Textron Motors MPE 850 OFF-ROAD Operating instructions

TD409135_RLF

Rev A

04.09.2015

MPE 850 OFF-ROAD

– 409135 I2 846 UTV NA-80

This repair manual is valid for the following engine models:

en_English

REPAIR MANUAL

4-Stroke Engine

Read the introductory chapter before performing the task on the engine.

Pay particular attention to the safety messages.

Textron Motors GmbH

Daimlerstraße 5

88677 Markdorf

Germany

www.weber-motor.com

Textron Motors GmbH strives to make continual improvements as part of the ongoing technical development

of its products. All documentation is therefore subject to technical modifications.

Reprints and translations, in whole or in part, require written permission from Textron Motors GmbH.

All rights reserved according to the copyright law.

4 RLF MPE850 Rev A | 409135 |

Table of contents

Table of contents

1 About this document 9

1.1 Meaning of the symbols and signal words........................................ 9

1.2 Change management .......................................................9

1.3 Finding the required information ..............................................10

2 Safety 11

2.1 Meaning of the safety alert symbol and signal words .............................. 11

2.2 Important safety messages .................................................. 12

3 Basic instructions for working on the engine 15

3.1 Before you begin working ...................................................15

3.1.1 Removing engine from vehicle ..............................................15

3.2 While working ............................................................15

3.2.1 Lift and transport the engine................................................15

3.2.2 Secure the engine while working ............................................15

3.2.3 Tightening torque ........................................................ 16

3.2.4 Cleaning ...............................................................16

3.2.5 Disposal ...............................................................16

3.3 After working .............................................................16

3.3.1 Updating engine control unit calibration ....................................... 16

3.3.2 Checking the work carried out ..............................................16

4 Tools and accessories 17

4.1 Equipment workshop .......................................................17

4.1.1 Textron Motors special tools ................................................17

4.1.2 Textron Motors Diagnostic Tool.............................................. 18

4.1.3 Commercially available workshop equipment and standard tools ...................18

4.1.4 Commercially available special tools .........................................20

4.1.5 Supplies ...............................................................21

5 Overview of activities 22

010 Crankcase ..............................................................22

010.01-1 Crankcase ..........................................................22

Replacing crankcase.........................................................22

Replacing welch plugs .......................................................22

Replacing tie rod ............................................................22

Replacing plugs ............................................................22

010.01-2 Crankcase NA .......................................................22

Replacing cylinder liners ......................................................22

Replacing oil seal ...........................................................23

Replacing plug .............................................................23

010.01-3 Crankcase ..........................................................23

Removing plug .............................................................23

Installing plug ..............................................................23

5RLF MPE850 Rev A | 409135 |

Table of contents

Replacing plugs ............................................................23

Removing fitting ............................................................23

Installing fitting .............................................................23

Removing sensor crankshaft ..................................................23

Installing sensor crankshaft ...................................................23

Removing sensor knock ......................................................23

Installing sensor knock .......................................................23

010.02-1 Oil cooler bracket ..................................................... 24

Removing oil cooler bracket ...................................................24

Installing oil cooler bracket ....................................................24

010.02-2 Oil cooler bracket ..................................................... 24

Replacing blanking cover .....................................................24

Replacing plug .............................................................24

Sealing cover oil cooler bracket ................................................24

010.03 Generator cover........................................................ 24

Removing generator cover ....................................................24

Installing generator cover .....................................................24

Replacing generator cover ....................................................24

Replacing oil seal ...........................................................25

Replacing vent plug .........................................................25

020 Crank drive ..............................................................25

020.01 Crankshaft ............................................................25

Removing crank drive ........................................................25

Installing crank drive .........................................................26

Replacing crankshaft ........................................................26

Replacing balance shaft ......................................................26

Removing pistons and con rods ................................................26

Installing pistons and con rods .................................................27

Replacing piston ............................................................27

Replacing con rod ...........................................................27

Checking con rod bearing play .................................................27

