Textron Motors MPE 850 MARINE User manual

TD407477_DHB

Rev B

06.07.2015

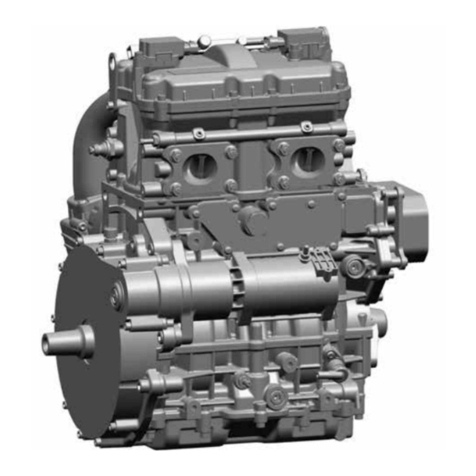

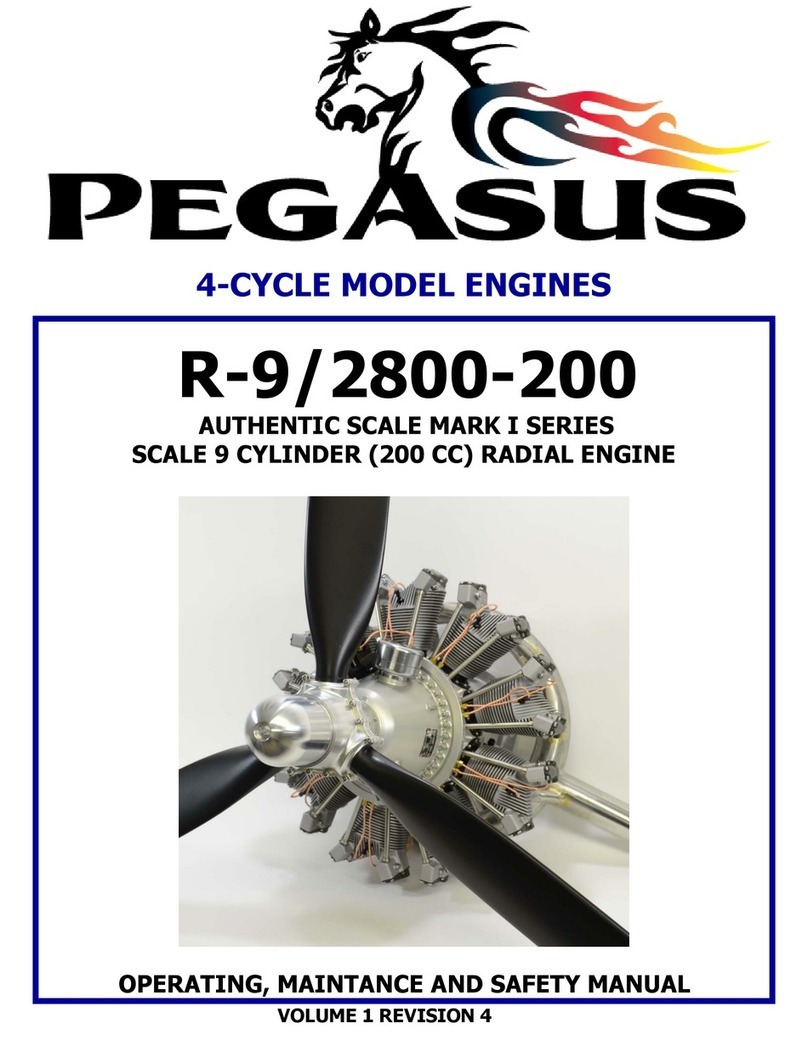

MPE 850 MARINE

– 408101 I2 846 MAR TC-100 (TC-80) (TC-120)

– 408014 I2 846 MAR TC-120

– 408090 I2 846 MAR TC-155

– 408246 I2 846 MAR NA-80

This diagnostic manual is valid for the following engine models:

en_English

DIAGNOSTIC MANUAL

4-Stroke Engine

Read the introductory chapter before performing the task on the engine.

Pay particular attention to the safety messages.

