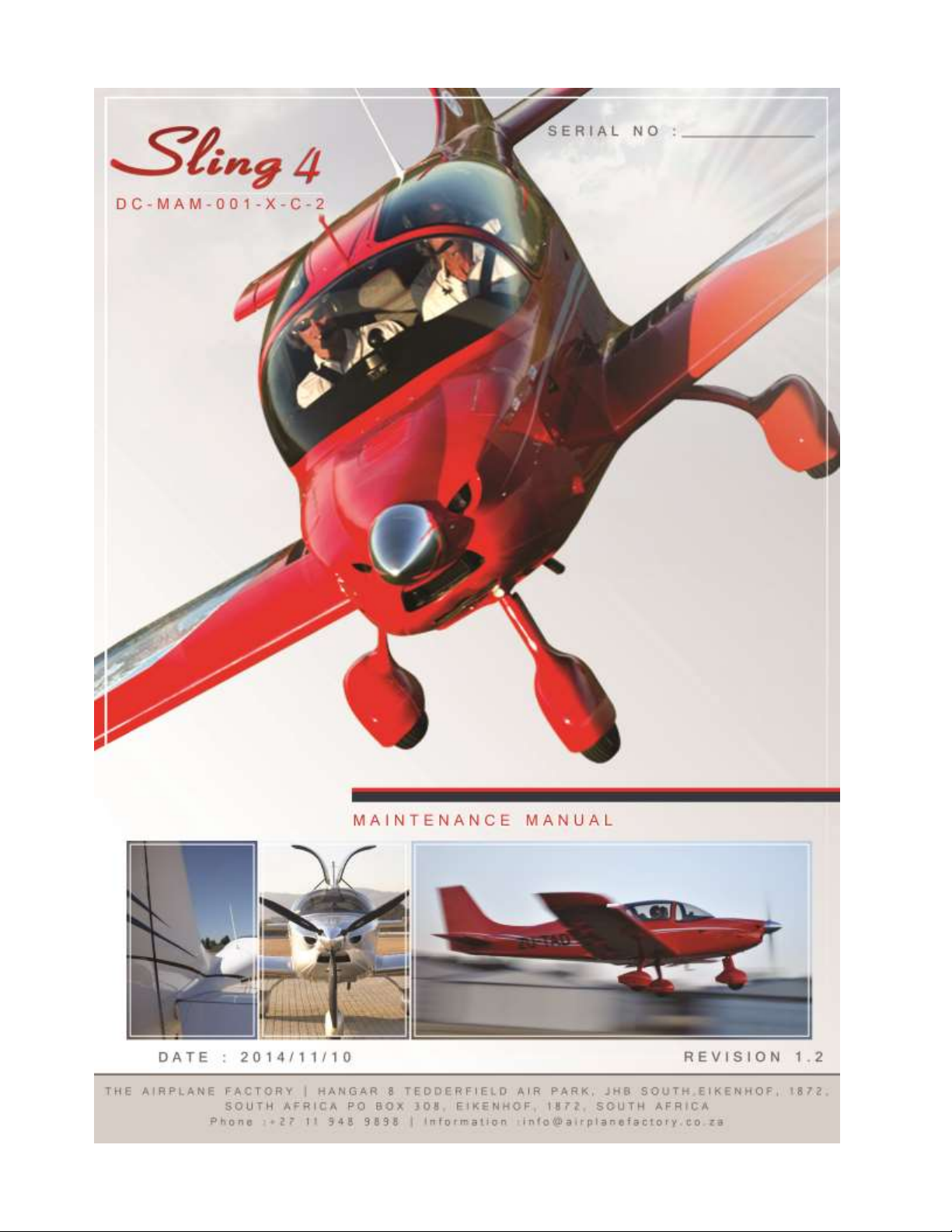

The Airplane Factory Sling 4 User manual

DOCUMENT No.: REVISION: 1.2 DATE: 2014/11/10

DC-MAM-001-X-C-2 Page ii

GENERAL INFORMATION

Equipment fitted to the aircraft must be done so in accordance to the requirements of the national regulations of the

country of registration.

PLEASE INFORM THE AIRPLANE FACTORY (AIRCRAFT MANUFACTURER) ON CHANGE

OF OWNERSHIP OF THE AIRCRAFT

NOTICE

AIRCRAFT WHICH DIFFER FROM THE PRODUCTION STANDARD, IN WHATEVER WAY, ARE NOT

ADDRESSED IN THIS MANUAL, EXCEPT TO THE EXTENT SAID AIRCRAFT CORRESPOND WITH THE

PRODUCTION STANDARD.

NOTICE

THIS EDITION OF THIS MANUAL IS APPLICABLE TO AIRCRAFT REGISTERED IN THE REPUBLIC OF

SOUTH AFRICA. DEFINITIONS ARE ACCORDINGLY CONSISTENT WITH RSA REGULATIONS ONLY.

DOCUMENT No.: REVISION: 1.2 DATE: 2014/11/10

DC-MAM-001-X-C-2 Page iii

PRESENTATION

This manual is divided into the following sections:

SECTION 1 –GENERAL: This section provides general information, capacities and general procedures and

specifications.

SECTION 2 –INSPECTION: This section provides information regarding general inspection considerations,

inspection schedules and inspection procedures.

SECTION 3 –SERVICE: This section provides information regarding general service considerations and service

schedules.

SECTION 4 –STRUCTURES, SYSTEMS AND PROCEDURES: This section describes the various structures,

substructures, systems and subsystems comprising the aircraft, and describes maintenance procedures applicable

to these structures, substructures, systems and subsystems, as the case may be.

APPENDICES

Provides useful additional information.

