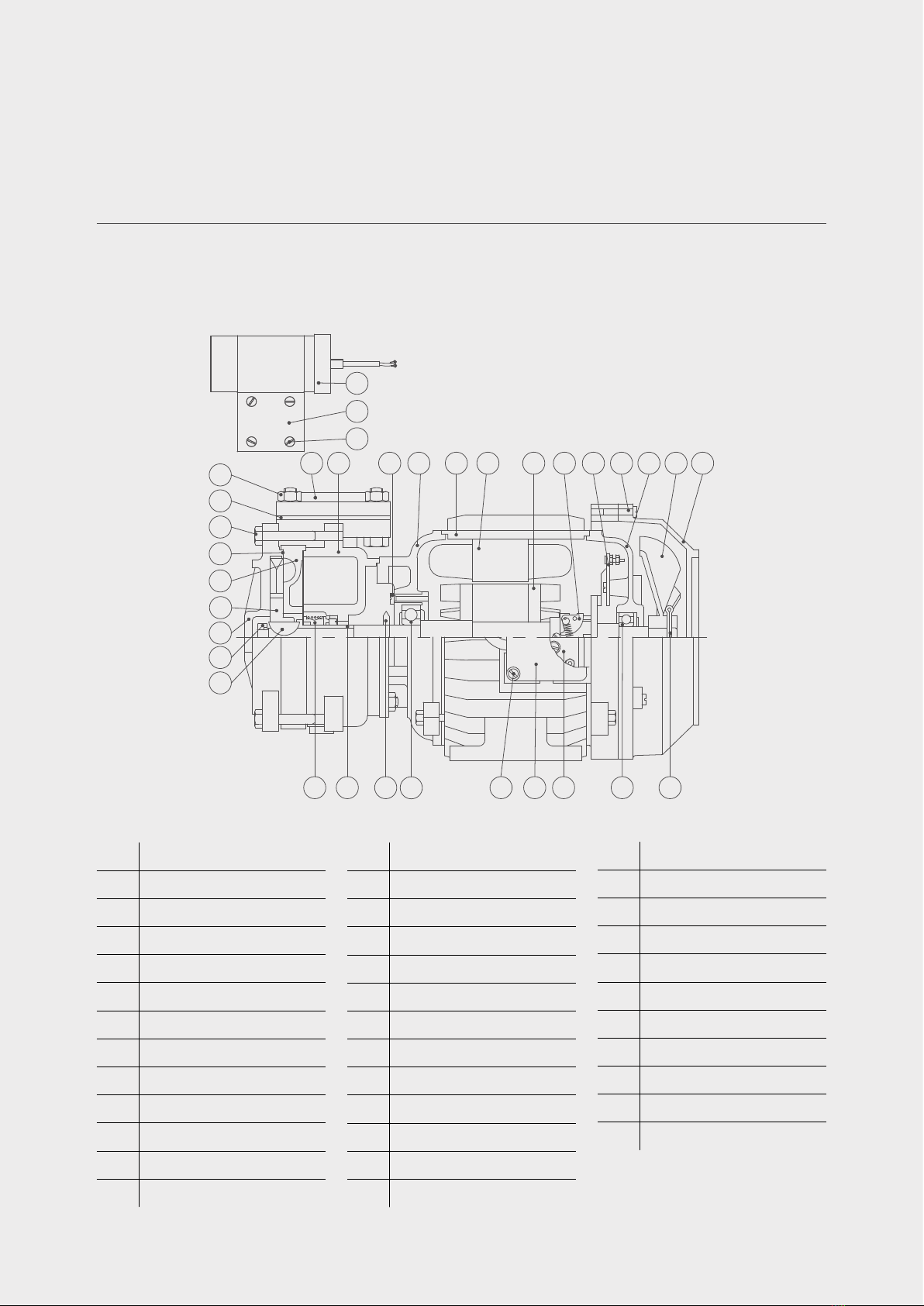

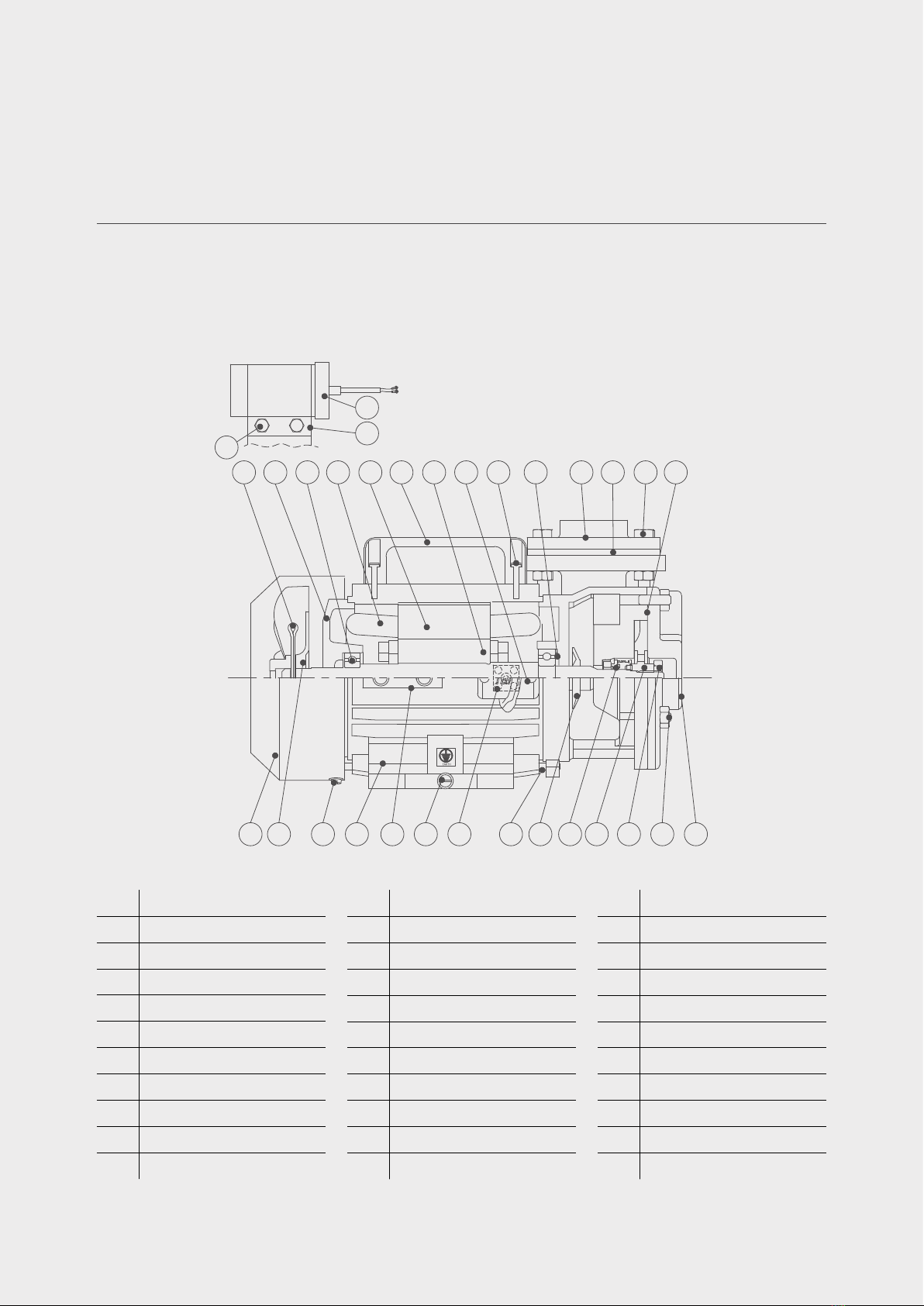

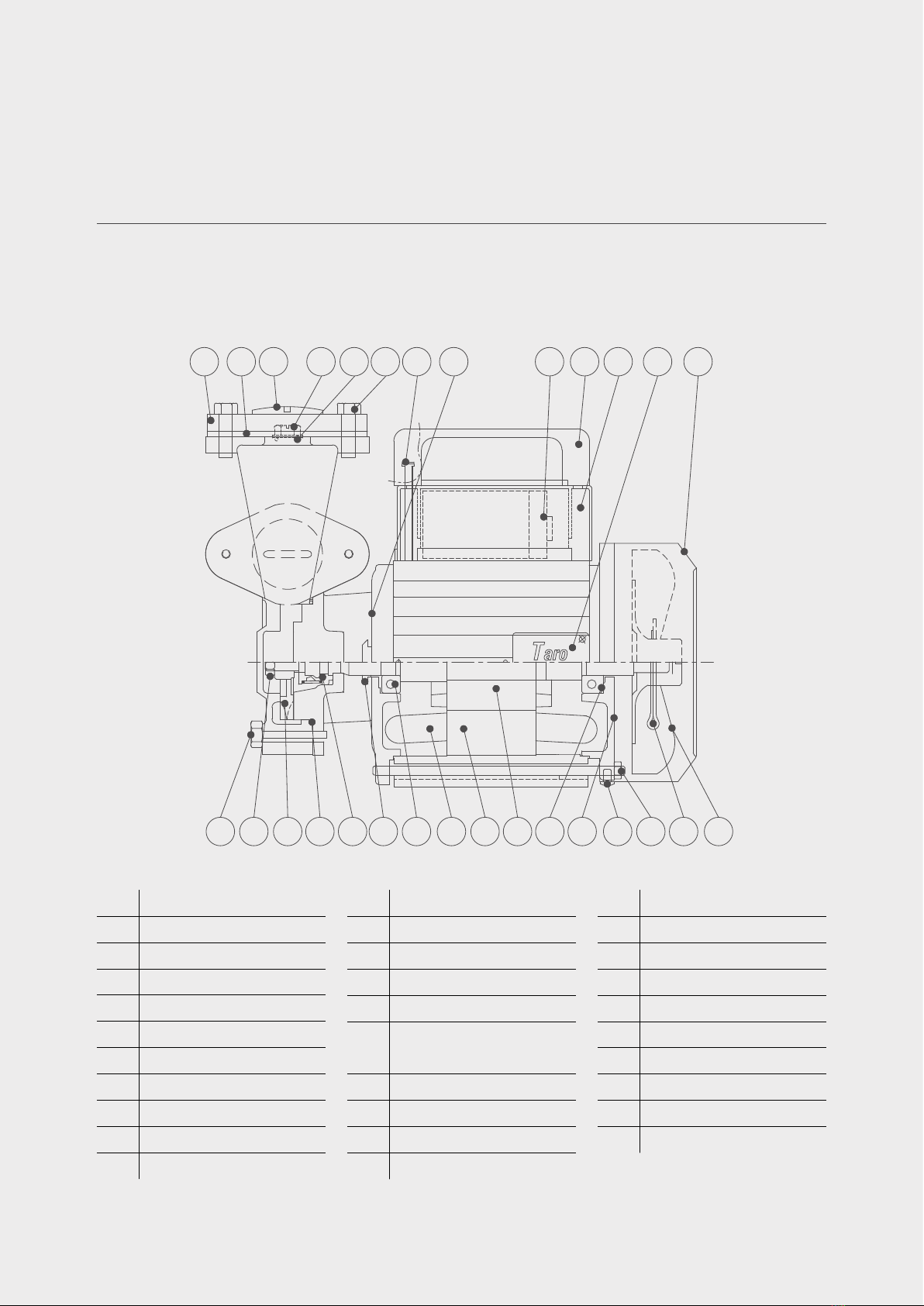

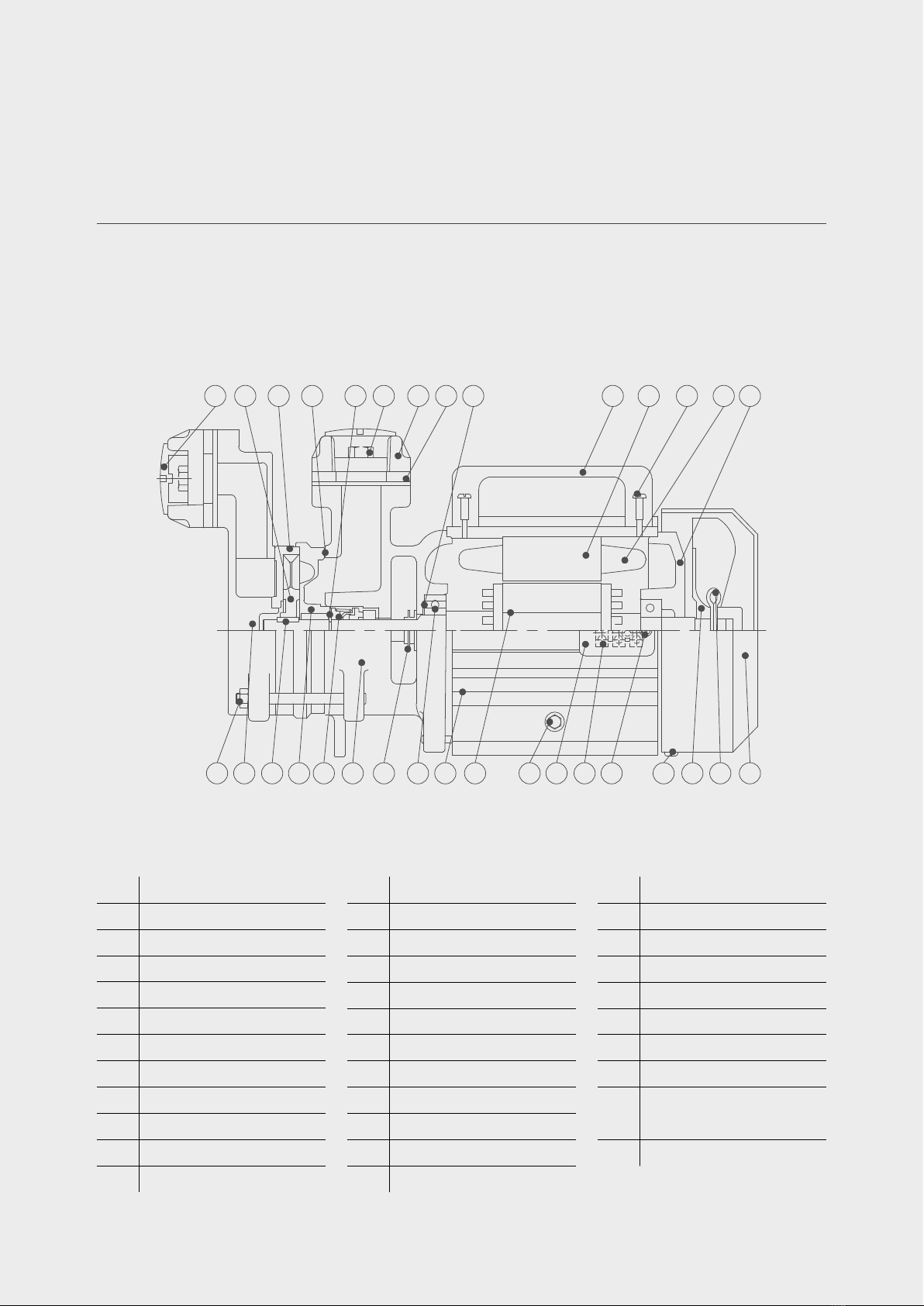

Texmo Industries Taro Single Phase Domestic Monoblock Parts list manual

This manual suits for next models

1

Table of contents

Other Texmo Industries Water Pump manuals

