Thermal-Grip IP50D Guide

MODEL

GAS INSULATION NAILER

SAFETY OPERATION MANUAL

IP50D

IMPORTANT INFORMATION TO READ BEFORE

OPERATION.

Read and understand tool labels

and all operating instructions,

safety precautions and warningsin

this manual before operating or

maintaining this tool.

Failure to follow warnings could result in DEATH

or SERIOUS INJURY.

Most accidents that result from the operation and

maintenance of Nailers are caused by the failure

to observe basic safety rules or precautions. An

accident can often be avoided by recognizing a

potentially hazardous situation before it

occurs, and by observing appropriate safety

procedures.

Basic safety precautions are outlined in the

“SAFETY” section of this Manual

Hazards that must be avoided to prevent bodily

injury or machine damage are identified by

DANGERS and WARNINGS on the Nailer and in

this Manual

Never use this Nailer for applications other than

those specified in this Manual.

SAFETY

IMPORTANT SAFETY INSTRUCTIONS FOR

USING NAILERS

READ ALL INSTRUCTIONS

This Nailer is powered by an

internal combustion device.

This Nailer shall only be used with

dispensers for combustible gas

which are listed in this manual.

DANGER

1.

OPERATORS AND OTHERS IN WORK AREA

MUST WEAR SAFETY GLASSES WITH SIDE

SHIELDS.

When operating the Nailer, always

wear safety glasses with side

shields, and make sure others in

work area wear safety glasses.

2.

NEVER USE IN PRESENCE OF FLAMMABLE

LIQUIDS OR GASES.

This Nailer must not be used in a

combustible environment or in

presence of flammable liquids or

gases, e.g. lacquer, paint, benzine,

thinner or gasoline.

This Nailer produces hot exhaust gases that

may ignite flammable materials and produces

sparks during operation.

3.

DO NOT TOUCH AROUND THE EXHAUST

OUTLET.

This Nailer produces hot exhaust

gases that may flammable materials.

The pus h lever and nose will

become hot and get heated up after

prolonged or rapid use.

Do not touch with bare hands.

4.

EXPLOSION AND FIRE HAZARD.

The fuel cell is an aerosol dispenser

with flammable contents.

Press ured contai ner and the

propellant will remain in the fuel cell.

Faillure to follow instructions may

result in explosion or fire.

1

MAX

Keep the Nailer, fuel cells and battery

away from tem pera tures

exceeding 120°F (50°C).

Fuel cell and/or battery may burst,

releasing flammable gas.

Do not pierce or burn the container,

even after use.

Do not incinerate, refill, reclaim or

recycle the fuel cell.

Do not spray into a flame or any

incandescent material.

Keep away from ignition sources

No smoking.

Keep out of the reach of children.

120°F

WARNING

9.

STORE NAILER PROPERLY WITH FUEL CELL

AND BATTERY REMOVED.

When not in use, the Nailer, fuel cell and battery

should be stored in tool case and in a dry place.

Store indoors at temperature41°F(5°C) ~77°F(25°C).

Keep the Nailer, fuel cell and battery out of

direct sunlight and out of vehicle.

Keep out of reach of children.

10.

KEEP WORK AREA CLEAR.

5.

NEVERPOINTTOOLAT YOURSELF OR OTHERS

IN WORK AREA.

Always assume the Nailer contains

fasteners.

Never point the Nailer at yourself or

others, whether it contains fasteners

or not.

If fasteners are mistakenly driven, it can lead to

severe injuries.

6.

KEEP FINGERS AWAY FROM TRIGGER

WHE N NOT DRIVING FASTENERS TO

AVOID ACCIDENTALFIRING.

Never carry the Nailer with finger on trigger

since you could drive a fastener unintentionally

and injure yourself or someone else.

Always carry the Nailer by the handle only.

7.

ALWAYS WEAR EAR AND HEAD PROTECTION.

Always wear ear protection to protect your ears.

Always wear head protection to protect your head

from flying objects.

8.

USEOUTSIDE OR WELL-VENTILATEDAREAS.

This Nailer shall not be used in

enclosed or poorly ventilated areas.

This Nailer exhausts carbon

monoxide which is a danger to

health when inhaled.

Do not inhale.

2

11.

DRESS PROPERLY.

Always wear proper protective clothing on jobsite.

12.

KEEP ALL SCREWS AND COVERS TIGHTLY

IN PLACE.

Keep all screws and covers tightly mounted.

Check their condition periodically.

Never use the Nailer if parts are missing or

damaged.

13.

DO NOT LOAD FASTENERS WITH TRIGGER

OR PUSH LEVER DEPRESSED.

When loading fasteners into the Nailer,

1)

do not depress the trigger;

2)

do not depress the push lever;

3)

keep the Nailer pointed downward.

14.

KEEP FACE, HANDS ANDFEETAWAYFROM

FIRING HEAD DURING USE.

Never place your face, hands or feet closer than

8 inches (200 mm) from the firing head.