Checking main bearing play ...................................................27

020.02 Stub shaft ............................................................27

Removing stub shaft .........................................................27

Installing stub shaft ..........................................................27

020.03 Abdeckung Kurbelwelle ..................................................28

Removing crankshaft cover....................................................28

Installing crankshaft cover ....................................................28

030 Cylinder head ............................................................28

030.01 Valve cover ........................................................... 28

Removing valve cover........................................................28

Installing valve cover.........................................................28

Replacing valve cover........................................................28

Removing ignition coils .......................................................28

Installing ignition coils ........................................................28

Removing sensor camshaft....................................................28

Installing sensor camshaft ....................................................28

030.02 Cylinder head .........................................................29

Removing cylinder head ......................................................29

Installing cylinder head .......................................................29

Replacing cylinder head ......................................................29

Removing spark plugs........................................................29

6 RLF MPE850 Rev A | 409135 |

Table of contents

Installing spark plugs ........................................................30

Removing switch oil pressure ..................................................30

Installing switch oil pressure ...................................................30

Removing fitting ............................................................30

Installing fitting .............................................................30

Replacing plugs ............................................................30

040 Valve train............................................................... 30

040.01 Camshaft .............................................................30

Replacing camshaft..........................................................30

Replacing timing chain .......................................................31

Checking and setting valve timing ..............................................31

Replacing chain rail..........................................................31

Replacing chain guide........................................................31

040.02 Rocker arms ..........................................................31

Replacing rocker arms .......................................................31

040.03 Valves ...............................................................32

Removing valve.............................................................32

Installing valve..............................................................32

050 Cooling system ...........................................................32

050.01 Thermostat housing.....................................................32

Removing thermostat housing .................................................32

Installing thermostat housing .................................................. 32

Removing fitting ............................................................32

Installing fitting .............................................................32

Replacing thermostat ........................................................33

Replacing sensor coolant temperature ...........................................33

Replacing plug thermostat housing..............................................33

Removing closing cap thermostat housing ........................................33

Installing closing cap thermostat housing .........................................33

050.02 Coolant pump .........................................................33

Removing impeller ..........................................................33

Installing impeller ...........................................................33

Removing coolant pump ......................................................34

Installing coolant pump .......................................................34

050.03 Oil cooler .............................................................34

Removing oil cooler..........................................................34

Installing oil cooler...........................................................34

060 Exhaust system ..........................................................34

060.01 Mounting exhaust manifold ............................................... 34

Removing/Installing exhaust system.............................................34

Replacing studs.............................................................34

070 Intake area .............................................................. 35

070.01 Intake manifold ........................................................35

Removing intake manifold.....................................................35

Installing intake manifold......................................................35

Replacing intake manifold.....................................................35

Removing sensor intake manifold pressure/temperature .............................35

Installing sensor intake manifold pressure/temperature ..............................35

Replacing cap ..............................................................35

070.02 Mounting throttle body ...................................................35

Removing throttle body .......................................................35

Installing throttle body ........................................................35

7RLF MPE850 Rev A | 409135 |

Table of contents

Replacing throttle body .......................................................35

Replacing rubber mount ......................................................35

080 Engine management system ................................................ 36

Sensor crankshaft ...........................................................36

Sensor camshaft ............................................................36

Sensor coolant temperature ...................................................36

Sensor lambda .............................................................36

Sensor intake manifold pressure/temperature NA ..................................36

Sensor knock ..............................................................36

Engine control unit NA .......................................................36

Ignition coils ...............................................................36

Spark plugs ................................................................36

Injectors NA................................................................36

Throttle body ...............................................................36

Switch oil pressure ..........................................................36

090 Starter, Generator......................................................... 36

090.01 Starter ...............................................................36

Removing starter............................................................36

Installing starter.............................................................36

Replacing starter............................................................36

090.02 Generator ............................................................37

Removing generator .........................................................37

Installing generator ..........................................................37

090.03 Voltage regulator ....................................................... 37

Removing/Installing voltage regulator............................................37