Textron Motors GmbH

Zepernicker Chaussee 23-37

16321 Bernau bei Berlin

Germany

www.weber-motor.com

Textron Motors GmbH strives to make continual improvements as part of the ongoing technical development

of its products. All documentation is therefore subject to technical modifications.

Reprints and translations, in whole or in part, require written permission from Textron Motors GmbH.

All rights reserved according to the copyright law.

4 DHB MPE850 MAR Rev B | 408014 | 408090 | 408101 | 408246 |

Table of contents

1 About this document 6

1.1 Meaning of the symbols and signal words........................................ 6

1.2 Change management .......................................................6

2 Safety 7

2.1 Meaning of the safety alert symbol and signal words ...............................7

2.2 Important safety messages ................................................... 8

3 Tools and accessories 10

3.1 Textron Motors diagnostic case ...............................................10

3.2 Equipment workshop .......................................................10

4 Lights in vehicle 11

4.1 Oil pressure warning light ................................................... 11

4.2 Service light .............................................................. 11

4.3 Malfunction indicator light (MIL)............................................... 12

4.4 Temperature warning light ...................................................12

5 Troubleshooting with trouble codes 13

5.1 Displaying trouble codes .................................................... 13

5.1.1 Displaying trouble codes with Textron Motors Diagnostic Tool ......................13

5.1.2 Displaying trouble codes with flash codes .....................................14

5.1.3 Conversion table for flash code to trouble code .................................15

5.2 Description of trouble codes .................................................17

6 Test procedures at engine 39

6.1 Checking voltage regulator ..................................................39

6.2 Checking generator ........................................................40

6.3 Checking crankshaft reluctor .................................................41

6.4 Checking thermostat ....................................................... 42

6.5 Checking cam spike at rocker arm ............................................43

6.6 Checking oil pressure ......................................................44

6.6.1 Troubleshooting guide too low oil pressure .................................... 45

6.6.2 Troubleshooting guide too high oil pressure....................................45

6 DHB MPE850 MAR Rev B | 408014 | 408090 | 408101 | 408246 |

This diagnostic manual was designed to help you operate the engine safely and reliably.

Observe the following information:

– Read the service manual before you begin working.

– Always you also need the engine’s repair manual and the vehicle manufacturer's documentation.

– Some figures in this diagnostic manual are general illustrations and may differ from the actual engine.

1 About this document

1.1 Meaning of the symbols and signal words

Item Meaning

NOTICE The signal word NOTICE indicates potential property damage.

Information The signal word Information indicates specific features and recommendations.

1.2 Change management

Textron Motors GmbH strives to make continual improvements as part of the ongoing technical development

of its products. Therefore descriptions in the diagnostic manual can be changed or added. All changes are

described in the chapter Overview of revisions.

Observe the following information:

– Always use the most current diagnostic manual from the protected area on our web site www.weber-

motor.com.

1 About this document

1.1 Meaning of the symbols and signal words | 1.2 Change management

7DHB MPE850 MAR Rev B | 408014 | 408090 | 408101 | 408246 |

This engine is state-of-the-art and built according to recognized safety-technical regulations. Ignoring the

information in this diagnostic manual may result in personal injury or property damage.

This diagnostic manual is solely intended for use in a workshop authorized by Textron Motors or the vehicle

manufacturer. All work on the engine must be performed by appropriately trained personnel.

Before beginning any work, trained personnel authorized to work on the engine must have access to the

complete documentation of the engine. Make sure that trained personnel have read and understand all

introductory chapters and in particular, the chapter on safety.

Observe all generally applicable laws and regulations in addition to the information in this diagnostic manual:

– accident prevention

– environmental protection

– handling of hazardous materials

– personal safety equipment

– traffic laws

2 Safety

2.1 Meaning of the safety alert symbol and signal words

Item Meaning

The safety alert symbol draws your attention to possible dangers.

WARNING

The signal word WARNING indicates a potentially dangerous situation that may

lead to a serious or fatal injury.

CAUTION

The signal word CAUTION indicates a potentially dangerous situation that may

lead to a minor or moderately severe injury.