A serious injury can result if the fasteners are

deflected by the workpiece, or are driven away

from the point of entry.

15.

PLACE NAILER PROPERLY ON WORKPIECE.

Do not drive fasteners on top of other fasteners

or with the Nailer at too steep of an angle.

16.

CHECK FOR LIVE WIRES.

Avoid the risk of severe electrical shock by

checking for live electrical wires that may be

hidden by walls, floors or ceilings. Turn off the

breaker switch to ensure there are no live wires.

17.

DO NOT OVERREACH.

Keep proper footing and balance at all

times. Do not operate the nailer on a

scaffold and ladder.

18.

NEVER USE NAILER WHICH IS DEFECTIVE

OR OPERATING ABNORMALLY.

If the Nailer appears to be operating unusually,

making strange noises, or otherwise appears

defective, stop using it immediately and arrange

for repairs by a dealer authorized service center.

19.

TAKE FUEL CELL AND BATTERY OUT OF

NAILER WHEN:

1)

doing maintenance and inspection;

2)

clearing a jam;

3)

it is not in use;

4)

leaving work area;

5)

moving it to another location;

6)

handing it to another person.

Never attempt to clear a jam or repair the Nailer

unless you have taken fuel cell and battery out of

the Nailer and removed all remaining fasteners

from the Nailer.

20.

HANDLE NAILER CORRECTLY.

Operate the Nailer according to this Manual.

Never allow the Nailer to be operated by children,

individuals unf amiliar with its operation or

unauthorized personnel.

21.

NEVER USE NAILER FOR APPLICATIONS

OTHER THAN THOSE SPECIFIED IN THIS

MANUAL.

22.

HANDLE NAILER CAREFULLY.

Do not drop the Nailer or strike the Nailer against

hard surfaces. Handle the Nailer carefully.

23.

MAINTAIN NAILER WITH CARE.

Keep the Nailer clean and lubricated for better

and safer performance.

24.

USE ONLY PARTS, ACCESSORIES OR

FASTENERS SUPPLIED OR RECOMMENDED

BY DEALER.

Unauthorized parts, accessories, or fasteners

may void your warranty and can lead to malfunction

and resulting injuries.

Only service personnel trained by dealer,

distributor or employer trained personnel shall

repair the Nailer.

25.

NEVER MODIFY OR ALTER A NAILER. Doing

so may cause it to malfunction and personal

injuries may result.

3

FUEL CELL IMPORTANT SAFETY INSTRUCTIONS

DANGER

■

Fuel cell, fuel and propellant are flammable

under pressure.

Explosion / Fire Hazard

Must follow all instructions

otherwise it may result in fire

and explosion when handling

dispensers for combustible gas for

the purpose

of storage, transportation, inserting into and

taking out of the tool and disposal.

■

Do not smoke when handling the fuel cell.

WARNING Do not inhale its contents.

Expanding gases cause low temperatures.

Fluid gases might cause injuries when getting

in touch with skin oreyes.

In case of contact with skin ; wash the contact

surface carefully with warm water and soap.

In case of contact with eyes ; rinse the open eyes

under running water.

Contact a doctor if necessary.

Store in well-ventilated area.

Store under 41°F (5°C) ~77°F (25°C )(e.g .

Do not store under the direct sunlight or in a

vehicle).

Do not expose to an open flame and sparks.

Do not puncture or open the fuel cell.

Do not refill, reclaim or recycle the fuel cell.

Dispose of according to local regulations for

aerosol products.

Do not dispose of fuel cell with other scrap for

recycling.

Keep out of reach of children.

8.

Do not operate battery charger with damaged

cord or plug.

9.

Do not disassemble battery charger.

10.

Please read this Manual before using the battery

charger.

IMPORTANT SAFETY INSTRUCTIONS FOR USE

OF THE BATTERY AND BATTERY CHARGER

You must charge the battery before you use the

Nailer. Before using the model 503.1.16.001.01

battery charger, be sure to read all instructions and

cautionary statements on the battery and in this

manual.

REMEMBER : ONLY USE BATTERY

TYPE:No.503.1.10.001.01.

OTHER TYPES OF BATTERIES MAY BURST

AND CAUSE INJURY!

Follow these instructions to avoid the risk of injury:

WARNING

Improper use of the battery or battery charger

can lead to serious injury. Toavoidtheseinjuries:

1.

DO NOT disassemble the battery.

2.

DO NOT incinerate the battery.

3.

DO NOT short-circuit the battery.

4.

DO NOT insert any objects into the battery

charger's air vents. Electric shock or

damage to the battery charger may result.

5.

DO NOT charge outdoors. Keep the battery away

from direct sunlight and use only where

there is low humidity and good ventilation.

6.

DO NOT charge when the temperature is below

50°F (10°C) or above 104°F (40°C).

7.

DO NOT connect two battery chargers together.

8.

DO NOT insert foreign objects into the hole for

the battery or the battery charger.

9.

DO NOT use a booster transformer when charging.

10. DO NOT store the battery or battery charger in

places where the temperature may reach or

exceed 104°F (40°C).