Texmo Industries

Texmo Industries TARO TSM Series Parts list manual

Texmo Industries

Texmo Industries Taro Jet Monoblock Operating and maintenance manual

Texmo Industries

Texmo Industries Taro Pumps NMH 7040 Parts list manual

Texmo Industries

Texmo Industries Taro Pumps Borewell Parts list manual

Texmo Industries

Texmo Industries Taro Pumps Borewell Parts list manual

Texmo Industries

Texmo Industries Taro Pumps TSSM Series Parts list manual

Texmo Industries

Texmo Industries Taro HCSJ 40 Series Parts list manual

Popular Water Pump manuals by other brands

DIPRA

DIPRA SPIDO JE-600-P Original operating instructions

Frymaster

Frymaster SDU 50 90 quick start guide

Graco

Graco Husky 1050A Operation

BVA Hydraulics

BVA Hydraulics PE60M3N06J instruction manual

Grundfos

Grundfos APG Series Installation and operating instructions

AquaMark

AquaMark AM-15V Installation, operation & maintenance manual

EINHELL

EINHELL LE-HW 1300 Niro operating instructions

Beckett

Beckett Fountain Pump M250AUL16 Specifications

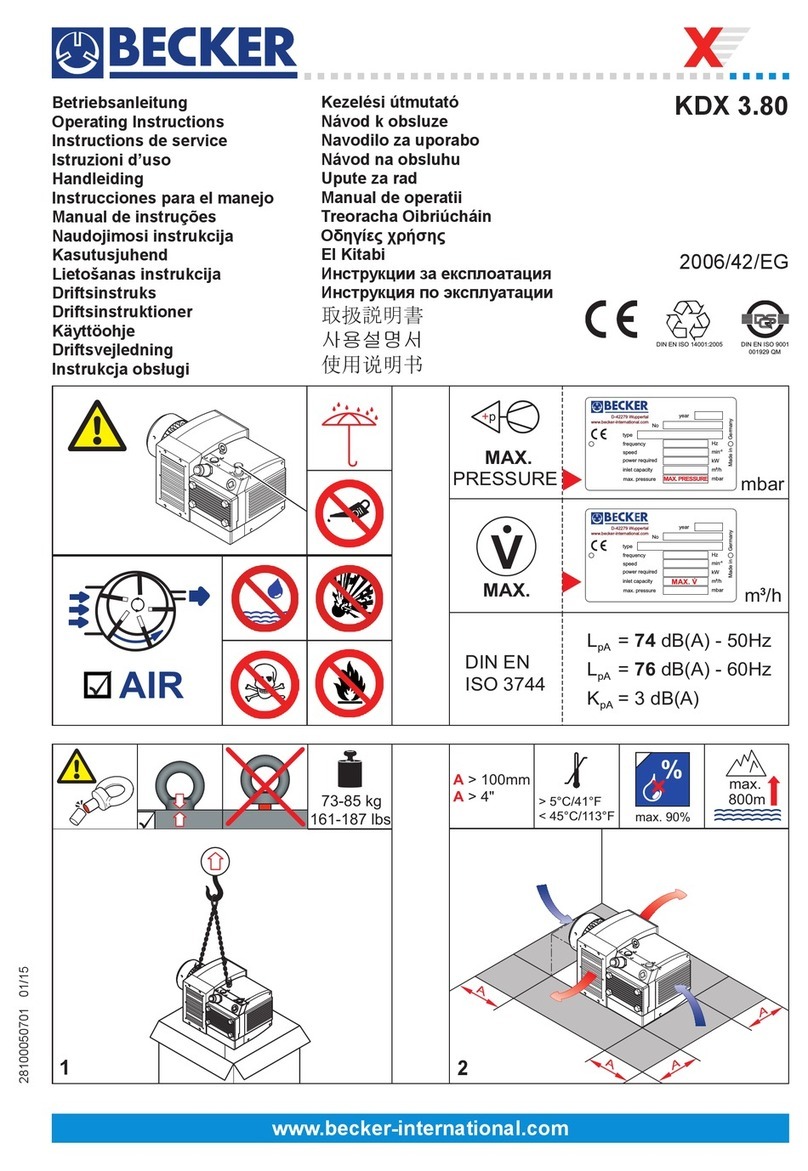

Becker

Becker KDX 3.80 operating instructions

Ion Technologies

Ion Technologies SH50 Operation manual

BUSCH

BUSCH COBRA Oxygen NC 0400 B instruction manual

VERDER

VERDER JEC JRZLF Series Operation and maintenance manual

Osaka

Osaka TG220F Series Operation manual

