TG drives TGA-24-9/20 User manual

1

DIGITAL SERVOAMPLIFIER

TGA-24-9/20

Instruction manual

Edition 06/2012

servotechnics

2

Type description:

TGA-24-9/20 standard version

TGA-24-9/20-O1 optional communication connector X1 – 8 pin

TGA-24-9/20-O3 optional supply voltage 48VDC

TGA-24-9/20-O4 analog input

± 10V

TGA-24-9/20-O8 lite version design

3

Safety instructions

•Read this documentation before carying out instalation. Incorrect handling of the

servoamplifier can lead to personal injury or material damage.

•The servoamplifier contain electrostatically sensitive components which may be

damaged by incorrect handling. Ground yourself before touching the

servoamplifier.

•Do not open the units. Keep all cover and switchgear cabinet doors closed during

operation.

•Servoamplifiers may have hot cooling surfaces during operation.

•Never undo the electrical connections to the servoamplifier while it is live. There

is danger of electric arcing with damage to contacts.

European directives and standards

Servoamplifiers are components, which are intended to be incorporated into electrical

plants and machines for industrial use.

When the servoamplifiers are built into machines or plants, the intended operation of

the amplifier is forbidden until it has been established that the machine or plant

fulfills the requirements of the EC Directive on Machines 98/37/EC and the EC

Directive on EMC (89/336/EEC).

The manufacturer of of the machine or plant is responsible for ensuring that they

meet the limits which are required by the EMC regulations.

CE – conformance

Conformance with the EC Directive on EMC 89/336/EEC is mandatory for the

supply of servoamplifiers within the European Cummunity.

The servoamplifiers TGA-24 have been tested by an authorized testing laboratory in a

defined configuration with the system components which are described in this

documentation. Any divergence from the configuration anf installation described in

this documentation means that you will be responsible for the performance of new

measurements to ensure that the regulatory requirements are met.

Prescribed use of the servoamplifier

The servoamplifiers are components which are built into electrical equipment or

machines, and can only be used as integral components of such equipment.

The servoamplifiers TGA-24 is only intended to drive with specific brushless

synchronous servomotors, with closed-loop control of torque, speed and/or position.

The servoamplifiers may only be operated in a closed switchgear cabinet, taking into

account the ambient conditions in technical specification. Use only copper wire. Wire

size may be determined from EN60204.

We only guarantee the conformance of the servoamplifiers with the standards for

industrial areas, if the components (motors, cables, amplifiers etc) are delivered by

TG Drives s.r.o.

4

Technical data

Parameters Unit

Data

Rated supply voltage V = 24 (15 - 42)

option O3: 48

Rated installed load for S1 operation W 230

Rated output current A

rms

9

Peak output current (max. ca 5 s) A

rms

18,5

Overvoltage protection treshold (transil) V 47

Dissipation at rated load W 20

Fusing

Supply 24 VDC – internal

– external – T 10 A

– C 8 A

Inputs / outputs

Analog input, resolution 12 bit

Input resistance V 0 - 5

option O4: ±10

k

Ω

15

Digital inputs with adjustable function 24 VDC

qty 8

V low 0 .. 5 / high 7 .. 30

mA 6

Digital outputs with adjustable function,

24 VDC, PNP

qty 4

V max. 42

mA 25

Counter inputs for IRC or stepper-motor signals

– 5V (RS422)

Connectors

Control signals

–

Interhart 3.81, 1.5mm

2

Power – Interhart 5.08, 2.5mm

2

Resolver input – Interhart 3.81, 1.5mm

2

Communication – SubD 9-pole plug

option O1

8-pole Interhart 3.81

Mechanical

Weight kg 0.6

RoDimensions without connectors mm 157

×

86

×

40

Environment

Operating temperature °C 0 - 40

Relative humidity % max. 85

5

Instalation

Dimensions

Material: 2 or 4 screws M4

6

Interfaces description

7

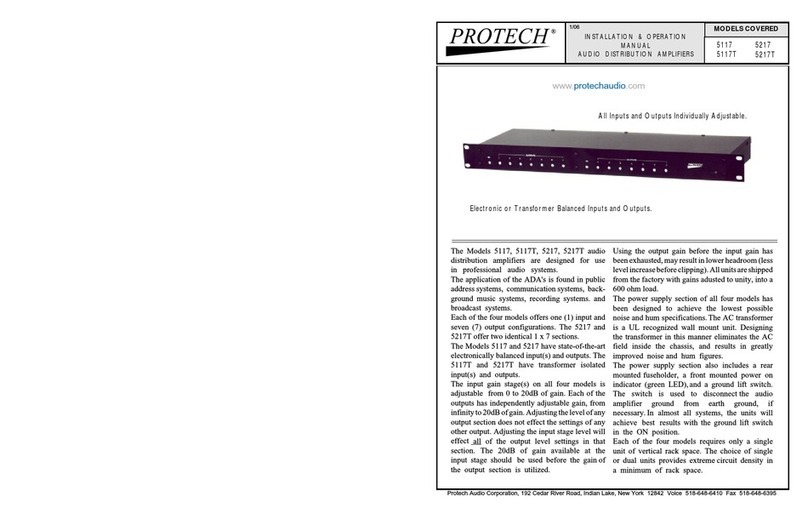

Recommended connection diagram

The ferrite rings use to decrease the

electromagnetic noice.