DISPOSAL OF THE BATTERY

WARNING

Dispose of damaged or worn out batteries

according to local recycling or refuse rules.

4

IMPORTANT SAFETY INSTRUCTIONS FOR

BATTERY CHARGER

WARNING

Death or serious bodily injury could result from

improper or unsafe use of battery chargers.

To avoid these risks, follow these basic safety

instructions:

READ ALL INSTRUCTIONS

1.

This manual contains important safety and

operating instructions for battery charger Model

504.4.04.013.XX.

2.

Before using battery charger, read all instructions

and cautionary markings on (1)nailer,(2) battery

charger, (3) battery.

3.

To reduce risk of injury, only use rechargeable

battery type504.4.04.011.01. Other type of

batteries may burst causing personal injury and

damage.

4.

Do not expose battery charger to rain or snow.

5.

Use of an attachment not recommended or sold

by the battery charger manufacturer may result

in a risk of fire, electric shock, or injury to persons.

6.

Make sure cord is located so that it will not be

stepped on, tripped over, or otherwise subjected

to damage.

7.

An extension cord should not be used unless

necessary.

Use of improper extension cord could result in a

risk of fire and electric shock.

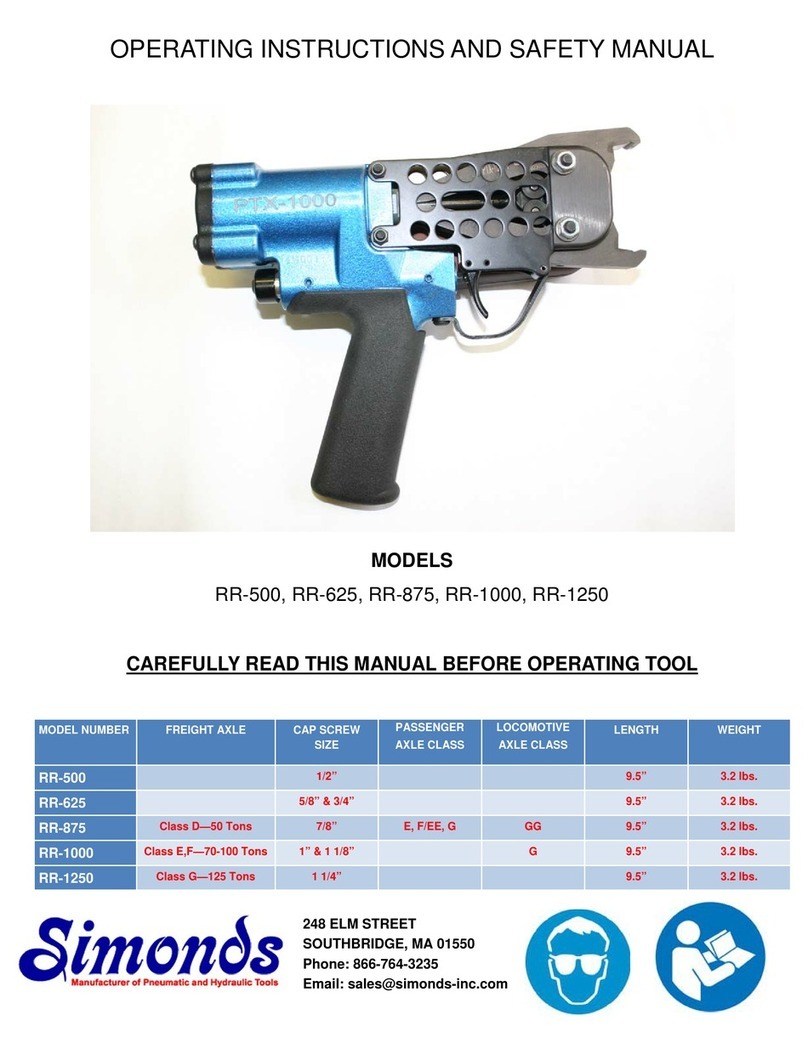

SPECIFICATION

1.

GAS INSULATION NAILER

TYPE

IP50D

Type of power

Piston reciprocating

Applicable nails

See 2. Available Nails.

Nail Capacity

1 nails

Ambient temperature

-5 ℃~ 50℃(23℉to 120℉)

Dimensions

18.30 "(L)×14.55"(H)×4.80"(W)

465mm(L)×370mm (H)×122mm (W)

Weight

8.2lbs. (3.7kg Include battery )

Cycle Rate

1 nails/second

Battery Pack

NiMH 7.2V

2.

Available Nails

WARNING

Be sure to use only the genuine dealer nails as the above sizes. The use of any other nails can result in

tool malfunction or nail breakdown, leading to serious injuries.

Only nails shown in the above table can be driven with this Nailer.

3.

