Thermal-Eye TSC4500 Instructions for use

EXPORT CONTROL NOTICE – This technical data and software is

considered as Technology Software Publicly Available (TSPA) No

License Required (NLR) as defined in Export Administration

Regulations (EAR) Part 734.7-11.

Application Manual for the

Thermal-Eye™

Thermal Security Camera

Copyright L3 Communications

All Rights Reserved

PN 4000161-1 Rev C

2

W E L C O M E

TO THE WORLD

OF INFRARED!

Worldwide Patent Rights Reserved.

This product is covered by one or more of the following patents:

U.S. Patent Nos.: 5,288,649; 5,367,167; 6,267,501; 6,586,831; 6,521,477;

6,690,014; 6,479,320; and under license to 5,196,703.

Euro.Pat.Appln. 1159591.

Additional Patents Pending.

www.Thermal-Eye.com

L3 Communications Infrared Products (L-3 IP)

(Formerly Raytheon Commercial Infrared)

13532 North Central Expressway

PO Box 741148, MS 37

Dallas Texas 75374

PN 4000161-1 Rev C

3

Important Safeguards

WARNING

WARNINGWARNING

WARNING

WARNING:

WARNING:WARNING:

WARNING: TO REDUCE THE RISK OF ELECTRIC

SHOCK, DO NOT OPERATE WITH CAMERA COVER

REMOVED.

DO NOT OPEN COVERS AS THERE ARE NO

USER-SERVICEABLE PARTS INSIDE. REFER

SERVICING TO QUALIFIED SERVICE PERSONNEL.

1) Instructions: Read all safety and operating instructions

before operating your Thermal Security Camera.

2) Cleaning: To clean camera housing, use only a soft cloth

dampened with water. To clean camera lens, use a soft

cotton cloth and mild neutral soap diluted with lukewarm

distilled water (1 part soap to 100 parts water), followed by

use cotton swab or lens cleaning cloth dampened with

reagent grade isopropyl alcohol or acetone. Acetone will

damage plastic components of the camera.

3) Servicing: Do not remove the cover. There are no

user-serviceable parts inside. Refer all servicing to qualified

service personnel. Opening the TSC4500 will void your

warranty.

4) Power Sources: This product should be operated only from

the type of power source indicated on the marking label. For

products intended to operate from battery power, or other

sources refer to the operating instructions.

5) Restriction of Use Environments: The unit is not intended

or warranted for use in the following conditions. Damage

resulting from such exposure would not be covered by the

warranty.

Unit is intended for outdoor applications. A solar

shield is available to limit sun’s heating of the

TSC4500 body.

Unit is not intended to operate submerged in water.

However, the TSC4500 is designed to withstand

immersion or exposure to rain or high humidity.

PN 4000161-1 Rev C

4

Unit is not intended for exposure to a salt-water

atmosphere.

Unit is not intended for dynamic–mount applications,

such as on vehicles or heavy machinery, in which

transmitted vibration is continuously sustained.

Unit (whether powered On or Off) is not intended for

viewing of direct or indirect (reflected) sunlight. Unit

is intended for non-horizon exposure looking

downward from intended mounting plane. Exposure

to the sunlight, for even very short periods of time,

may permanently damage the camera and therefore

nullify any warranties.

Unit is not intended for intentional or unintentional

exposure directed towards solar activities, welding, or

other activities of similar heat dynamics, which if

performed may damage the camera and therefore will

nullify any warranties.

