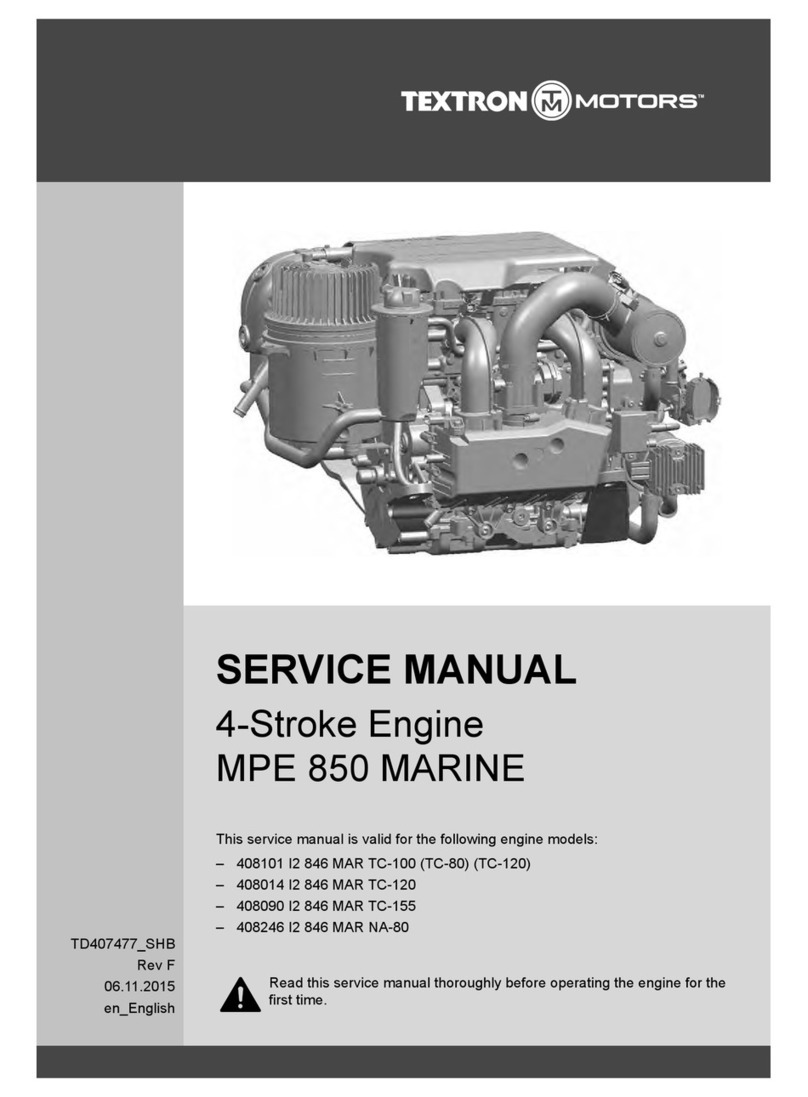

3TD410023-B RLF

TABLE OF CONTENTSTABLE OF CONTENTS

ABOUT THIS DOCUMENT 5

Meaning of the symbols and signal words . . . . . . 5

Change management. . . . . . . . . . . . . . . . . . . . . . 5

SAFETY 6

Meaning of the safety alert symbol and signal

words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Important safety messages . . . . . . . . . . . . . . . . . 6

BEFORE YOU BEGIN WORKING 9

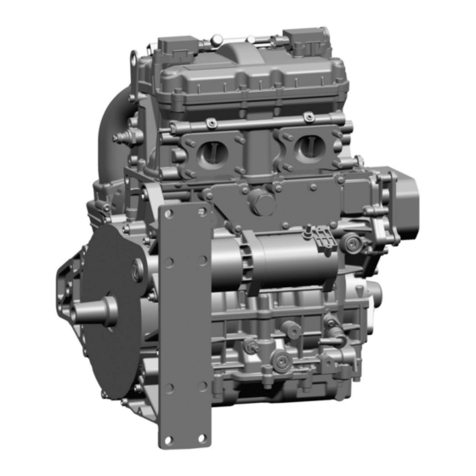

Engine identifikation . . . . . . . . . . . . . . . . . . . . . . . 9

Engine components . . . . . . . . . . . . . . . . . . . . . . . 9

Workshop equipment . . . . . . . . . . . . . . . . . . . . . 11

TEXTRON MOTORS Special tools . . . . . . . 11

Workshop equipment and tools . . . . . . . . . . 12

Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SECTION A – ENGINE DISASSEMBLY 16