DOCUMENT No.: REVISION: 1.2 DATE: 2014/11/10

DC-MAM-001-X-C-2 Page iv

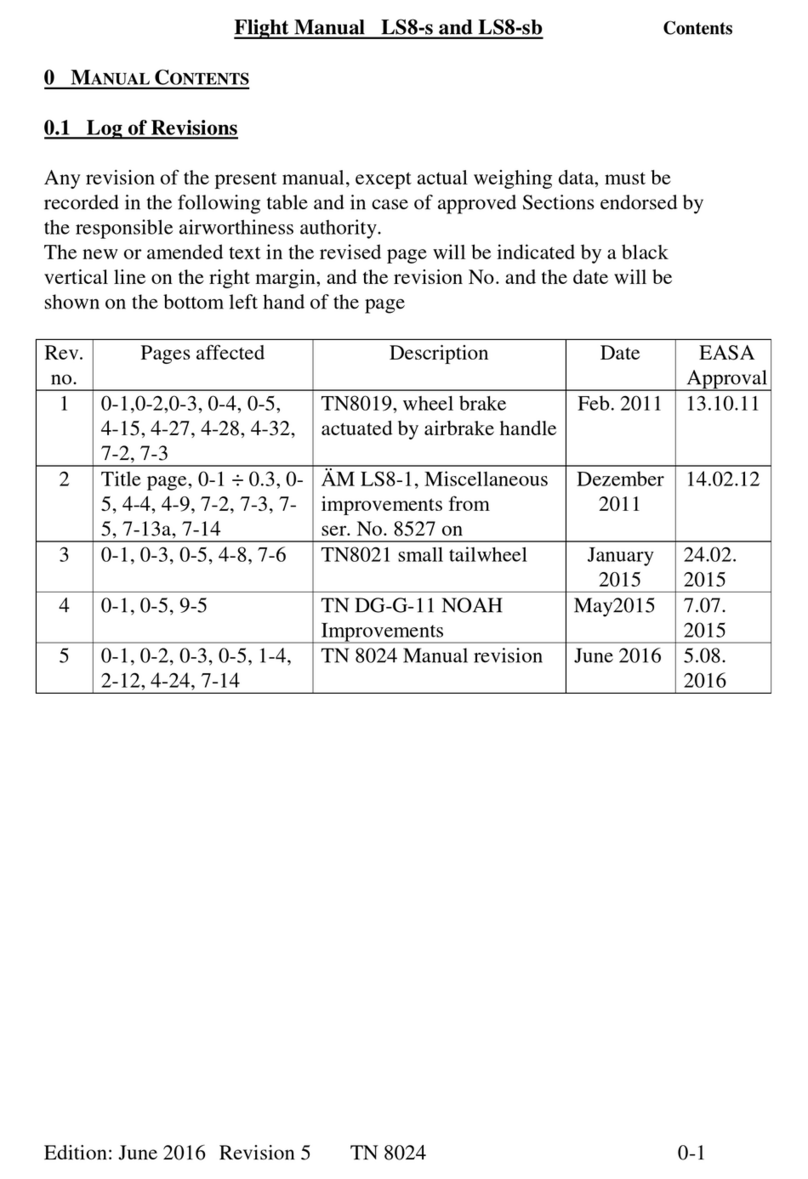

REVISION RECORD

REVISION

NUMBER

DATE

DESCRIPTION OF CHANGE

PARAGRAPHS

SIGN

1.0

2013/12/01

Original document

N/A

1.1

2014/05/16

All.

All

1.2

2014/11/10

1. Corrected servo motor body

orientation in Figure 14 and Figure

28.

2. Updated wiring diagrams.

3. Updated front occupant(s) safety

harness(es) removal

4. Changed wing rear attachment bolt

torque from 20 Nm to 18 Nm.

5. Correct bolt size from AN7-25A to

AN7-26A in Figure 5.

6. Added M4 metal washers to fuel

sender mounting plate installation.

7. Updated fuel pump labelling.

1.5,

4.1.1.1, 4.1.2.4,

4.2.1.7,

6.5, 6.6, 6.9,

12.2.1

13

DOCUMENT No.: REVISION: 1.2 DATE: 2014/11/10

DC-MAM-001-X-C-2 Page v

LIST OF ACRONYMS

AC

Alternating Current

A/C

Aircraft

A/H

Ampere Hour

AHRS

Attitude and Heading Reference System

AKI

Anti-Knock Index

AOA

Angle Of Attack

API

American Petroleum Institute

ATF

Authority To Fly

ATF

Automatic Transmission Fluid

AUX

Auxilliary

AVGAS

Aviation Gasoline

AWG

American Wire Gauge

BATT

Battery

BNC

Bayonet Neill Concelman (connector type)

C

Common

CAN

Controller Area Network

CG

Centre of Gravity

DC

Direct Current

EFIS

Electronic Flight Information System

EXT

External

FAA

Federal Aviation Authority

GLS

GPS Landing System

GmbH

Gesellschaft mit beschränkter Haftung (company with limited liability).

GND

Ground

GPS

Global Positioning System

ID

Inner Diameter

IGN

Ignition

KIAS

Indicated airspeed (Knots)

LAN

Local Area Network

MAC

Mean Aerodynamic Chord

MIC

Microphone

MOGAS

Motorcar Gasoline

DOCUMENT No.: REVISION: 1.2 DATE: 2014/11/10

DC-MAM-001-X-C-2 Page vi

NC

Normally Closed

NGL

Normal Ground Line

NO

Normally Open

NRV

Non Return Valve

PASS

Passenger

POH

Pilot Operating Handbook

PTT

Push To Talk

QFE

Setting on altimeter subscale equal to ambient atmospheric pressure at a

specified datum

QNH

Barometric pressure adjusted to sea level

RDAC

Remote Data Acquisition Computer

RSA

Republic of South Africa

RON

Research Octane Number

RS232

Recommended Standard 232

RX

Receive

SCN

Screen (wire)

SPST

Single Pole Single Throw (switch contact(s) configuration)

SW

Switch

TCU

Turbocharger Control Unit

TX

Transmit

US

-

United States (of America)

USB

-

Universal Serial Bus

VHF

Very High Frequency

VMC

-

Visual Meteorological Conditions

VSI

-

Vertical Speed Indicator

DOCUMENT No.: REVISION: 1.2 DATE: 2014/11/10

DC-MAM-001-X-C-2 Page vii

REFERENCED DOCUMENTS

The following documents are referred to / mentioned in this document and should be read in conjunction with

this document, as applicable.