PN 4000161-1 Rev C

5

SECTION 1: INTRODUCTION ......................................... 6

INFRARED IMAGING ..............................................................6

THE TSC4500

TM

PRODUCT LINE ...........................................6

FEATURES AND OPTIONS: .............................................9

Performance................................................................... 11

Lens Option Capability for TSC4500............................. 11

Electrical........................................................................ 11

Interfaces .......................................................................11

Environmental................................................................ 11

Physical (25

o

HFOV) ..................................................... 12

Physical (12

o

HFOV) ..................................................... 12

SECTION 2: CARE AND MAINTENANCE.................... 13

CLEANING OF OPTICS .........................................................13

RESTRICTIONS OF USE ........................................................13

SECTION 3: INSTALLATION INSTRUCTIONS .......... 14

MOUNTING THE CAMERA ...................................................14

SYSTEM INTERFACE CONNECTOR .......................................14

CONNECTING INPUT POWER ...............................................15

VIDEO OUTPUT ...................................................................16

USER INTERFACE WITH TSC4500.......................................16

RS-232 Serial Communication: ..................................... 17

Using RS-232/485 Serial Communication: .................... 17

FOCUS ADJUSTING..............................................................18

PN 4000161-1 Rev C

6

SECTION 1: INTRODUCTION

Infrared Imaging

Visible light, the rainbow of colors that can be sensed by the

human eye, is electromagnetic radiation within a certain

frequency band. ‘Infra-‘ means ‘below’ and ‘red’ is the lowest

frequency in the visible spectrum. Hence, ‘infrared’ (or ‘IR’)

refers to that range of electromagnetic wavelengths just below

that capable of sight by the human eye. In the IR range,

energy from a scene is not sensed by sight ‘light but rather by

temperature.

Most objects that you see are not radiating visible light but

instead, are reflecting light radiated from another source.

Most objects have to be heated to extreme temperatures before

they radiate energy in the visible light spectrum. However,

energy in the infrared range is being radiated by all objects

that are above absolute zero (-459F). Hence, everything has a

thermal signature, regardless of light conditions.

Your TSC4500 infrared detecting system distinguishes

between very small differences in thermal (infrared) radiation,

converts it to electrical signals, amplifies those differences,

and reproduces them correspondingly in the visible light

(video) range. Powerful advantages are achieved in being able

to turn a pitch black night into a black and white TV image of

the scene. As your infrared knowledge and experience grows,

further applications will develop as you recognize heat clues

beyond the naked eye in both day and night conditions.