2Safety

2.1 Meaning of the safety alert symbol and signal words

8 DHB MPE850 MAR Rev B | 408014 | 408090 | 408101 | 408246 |

2 Safety

2.2 Important safety messages

2.2 Important safety messages

Operating the engine during diagnostic work poses a safety risk to

persons.

►Pay particular attention to the safety messages in the vehicle

manufacturer‘s documentation.

►All diagnostic tasks on the engine must be performed by

appropriately trained personnel.

►Operate the engine during the diagnostic work only if it is absolutely

necessary.

►Only connect the power supply to the engine if it is absolutely

necessary.

►Always be aware that engines requiring diagnostic work may not be

in expected condition.

Defective parts on the engine pose a safety risk to persons.

►Replace defective parts.

All the components in your engine have been carefully tested and fulfill

strict quality and safety requirements.

►Textron Motors offers spare parts to the highest quality. Ensure that

equivalent spare parts corresponds with this quality requirements.

Engine modifications may pose a safety risk to persons.

►Do not install add-on parts or modify the engine.

Missing protective equipment poses a safety risk to persons.

►Attach all protective equipment after completing the service tasks.

Unsuitable tools pose a safety risk to persons.

►Use tools listed in chapter 3 Tools and accessories or equivalent

tools.

Engine components become extremely hot during operation.

►Do not touch any engine components during operation.

►Turn off the engine and wait until the components have cooled

before making contact.

Operate the engine

Defective parts

Spare parts

Add-on parts and modifications

Protective equipment

Tools

Hot engine components

9DHB MPE850 MAR Rev B | 408014 | 408090 | 408101 | 408246 |

2 Safety

2.2 Important safety messages

Engine exhaust gases contain carbon monoxide (CO). Inhalation of

carbon monoxide can deprive the body of oxygen and result in organ

damage or death by asphyxiation.

►Never operate the engine in enclosed spaces.

Engine fluids pose a health risk.

►Always read the manufacturer‘s instructions.

►Always wash your hands prior to eating, smoking and using the

restroom as well as at the end of the working shift when working

with engine fluids.

Engine fluids are hazardous to the environment.

►Never allow engine fluids to escape into the groundwater, water

courses or sewage system. Always dispose of engine fluids

according to applicable regulations.

Danger of slipping on spilled fluids.

►Always use a filler neck or funnel when filling the engine with fluids.

►Always clean up any spilled engine fluids immediately.

Fuel is highly flammable. Vapors may ignite and cause an explosion.

►Do not smoke in the vicinity of the engine and do not allow open

flames or sparks near the engine or the fuel system.

►Always turn off the engine before fueling.

►Never fill with fuel while the engine is running.

►Do not start the engine if you smell fuel or see a fuel leak.

►Fuel on hot surfaces can cause fires.

►In the event of a fire, use foam, dry chemical or carbon dioxide fire

extinguishers. Do not extinguish with water.

Engine oil is flammablew and can emit toxic gases.

►Do not smoke in the vicinity of the engine and do not allow open

flames or sparks near the engine.

►Engine oil on hot surfaces can cause fires.

►In the event of a fire, use foam, dry chemical or carbon dioxide fire

extinguishers. Do not extinguish with water.

This engine und engine exhaust contains chemicals known to the State of

California to cause cancer, birth defects, or other reproductive harm.

Engine exhaust gases

Fuel, engine oil and coolant

handling

Fuel

Engine oil

California Proposition 65

10 DHB MPE850 MAR Rev B | 408014 | 408090 | 408101 | 408246 |

3 Tools and accessories

3.1 Textron Motors diagnostic case | 3.2 Equipment workshop

3 Tools and accessories

Textron Motors offers a diagnostic case that contains the following parts. Visit our web site

www.weber-motor.com for more information.

3.1 Textron Motors diagnostic case

Figure Description

Textron Motors

diagnostic interface

module

Diagnostic cable

Figure Description

USB cable

Data on USB flash

drive: Textron Motors

Diagnostic Software

(english)

Manual (german and

english)

3.2 Equipment workshop

Figure Description

Digital-multimeter

In addition to the diagnostic case, the following test and diagnostic tools are required. The figures are only

examples of suitable test and diagnostic tools and available from specialist retailers.