090.04 Relay starter ..........................................................37

Removing/Installing relay starter ...............................................37

100 Fuel system .............................................................37

100.01 Fuel rail ..............................................................37

Removing fuel rail ...........................................................37

Installing fuel rail ............................................................37

Replacing injector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

110 Lubrication system ........................................................ 37

110.01 Dry sump ............................................................. 37

Removing suction pump cover .................................................37

Installing suction pump cover ..................................................37

Replacing suction pump cover .................................................38

Removing oil suction pump....................................................38

Installing oil suction pump.....................................................38

Stutzen ersetzen ............................................................38

Removing intermediate gear suction pump .......................................38

Installing intermediate gear suction pump ........................................38

110.02 Oil pressure pump ......................................................39

Removing oil pressure pump ..................................................39

Installing oil pressure pump ...................................................39

110.03 Oil pressure valve ...................................................... 39

Removing oil pressure valve...................................................39

Installing oil pressure valve....................................................39

110.04 Oil filter...............................................................39

Removing oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Installing oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Removing threaded sleeve ....................................................39

8 RLF MPE850 Rev A | 409135 |

Table of contents

Installing threaded sleeve .....................................................40

110.05 Oil tank...............................................................40

Removing/Installing oil tank ...................................................40

120 Engine mount ............................................................40

120.01 Lifting eye ............................................................40

Removing bracket on the drive side .............................................40

Installing bracket on the drive side ..............................................40

Removing pipe clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Installing pipe clamp .........................................................40

Removing bracket across from the drive side......................................40

Installing bracket across from the drive side.......................................40

6 Working instructions, single 41

6.1 List of working instructions, single .............................................41

Appendix 231

Overview of revisions ..........................................................231

Index ......................................................................232

This repair manual describes how to safely and correctly remove, install and replace engine components.

Observe the following information:

– Read through the service manual before performing any tasks.

– Some figures in this repair manual are general illustrations and may differ from the actual engine.

1 About this document

1.1 Meaning of the symbols and signal words

Item Meaning

NOTICE The signal word NOTICE indicates potential property damage.

Information The signal word Information indicates specific features and recommendations.

For the activity required special tools.

For the activity additionally required spare parts.

For the activity required supplies.

For the activity additionally required documents.

1About this document

1.1 Meaning of the symbols and signal words | …

1.2 Change management

Textron Motors GmbH strives to make continual improvements as part of the ongoing technical development

of its products. You may find that descriptions in the repair manual are changed or amended. All changes are

described in the chapter Overview of revisions.

Observe the following information:

– Always use the most current repair manual from the protected area on our web site

www.weber-motor.com.

– Always print the required chapter and all chapters referred to completely and then destroy the printouts.

9

RLF MPE850 Rev A | 409135 |

1About this document

1.3 Finding the required information

1.3 Finding the required information

►Open chapter 5 Overview of activities in

the repair manual.

►Locate the section with the same

designation 010.01-2 Crankcase NA 3.

In this section you will find the activity

Replacing cylinder liners 5.

►Check whether the activity is valid for the

engine model 4.

►Perform all for the activity required working

instructions 6in the order shown.

Observe the following references:

– A list of all working instructions is located in

chapter 6.1 List of working instructions,

single.

– Each working instruction contains information

on required special tools, additional required

spare parts, supplies and documents.

When you planning a work on the engine, proceed

as follows:

For example, you want to replace the cylinder

liners 2.

►Identify the corresponding component in the

spare parts catalog..

The cylinder liners can be found in the spare

parts catalog in chapter

010.01-2 Crankcase NA 1

10 RLF MPE850 Rev A | 409135 |

2

3

4

5

6

1

11RLF MPE850 Rev A | 409135 |

This engine is state-of-the-art and built according to recognized safety-technical regulations. Ignoring the

information in this repair manual may result in personal injury or property damage.

This repair manual is solely intended for use in a workshop authorized by Textron Motors or the vehicle

manufacturer. All work on the engine must be performed by appropriately trained personnel.