DOCUMENT / TITLE

1

FAA Advisory Circular AC43.13-1B: Acceptable Methods, Techniques and Practices - Aircraft

Inspection and Repair.

2

AP3 Series and AP4 Series Constant Speed Propeller Operator’s Manual.

3

Rotax Service Information SI-914-019.

4

Maintenance Manual (Heavy Maintenance) for Rotax Engine Types Rotax 912 and Rotax 914 Series

(Reference no. MMH-914).

5

Maintenance Manual (Line Maintenance) for Rotax Engine Type 914 Series.

6

Operators Manual for Rotax Engine Type 914 Series (Reference no. OM-914).

7

Installation Manual for Rotax Engine Type 914 Series (Reference no, IM-914).

8

MGL Avionics EFIS Integrated Autopilot user and Installation Manual.

9

ASTM D7547: Standard Specification for Hydrocarbon Unleaded Aviation Gasoline.

10

ASTM D910: Standard Specification for Aviation Gasolines.

11

ASTM D4814: Standard Specification for Automotive Spark-Ignition Engine Fuel.

12

DIN EN 228: Automotive Fuels - Unleaded Petrol - Requirements and Test Methods.

13

RDAC XF Installation Manual (MGL Avionics).

14

MIL-G-3278: Military Specification - Grease, Aircraft and Instrument (For Low and High

Temperatures).

15

MIL-C-16173: Military Specification –Corrosion Preventive Compound, Solvent Cutback, Cold

Application.

16

MIL-C11796: Military Specification - Corrosion Preventive Compound, Petrolatum, Hot Application

17

AMS-S-8802: Sealing Compound, Temperature Resistant, Integral Fuel Tanks and Fuel Cell Cavities,

High Adhesion.

18

MGL Avionics iBOX V1 Installation Manual.

19

MIL-G-81322: Military Specification –Grease, Aircraft, General Purpose, Wide Temperature Range.

20

iEFIS Panel Installation Manual (MGL Avionics).

DOCUMENT No.: REVISION: 1.2 DATE: 2014/11/10

DC-MAM-001-X-C-2 Page viii

TABLE OF CONTENTS

1. GENERAL......................................................................................................................................... 1

1.1. DESCRIPTION ................................................................................................................................. 1

1.2. AIRCRAFT SPECIFICATIONS AND DATA ..................................................................................... 2

1.2.1 AIRCRAFT 3-VIEW DRAWING........................................................................................................ 2

1.2.2 AIRCRAFT GEOMETRIC DIMENSIONS......................................................................................... 3

1.2.3 AIRCRAFT WEIGHTS...................................................................................................................... 4

1.3. ENGINE............................................................................................................................................ 5

1.4. APPROVED SUBSTANCES, FLUIDS, LUBRICANTS AND CAPACITIES..................................... 6

1.5. FASTENER TORQUE VALUES AND WRENCH SIZES ............................................................... 10

1.5.1 GENERAL....................................................................................................................................... 10

1.5.2 SPECIFIC ....................................................................................................................................... 10

1.6. EQUIPMENT LIST.......................................................................................................................... 11

1.7. TYRE SPECIFICATION AND PRESSURES.................................................................................. 12

1.8. GROUND HANDLING.................................................................................................................... 12

1.9. JACKING ........................................................................................................................................ 13

1.10. PARKING AND TIE DOWN............................................................................................................ 14

1.11. AIRCRAFT LEVELLING................................................................................................................. 14

1.11.1 LONGITUDINAL LEVELLING ........................................................................................................ 15

1.11.2 TRANSVERSE LEVELLING........................................................................................................... 17

1.12. AIRCRAFT ALIGNMENT................................................................................................................ 19

1.13. CONTROL SURFACE DEFLECTION / TRAVEL........................................................................... 20

1.14. RUDDER CONTROL CABLE TENSION........................................................................................ 20

1.15. AIRCRAFT RIGGING..................................................................................................................... 21

1.15.1 RUDDER CABLE TENSION ADJUSTMENT................................................................................. 21

1.15.2 ELEVATOR ADJUSTMENT ........................................................................................................... 21

1.15.3 ELEVATOR TRIM TAB ADJUSTMENT ......................................................................................... 21

1.15.4 AILERON ADJUSTMENT............................................................................................................... 21

1.15.5 FLAP ADJUSTMENT...................................................................................................................... 21

1.16. WEIGHT AND BALANCE INFORMATION..................................................................................... 22

1.16.1 REQUIREMENT / SCHEDULE ...................................................................................................... 22

1.16.2 MOMENT ARMS ............................................................................................................................ 22

1.16.3 CENTRE OF GRAVITY FORMULAE............................................................................................. 23

1.16.4 EMPTY WEIGHT CENTRE OF GRAVITY TABLE......................................................................... 23

DOCUMENT No.: REVISION: 1.2 DATE: 2014/11/10

DC-MAM-001-X-C-2 Page ix

1.16.5 EMPTY WEIGHT CENTRE OF GRAVITY DETERMINATION...................................................... 24

1.17. CORROSION PREVENTION......................................................................................................... 26

1.18. AIRCRAFT STORAGE................................................................................................................... 28

1.18.1 SHORT TERM STORAGE............................................................................................................. 28

1.18.2 MEDIUM LONG TERM STORAGE................................................................................................ 28

1.18.3 OUTSIDE STORAGE..................................................................................................................... 29

1.18.4 RETURNING THE AIRCRAFT TO SERVICE................................................................................ 29

1.19. SOURCES FOR THE PURCHASING OF PARTS......................................................................... 30

1.20. DISPOSABLE REPLACEMENT PARTS........................................................................................ 30

1.21. AIRCRAFT PLACARDS AND EQUIPMENT LABELLING ............................................................. 31

1.21.1 MARKINGS AND PLACARDS ....................................................................................................... 31

2. INTRODUCTION............................................................................................................................ 39