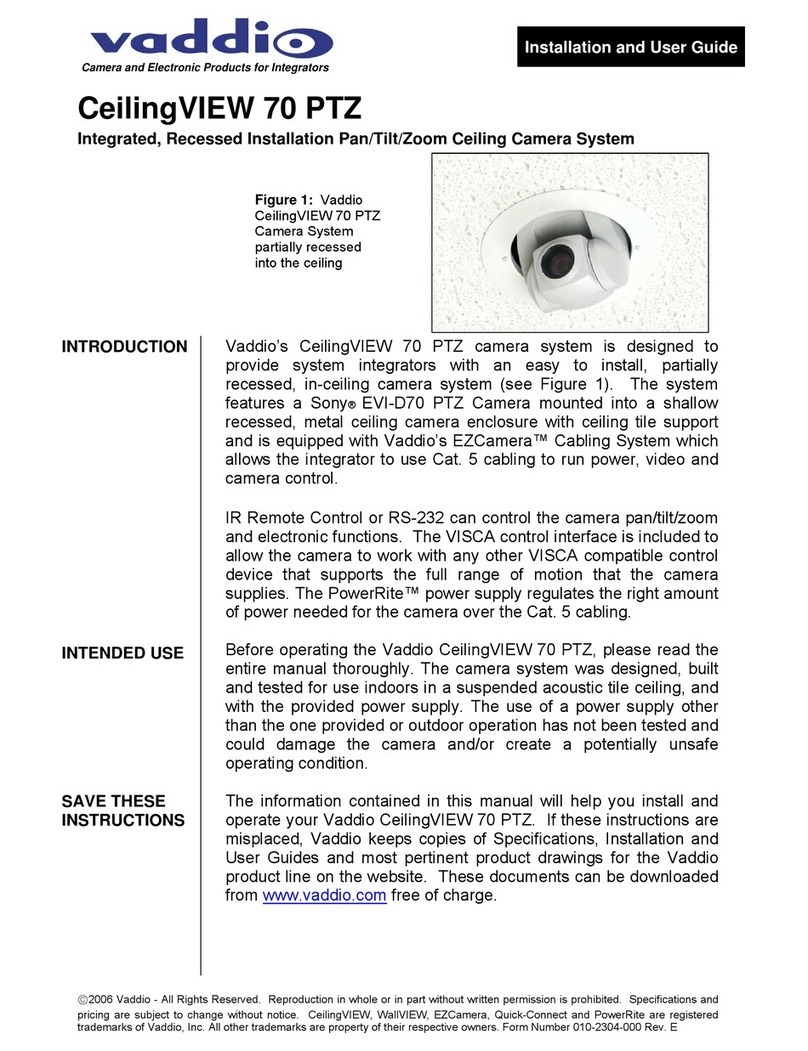

The TSC4500

tm

Product Line

The Thermal Security Camera 4500 (TSC4500) is part of L3

Communications Infrared Products (L-3 IP) Thermal-Eye

TM

family of un-cooled infrared camera product lines. The

TSC4500 utilizes amorphous silicon bolometer technology in

a Long Wave Infrared (LWIR) camera designed as a drop-in

replacement for CCTV cameras for new and existing security

systems. The TSC4500 provides the advantage of viewing

PN 4000161-1 Rev C

7

scenes in total darkness and in some conditions of smoke, dust

and fog. Unlike many of the low-light security cameras, the

TSC4500 does not require any kind of IR illuminator or any

visible light.

The TSC4500 camera operates with a 9-30 Volt DC.

The TSC4500 camera offers an optional interface cable design

that comes in a variety of lengths, 3ft, 15ft and 30ft, to allow

the customer to integrate into their system.

L-3 IP also offers an optional breakout interface cable to

operate the TSC4500 camera. This cable facilitates the user

for bench top checkout and also to power the camera with a

24VAC power converter kit available from L-3 IP to be

compatible with most CCTV setups. The interface cable has

flying leads (wires) for power, video on a BNC output, and a

serial connector for RS-232 communication.

The optional 24VAC power converter accessory allows the

user the flexibility to easily install the camera into the many

existing CCTV systems that use 24VAC. The 24VAC

converter can be used in a user’s junction box with the

standard interface cable or placed inside a weatherized

enclosure.

The TSC4500 camera model is rated IP67 and has an optional

shroud cover compatible for outdoor solar shielding use.

The TSC4500 camera model has an accessory Developer’s Kit

that allows access by the user through the RS-232 Interface

I/O to the following discrete controls:

•Polarity (WHT, BHT)

•

E-zoom (1X, 2X etc.)

•

Shutter (the TSC

4500

has a bi-phase shutter that can be

commanded “closed’ to protect the FPA detector to

solar exposure when power is OFF) & touch-up

PN 4000161-1 Rev C

8

Also through the accessory, RS-232 GUI Developers Kit, user

can setup the camera software with the following User

Controllable Graphic User Interfaces:

•User Parameter GUI

•

User Control GUI

•

Symbology GUI

•

Temperature Sense Color GUI

•

Image/Frame Capture GUI

•

Manual Gain/Level GUI

•

Manual Pixel Substitution GUI

PN 4000161-1 Rev C

9

FEATURES AND OPTIONS:

Accessories and Cables,

User Interface Cable, 3ft (.9m)

15ft (4.5m)

30ft (9.1M)

Enclosure Interface Cable, 4in (.1m)

AC/DC Converter

Solar Shield Kit

Extended calibration for -20º to +70º C operating range

Athermalized lens for self-focusing over temperature.