Before beginning any work, trained personnel authorized to work on the engine must have access to the

complete documentation of the engine. Make sure that trained personnel have read and understand all

introductory chapters and in particular, the chapter on safety.

Observe all generally applicable laws and regulations in addition to the information in this repair manual:

– accident prevention

– environmental protection

– handling of hazardous materials

– personal safety equipment

– traffic laws

2 Safety

2.1 Meaning of the safety alert symbol and signal words

Item Meaning

The safety alert symbol draws your attention to possible dangers.

WARNING

The signal word WARNING indicates a potentially dangerous situation that may

lead to a serious or fatal injury.

CAUTION

The signal word CAUTION indicates a potentially dangerous situation that may

lead to a minor or moderately severe injury.

2Safety

2.1 Meaning of the safety alert symbol and signal words

12 RLF MPE850 Rev A | 409135 |

2.2 Important safety messages

2Safety

2.2 Important safety messages

You endanger the safety of personnel if you do not perform work exactly

as described in this repair manual.

►Do not deviate from the working instructions in this repair manual.

►Pay attention to the safety messages in the vehicle manufacturer’s

documentation.

Engine malfunctions can cause pose a safety risk to persons.

►Only operate the engine in perfect condition.

Defective engine components can cause serious engine damages and

pose a safety risk to persons.

►Check all components before installation.

►Always replace defective components.

Work performed incorrectly poses a safety risk to personnel.

►Check the vehicle safety each time after working on the engine.

(See chapter 3.3.2 Checking the work carried out.)

All the components in your engine have been carefully tested and fulfill

strict quality and safety requirements.

►Textron Motors offers spare parts to the highest quality. Ensure that

equivalent spare parts corresponds with this quality requirements.

Engine modifications may pose a safety risk to persons.

►Do not install add-on parts or modify the engine.

Spinal column injury due to incorrect lifting of heavy loads.

►Always use a workshop crane to lift and transport the engine on the

brackets provided. (See chapter 3.2 Lift and transport the engine.)

Crush injuries due to the engine overturning.

►Mount the engine to the engine stand before starting any work.

(See chapter 3.2.2 Secure the engine while working.)

Unsuitable tools and accessories pose a safety risk to personnel.

►Always use tools listed in chapter 4 Tools and accessories.

Working instructions

Malfunctions

Defective components

Checking the work carried out

Spare parts

Add-on parts and modifications

Lift and transport the engine.

Securing the engine

Tools and accessories

13RLF MPE850 Rev A | 409135 |

2Safety

2.2 Important safety messages

Missing protective equipment poses a safety risk to personnel.

►Attach all protective equipment after completing the tasks.

Engine components become extremely hot during operation.

►Do not touch any engine components during operation.

►Switch off the engine and wait until the components have cooled.

The engine must be disconnected from the power supply before any work

is carried out. Leaving the engine connected to the power supply poses a

risk to personnel.

►Only reconnect the power supply when prompted to do so by the

vehicle manufacturer.

►Pay attention to the safety messages in the vehicle manufacturer’s

documentation.

Engine exhaust gases contain carbon monoxide (CO). Inhalation of

carbon monoxide can deprive the body of oxygen and result in organ

damage or death by asphyxiation.

►Never operate the engine in enclosed spaces.

Engine fluids pose a health risk.

►Always read the manufacturer's instructions.

►Always wash your hands prior to eating, smoking and using the

restroom as well as at the end of the working shift when working

with engine fluids.

Engine fluids are hazardous to the environment.

►Never allow engine fluids to escape into the groundwater, water

courses or sewage system. Always dispose of engine fluids

according to applicable regulations.

Danger of slipping on spilled fluids.

►Always use a filler neck or funnel when filling the engine with fluids.

►Always clean up any spilled engine fluids immediately.

Fuel is highly flammable. Vapors may ignite and cause an explosion.

►Do not smoke in the vicinity of the engine and do not allow open

flames or sparks near the engine or the fuel system.