2.1. GENERAL CONSIDERATIONS REGARDING INSPECTION....................................................... 39

2.2. INSPECTION PANELS .................................................................................................................. 42

2.3. INSPECTION SCHEDULE............................................................................................................. 43

2.3.1 ENGINE.......................................................................................................................................... 43

2.3.2 PROPELLER.................................................................................................................................. 43

2.3.3 AIRFRAME AND SYSTEMS.......................................................................................................... 43

2.4. CONDITION INSPECTION (100 HOUR / ANNUALLY)................................................................. 44

2.4.1 INSPECTION PANELS AND INITIAL INSPECTION AND CLEANING......................................... 44

2.4.2 FUSELAGE GROUP ...................................................................................................................... 44

2.4.3 CABIN AND COCKPIT GROUP..................................................................................................... 44

2.4.4 ENGINE AND COWLING GROUP................................................................................................. 45

2.4.5 LANDING GEAR GROUP.............................................................................................................. 45

2.4.6 WING AND CENTRE SECTION ASSEMBLY................................................................................ 46

2.4.7 EMPENNAGE ASSEMBLY............................................................................................................ 46

2.4.8 PROPELLER GROUP.................................................................................................................... 46

2.4.9 RADIO GROUP / AVIONICS / ELECTRONIC EQUIPMENT......................................................... 47

2.4.10 OPTIONAL EQUIPMENT............................................................................................................... 47

2.5. 25 HOUR, 100 HOUR AND ANNUAL SERVICE INSPECTION CHECKLIST............................... 48

3.1 LUBRICATION POINTS, LUBRICANTS AND INTERVALS .......................................................... 62

3.2 SERVICE BULLETINS / INSTRUCTIONS / LETTERS.................................................................. 62

3.3 SERVICE SCHEDULE................................................................................................................... 62

3.3.1 SERVICE PERIOD ADJUSTMENT................................................................................................ 63

3.3.2 ITEMS WITH CALENDAR BASED SERVICING............................................................................ 64

3.3.3 DAILY ............................................................................................................................................. 65

3.3.4 AS NEEDED................................................................................................................................... 65

DOCUMENT No.: REVISION: 1.2 DATE: 2014/11/10

DC-MAM-001-X-C-2 Page x

3.3.5 FIRST 25 HOURS .......................................................................................................................... 65

3.3.6 FIRST 50 HOURS .......................................................................................................................... 66

3.3.7 EVERY 50 HOURS / ANNUALLY .................................................................................................. 66

3.3.8 EVERY 100 HOURS / ANNUALLY ................................................................................................ 67

4. AIRFRAME ..................................................................................................................................... 68

4.1 WING.............................................................................................................................................. 69

4.1.1 MAIN WING SECTION................................................................................................................... 69

4.1.1.1 WING REMOVAL / INSTALLATION............................................................................................... 70

4.1.2 AILERON(S ) .................................................................................................................................. 76

4.1.2.1 AILERON CONTROL SYSTEM ..................................................................................................... 76

4.1.2.2 AILERON REMOVAL / INSTALLATION......................................................................................... 77

4.1.2.3 AILERON ADJUSTMENT............................................................................................................... 82

4.1.2.4 AILERON AUTOPILOT SERVO / SERVO PUSHROD REMOVAL / INSTALLATION .................. 86

4.1.3 FLAPS ............................................................................................................................................ 90

4.1.3.1 FLAP CONTROL SYSTEM ............................................................................................................ 90

4.1.3.2 FLAP REMOVAL / INSTALLATION ............................................................................................... 91

4.1.3.3 FLAP ADJUSTMENT...................................................................................................................... 97

4.1.3.4 FLAP ACTUATOR MOTOR REMOVAL / INSTALLATION............................................................ 99

4.2 EMPENNAGE............................................................................................................................... 102

4.2.1 HORIZONTAL TAIL AND ELEVATOR......................................................................................... 102

4.2.1.1 ELEVATOR CONTROL SYSTEM................................................................................................ 103

4.2.1.2 ELEVATOR REMOVAL / INSTALLATION................................................................................... 104

4.2.1.3 HORIZONTAL STABILIZER REMOVAL / INSTALLATION ......................................................... 108

4.2.1.4 ELEVATOR TRIM TAB MOTOR REMOVAL / INSTALLATION................................................... 111

4.2.1.5 ELEVATOR ADJUSTMENT ......................................................................................................... 114

4.2.1.6 ELEVATOR TRIM TAB ADJUSTMENT ....................................................................................... 117

4.2.1.7 ELEVATOR AUTOPILOT SERVO / SERVO PUSHROD REMOVAL / INSTALLATION............. 119

4.2.2 VERTICAL TAIL AND RUDDER .................................................................................................. 123

4.2.2.1 RUDDER CONTROL SYSTEM.................................................................................................... 124

4.2.2.2 RUDDER REMOVAL / INSTALLATION....................................................................................... 125

4.2.2.3 VERTICAL STABILIZER REMOVAL............................................................................................ 129

4.2.2.4 RUDDER PEDAL ADJUSTMENT ................................................................................................ 133

4.2.2.5 RUDDER CABLE TENSION ADJUSTMENT............................................................................... 134

4.3 FUSELAGE................................................................................................................................... 137

4.3.1 REAR FUSELAGE........................................................................................................................ 137

4.3.2 CENTRE FUSELAGE................................................................................................................... 138

DOCUMENT No.: REVISION: 1.2 DATE: 2014/11/10

DC-MAM-001-X-C-2 Page xi

4.3.2.1 FRONT SEAT REMOVAL AND INSTALLATION......................................................................... 138

4.3.2.2 REAR SEAT REMOVAL AND INSTALLATION........................................................................... 140

4.3.2.3 CANOPY AND WINDSHIELD CLEANING................................................................................... 142

4.3.2.4 UPHOLSTERY CLEANING.......................................................................................................... 142

4.3.3 FORWARD FUSELAGE AND FIREWALL................................................................................... 143

4.4 LANDING GEAR .......................................................................................................................... 144

4.4.1 MAIN GEAR.................................................................................................................................. 144