TSC4500 Camera, 30Hz Video

Lens Option Video Out

25°

NTSC

25°

PAL

12°

NTSC

12°

PAL

THERMAL SECURITY CAMERA

TSC4500 Camera, 9Hz Video

Lens Option Video Out

25°

NTSC

25°

PAL

12°

NTSC

12°

PAL

PN 4000161-1 Rev C

10

Optional Enclosure Window Kits & Part numbers

For Pelco 2500 Series 4” dia. Window frame 4978525-1*

or 4978525-2**

For Pelco 3500 Series 2.9”x2.5” window frame 4978535-1*

or 4978535-2**

For Pelco 4700 Series 4.2”x3.9” window frame 4978547-1*

or 4978547-2**

For Universal Series

(Note 2)

6”x6” window frame 4978540-1*

or 4978540-2**

* -1 Germanium Window (96% Trans in 7-14µm) 2.25” diameter

** -2 Silicon Window (73% Trans in 7-14µm) 2.25” diameter

Note 1 – When the TSC4500 is used in an Enclosure, an infrared-

transmitting window must be installed.

Note 2 – Universal Series Enclosure kit is designed to fit the intended

enclosure after being sized by the integrator. The window

material is bonded to the frame after properly fitted using

provided materials and procedural instructions.

Application Note – the TSC4500 camera interface is

RS-232 only. One camera, one GUI (no daisy chains).

