GD3 1200

This model has one

gas injector at the

right hand side of

the burner tray.

•Install the burner tray by carefully

lowering the end opposite from the pilot

meanwhile holding up the pilot end,

lower the burner tray down and move

towards the pilot in one movement.

•Ensure the burner tray is located

correctly into the burner bracket and the

jets are aiming into the burner tube inlet

holes.

•Replace the stainless steel burner end

caps (2 x screws on each cap) at either

end of the burner.

• Install the burner tray by carefully lowering the end opposite from

the pilot meanwhile holding up the pilot end, lower the burner tray

down and move towards the pilot in one movement.

• Ensure the burner tray is located correctly into the burner bracket

and the jets are aiming into the burner tube inlet holes.

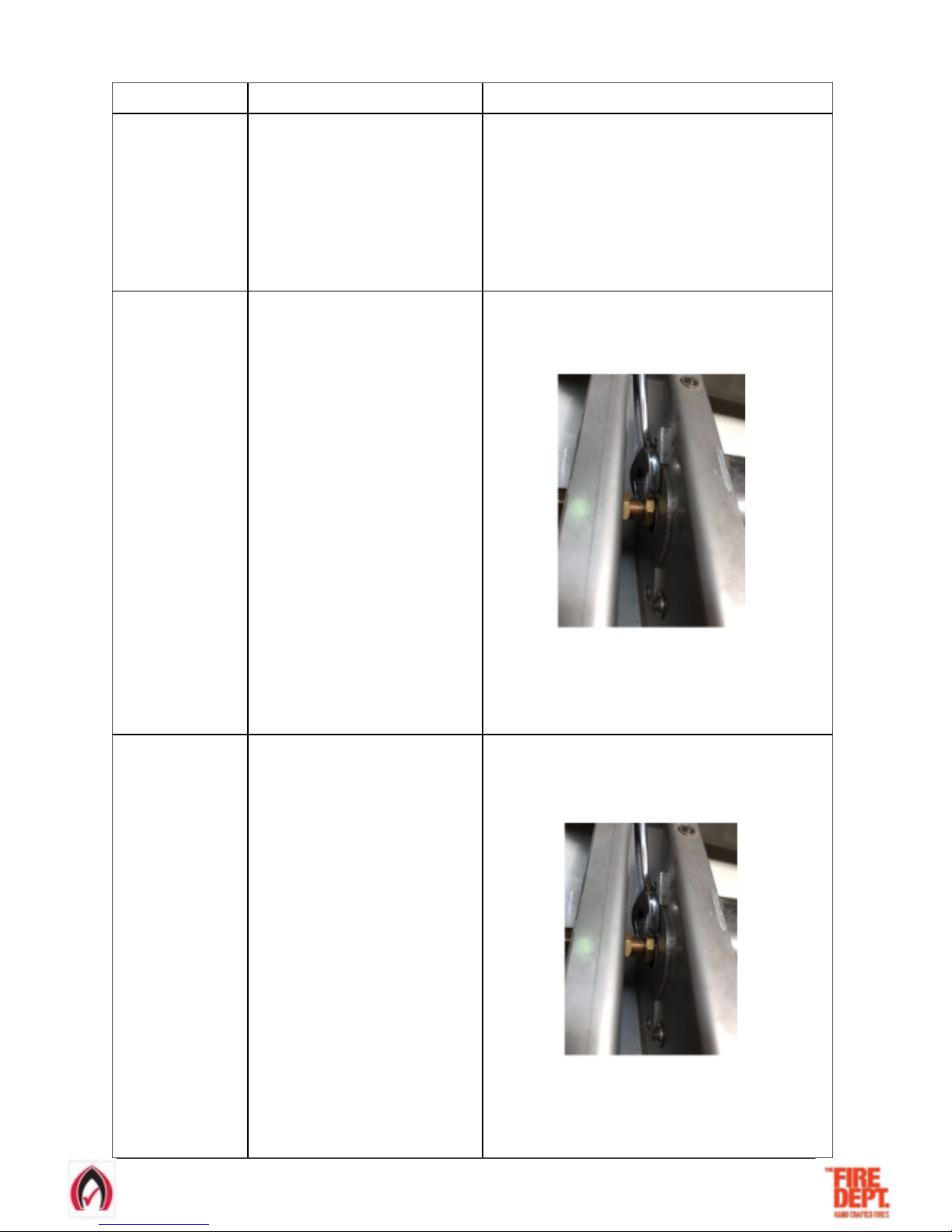

• On the left hand side gas injector, gently tighten (do not

overtighten) the 12mm brass nut closest to the burner tray.

• Replace the stainless steel burner end caps (2 x screws on each

cap) at either end of the burner.

GD3 1500

This model has two

gas injectors at the

right and left hand

sides of the burner

tray.

• Install the burner tray by carefully lowering

the end opposite from the pilot meanwhile

holding up the pilot end, lower the burner

tray down and move towards the pilot in

one movement.

• Ensure the burner tray is located correctly

into the burner bracket and the jets are

aiming into the burner tube inlet holes.

•Replace the stainless steel burner end

caps (2 x screws on each cap) at either

end of the burner.

GD3 1600

This model has two

gas injectors at the

right and left hand

sides of the burner

tray.