►Always turn off the engine before fueling.

►Never fill with fuel while the engine is running.

►Do not start the engine if you smell fuel or see a fuel leak.

►Fuel on hot surfaces can cause fires.

►In the event of a fire, use foam, dry chemical or carbon dioxide fire

extinguishers. Do not extinguish with water.

Protective equipment

Hot engine components

Engine power supply

Engine exhaust gases

Fuel, engine oil and coolant

handling

Fuel

14 RLF MPE850 Rev A | 409135 |

2Safety

2.2 Important safety messages

Engine oil is flammable and can emit toxic gases.

►Do not smoke in the vicinity of the engine and do not allow open

flames or sparks near the engine.

►Engine oil on hot surfaces can cause fires.

►In the event of a fire, use foam, dry chemical or carbon dioxide fire

extinguishers. Do not extinguish with water.

Engine oil

15RLF MPE850 Rev A | 409135 |

1

1

See the vehicle manufacturer‘s documentation.

3Basic instructions for working on the engine

3.1 Before you begin working | 3.2 While working

3 Basic instructions for working on the engine

The following requirements must be met before performing any tasks:

– The engine has been removed from the vehicle.

– The engine has been disconnected from the power supply.

– There is no engine oil or coolant in the engine.

– The engine is in original factory condition. You identify the factory condition in the spare parts catalog.

3.1 Before you begin working

3.1.1 Removing engine from vehicle

3.2 While working

WARNING! Spinal column injury due to

incorrect lifting of heavy loads. Always lift the

engine using a workshop crane.

NOTICE! Components can break. Lift the engine

only using the brackets.

►Lift the engine using the brackets 1.

3.2.1 Lift and transport the engine

WARNING! Crush injuries due to the engine overturning. Mount the engine to the engine stand before

starting any work.

If not otherwise specified, mount the engine on the drive side or across from the drive side. (See

chapter 000.01 Mount the engine on the engine stand.)

3.2.2 Secure the engine while working

16 RLF MPE850 Rev A | 409135 |

3Basic instructions for working on the engine

3.2 While working | 3.3 Checking the work carried out

When disposing of operating materials, replaced parts or the whole engine, always comply with the relevant

applicable national laws and guidelines.

3.2.5 Disposal

For all details about tightening torque in this repair manual, observe the following information:

– If not otherwise specified, threads are dry and free of engine oil.

– For components with coated threads, the tightening torques always refer to new components.

3.2.3 Tightening torque

Observe the following information:

– Before assembling components, clean all joint surfaces.

– If there is contamination in the lubrication system, cooling system or fuel unit, clean all components

concerned.

3.2.4 Cleaning

Check the engine when installed again in the vehicle.

►Turn the ignition on for about a minute, until the throttle body opens and closes again.

►Allow the engine to warm up as described in the service manual of the engine. You should not hear

any unusual noises.

►Perform a visual inspection. No fluids should be escaping.

►Run the engine through all operating modes.

3.3.2 Checking the work carried out

Update the calibration of the engine control unit when engine installed again in the vehicle.

►Update the engine control unit calibration. (See the Textron Motors Diagnostic Tool manual.)

►Clear the trouble codes. (See the Textron Motors Diagnostic Tool manual.)

3.3.1 Updating engine control unit calibration

3.3 After working

17RLF MPE850 Rev A | 409135 |

4Tools and accessories

4.1 Equipment workshop

4Tools and accessories

Textron Motors offers a tool case that contains the following Textron Motors special tools. Visit our web site

www.weber-motor.com for more information.