Fuel cell

Fuel Cell

Sold Separately, Specification as below:

1 )Φ31.5mm x 165mm Pressure 16 ~18 bar,

Using temperature range: 23 ℉(-5℃)~120℉(50℃)

Model No: FC165-1-1

2 )Φ31.5mm x 165mm Pressure 10.8 ~11.8 bar,

Using temperature range: 23 ℉(-5℃)~120℉(50℃)

Model No: FC165-2-1

4.

Charger

Input power source

AC110 ~240V / 50 ~60Hz

Charge time

Charging voltage

DC 12V

Charging current

DC 0.8A

Charger Weight

0.15Kg

Adapter Weight

0.085Kg

5

30-160mm

About 60minutes

GENERAL OPERATION MANUAL

NOTE:

The information contained in this Manual is designed to assist you in the safe operation of the Nailer.

Some illustrations in this Manual may show details or attachments that differ from those on your own

Nailer.

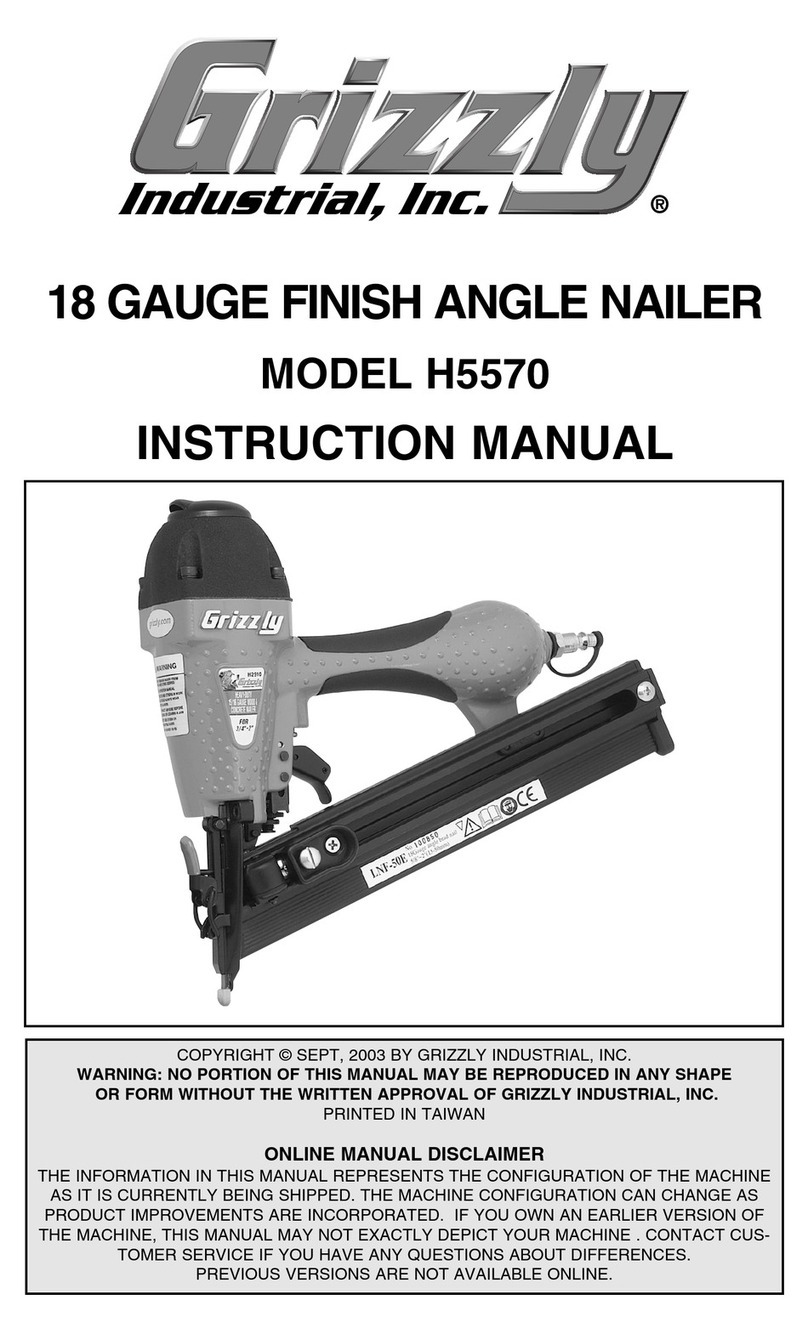

NAME OF PARTS

1. Gas Insulation Nailer ( MODEL: IP50D )

Cap

Piston Assembly

Fuel Cell Door

Fuel Cell

Handle Battery Pack

Trigger

Fastener guide Support Guide Sleeve

Fastener guide

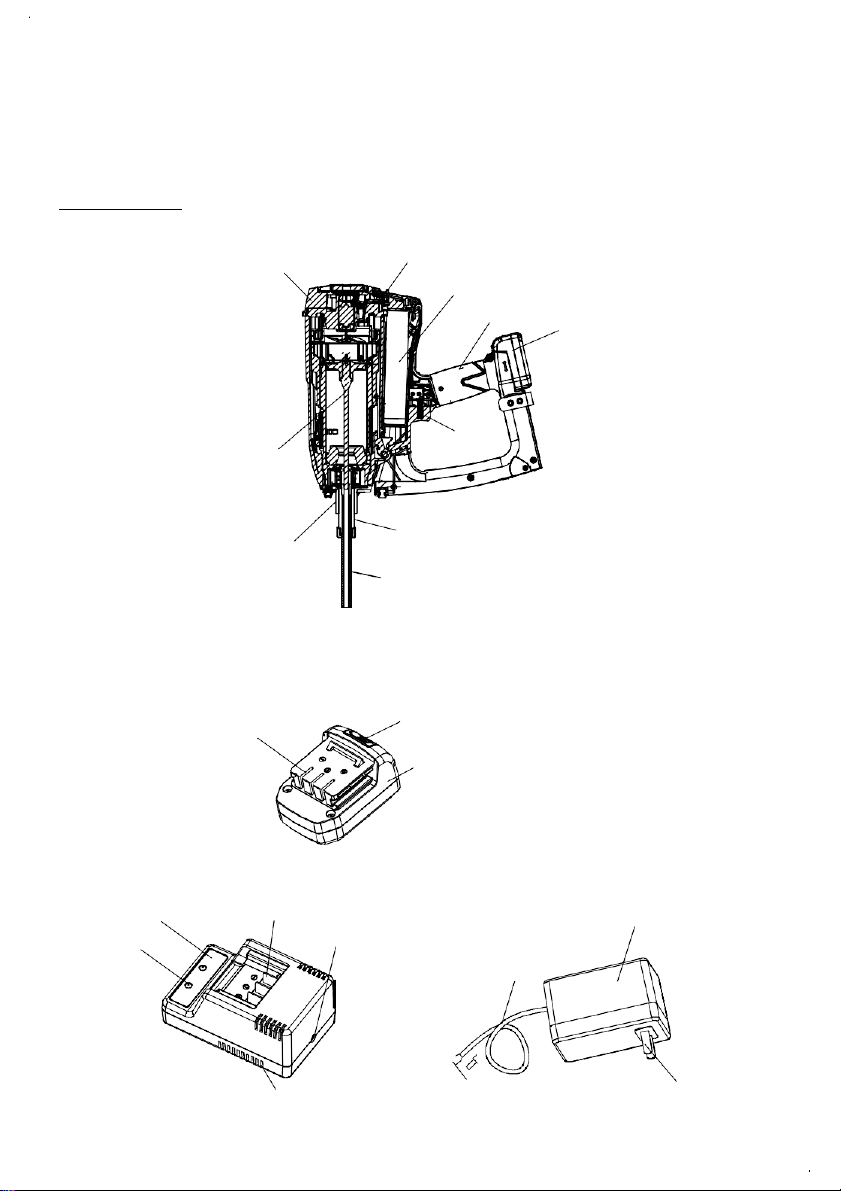

2. Battery Pack( 503.1.10.001.02)

Terminal

Latch

Battery Pack

3.

Battery Charger(503.1.16.001.02) (include Adapter and Charger Base)

