Thermal Fogger Pioneer User manual

KNAPSACK CORDLESS BATTERY POWERED

ULV COLD FOGGER

Model : Pioneer

Model: Pioneer

User’sManual

USER’S MANUAL

- 1 -

CONTENTS

Contents······························································································1

Illustration····························································································2

Warning·······························································································2

Technical specification ········································································3

Work principle ·····················································································3

Flow rate knob·····················································································3

Operation ····························································································4

Install, move out battery…………...……………………...……….……...5

Spare parts list·····················································································6

Inform

Due to further improvement, we are sorry if could not inform individually.

- 2 -

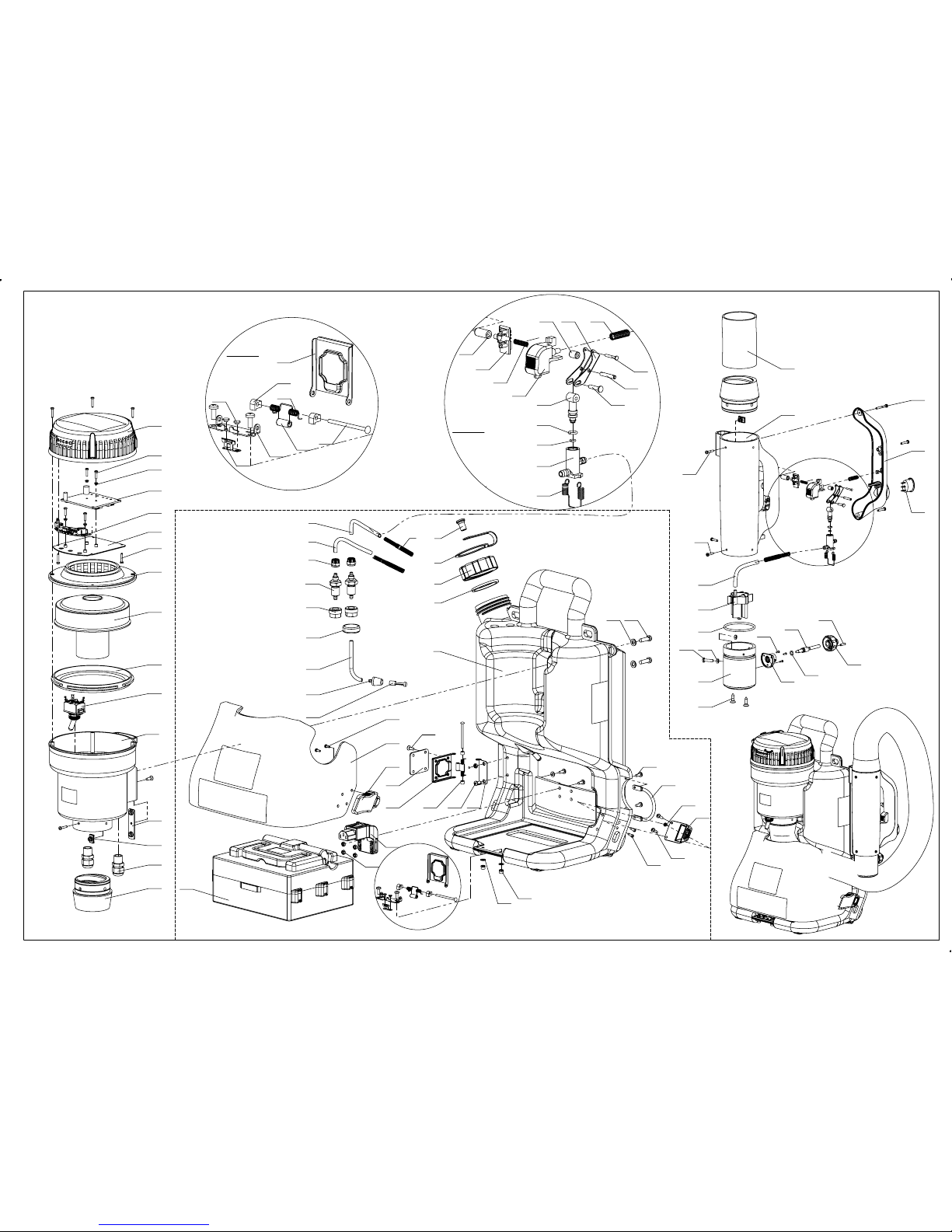

Illustration

Warning

1. Before operation, check battery have enough power.

2. For better maintain battery, please remember every 2 month, run

out off battery then fully charge.

3. Do not upside down if tank has liquid.

4. After spray chemicals, then spray clean water.

5. Do not splash machine.

6. Switch, cable’s insulating layer, hose, gasket broke, fix.

7. Do not spray strong corrosive chemicals, if sprayed, immediately

spray clean water.

8. Do not point people or other object while adjust flow rate.

9. Before store, clean, dry up.

Pressure Chamber

Chemicals Tank

Main Power Switch

Flexible Hose

Flow Rate Knob

Nozzle Cover

B

A

C

D

E

F

A

B

C

D

E

F

- 3 -

Technical specification

Voltage DC 24 V

Power 450 W

Dimension 33 x 24 x 49 CM

Net Weight 9.70 KG

Tank capacity 5 L / 1.3 GAL.