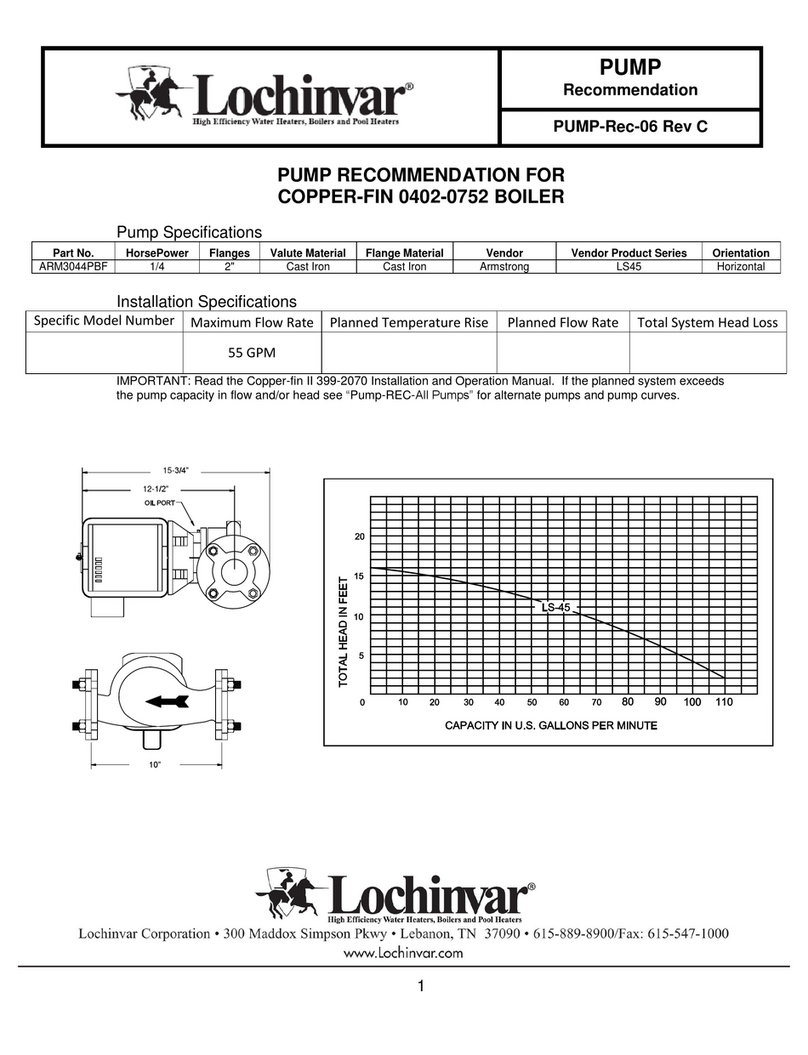

Lochinvar

Lochinvar 0402-0752 Recommended repair procedures

KSB

KSB Calio-Therm S Installation & operating manual

Greenlee

Greenlee 1725 instruction manual

Pfeiffer Vacuum

Pfeiffer Vacuum Duo 2.5 Original operating instructions

Wilo

Wilo Drain LP 40 Installation and operating instructions