6

Power Cord

Charger Base Battery Installation Charger Adaptor

Light Indication Connection

Air Vent Connection Plug Power Plug

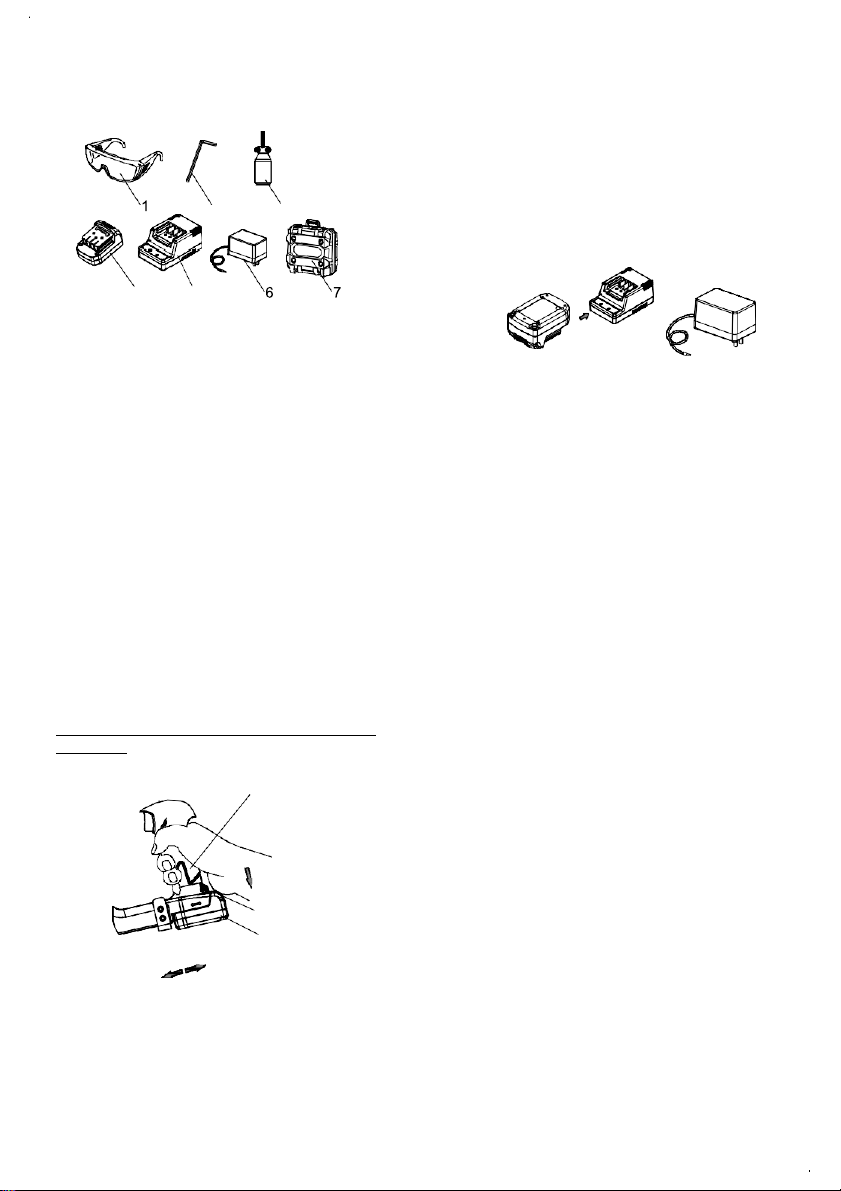

4.

Accessories

2 3

4 5

DANGER

Accessories other than those shown below can lead

to malfunction and resulting injuries.

STANDARD ACCESSORIES

1.

How to install the battery

Align the battery with the groove in tool handle

and slip it into place. Always insert it all the way

until it locks in place with a little click. If not, it

may accidentally fall out of the tool, causing

injury to you or someone around you.

2.

How to remove the battery

Withdraw battery from the tool handle while

pressing top button on the battery.

1.Safety Glasses····································

2.

Wrench M5

·······································

3.

lubricating oil

·····································

4.BatteryPack······································

5.Charger Base ·····································

6.Charger Adaptor··································

7.Blow Case Assembly ····························

OPTIONAL ACCESSORIES

sold separately

1.Fuel Cell

2.Cleaner

REMOVAL AND INSTALLATION METHOD OF

BATTERY

Handle

Latch

Battery Pack

pull out

STEP:

1.

Insert the battery into the charger base. Make

sure it contacts the bottom of the charger base .

2.

Insert the connection plug of adapter into the

receptacle of the charge base.

3.

Insert the power plug of the adapter into the

plug seat.

4.

Charging

■When the charger adapter has been inserted into the

plug seat , charging will commence and the red &

green pilot lamp will light up together.

■When done charging, the red light will turn

off and only green light will be on.

7

NOTE: The battery charging time becomes longer

when a temperature is low or the voltage of

the power source is too low.

5.

Disconnect battery charger from the power plug.

CAUTION

■

If the battery is recharged when it is warm due

to battery use or exposure to sunlight, thepilot

lamp may not light. The battery will not be

recharged. In such a case, let the battery cool

before charging.

BEFORE OPERATION

Read section titled “SAFETY”

Make sure of the followings before operation.

WORKING ENVIRONMENT

WARNING

■

No flammable gas, liquid or other

flammable objects at worksite.

■

Use outside or well- ventilated

areas. Do not inhale.

■

Keep the Nailer, fuel cell and

battery away from sunshine and

from temperature exceeding

120°F (50°C).

■

Keep away from ignition sources.

No smoking.

■

Clear the area of children or

unauthorized personnel.

COLD WEATHER CARE

■

Do not store the Nailer, fuel cell and battery in a

cold weather environment. Keep the Nailer, fuel

cell and battery in a warm area until beginning

the work.

■

If the Nailer, fuel cell and battery are already

cold, bring it in a warm area and allow the Nailer

to warm up before use. Observe temperature

limit of max. 120°F (50°C).

Do not expose to an open flame and sparks!

CAUTION

■

This Nailer may not drive completely when:

at low temperature fuel cell may lose the

required propellant force;

or at high temperature.

■

Do not use the Nailer in the rain or where

excessive moisture is present.