Flow rate 0 - 0.325 L/min, 0 - 9.61 OZ/min

Work principle

ULV cold fogger produce high-speed airflow, press chemicals solution

to nozzle breaks into small particle around 20 micron, float in air longer,

eliminate pest, disinfect air continuously.

Flow rate knob

Turn “Flow rate knob” to clockwise direction, decrease flow rate,

produce smaller fog droplet;

Turn “Flow rate knob” to anti-clockwise direction, increase flow rate,

produce bigger fog droplet;

FlowRateKnob

- 4 -

Operation

1. Fill chemicals to tank, tighten cover.

2. Turn on Main power switch, carry on shoulder.

3. Turn on Handle switch (Ⅰ-slow speed, Ⅱ-fast speed, O-stop).

4. Trigger under handle

4.1 Pull trigger spray.

4.2 Hold on-pull trigger continuous spay.

4.3 Press lock up button inside continuous spray.

4.4 Release pull trigger stop spray.

4.5 Pull trigger stop spray.

5. Adjust flow rate knob for appropriate flow rate.

6. Pull or release pull trigger stop spray, close knob.

7. Turn off Handle switch,

8. Please remember turn off Main power switch.

Trigger

LockUpButton

- 5 -

9. Discharge residual chemicals.

Install, move out battery,

Push down battery catch device,

Move out battery along slide,

Push in battery along slide, catch device will automatically rebound

back lock appropriately.

- 6 -

Spare parts list

Item No. Spare parts name Quantity Remark

1 Tank 1

2 Gasket 1 50×42×3.5

3 Cover 1

4 Connecting ring 1

5 Pressing buckle 1

6 Spring 3 Φ6.5

7 PVC Pipe 1 Φ4×Φ6×1900mm

8 PVC Pipe 1 Φ4×Φ6×1800mm

9 Nut 2

10 Fixed sets 2

11 Nut 2

12 Suction head accessory 1

13 PVC Pipe 1 Φ4×Φ6×250mm

14 Suction head 1

15 Filter 1

16 Screw 6 ST2.9×8.5

17 Cover 1

18 Self-locking block 1

19 Brand label 1

20 Spade hook 1

21 PTFE pipe 2 Φ6×Φ4×5

22 Screw 1 ST4.2×13

23 Fixed plate 1

24 Screw 5 M4×10

25 Screw 2 M6×20

26 Flat wash 2 6

27 Screw 9 M4×10

28 Fixed ring 1

29 Nut 2 M3

30 Self-locking stand 1

- 7 -

31 Screw 2 ST3.5×13

32 Screw 2 M3×10

33 Nut 2 M4

34 Flat wash 3 4

35 Rivet 2 3×5.5

36 Spring card 1

37 Fixed plate 1

38 PTFE pipe 2 Φ6×Φ4×13

39 Rivet 2 3.5×50

40 Torsional spring 2

41 Rolling bearing 2

42 Hook 1

43 Pin 1

44 Storage battery 1

45

46 Connecting ring 2

47 Water-proof joint 2

48 Sleeve 8

49 Connecting strip 1

50 Pressure chamber 1

51 Switch 1

52 Seal 1

53 Motor assembly 1

54 Motor plate 1

55 Screws 17 ST2.9×16

56 Butt plate 1

57 Electricity display board 1 Voltage Show1-1

58 Control board 1

59 Gasket 4 Ф3

60 Screw 4 M3×12

61 Rear housing 1

62

- 8 -

63 Bellows 1

64 Handle, under part 1

65 Screws 1 ST2.9×25

66 Handle, top part 1

67 Switch 1

68 Button 1

69 Slide block 1

70 Compression spring 1

71 Valve switch button 1

72 Compression spring 1

73 Adjustable block 1

74 Pulley 1

75 Rivet 1 2×13

76 Rivet 1 3×18

77 Rivet 1 3×13

78 Valve core 1

79 O-ring 1 Ф5.1×1.6

80 O-ring 1 Ф3×1.25

81 Valve 1

82 Extension spring 1

83 Screw 1 M3×12

84 Accelerator knob 1

85 Adjustable lever 1

86 O-ring 1 Φ5×1.5

87 Screw 3 ST1.9×6

88 Limited block 1

89 Screw 2 ST4.2×16

90 Nozzle cover 1

91 Screw 1 M4×16

92 Nut 7 M4

93 O-ring 1 Φ56×3

94 Vortex device 1

- 9 -

95 PVC Pipe 1 Φ4×Φ6×100mm

96 Screw 3 ST2.9×13

I

II

5

4

3

2

1

6

7

8

9

10

11

12

13

14

15

24

19

20

17

16

18

43

21 23

28

30

29

44

22

2526

27

31

32

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

63

64

66

65

67

83

84

85

86

87

88

89

90

91

93

94

95

55

33

34

92

92

96

I

1 : 2

36

37

35

41

40

38 39

42

II

1 : 2

68

69

70

71

72

75

76

77

74

78

79

80

81

82

73

Table of contents