4.4.1.1 MAIN WHEEL FAIRING REMOVAL / INSTALLATION................................................................ 145

4.4.1.2 MAIN WHEEL REMOVAL / INSTALLATION ............................................................................... 147

4.4.1.3 MAIN WHEEL AXLE AND BRAKE MECHANISM REMOVAL..................................................... 150

4.4.1.4 MAIN WHEEL DISASSEMBLY / ASSEMBLY.............................................................................. 154

4.4.1.5 MAIN WHEEL BEARING REMOVAL / INSTALLATION AND LUBRICATION............................ 157

4.4.1.6 MAIN GEAR REMOVAL / INSTALLATION.................................................................................. 158

4.4.2 NOSE GEAR ................................................................................................................................ 162

4.4.2.1 NOSE WHEEL FAIRING REMOVAL / INSTALLATION .............................................................. 163

4.4.2.2 NOSE WHEEL REMOVAL / INSTALLATION.............................................................................. 164

4.4.2.3 NOSE WHEEL DISASSEMBLY / ASSEMBLY............................................................................. 167

4.4.2.4 NOSE WHEEL BEARING REMOVAL / REPLACEMENT ........................................................... 170

4.4.2.5 NOSE GEAR REMOVAL / INSTALLATION................................................................................. 171

5. POWER PLANT ........................................................................................................................... 174

5.1 COWLING..................................................................................................................................... 174

5.1.1 COWLING REMOVAL / INSTALLATION..................................................................................... 175

5.2 ENGINE........................................................................................................................................ 178

5.2.1 GENERAL MAINTENANCE AND SERVICING............................................................................ 178

5.2.2 CARBURETTOR SYNCHRONISATION...................................................................................... 178

5.2.3 REPLACING ENGINE OIL........................................................................................................... 178

5.2.4 REPLACING ENGINE COOLANT................................................................................................ 178

5.2.5 SPARK PLUG REPLACEMENT................................................................................................... 178

5.2.6 VERIFYING ENGINE OIL LEVEL ................................................................................................ 179

5.2.7 AIR FILTER REMOVAL, CLEANING AND REPLACEMENT ...................................................... 180

5.2.8 MUFFLER / HEAT EXCHANGER ASSEMBLY REMOVAL / REPLACEMENT........................... 183

5.2.9 MUFFLER / HEAT EXCHANGER DISASSEMBLY / ASSEMBLY............................................... 185

5.2.10 REMOVAL / INSTALLATION OF OIL AND COOLANT RADIATORS......................................... 187

5.2.11 OIL COOLER / RADIATOR PIPE CONNECTION / DISCONNECTION...................................... 188

5.2.12 COOLANT RADIATOR PIPE CONNECTION / DISCONNECTION............................................. 191

5.2.13 ENGINE REMOVAL / INSTALLATION ........................................................................................ 193

DOCUMENT No.: REVISION: 1.2 DATE: 2014/11/10

DC-MAM-001-X-C-2 Page xii

5.2.14 ENGINE CONTROL SYSTEM (THROTTLE AND CHOKE) ........................................................ 200

5.2.14.1 THROTTLE LEVER FRICTION ADJUSTMENT .......................................................................... 201

5.2.14.2 THROTTLE LEVER FRICTION DISC REPLACEMENT.............................................................. 202

5.3 PROPELLER ................................................................................................................................ 204

5.3.1 GENERAL MAINTENANCE AND SERVICE................................................................................ 204

5.3.2 PROPELLER HUB AND PROPELLER EXTENSION TORQUE PATTERN................................ 204

5.3.3 SPINNER REMOVAL / REPLACEMENT..................................................................................... 205

5.3.4 GENERAL CONSIDERATIONS WHEN FITTING PROPELLER EXTENSION TO ENGINE FLANGE

................................................................................................................................................... 207

5.3.5 PROPELLER REMOVAL / INSTALLATION................................................................................. 208

5.3.6 PROPELLER ASSEMBLY / DISASSEMBLY............................................................................... 217

5.3.7 PROPELLER ADJUSTMENT / SET-UP....................................................................................... 219

5.3.8 PROPELLER BALANCING .......................................................................................................... 219

6. FUEL SYSTEM............................................................................................................................. 220

6.1 GENERAL SERVICE INFORMATION AND CONSIDERATIONS............................................... 222

6.2 FUEL FILTER REPLACEMENT................................................................................................... 223

6.3 FUEL SELECTOR UNIT REMOVAL / INSTALLATION............................................................... 225

6.4 FUEL SELECTOR UNIT ASSEMBLY / DISASSEMBLY.............................................................. 228

6.5 FUEL PUMP ASSEMBLY REMOVAL / INSTALLATION............................................................. 230

6.6 FUEL PUMP REMOVAL / INSTALLATION FROM / INTO FUEL PUMP ASSEMBLY................ 236

6.7 FUEL TANK LEAK REPAIR......................................................................................................... 238

6.8 FUEL TANK DRAIN REMOVAL / INSTALLATION (DRAINING WING TANK)............................ 239

6.9 FUEL LEVEL SENDER ASSEMBLY REMOVAL / INSTALLATION (FROM / TO FUEL TANK). 241

6.10 REPLACING FUEL LEVEL SENDER ASSEMBLY SENSOR...................................................... 245

6.11 FINGER STRAINER (ON FUEL PICK-UP) INSPECTION........................................................... 249

7. AVIONICS AND INSTRUMENTS................................................................................................. 251

7.1 GENERAL MAINTENANCE AND SERVICE OF INSTRUMENTS .............................................. 252

7.2 REMOVAL / INSTALLATION OF INSTRUMENT PANEL AND INSTRUMENTS........................ 253

7.3 PITOT AND STATIC SYSTEMS .................................................................................................. 255

7.3.1 PITOT SYSTEM LEAK TEST....................................................................................................... 256

7.3.2 STATIC SYSTEM LEAK TEST..................................................................................................... 257

7.3.3 PITOT AND / OR STATIC SYSTEM CLEANING AND SERVICING ........................................... 258

7.4 AHRS AND COMPASS................................................................................................................ 259