PN 4000161-1 Rev C

11

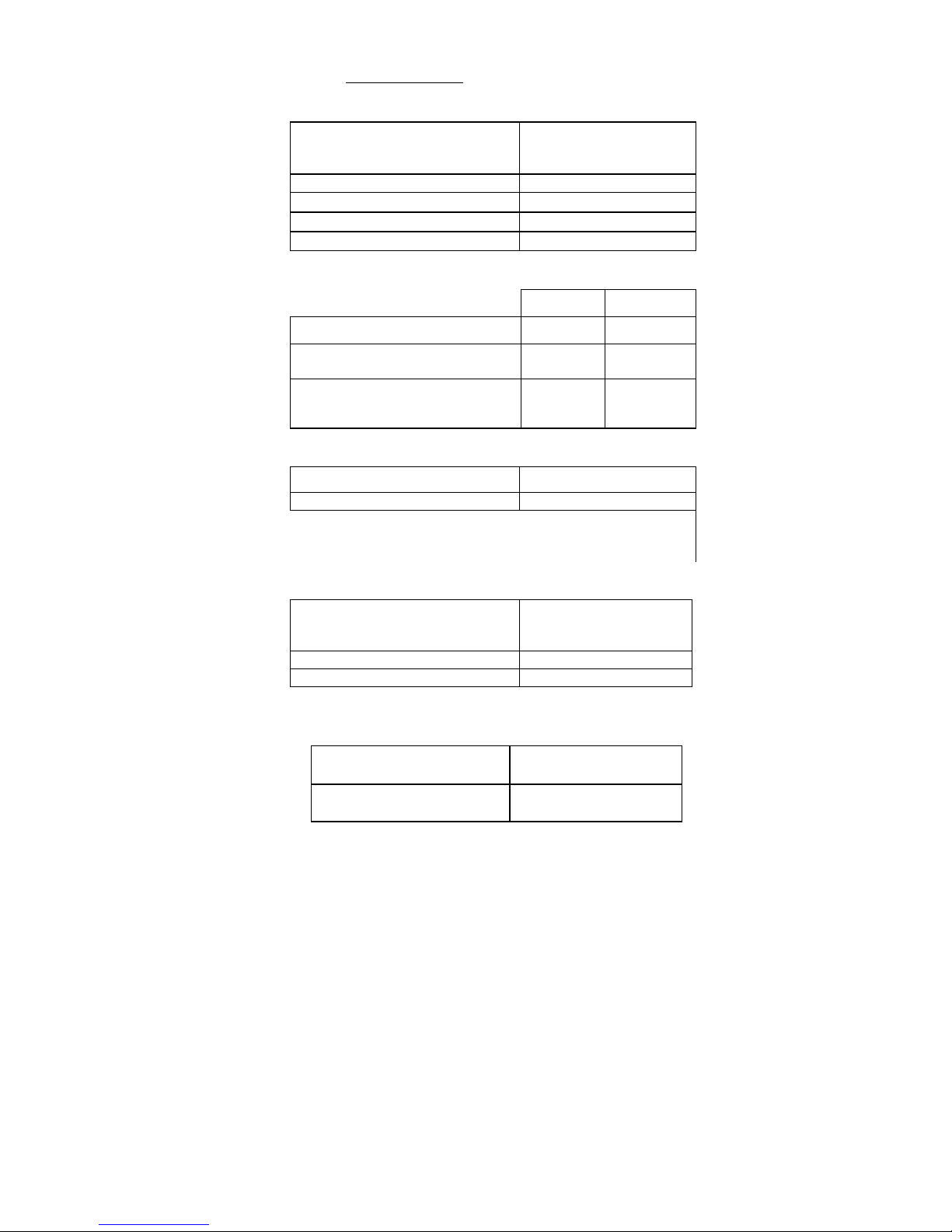

SPECIFICATIONS

Performance

Detector Type Format Uncooled Amorphous

Silicon (320 x 240) pixel

array

Spectral Response 7 to 14 µm

Detector NETD (typical)

< 70 mK

@ 25°C

Uniformity, (typical) >90% @ 25°C, small area

Time to Operation (typical) 4 seconds @ 25°C

Lens Option Capability for TSC4500

25

o

Lens

12

o

Lens

Field of View (FOV) 25°x 19°12°x 9°

Range to detect Human Activity 1465 Feet

(445 m)

3330 Feet

(1015 m)

Focus

Manual

Adjust

athermalized

Manual

Adjust

athermalized

Electrical

Power Source Class 2, 9-30V DC

1

Power Consumption (Typical) < 2W DC @ 12VDC

NOTES

1

Using a 30V DC supply and 18AWG wire, it is recommended that

the power supply wires are no longer than 1000 feet.

Interfaces

Video Output NTSC (Monochrome

SMPTE-170M) and PAL

models available

Video Field Rate 60 Hz

Serial Communications RS – 232

NOTES

Environmental

Operating Temperature –

Thermal-Eye

TSC4500

-20°to +70°C

(-4°to 158°F)

Storage Temperature -40°to +105°C

(-40°to 221°F)

PN 4000161-1 Rev C

12

Water resistance IP67, IEC pub. 529

Operating Humidity 0 – 95% (non-condensing)

Physical (25

o

HFOV)

Thermal-Eye TSC4500 w/25º lens

Dimensions 8.3” x 2.6” x 2.5”

[210.8 x 66.0 x 63.5]

Weight

Mounting

Provisions

¼-20 top or bottom mounting bracket

(using the same mounting bracket by sliding

onto camera body)

Physical (12

o

HFOV)

Thermal-Eye TSC4500 w/12º lens

Dimensions 8.3” x 2.6” x 2.5”

[210.8 x 66.0 x 63.5]

Weight

Mounting

Provisions

1/4-20 top or bottom mounting bracket

(using the same mounting bracket by sliding

onto camera body)

Customer Service

L3 Communications Infrared Products (L-3 IP) personnel and

dealers are trained to help you install and use our Thermal-Eye

TSC4500 line of products. If you have questions or comments,

please call L-3 IP Customer Service at 972-528-1300 or toll

free at 800-990-3275.

EU Representative

BFi OPTiLAS INTERNATIONAL SA

Z. I. La Petite Montagne Sud

4 allée du Cantal – 91018

EVRY CEDEX

France

Phone: 33 - (0) 1 60 79 59 55

PN 4000161-1 Rev C

13

SECTION 2: CARE AND MAINTENANCE

Cleaning of Optics

The lens assembly is a long wave thermal imaging objective

lens that collects and focuses radiation in the 7–14 µm spectral

region.