The unscreened ends of the cabels should

be as short as possible.

8

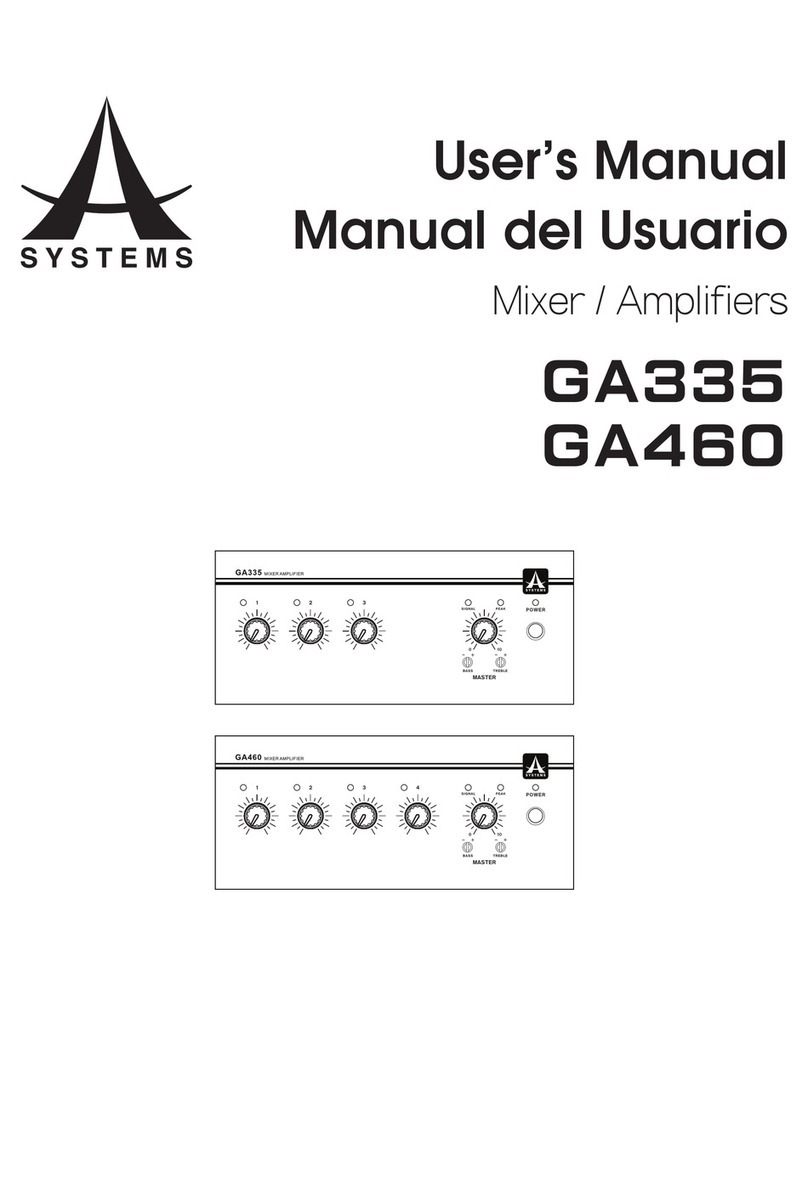

Resolver cable connection (X7)

