PSC Inducer Motor

Housing Assembly Kit

Installation Instructions

Part No. 320725-753

NOTE: Read the entire instruction manual before starting the

installation.

This symbol →indicates a change since the last issue.

SAFETY CONSIDERATIONS

Installing and servicing of heating equipment can be hazardous

due to gas and electrical components. Only trained personnel

should install or service heating equipment.

Untrained personnel can perform basic maintenance functions

such as cleaning coils or cleaning and replacing filters. All other

operations should be performed by trained service personnel.

When working on heating equipment, observe precautions in the

literature, on tags, and on labels attached to the unit.

Follow all safety codes. Wear safety glasses and work gloves.

Have fire extinguisher available.

Recognize safety information. This is the safety-alert symbol .

When you see this symbol on the furnace and in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, and CAU-

TION. These words are used with the safety-alert symbol. DAN-

GER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies a hazard which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which would result in minor personal

injury or product and property damage.

Before beginning any installation or modification, be sure the

main electrical disconnect switch is in the OFF position.

Electrical shock can cause personal injury or death.

Label all wires prior to disconnection when servicing con-

trols. Wiring errors can cause improper and dangerous

operation.

INTRODUCTION

This instruction covers installation of the permanent split capacitor

(PSC) inducer motor kit Part No. 320725-753 on models

340MAV, 345MAV, 350MAV, 490AAV, 58MCA, 58MSA, and

58MXA Condensing Gas Furnaces. See Table 1 for kit applica-

bility.

DESCRIPTION AND USAGE

Use this PSC inducer motor kit to replace a failed inducer motor

assembly.

This kit contains the following items:

Inducer assembly 1

Installation Instructions 1

NOTE: Inducer assembly consists of motor and fan, capacitor,

wheel, motor mount, inducer cover, inducer housing, vent cap, and

vent clamp.

INSTALLATION

Step 1—Remove Old Motor Assembly

1. Turn off gas and electrical supplies to unit.

2. Remove main furnace door.

3. Remove drain tube from inducer motor mounting cover plate.

4. Remove pressure switch tubes. (See Fig. 1.)

a. Remove tube attached to pressure switch from collector

box.

b. Remove tube attached to pressure switch from burner

enclosure and gas valve.

5. Remove screw securing pressure switch and capacitor to

inducer housing.

6. Disconnect motor lead connector at quick-connect.

7. Using backup wrench, disconnect gas supply pipe from gas

valve.

8. Remove wires from gas valve. Note location for reassembly.

9. Remove burner box cover.

10. Remove screws securing manifold to burner box.

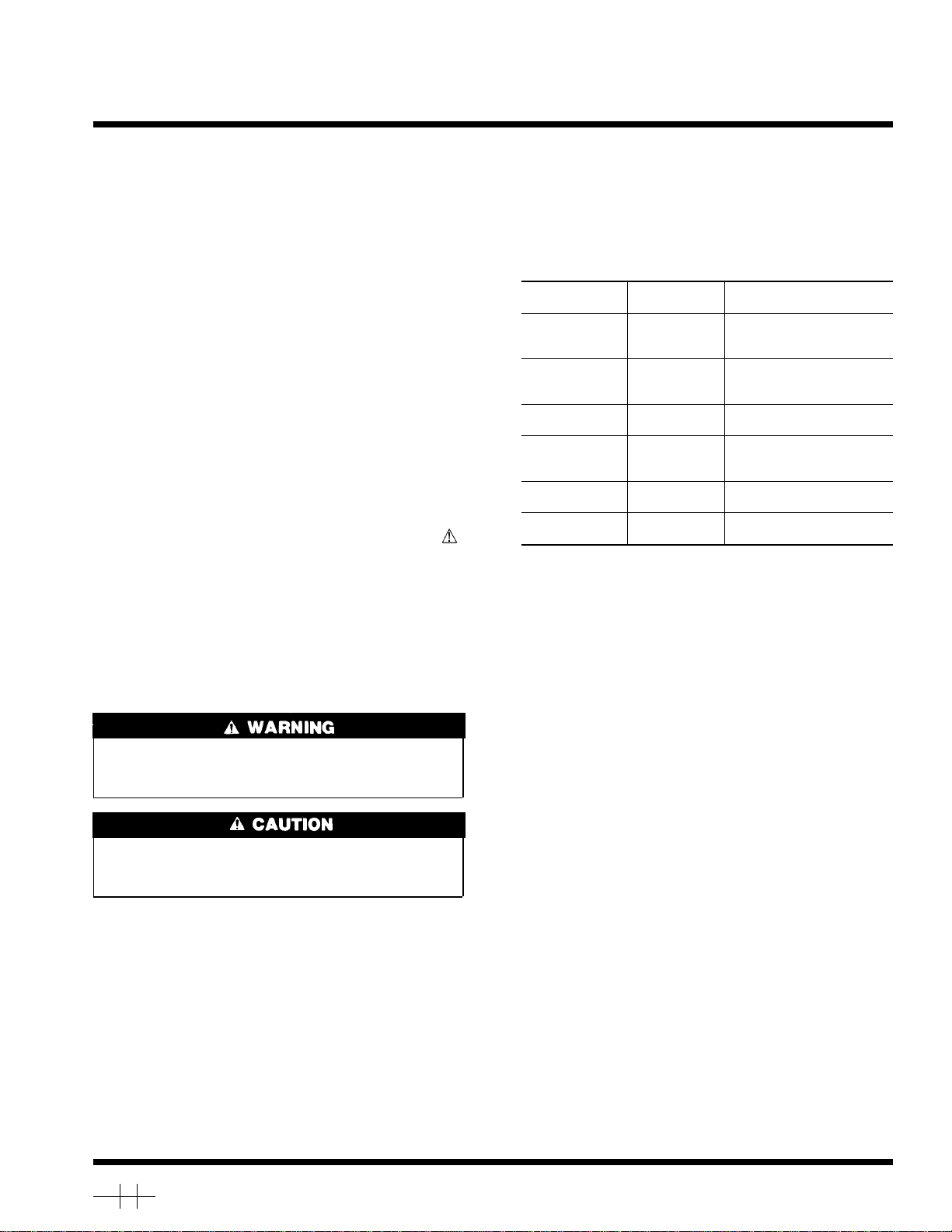

→Table 1—Kit Usage

MODEL

NUMBER SERIES USED ON

340MAV

350MAV

490AAV

A

B

CAll Sizes

340MAV

350MAV

490AAV DAll Sizes Except

060120 and 060140*

345MAV AAll Sizes Except

060120*

58MCA

58MXA

101

111

121 All Sizes

58MCA

58MXA 131 All Sizes Except

120-20 and 140-20*

58MSA 101 All Sizes Except

120-20*

* For 060120 and 120-20 size units on models and series specified, use high

output PSC inducer motor housing assembly kit, Part No. 320725-754. For

060140 and 140-20 size units on models and series specified, use high output

PSC inducer motor housing assembly kit, Part No. 320725-755.

Cancels: IIK 340M-40-15 IIK 340M-40-24

11-96

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 6a 8a PC 101 Catalog No. 565-826 Printed in U.S.A. Form 58M-39SI Pg 1 11-96 Replaces: 58M-37SI

→