7.4.1 AHRS AND / OR COMPASS SENSOR REMOVAL / INSTALLATION........................................ 259

7.5 HEADPHONE SOCKETS............................................................................................................. 261

7.5.1 HEADPHONE SOCKET REMOVAL / INSTALLATION................................................................ 261

7.6 ANTENNAE .................................................................................................................................. 263

DOCUMENT No.: REVISION: 1.2 DATE: 2014/11/10

DC-MAM-001-X-C-2 Page xiii

7.6.1 VHF COMMUNICATION ANTENNA............................................................................................ 263

7.6.1.1 VHF ANTENNA REMOVAL / INSTALLATION............................................................................. 263

7.6.2 GPS ANTENNA............................................................................................................................ 265

7.6.2.1 GPS ANTENNA REMOVAL / INSTALLATION ............................................................................ 265

8. UTILITY SYSTEMS...................................................................................................................... 267

8.1 CABIN HEATING AND COOLING ............................................................................................... 267

8.1.1 HEAT EXCHANGER ASSEMBLY REMOVAL AND INSTALLATION.......................................... 267

9. BRAKE SYSTEM.......................................................................................................................... 268

9.1 BRAKE FLUID DRAINING, REPLACEMENT AND BRAKE SYSTEM BLEEDING..................... 269

9.2 BRAKE MECHANISM REMOVAL / INSTALLATION................................................................... 271

9.3 BRAKE DISC REPLACEMENT.................................................................................................... 272

9.4 BRAKE LINING REPLACEMENT ................................................................................................ 273

10. ELECTRICAL SYSTEM................................................................................................................ 276

10.1 BATTERY REMOVAL / INSTALLATION...................................................................................... 278

10.2 EFIS BACK-UP BATTERY REMOVAL / INSTALLATION ........................................................... 280

10.3 ALTERNATOR MAINTENANCE.................................................................................................. 282

10.4 REPLACEMENT OF CIRCUIT BREAKERS AND / OR SWITCHES........................................... 282

10.5 REGULATOR / RECTIFIER REMOVAL AND REPLACEMENT.................................................. 285

11. EXTERIOR LIGHTING................................................................................................................. 287

11.1 NAVIGATION LIGHTS ................................................................................................................. 287

11.1.1 NAVIGATION LIGHT REMOVAL / INSTALLATION .................................................................... 288

11.2 LANDING AND TAXI LIGHTS...................................................................................................... 290

11.2.1 LANDING AND / OR TAXI LIGHT REMOVAL / INSTALLATION ................................................ 290

11.2.2 LANDING AND / OR TAXI LIGHT REPLACEMENT.................................................................... 293

11.2.3 LANDING AND / OR TAXI LIGHT ADJUSTMENT....................................................................... 295

11.3 STROBE LIGHT ........................................................................................................................... 296

11.3.1 STROBE LIGHT REMOVAL / INSTALLATION............................................................................ 296

12. EMERGENCY AND SAFETY SYSTEMS .................................................................................... 298

12.1 BALLISTIC PARACHUTE ............................................................................................................ 298

12.1.1 GENERAL SERVICE AND MAINTENANCE................................................................................ 298

12.2 SAFETY HARNESSES ................................................................................................................ 299

12.2.1 REMOVAL / INSTALLATION OF FRONT OCCUPANT SAFETY HARNESS(ES)...................... 299

12.2.2 REMOVAL / INSTALLATION OF REAR OCCUPANT SAFETY HARNESS(ES)........................ 302

13. APPENDIX A (AVIONICS AND ELECTRICAL SYSTEM WIRING DIAGRAMS)......................... 303

13.1 CHARGE AND START SYSTEM / FUEL PUMPS WIRING DIAGRAM ...................................... 303

13.2 SWITCHES AND CIRCUIT BREAKERS WIRING DIAGRAM ..................................................... 304

DOCUMENT No.: REVISION: 1.2 DATE: 2014/11/10

DC-MAM-001-X-C-2 Page xiv

13.3 EXTERNAL ALTERNATOR WIRING DIAGRAM......................................................................... 305

13.4 FLAP SYSTEM WIRING DIAGRAM............................................................................................. 306

13.4.2 INOTEC ........................................................................................................................................ 307

13.4.3 E-FLAPS....................................................................................................................................... 308

13.5 ELEVATOR TRIM MOTOR WIRING DIAGRAM.......................................................................... 309

13.5.1 DUAL STICK TRIM....................................................................................................................... 309

13.5.2 SINGLE STICK TRIM................................................................................................................... 310

13.6 EFIS SYSTEM / COMMUNICATIONS BUS LAYOUT................................................................. 311

13.7 AHRS AND COMPASS WIRING DIAGRAM................................................................................ 312

13.8 AUTOPILOT ROLL SERVO AND PITCH SERVO WIRING DIAGRAM....................................... 313

13.9 EFIS BACK-UP BATTERY CHARGE CIRCUIT........................................................................... 314

13.10 HEADPHONE / RADIO / INTERCOM WIRING DIAGRAM.......................................................... 315

13.10.1 GARMIN GTR 200 RADIO ........................................................................................................... 315

13.10.2 GARMIN GTR 225 RADIO ........................................................................................................... 316

13.11 POSITION / NAVIGATION LIGHTS WIRING DIAGRAM............................................................. 317

13.12 RDAC TO OIL PRESSURE TRANSDUCER WIRING DIAGRAM ............................................... 318

13.13 DUAL EFIS INSTALLATION WIRING DIAGRAM........................................................................ 319

13.14 TRANSPONDER WIRING DIAGRAM.......................................................................................... 320

13.14.1 TRIG TT21 TRANSPONDER WIRING DIAGRAM....................................................................... 320

13.14.2 SANDIA STX 165R TRANSPONDER WIRING DIAGRAM.......................................................... 321

13.15 ENGINE MONITORING TRANSDUCERS (SENSORS) / RDAC ELECTRICAL WIRING........... 322

13.16 EFIS AND IBOX ELECTRICAL WIRING...................................................................................... 322