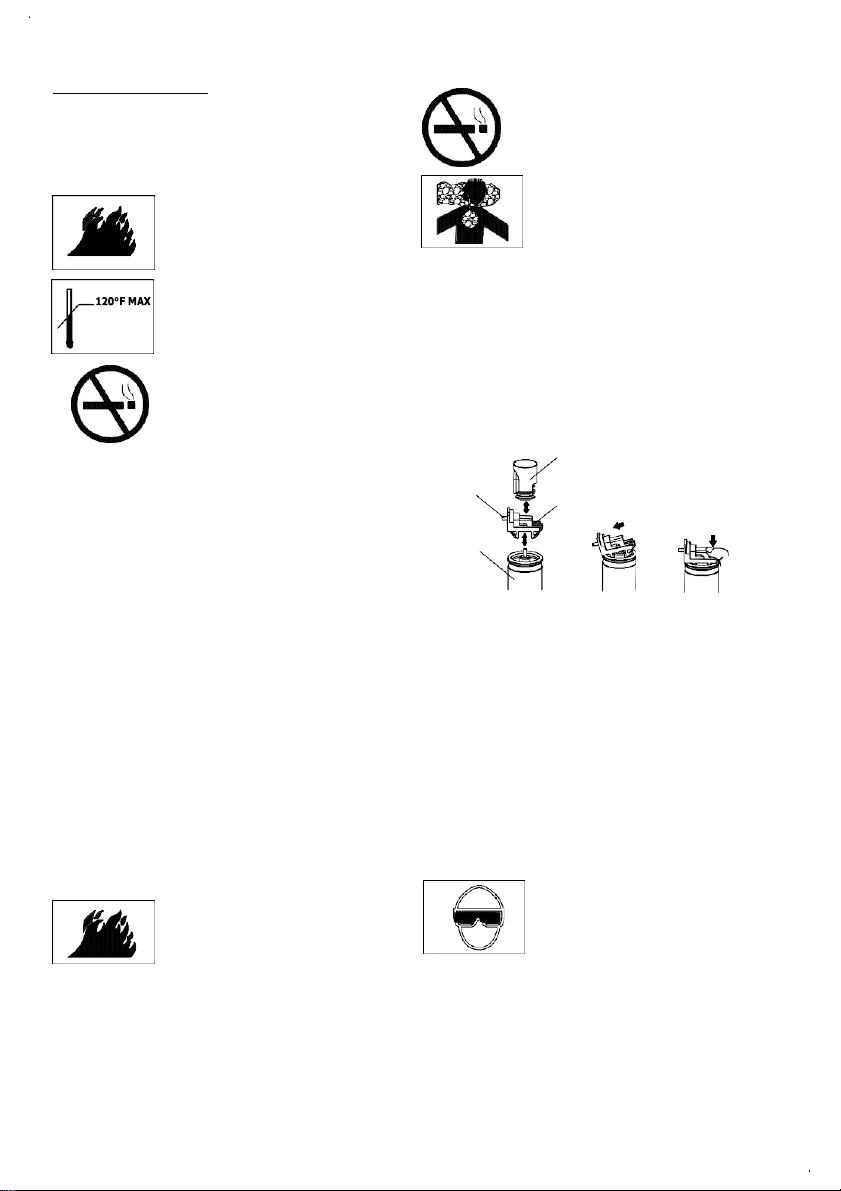

PREPARING THE FUEL CELL

Read section titled “FUEL CELL IMPORTANT

SAFETY INSTRUCTIONS ”

DANGER

■

The fuel cell is flammable.

■

Keep away from ignition sources.

8

(50℃)

CAUTION

■

Do not spray into flame or any

incandescentmaterial.

■

Do not smoke when handling

fuel cell.

■

Keep stem of fuel cellawayfrom

face or skin. Expanding gases

cause low temperatures.

■

Do not inhale.

■

Keep out of reach of children.

■

If the gas leaks from the metering valve orthe

gascartridge after attachingthemeteringvalve,

replace with the new metering valve.

■

Do not attempt to reuse the metering valve.

Replace with the new metering valve.

To attach the metering valve to a fuel cell:

Cap

Stem

Fuel Cell

Metering Valve

(1)

Separate the metering valve and the cap from

the gas cartridge.

(2)

Stem downward, put the metering valve inclined

forward to the bowl cover.

(3)

Press downward on the rear of the metering valve

until it seals, no gas leakage.

Check the metering valve:

Press the metering valve stem on fuel cell two or

three times against a stationary object and

release.

If gas is not dispersed, fuel cell is empty.

TESTING THE NAILER

DANGER Operatorsand others in work area

MUST wear safety glasses with

side shields.

WARNING

Never use Nailer unless push lever is operating

properly.

(3) INSERT FUEL CELL INTO

NAILER.

①Pulling the latch and open the cell cover.

(2) Installing the battery.

Handle

Trigger Fuel Cell Door

②Insert the fuel cell into nailer.

Fuel Cell

③Insert the stem of fuel cell into the hole of

adaptor.

Battery Pack

Insert

Make sure the battery indicator light is flashing green.

If the battery indicator light is flashing red, the battery

doesn't have enough power and it needs to be charged.

BATTERY INDICATOR LIGHT

Battery Indicated Light

Flashing GREEN: Enough power remaining

(The light turns steady during operation).

Flashing RED: Insufficient power remaining

(The light turns steady during operation).

Adapter

Stem

④Close the fuel cell door.

⑤Lock up the latch.

Stem

Fuel Cell

9

Latch

Fuel Cell Door

Fastener Guide

MAINTENANCE

NOTE:

■

The information contained in this Manual is designed

to assist you in the safe maintenance of the Nailer.