• Install the burner tray by carefully lowering

the end opposite from the pilot meanwhile

holding up the pilot end, lower the burner

tray down and move towards the pilot in

one movement.

• Ensure the burner tray is located correctly

into the burner bracket and the jets are

aiming into the burner tube inlet holes.

•Replace the stainless steel burner end

caps (2 x screws on each cap) at either

end of the burner.

• Install the burner tray by carefully lowering the end opposite from

the pilot meanwhile holding up the pilot end, lower the burner tray

down and move towards the pilot in one movement.

• Ensure the burner tray is located correctly into the burner bracket

and the jets are aiming into the burner tube inlet holes.

• On both the left and right hand gas injectors, gently tighten (do not

overtighten) the 12mm brass nuts closest to the burner tray.

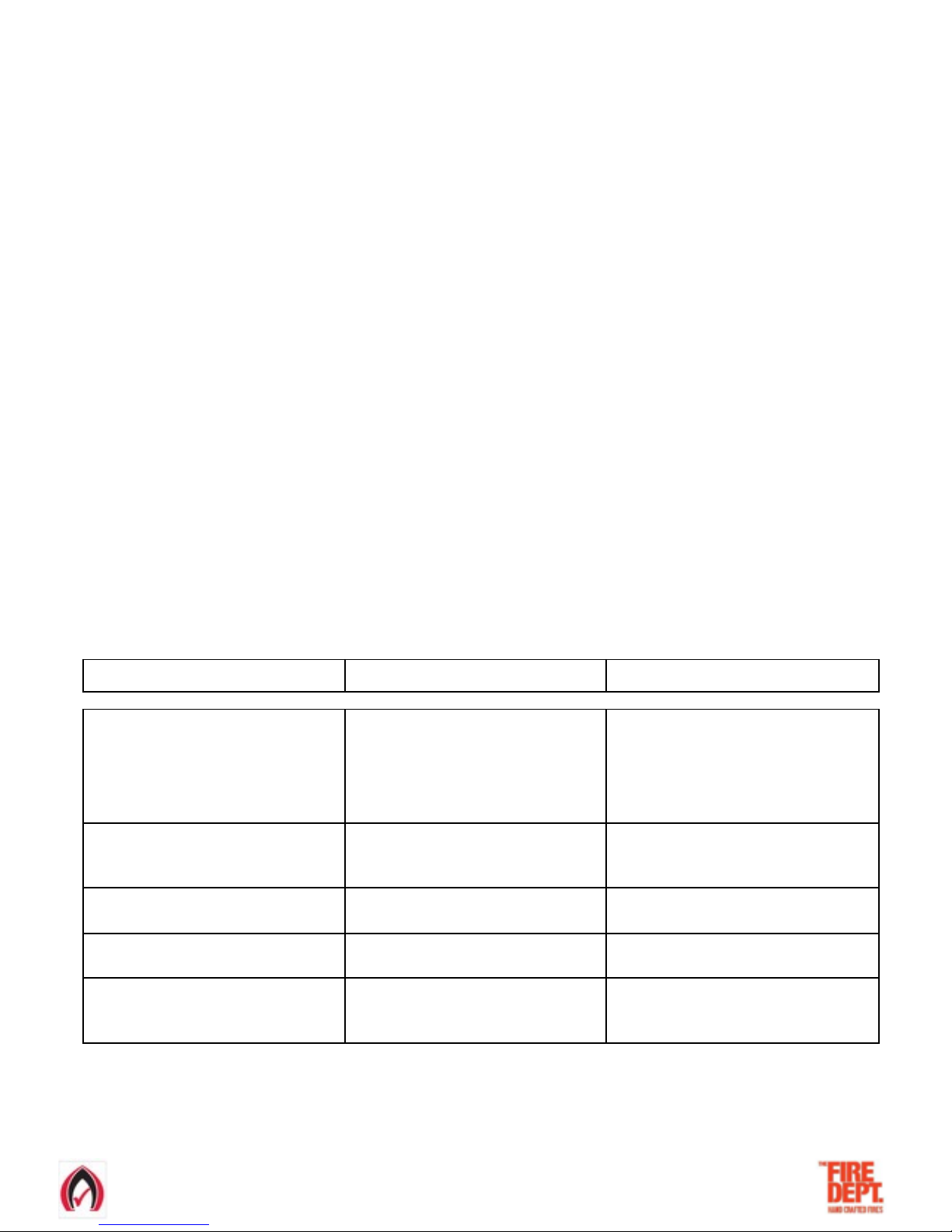

LH Gas Injector RH Gas Injector

• Replace the stainless steel burner end caps (2 x screws on each

cap) at either end of the burner.

Burner Tray Installation Process

21-3-2017 VERSION 4 Page of 720

• Install the burner tray by carefully lowering the end opposite from

the pilot meanwhile holding up the pilot end, lower the burner tray

down and move towards the pilot in one movement.

• Ensure the burner tray is located correctly into the burner bracket

and the jets are aiming into the burner tube inlet holes.

• On both the left and right hand gas injectors, gently tighten (do not

overtighten) the 12mm brass nuts closest to the burner tray.

LH Gas Injector RH Gas Injector

• Replace the stainless steel burner end caps (2 x screws on each

cap) at either end of the burner.