The optical surface of the lens should only be cleaned when

visibly dirty. Care should be taken to avoid touching the

exposed lens face. Skin acid left behind with fingerprints can

be damaging to coatings and lens substrates. First use a jet of

air or blow across the surface to remove any sand or abrasive

particles before cleaning. If oil, water spots, or fingerprints

form on the optical surface, clean as soon as possible using a

soft cotton cloth and mild neutral soap diluted with lukewarm

distilled water (1 part soap to 100 parts water), followed by

reagent grade isopropyl alcohol or acetone swab. Dust can also

be removed gently using an alcohol or acetone swab.

N te: Av id swabs that inc rp rate plastic stems, as

N te: Av id swabs that inc rp rate plastic stems, as N te: Av id swabs that inc rp rate plastic stems, as

N te: Av id swabs that inc rp rate plastic stems, as

s me plastics will diss lv

s me plastics will diss lvs me plastics will diss lv

s me plastics will diss lve in alc h l r acet ne

e in alc h l r acet nee in alc h l r acet ne

e in alc h l r acet ne.

Restrictions of Use

The unit is not intended or warrantied for use in the following

conditions. Damage resulting from such exposure would not

be covered by the warranty.

Unit is compatible with outdoor applications with the

optional sun shroud.

Unit is not intended for exposure to a salt-water

atmosphere.

Unit is not intended for dynamic–mount applications,

such as on vehicles or heavy machinery, in which

transmitted vibration is continuously sustained.

Unit (whether powered On or Off) is not intended for

viewing of direct or indirect (reflected) sunlight. Unit

is intended for non-horizon exposure looking

downward from intended mounting plane. Exposure

to the sunlight, for even very short periods of time,

may permanently damage the camera and therefore

nullify any warranties.

PN 4000161-1 Rev C

14

Unit is not intended for intentional or unintentional

exposure directed towards solar activities, welding, or

other activities of similar heat dynamics, which if

performed may damage the camera and therefore will

nullify any warranties.

SECTION 3: INSTALLATION INSTRUCTIONS

Mounting the Camera

The removable mount assembly is made up of an extrusion

that can be locked in place by two setscrews. Each extrusion

is designed to fit into the grooves on the top and bottom of

camera housing. The mount can easily be removed and placed

on either the top or bottom of the camera housing.

See Figure 1.

Figure 1 – Mounting bracket on Thermal-Eye TSC4500

System Interface Connector

The TSC4500 uses a commercially available connector to

provide interface with the user’s system utilizing L-3 IP’s

interface cable. Conxall PN CXS3106A2027S300

PN 4000161-1 Rev C

15

Figure 2 – Camera Interface Connection

Connecting Input Power

The TSC4500 uses DC power into the interface connector:

The camera connector on the TSC4500 camera utilizes a DC

power input rated for a nominal 12, 18 or 24 VDC supply.

For DC power, use only an isolated Class 2

power supply rated for at least 2 Watts.

See Figure 3 for the wire color scheme and DC connection

schematic of the interface cable.

Figure3 – Interface Cable Schematic

PN 4000161-1 Rev C

16

See Figure 4 for the wire color scheme and DC connection

schematic of the interface cable.

Figure 4 – Breakout Interface Cable Schematic

Video Output

The Thermal-Eye TSC4500 outputs AC-coupled,

Monochrome SMPTE – 170M compatible video, which is

compatible with NTSC. The video is output on a BNC

connector and should be hooked up to a 75-ohm impedance

monitor. If user employs a video grounded loop, the video

ground connection going to this camera should be disrupted or

not terminated.

User Interface with TSC4500

Communication software may be commercially available to

interface with and control Thermal-Eye TSC4500 Full

Function cameras. The EIA/RS-232 serial port is necessary to

utilize any such software packages. For information on

compatible software to communicate with the Thermal-Eye

TSC4500 Full Function cameras, please call our Customer

Service at 1-972-528-1300 or toll free at 1-800-990-3275.

PN 4000161-1 Rev C

17

RS-232 Serial Communication:

The TSC4500 connector provides access to an EIA/RS-232

serial port for User interfacing. How to connect to this serial

port is described below. Also see Figure 3, Figure 4 and

Figure 5

.