Figure Description

Oil pressure tester with

M10x1 adapter

11DHB MPE850 MAR Rev B | 408014 | 408090 | 408101 | 408246 |

4 Lights in vehicle

4.1 Oil pressure warning light | 4.2 Service light

4 Lights in vehicle

4.1 Oil pressure warning light

The following lights are supported by the engine management system. Read the vehicle manufacturer‘s

documentation for more information.

– Oil pressure warning light

– Service light

– Malfunction indicator light (MIL)

– Temperature warning light

Description Cause Remedy

Illuminates a few seconds

when the engine is started.

There is no malfunction.

The oil pressure warning light

Illuminates until the required oil

pressure is achieved.

–

Illuminates while the engine is

running.

NOTICE! Oil pressure too low.

Serious engine damage due to

insufficient lubrication.

►Switch off the engine immediately.

►Check the oil pressure. (See

chapter 6 Test procedures at

engine.)

►Check the switch oil pressure.

►Check the oil pressure warning

light and wiring. (See the vehicle

manufacturer‘s documentation.)

4.2 Service light

Description Cause Remedy

Illuminates. There is no malfunction.

The integrated operating hours

counter has reached the next

service interval. Service tasks

must be performed.

►Perform the required service tasks

and clear the service counter

to reset service light. (See the

Textron Motors Diagnostic Tool

manual.)

12 DHB MPE850 MAR Rev B | 408014 | 408090 | 408101 | 408246 |

4.4 Temperature warning light

4 Lights in vehicle

4.3 Malfunction indicator light (MIL) | 4.4 Temperature warning light

4.3 Malfunction indicator light (MIL)

Description Cause Remedy

Illuminated for a few seconds

when the ignition is switched

on.

There is no malfunction.

Self test of the light.

–

Not illuminated when the

ignition is switched on.

The malfunction indicator light

(MIL) or wiring is defective.

►Check the wire harness. (See

chapter 7 Wiring diagram.)

►Check the malfunction indicator

light (MIL) and wiring. (See

the vehicle manufacturer‘s

documentation.)

Flashes when the ignition is on

and the engine is running.

Emission-related malfunction.

There is at least one trouble

code saved in the control unit.

►Display the trouble codes. (See

chapter 5.1 Displaying trouble

codes.)

Illuminates when the ignition is

on and the engine is running.

Malfunction.

There is at least one trouble

code saved in the control unit.

Description Cause Remedy

Flashes. NOTICE! The Coolant

temperature is too high.

Serious engine damage

caused by overheating.

►Display the trouble codes. (See

chapter 5.1 Displaying trouble

codes.)

Illuminates. NOTICE! The Exhaust

manifold temperature is too

high. Serious engine damage

caused by overheating.

13DHB MPE850 MAR Rev B | 408014 | 408090 | 408101 | 408246 |

1

5 Troubleshooting with trouble codes

5.1 Displaying trouble codes

5 Troubleshooting with trouble codes

5.1 Displaying trouble codes

5.1.1 Displaying trouble codes with Textron Motors Diagnostic Tool

The diagnostic connector is

integrated in the wire harness and

closed with an orange cap.

– Diagnostic connector 1

Notice! Wire harness damage due

to corrosion. Always close the

diagnostic connector with the cap

after diagnostic work.

►Connect the notebook to the engine und start Textron Motors Diagnostic Software. (See the Textron

Motors Diagnostic Tool manual.)

Information! Trouble codes can be displayed with the Textron Motors Diagnostic Tool or with flash

codes.

14 DHB MPE850 MAR Rev B | 408014 | 408090 | 408101 | 408246 |

5 Troubleshooting with trouble codes

5.1 Displaying trouble codes

5.1.2 Displaying trouble codes with flash codes

Information! Each flash code is assigned to a particular trouble code. The conversion table for flash

code to trouble code can be found in chapter 5.1.3 Conversion table for flash code to trouble code.

The engine is not started.

►Put the throttle control lever or pedal to full throttle.

►Turn on ignition.