13.17 PROPELLER AND PROPELLER CONTROLLER ELECTRICAL WIRING INFORMATION....... 322

13.18 ROTAX 914 UL ENGINE ELECTRICAL WIRING INFORMATION.............................................. 322

14. APPENDIX B (FIREWALL MOUNTED EQUIPMENT)................................................................. 323

15. APPENDIX C (GENERAL PROCEDURES AND TECHNIQUES NOT DESCRIBED ELSEWHERE)

................................................................................................................................................... 324

15.1 REMOVAL OF TWO-EAR CLAMPS............................................................................................ 324

15.2 PUSHROD ADJUSTMENT .......................................................................................................... 324

15.3 FITTING OF FIRE RESISTANT SLEEVING................................................................................ 325

16. APPENDIX D (AN WASHER AND NUT HARDWARE DESIGNATIONS)................................... 326

DOCUMENT No.: REVISION: 1.2 DATE: 2014/11/10

DC-MAM-001-X-C-2 Page xv

LIST OF FIGURES

Figure 1: Longitudinal leveling reference position.......................................................................................................16

Figure 2: Transverse leveling reference position. .......................................................................................................18

Figure 3: Aircraft alignment..........................................................................................................................................19

Figure 4: Moment arms................................................................................................................................................22

Figure 5: Front wing spar to fuselage connection. ......................................................................................................73

Figure 6: Rear wing spar to fuselage connection........................................................................................................74

Figure 7: Aileron pushrod-to-control stick connection. ................................................................................................74

Figure 8 : Aileron control system.................................................................................................................................76

Figure 9: Aileron hinge (inboard).................................................................................................................................79

Figure 10: Aileron hinge (outboard).............................................................................................................................80

Figure 11: Aileron pushrod -to-bellcranck connection.................................................................................................81

Figure 12: Aileron adjustment - cabin side..................................................................................................................83

Figure 13: Aileron adjustment - wing side. ..................................................................................................................84

Figure 14: Autopilot aileron servo installation..............................................................................................................88

Figure 15: Aileron autopilot servo pushrod –control stick / torque tube end. .............................................................89

Figure 16: Flap control system. ...................................................................................................................................90

Figure 17: Flap hinges.................................................................................................................................................93

Figure 18: Flap pushrod-to-flap connection.................................................................................................................94

Figure 19: Flap pushrod-to-flap torque tube control arm connection. .........................................................................96

Figure 20: Flap actuator motor removal. ...................................................................................................................100

Figure 21: Flap actuator motor installation. ...............................................................................................................101

Figure 22: Horizontal tail and elevator.......................................................................................................................102

Figure 23: Elevator control system............................................................................................................................103

Figure 24: Elevator pushrod to elevator connection..................................................................................................106

Figure 25: Horizontal stabilizer-to-elevator hinge......................................................................................................107

Figure 26: Horizontal stabilizer to fuselage attachment. ...........................................................................................110

Figure 27: Elevator adjustment..................................................................................................................................115

Figure 28: Autopilot elevator servo installation..........................................................................................................121

Figure 29: Autopilot elevator servo pushrod –torque tube end. ................................................................................122

Figure 30: Vertical tail and rudder. ............................................................................................................................123

Figure 31: Rudder control system. ............................................................................................................................124

Figure 32: Rudder to vertical stabilizer hinge connection..........................................................................................127

Figure 33: Rudder cable connection..........................................................................................................................128

DOCUMENT No.: REVISION: 1.2 DATE: 2014/11/10

DC-MAM-001-X-C-2 Page xvi

Figure 34: Vertical stabilizer to fuselage connection.................................................................................................131

Figure 35 : Rudder cable tension adjustment............................................................................................................135

Figure 36: Main landing gear.....................................................................................................................................144

Figure 37: Main wheel axle installation......................................................................................................................153

Figure 38: Main gear installation................................................................................................................................161

Figure 39: Nose gear.................................................................................................................................................162

Figure 40: Nose wheel installation.............................................................................................................................166

Figure 41: Front wheel hub assembly. .....................................................................................................................169

Figure 42: Nose gear installation...............................................................................................................................173

Figure 43: Engine cowling. ........................................................................................................................................174

Figure 44: Engine removal.........................................................................................................................................197

Figure 45: Engine installation. ...................................................................................................................................198

Figure 46: Throttle lever friction disc installation. ......................................................................................................203

Figure 47: Propeller installation / propeller extension installation torque pattern......................................................204

Figure 48: Airmaster propeller installation (standard)...............................................................................................211

Figure 49: Airmaster propeller signal wire to slip-ring disc connection (vacuum pump fitted). .................................214

Figure 50: Airmaster propeller installation (vacuum pump fitted).............................................................................215

Figure 51: Propeller installation (external alternator fitted)........................................................................................216

Figure 52: Fuel system. .............................................................................................................................................220

Figure 53: Fuel selector unit installation....................................................................................................................227

Figure 54: Fuel selector port allocation and fitting orientation...................................................................................229

Figure 55: Fuel selector fuel fitting alignment............................................................................................................229

Figure 56: Wing tank fuel drain installation................................................................................................................240

Figure 57: Fuel sender installation into fuel tank.......................................................................................................244

Figure 58: Fuel level sender assembly sensor replacement.....................................................................................248

Figure 59: Standard instrument panel (refer to key on next page)............................................................................251

Figure 60: Representative pitot and static system.....................................................................................................255

Figure 61: Headphone socket installation. ................................................................................................................262

Figure 62: VHF antenna installation. .........................................................................................................................264

Figure 63: Brake system............................................................................................................................................268

Figure 64: Electrical system (overview).....................................................................................................................276

Figure 65 : Landing and taxi light installation. ...........................................................................................................292

Figure 66: Charge and start system wiring diagram /fuel pump wiring. ....................................................................303

Figure 67: Switches and circuit breakers wiring diagram..........................................................................................304

Figure 68: External alternator wiring diagram............................................................................................................305