The resolver cable connection for

TGT1,TGT2, TGT3,TGH2,TGH3

servomotors with the cable glands

The resolver cable connection for

TGT1,TGT2, TGT3,TGH2,TGH3

servomotors with the round

connectors

The resolver cable connection for

TGH0 servomotors with the flying

leads

9

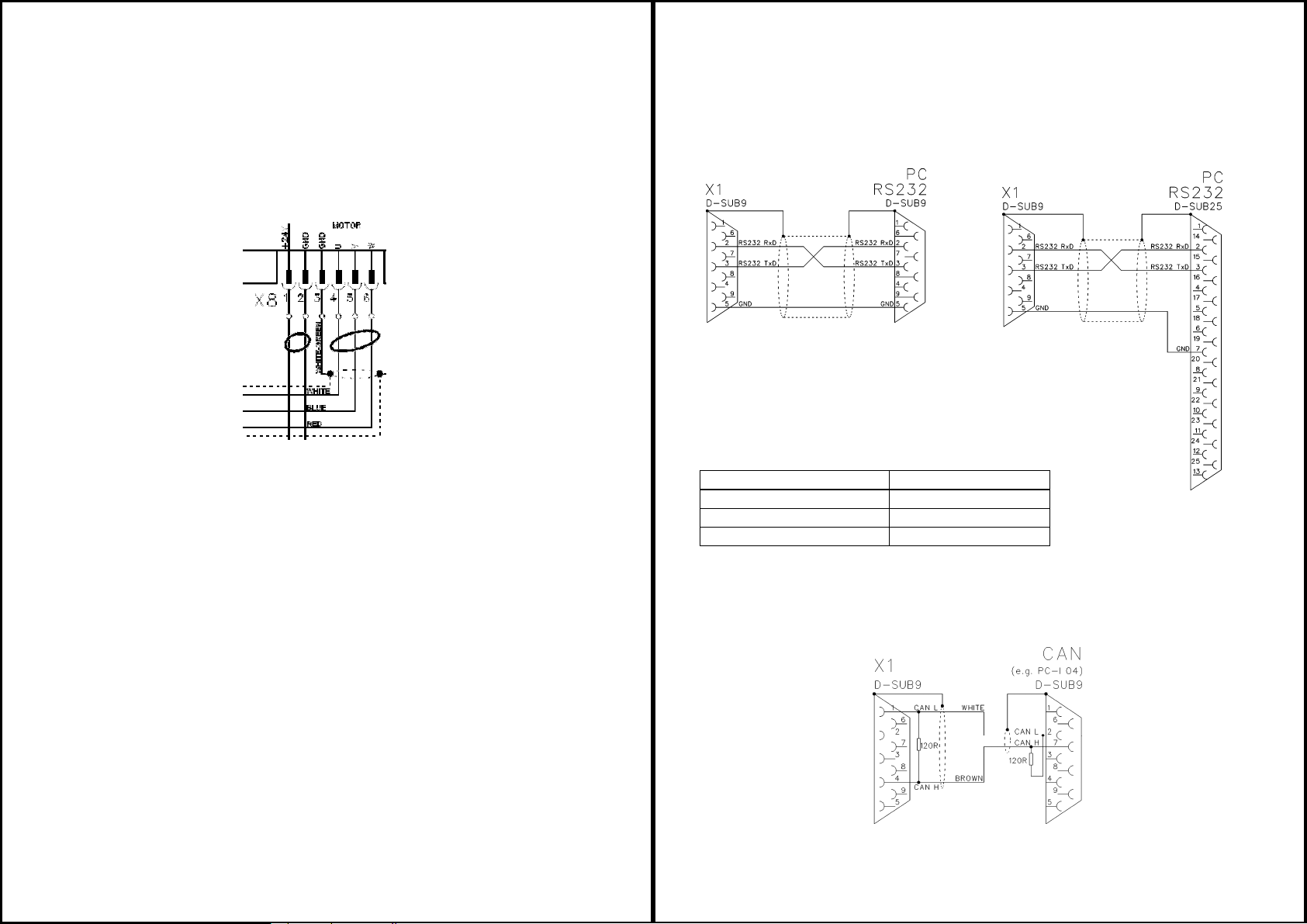

Motor cable connection (X8)

Motor cable connection for TGT1, TGT2, TGT3, TGH2 and TGH3 servomotors is

described in the chapter Recommended connection diagram (page 7). For TGH0

(only) with the flying leads is valid following motor connection:

10

RS232 interface, PC connection (X1)

The setting of the regulator parameters, inputs/outputs setting, position control and

position profiles can be carried out with an ordinary commercial PC.

Connect the PC interface (X1) of servoamplifier while the supply to the equipment is

switched off via a normal commercial 3-core null-modem cable to a serial interface

on the PC (see the diagrams below).

CAN-BUS interface

To meet ISO11898 you should use a bus cable

with a characteristic impedance of 120 Ω.

The maximum usable cable length for reliable communication

decreases with increasing transmission speed.

Cable length, depending on the transmission rate

Transmission rate (kbaud) max. cable lngth (m)

1 000 20

500 70

250 115

For EMC reasons, the SubD connector housing must fulfill the following conditions:

−metal or metalized housing

−provision for cable shielding connection

in housing, large-area connection

11

Connection to stepper-motor controller

(X2)

This interface can be used to connect the

servoamplifier to a stepper-motor controller

with 5V signal level. The value of R

according to line impedance: 150Ω– 1kΩ.

Interface for encoder input (X2)

This interface can be used to operate

the servoamplifier as a slave,

mastered by an encoder with RS422

signals level in gearing mode or by

another servoamplifier (electronic

gearing)

Interface for encoder simulation

(X2)

This interface can be used to output

incremental position value (RS422

signals level) in all of the operation

modes as feedback for the control

system or as setpoint position in

Master-Slave operation.

TG Drives, s.r.o.

Jeneweinova 37

617 00 Brno

Czech republic

www.tgdrives.com

phone: 00420 545 234 935

fax:

00420 545 234 735

This manual suits for next models

4

Table of contents