►If the malfunction indicator light (MIL) starts flashing, put the throttle control lever or pedal in neutral

position. The ignition switch should remain in the on position.

The flash codes will be displayed corresponding the following flow diagram.

Ignition ON

Light testing

Start of the

1st flash code

sequence

1st flash code = 132

13 times long illuminating corresponds to 13.

2 times short illuminating corresponds to 2.

Which trouble code corresponds to flash code 132, see chapter 5.1.3

Conversion table for flash code to trouble code.

End

of the

1st flash

code se-

quence

Start of the

2nd flash code

sequence or

restart.

3 s

1 s

1 s

1 s

1 s

1 s

1 s

1 s

1 s

1 s

1 s

1 s

1 s

1 s

0,5 s

0,5 s

...

3 s

0,5 s

0,5 s

0,5 s

0,5 s

0,5 s

0,5 s

0,5 s

0,5 s

0,5 s

0,5 s

0,5 s

0,5 s

1,5 s

0,5 s

3 s

Malfunction indicator

light (MIL)

illuminates

not illuminated

All existing flash codes will be displayed in sequence.

►Turn off ignition.

If you do not turn off the ignition after 5 complete cycles the non active trouble codes will be deleted from the

engine control unit (ECU) memory.

15DHB MPE850 MAR Rev B | 408014 | 408090 | 408101 | 408246 |

5 Troubleshooting with trouble codes

5.1 Displaying trouble codes

5.1.3 Conversion table for flash code to trouble code

Flash code Trouble code

4 P2229

5 P2228

6 C0001

7 P0501

8 P0501

9 P0016

10 P0315

11 P0370

12 P0372

13 P0373

14 P025D

15 P025C

16 P025A

17 P0246

18 P0245

19 P0244

20 P2119

21 P0500

22 P0503

23 P0032

24 P0031

25 P0030

26 P0052

27 P0051

28 P0050

29 P0687

30 P0686

31 P0685

32 P0108

33 P0107

34 P0238

35 P0237

36 P2118

37 P0812

38 P0617

39 P0616

40 P0615

Flash code Trouble code

41 P0118

42 P0117

43 P0116

44 P0113

45 P0112

46 P0114

47 P2123

48 P2122

49 P2128

50 P2127

51 P061B

52 P0132

53 P0131

54 P0130

55 P0152

56 P0151

57 P0150

58 P0123

59 P0122

60 P0223

61 P0222

62 P0659

63 P0658

64 P0643

65 P0641

66 P0653

67 P0651

68 P0692

69 P0691

70 P0691

71 P0694

72 P0693

73 P0693

74 P1502

75 P1501

76 P0857

77 P0726

Flash code Trouble code

78 P2101

79 P2101

80 P2100

81 P2103

82 P2102

83 P2103

84 P2102

85 P2103

86 P2301

87 P0351

88 P2304

89 P0352

90 P2307

91 P0353

92 P2310

93 P0354

94 P0262

95 P0261

96 P0201

97 P0265

98 P0264

99 P0202

100 P0268

101 P0267

102 P0203

103 P0271

104 P0270

105 P0204

106 P0899

107 P0888

108 P0802

109 P0219

110 P0521

111 P2299

112 P0504

113 P0504

114 P2138

16 DHB MPE850 MAR Rev B | 408014 | 408090 | 408101 | 408246 |

Flash code Trouble code

115 P0642

116 P060B

117 P0217

118 P0172

119 P0171

120 P0175

121 P0174

122 P211A

123 P063D

124 P063C

125 P063E

126 P063A

127 P063B

128 P063F

129 P0638

130 P0121

131 P0221

132 P2135

133 P0344

134 P0012

135 P0011

136 P0341

137 P0324

138 P0325

139 P0336

140 P0330

141 P0331

142 P1604

143 P0238

144 P0237

145 C0073

146 C0073

147 C0073

148 C0073

149 C0073

150 C0073

151 C0073

152 P0138

153 P0137

Flash code Trouble code

154 P0136

155 P0158

156 P0157

157 P0156

158 P0038

159 P0037

160 P0036

161 P0058

162 P0057

163 P0056

164 P2261

165 P2262

166 P0546

167 P0545

168 P0172

169 P0171

170 P0175

171 P0174

172 P0133

173 P0153

174 P0420

175 P0430

176 P0128

177 P0101

178 P2270

179 P2271

180 P227A

181 P2272

182 P2273

183 P227B

184 P0459

185 P0458

186 P0444

187 P0314

188 P0579