Removing engine from the vehicle . . . . . . . . . . . 18

Securing the engine . . . . . . . . . . . . . . . . . . . . . . 18

Mount the engine across from the drive side . . . 18

Removing generator cover . . . . . . . . . . . . . . . . . 19

Removing starter . . . . . . . . . . . . . . . . . . . . . . . . 19

Removing intake manifold . . . . . . . . . . . . . . . . . 20

Removing ignition coils. . . . . . . . . . . . . . . . . . . . 21

Removing spark plugs . . . . . . . . . . . . . . . . . . . . 21

Removing valve cover . . . . . . . . . . . . . . . . . . . . 21

Removing rocker arms . . . . . . . . . . . . . . . . . . . . 22

Mount the engine on the drive side . . . . . . . . . . 22

Removing oil cooler . . . . . . . . . . . . . . . . . . . . . . 23

Removing oil cooler bracket . . . . . . . . . . . . . . . . 23

Removing impeller . . . . . . . . . . . . . . . . . . . . . . . 24

Removing slide ring seal . . . . . . . . . . . . . . . . . . 24

Removing crankshaft cover . . . . . . . . . . . . . . . . 24

Removing crankshaft sensor . . . . . . . . . . . . . . . 25

Mount the engine across from the drive side . . . 25

Removing generator and stub shaft . . . . . . . . . . 25

Removing oil pressure pump . . . . . . . . . . . . . . . 26

Mount the engine on the drive side . . . . . . . . . . 27

Removing suction pump cover . . . . . . . . . . . . . . 27

Removing suction pump intermediate gear . . . . 28

Removing timing chain . . . . . . . . . . . . . . . . . . . . 28

Removing cylinder head. . . . . . . . . . . . . . . . . . . 29

Removing crank drive. . . . . . . . . . . . . . . . . . . . . 30

Removing thermostat housing . . . . . . . . . . . . . . 32

Removing chain guide . . . . . . . . . . . . . . . . . . . . 32

Removing chain rail . . . . . . . . . . . . . . . . . . . . . . 32

Replacing piston or con rod . . . . . . . . . . . . . . . . 33

Removing and reinstalling cylinder liners . . . . . . 33

SECTION B – ENGINE RESASSEMBLY 36

Mount the engine on the drive side . . . . . . . . . . 38

Replacing oil filter . . . . . . . . . . . . . . . . . . . . . . . . 38

Installing chain rail . . . . . . . . . . . . . . . . . . . . . . . 38

Installing chain guide . . . . . . . . . . . . . . . . . . . . . 39

Installing thermostat housing . . . . . . . . . . . . . . . 39

Installing crank drive. . . . . . . . . . . . . . . . . . . . . . 39

Installing cylinder head. . . . . . . . . . . . . . . . . . . . 44

Installing timing chain. . . . . . . . . . . . . . . . . . . . . 45

Installing suction pump intermediate gear . . . . . 47

Installing suction pump cover . . . . . . . . . . . . . . . 47

Mount the engine across from the drive side . . . 48

Installing crankshaft oil seal . . . . . . . . . . . . . . . . 48

Installing oil pressure pump . . . . . . . . . . . . . . . . 50

Installing generator and stub shaft . . . . . . . . . . . 51

Mount the engine on the drive side . . . . . . . . . . 52

Installing crankshaft sensor . . . . . . . . . . . . . . . . 52

Installing crankshaft cover . . . . . . . . . . . . . . . . . 52

Installing slide ring seal . . . . . . . . . . . . . . . . . . . 53

Installing impeller . . . . . . . . . . . . . . . . . . . . . . . . 55

Installing oil cooler bracket . . . . . . . . . . . . . . . . . 55

Installing oil cooler . . . . . . . . . . . . . . . . . . . . . . . 56

Mount the engine across from the drive side . . . 56

Installing rocker arms . . . . . . . . . . . . . . . . . . . . . 57

Installing valve cover . . . . . . . . . . . . . . . . . . . . . 57

Installing spark plugs . . . . . . . . . . . . . . . . . . . . . 58

Installing ignition coils. . . . . . . . . . . . . . . . . . . . . 58

Installing intake manifold . . . . . . . . . . . . . . . . . . 59

Installing starter . . . . . . . . . . . . . . . . . . . . . . . . . 60

Installing generator cover . . . . . . . . . . . . . . . . . . 61

Securing the engine . . . . . . . . . . . . . . . . . . . . . . 63

Installing engine into the vehicle. . . . . . . . . . . . . 63

Completing and checking of the work. . . . . . . . . 63