The connections needed for RS-232 communications are

provided in the three wires RS-232 DATA-, RS-232 DATA+,

and SIGNAL GROUND.

Figure 5 – RS-232 Connections for the TSC4500

Using RS-232/485 Serial Communication:

An RS-485 to RS-232 converter can be used to connect to a

PC (for example, the B&B Electronics

TM

p/n 485SD9RJ).

Category 5 (“Cat 5”) cable is recommended for the carrying

the RS-485 signals to the converter & PC. Follow the

directions for your particular RS-485/RS-232 device to

correctly connect it to the Thermal-Eye TSC4500 data lines

see Figure 6 and 7.

Figure 6 – RS-232/RS-485 Connections for the TSC4500

RS

-

232/485

To TSC4500

RS

DATA+

RS

DATA

--

S

IGNAL GND

RS

-

23

2

To TSC4500

DATA+

DATA

--

S

IGNAL GND

PN 4000161-1 Rev C

18

Figure 7 – RS-485 Connections to the PC

Focus Adjusting

The 25°and 12°Field of View lenses are manually focused

lenses. These lenses are also athermalized and maintain focus

over temperature extremes.

SIGNAL GROUND

RS-485 DATA

RS-485 DATA+

_

To a PC

Serial port

RS-485/232

Converter

PN 4000161-1 Rev C

19

SECTION 4: WARRANTY INFORMATION

THERMAL

THERMALTHERMAL

THERMAL-

--

-EYE

EYE EYE

EYE

THERMAL SECURITY CAMERA

THERMAL SECURITY CAMERATHERMAL SECURITY CAMERA

THERMAL SECURITY CAMERA

TM

TMTM

TM

L3 COMMUNICIATIONS INFRARED

L3 COMMUNICIATIONS INFRARED L3 COMMUNICIATIONS INFRARED

L3 COMMUNICIATIONS INFRARED

PRODUCTS

PRODUCTSPRODUCTS

PRODUCTS

PN 4000161-1 Rev C

20

Warranty

Product(s) will conform to L-3 IP’s current drawings and specifications at the time of delivery and be free from

defects in material and workmanship under normal use and service for twelve (12) months, beginning on the date the

product is delivered to the customer, or beginning on the date product is placed into service; collectively whichever is

the shorter period of time, but in no event shall the period become greater than eighteen months (the “warranty”). L-3

IP’s sole obligation, buyer’s exclusive remedy, under the warranty is for L-3 IP, at its option, to repair or replace any

part of the product which fails to meet the warranty or refund buyer’s purchase price, in the form of credit. For

warranty repairs/replacements, at L-3 IP’s cost for shipping, buyer shall return product(s) to L-3 IP’s facility

designated by L-3 IP, with a written explanation of failure. The warranty shall not apply to products; (i) used for

purposes for which they are not designated or intended, or (ii) which have been repaired or altered without L-3 IP’s

prior written consent, or (iii) which have been subjected to misuse, negligence, accident or improper maintenance or

installation, or (iv) upon L-3 IP’s examination, do not disclose to L-3 IP’s satisfaction nonconformance to the

warranty. In the event the product ‘warranty card” is not returned to L-3 IP, proof of purchase shall be required to

effectuate the warranty provisions stated herein above. NO OTHER WARRANTIES, EXPRESS OR IMPLIED,

ARE MADE WITH RESPECT TO THE PRODUCT(S) INCLUDING, BUT NOT LIMITED TO, ANY

IMPLIED WARRANTY OF MERCHANTABILITY, NON-INFRINGENT OR FITNESS FOR A

PARTICULAR PURPOSE. Buyer agrees that any documentation and / or representation provide to its customer(s)

shall include the preceding advisement by L-3 IP.

Repaired equipment should be returned prepaid (surface freight only). If goods are being returned from outside the

United States, the shipper is responsible for all customs and brokerage charges.

This manual suits for next models

1

Table of contents