189 P0578

190 P0567

191 P0570

192 P0569

Flash code Trouble code

193 P0315

194 P0300

195 P0136

196 P0156

197 P0139

198 P0139

199 P0139

200 P0159

201 P0159

202 P0159

203 P0336

204 P0626

205 P0625

206 P060C

207 P0606

208 P061A

209 P061C

5 Troubleshooting with trouble codes

5.1 Displaying trouble codes

17DHB MPE850 MAR Rev B | 408014 | 408090 | 408101 | 408246 |

5 Troubleshooting with trouble codes

5.2 Description of trouble codes

5.2 Description of trouble codes

Trouble code

Displayed fault

Trouble code description

Possible consequences

Affected part/system

►Possible consequences/remedy

P0011 "A" Camshaft Position - Timing Over-

Advanced or System Performance Bank 1

Invalid signal at the sensor camshaft.

Sensor camshaft

►Check the valve timing. (See the repair

manual.)

►Check wiring in the wire harness to the

affected part. (See chapter 7 Wiring

diagram.)

►Replace the affected part. (See the repair

manual.)

P0016 Crankshaft Position – Camshaft Position

Correlation Bank 1 Sensor A

The signals sensor crankshaft and sensor

camshaft are not synchronous.

Rough engine running.

Engine does not start or stalls.

Sensor crankshaft

►Check wiring in the wire harness to the

affected part. (See chapter 7 Wiring

diagram.)

►Replace the affected part. (See the repair

manual.)

►Check the crankshaft reluctor. (See

chapter 6 Test procedures at engine.)

P0030 HO2S Heater Control Circuit Bank 1 Sensor 1

Open circuit at part or wire harness.

Loss of power.

Rough engine running.

Sensor lambda 1

►Check wiring in the wire harness to the

affected part. (See chapter 7 Wiring

diagram.)

►Replace the affected part. (See the repair

manual.)

P0031 HO2S Heater Control Circuit Low Bank 1

Sensor 1

Short circuit to ground at part or wire harness.

Loss of power.

Rough engine running.

Sensor lambda 1

►Check wiring in the wire harness to the

affected part. (See chapter 7 Wiring

diagram.)

►Replace the affected part. (See the repair

manual.)

18 DHB MPE850 MAR Rev B | 408014 | 408090 | 408101 | 408246 |

5 Troubleshooting with trouble codes

5.2 Description of trouble codes

Trouble code

Displayed fault

Trouble code description

Possible consequences

Affected part/system

►Possible consequences/remedy

P0032 HO2S Heater Control Circuit High Bank 1

Sensor 1

Short circuit to plus at part or wire harness.

Loss of power.

Rough engine running.

Sensor lambda 1

►Check wiring in the wire harness to the

affected part. (See chapter 7 Wiring

diagram.)

►Replace the affected part. (See the repair

manual.)

P0036 HO2S Heater Control Circuit Bank 1 Sensor 2

Open circuit at part or wire harness.

Loss of power.

Rough engine running.

Sensor lambda 2

►Check wiring in the wire harness to the

affected part. (See chapter 7 Wiring

diagram.)

►Replace the affected part. (See the repair

manual.)

P0037 HO2S Heater Control Circuit Low Bank 1

Sensor 2

Short circuit to ground at part or wire harness.

Loss of power.

Rough engine running.

Sensor lambda 2

►Check wiring in the wire harness to the

affected part. (See chapter 7 Wiring

diagram.)

►Replace the affected part. (See the repair

manual.)

P0038 HO2S Heater Control Circuit High Bank 1

Sensor 2

Short circuit to plus at part or wire harness.

Loss of power.

Rough engine running.

Sensor lambda 2

►Check wiring in the wire harness to the

affected part. (See chapter 7 Wiring

diagram.)