4.1.1 Textron Motors special tools

Figure Description

Locking tool crankshaft

Chain tool

Installation spike valve

stem seal

Remover bearing cap

Figure Description

TDC-adjusting tool

Assembling kit oil seal

crankshaft

Pin punch axle

intermediate gear

Assembling kit slide

ring seal

4.1 Equipment workshop

18 RLF MPE850 Rev A | 409135 |

4Tools and accessories

4.1 Equipment workshop

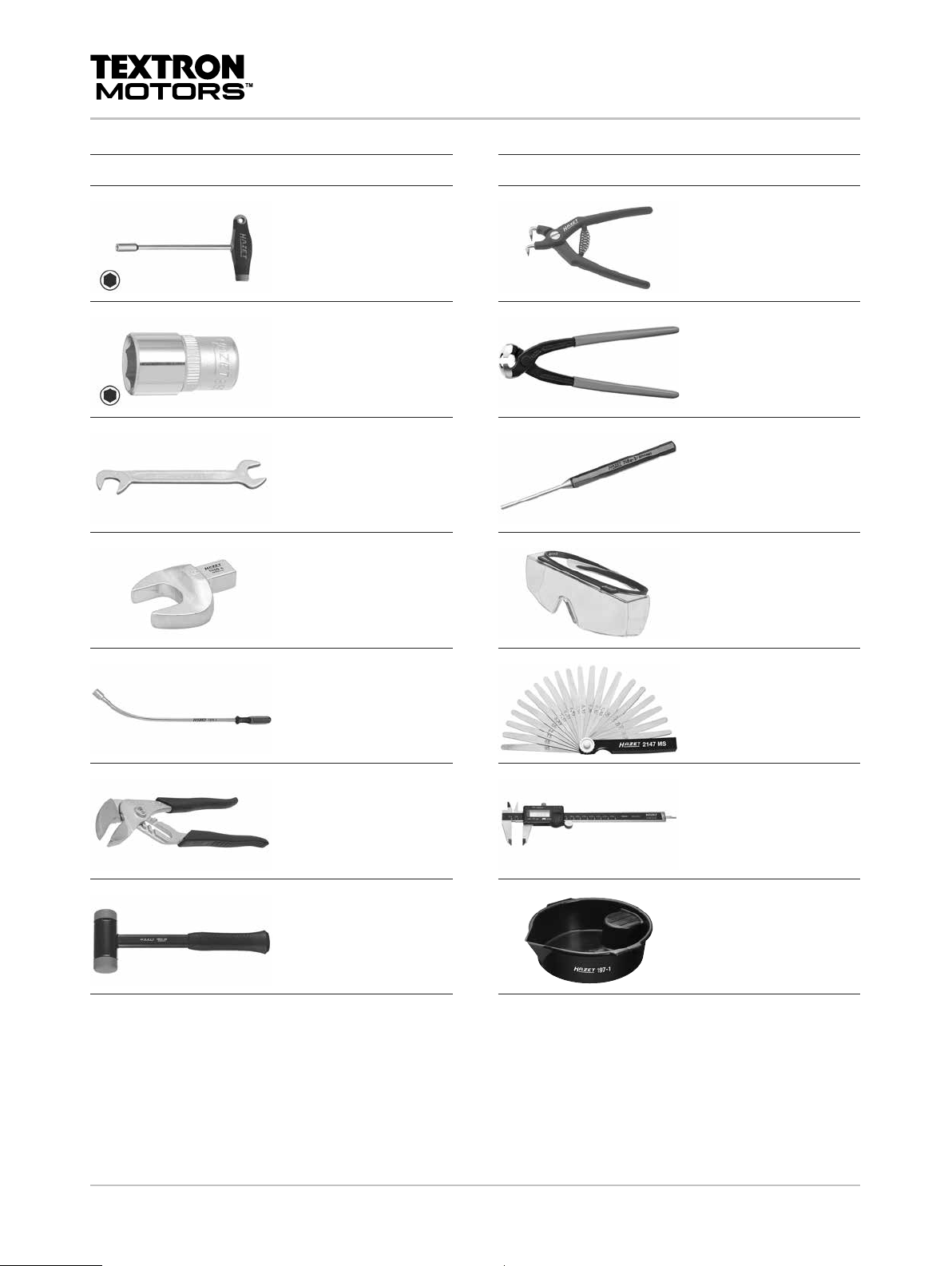

4.1.3 Commercially available workshop equipment and standard tools

Abbildung Bezeichnung

Workshop crane with

carrying strap

Minimum lifting

capacity 300 kg

[650 lb]