Figure 69: MGL SP 10 Flap / trim controller wiring diagram. ....................................................................................306

Figure 70: Flap system wiring diagram –INOTEC....................................................................................................307

DOCUMENT No.: REVISION: 1.2 DATE: 2014/11/10

DC-MAM-001-X-C-2 Page xvii

Figure 71: Flap system wiring diagram - E-Flaps......................................................................................................308

Figure 72: Elevator trim motor wiring diagram –dual control sticks..........................................................................309

Figure 73: Elevator trim motor wiring diagram –single control stick.........................................................................310

Figure 74: EFIS system / communications bus layout. .............................................................................................311

Figure 75: AHRS and compass wiring diagram. .......................................................................................................312

Figure 76: Autopilot roll servo and pitch servo wiring diagram..................................................................................313

Figure 77: EFIS back-up battery charge circuit........................................................................................................314

Figure 78: Headphone / radio (GARMIN GTR 200) / intercom wiring diagram.........................................................315

Figure 79: Headphone / radio (GARMIN GTR 225) / intercom wiring diagram.........................................................316

Figure 80: Position / navigation lights wiring diagram...............................................................................................317

Figure 81: RDAC to oil pressure transducer wiring diagram and settings. ...............................................................318

Figure 82:Dual EFIS installation................................................................................................................................319

Figure 83: TRIG TT21 transponder wiring diagram...................................................................................................320

Figure 84: SANDIA STX 165 R transponder wiring diagram.....................................................................................321

Figure 85: Firewall mounted equipment. ...................................................................................................................323

Figure 86: Two-ear clamp removal...........................................................................................................................324

Figure 87: Pushrod adjustment. ................................................................................................................................324

DOCUMENT No.: REVISION: 1.2 DATE: 2014/11/10

DC-MAM-001-X-C-2 Page xviii

WARNINGS, CAUTIONS AND NOTES

The following definitions apply to warnings, cautions and notes as used in this aircraft maintenance manual:

Indicates an action necessary to prevent injury or death.

Indicates an action necessary to prevent damage to the aircraft, aircraft parts or property.

Provides valuable additional information.

WARNING

CAUTION

NOTE

DOCUMENT No.: REVISION: 1.2 DATE: 2014/11/10

DC-MAM-001-X-C-2 Page 1

SECTION 1

GENERAL

This section provides general information, capacities and general procedures and specifications.

1. GENERAL

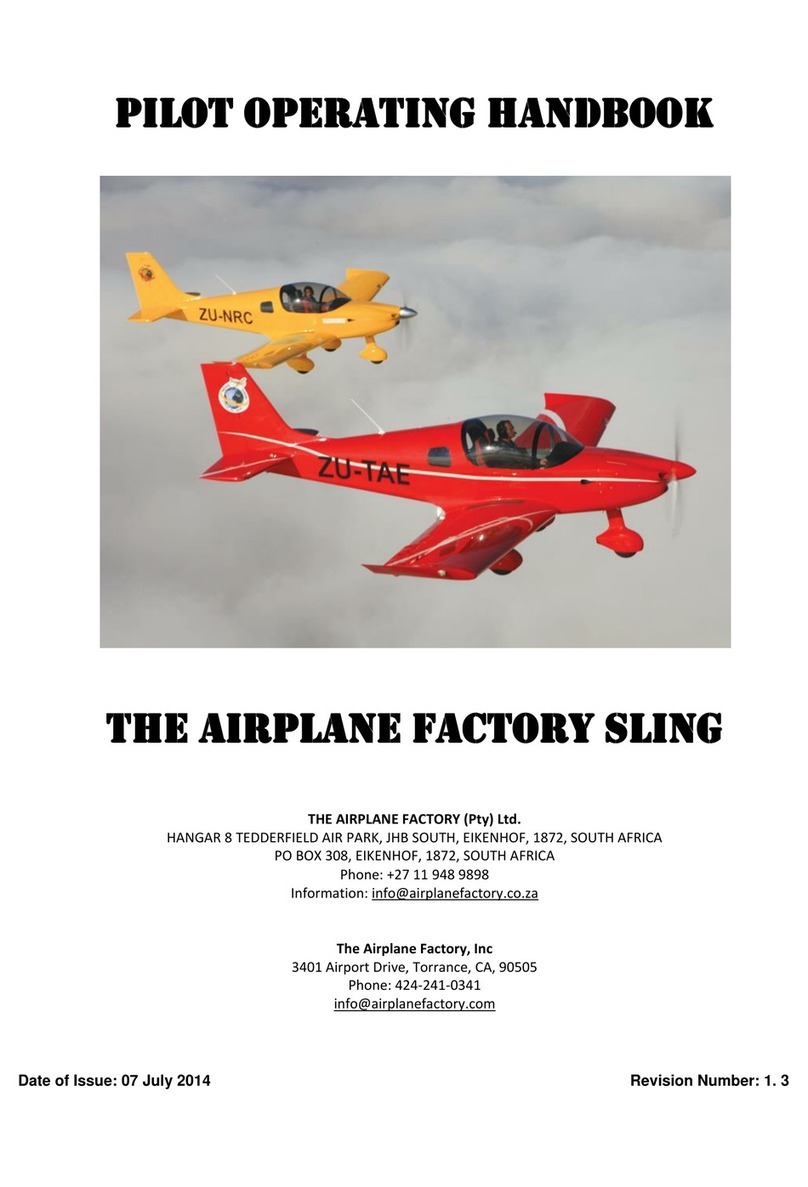

1.1. DESCRIPTION

The Airplane Factory Sling 4 is a four seat, single engine, tricycle fixed undercarriage aluminum aircraft

with a conventional low wing design.

DOCUMENT No.: REVISION: 1.2 DATE: 2014/11/10

DC-MAM-001-X-C-2 Page 2

1.2. AIRCRAFT SPECIFICATIONS AND DATA

1.2.1 AIRCRAFT 3-VIEW DRAWING

Note that dimensions in this drawing are

in millimetres (metric).

Table of contents

Other The Airplane Factory Aircraft manuals