►Replace the affected part. (See the repair

manual.)

19DHB MPE850 MAR Rev B | 408014 | 408090 | 408101 | 408246 |

5 Troubleshooting with trouble codes

5.2 Description of trouble codes

Trouble code

Displayed fault

Trouble code description

Possible consequences

Affected part/system

►Possible consequences/remedy

P0101 Mass or Volume Air Flow Circuit Range/

Performance

Implausible values in air mass calculation.

Loss of power.

Starting difficulties.

Sensor intake manifold pressure/temperature

►Check wiring in the wire harness to the

affected part. (See chapter 7 Wiring

diagram.)

►Replace the affected part. (See the repair

manual.)

►Leak air in the intake system can cause the

fault. Check the intake system.

WARNING! The throttle body is a safety

critical component. Improper repair or

cleaning of the throttle body may endanger

the safety of persons. Always replace a

defective throttle body.

►Corrosion or soiling in the throttle body can

cause the fault. Check the throttle body.

(See the repair manual.)

P0107 Manifold Absolute Pressure/Barometric

Pressure Circuit Low Input

Open circuit or short circuit to ground at part or

wire harness.

Loss of power.

Starting difficulties.

Sensor intake manifold pressure/temperature

►Check wiring in the wire harness to the

affected part. (See chapter 7 Wiring

diagram.)

►Replace the affected part. (See the repair

manual.)

P0108 Manifold Absolute Pressure/Barometric

Pressure Circuit High Input

Short circuit to plus at part or wire harness.

Loss of power.

Starting difficulties.

Sensor intake manifold pressure/temperature

►Check wiring in the wire harness to the

affected part. (See chapter 7 Wiring

diagram.)

►Replace the affected part. (See the repair

manual.)

20 DHB MPE850 MAR Rev B | 408014 | 408090 | 408101 | 408246 |

5 Troubleshooting with trouble codes

5.2 Description of trouble codes

Trouble code

Displayed fault

Trouble code description

Possible consequences

Affected part/system

►Possible consequences/remedy

P0112 Intake Air Temperature Sensor 1 Circuit Low

Short circuit to ground at part or wire harness.

Loss of power.

Starting difficulties.

Sensor intake manifold pressure/temperature

►Check wiring in the wire harness to the

affected part. (See chapter 7 Wiring

diagram.)

►Replace the affected part. (See the repair

manual.)

P0113 Intake Air Temperature Sensor 1 Circuit High

Open circuit or short circuit to plus at part or

wire harness.

Loss of power.

Starting difficulties.

Sensor intake manifold pressure/temperature

►Check wiring in the wire harness to the

affected part. (See chapter 7 Wiring

diagram.)

►Replace the affected part. (See the repair

manual.)

P0116 Engine Coolant Temperature Circuit Range/

Performance

Measured data implausible.

Sensor coolant temperature

►Check wiring in the wire harness to the

affected part. (See chapter 7 Wiring

diagram.)

►Replace the affected part. (See the repair

manual.)

P0117 Engine Coolant Temperature Circuit Low

Short circuit to ground at part or wire harness.

Sensor coolant temperature

►Check wiring in the wire harness to the

affected part. (See chapter 7 Wiring

diagram.)

►Replace the affected part. (See the repair

manual.)

P0118 Engine Coolant Temperature Circuit High

Open circuit or short circuit to plus at part or

wire harness.

Sensor coolant temperature

►Check wiring in the wire harness to the

affected part. (See chapter 7 Wiring

diagram.)

►Replace the affected part. (See the repair

manual.)

This manual suits for next models

9

Table of contents

Other Textron Motors Engine manuals

Popular Engine manuals by other brands

Becker

Becker R8-17-E22 Assembly and operating instructions

Nanni

Nanni Z4.205 Operator's manual

ABB

ABB TPL71-C35 Operation manual

3T-Components

3T-Components 3T-MOTORS 3T45-20 Installation & operating instructions

NSK

NSK Megatorque Motor EGA Startup guide

Briggs & Stratton

Briggs & Stratton 120000 Operating & maintenance instructions