Engine stand

Minimum lifting capacity

300 kg [650 lb]

Mounting bolts M6 and

M10

Torque wrench

0,5 – 80 Nm

[0.4 – 59 lbf ft]

with extension and

insert adapter

Reversible ratchet

with extension and

insert adapter

Abbildung Bezeichnung

Torx® screwdriver

T20, T30, T45

Torx® screwdriver

socket

T20, T30, T45

Hexagon screwdriver

4, 5, 6, 7, 8

6-point socket

4, 5, 6, 7, 8

In addition to the Textron Motors special tools, you will require the following tools and accessories. The

figures are only examples of suitable tools. All tools and accessories are available from specialist retailers.

Textron Motors offers a diagnostic case that

contains the Textron Motors Diagnostic Tool. The

Textron Motors Diagnostic Tool is designed for fault

diagnostics and service tasks for Textron engines

using a Synerject engine management system.

Visit your local vehicle dealer or our web site

www.weber-motor.com for more information.

4.1.2 Textron Motors Diagnostic Tool

19RLF MPE850 Rev A | 409135 |

4Tools and accessories

4.1 Equipment workshop

Abbildung Bezeichnung

Hexagon nut-driver

7

6-point socket wrench

7, 10, 12, 14

Open-end wrench

7, 12, 15, 19, 22, 24,

27

Insert open-end

wrench

7, 12, 15, 16, 19, 22,

24, 27

Bar magnet

Universal pliers

Plastic hammer

Abbildung Bezeichnung

Lockring pliers (bore

holes)

Clamp pincer

Pin punch

5, 7, 8

Protective glasses

Feeler gauge

0,05 – 2 mm

Caliper

Measuring accuracy

0,05 mm

Drip tray

20 RLF MPE850 Rev A | 409135 |

4Tools and accessories

4.1 Equipment workshop

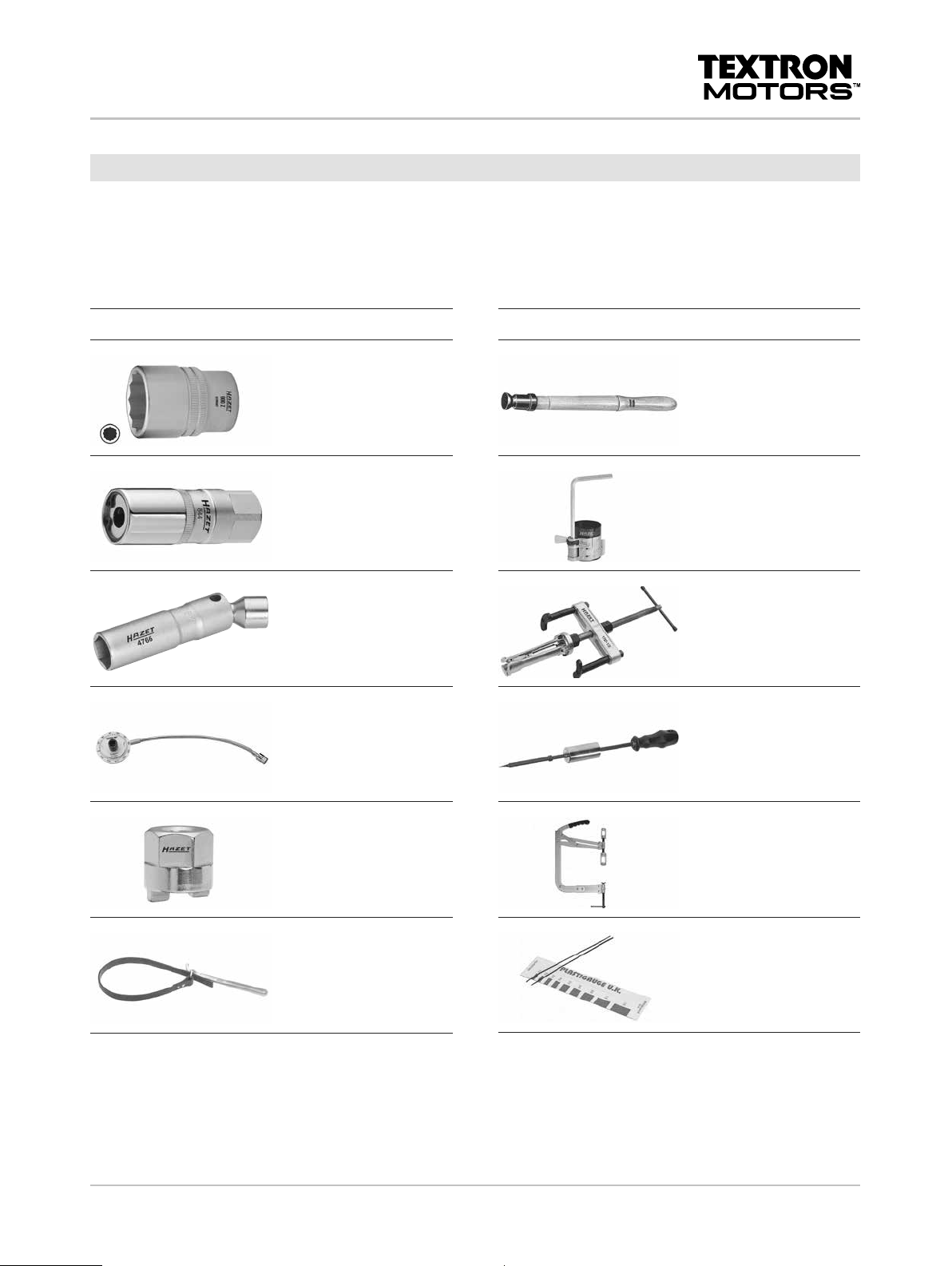

4.1.4 Commercially available special tools

Abbildung Bezeichnung

12-point socket

wrench

12

Stud extractor

8, 10

Spark plug wrench

Wrench size 16 mm

[5/8“]

Diameter: maximum

22 mm [0.87 in]

Angle indicator

Crown wrench

Width of pins

maximum 3 mm

Universal strap wrench

Abbildung Bezeichnung

Valve refacer

Piston ring compressor

Cylinder liner puller

Oil seal slide hammer

Valve spring

compressor

Precision clearance

gauges

0,025 mm - 0,04 mm

In addition you will require the following commercially available special tools. In the working instructions will

be separately referred on these special tools. The figures are only examples of suitable tools. All tools and

accessories are available from specialist retailers.

Other manuals for MPE 850 OFF-ROAD

1

Table of contents

Other Textron Motors Engine manuals

Popular Engine manuals by other brands

Mazda

Mazda L8 Workshop manual

Simu

Simu T5 AUTOSHORT BHz Series Original instructions

Doosan

Doosan D1146 Installation operation & maintenance

Continental Motors

Continental Motors TSI0L-550-C Operation, maintenance & installation manual

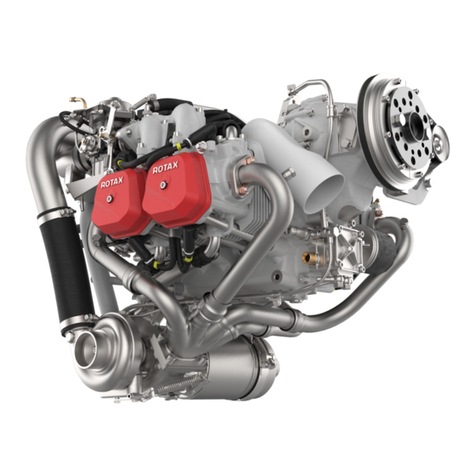

Rotax

Rotax 914 F Maintenance manual

Hyundai Seasall

Hyundai Seasall S250S Workshop manual