■

Some illustrations in this Manual may show details

or attachments that differ from those on your own

Nailer.

MAINTENANCE AND INSPECTION

Read section titled “SAFETY”.

DANGER

■

Never use and test inpresence

of flammable liquids or gases.

■

Keep away from ignitionsource.

Note After completion of each cleaning, drip the

lubricating oil (504.6.03.001.01) into the

nailer, which is shown in attachment Gas

Insulation Nailer Cleaning Guide .

If you have any questions about of the cleaning

operating procedures and methods, please contact

with dealer authorized service center.

WARNING

■

No smoking.

1. Daily cleaning

Users must regularly clean the nailer.,Remove

the internal accumulation of,carbon and dust to

ensure the normal operation.

Follow the attachment Gas Concrete Nailer

Cleaning Guide.

2.

Storing

DANGER

■

Store Nailer properlywithnails,

fuel cell and batteryremoved .

■

Thefuelcellisanaerosol

dispenserswith flammable

contents.

■

When not in use, the Nailer, fuel celland battery

should be stored in tool caseandin a dryplace

and below temperature 122°F (50°C).

■

Store indoors at temperature 41°F (5°C) ~77°F

(25°C).

■

When not in use for an extended period, apply a

thin coat of the lubricant to the steel parts to avoid

rust.

■

Do not store the Nailer / fuel cell and battery in a

cold weather environment.

10

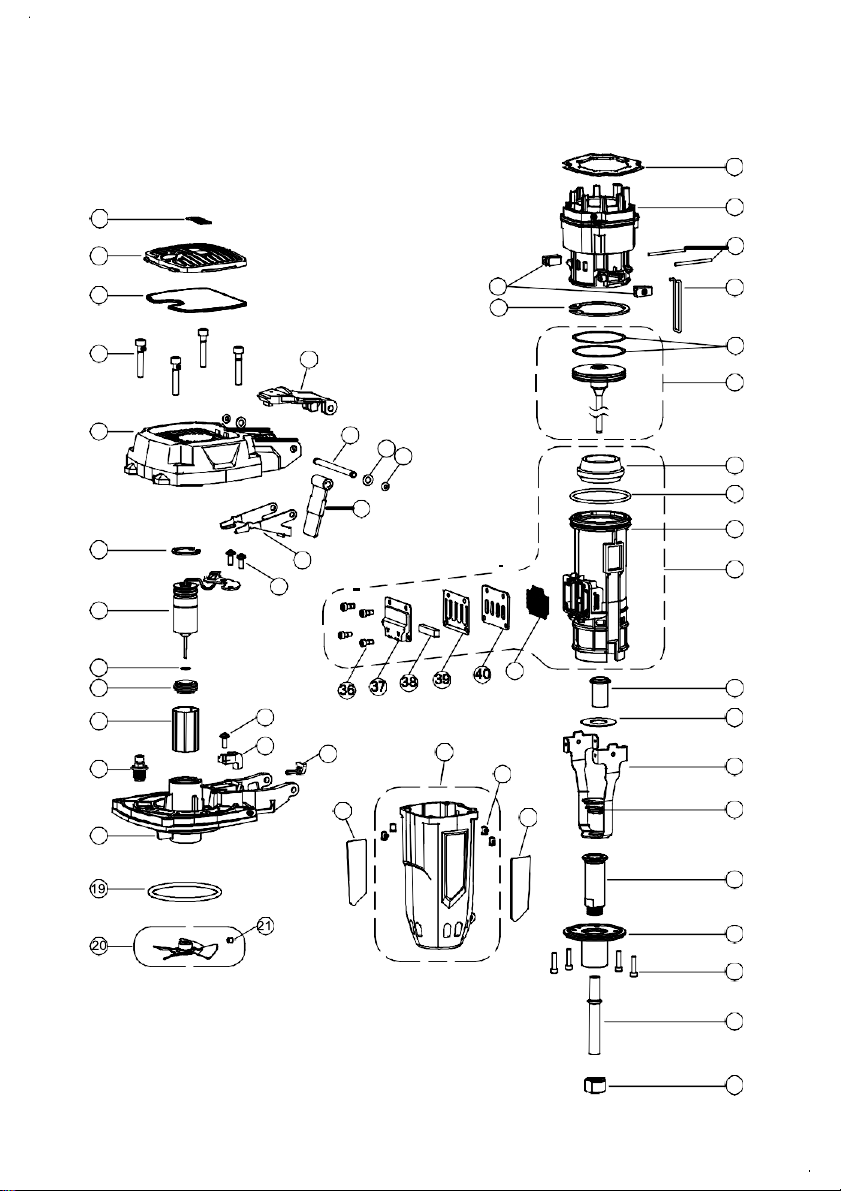

EXPLODED DRAWING AND PARTS LIST

GAS INSULATION NAILER

MODEL: IP50D

25

201

26

1

28 27

2

29

30

3 5

31

4 6

7 832

33

9

34

12 10 35

11

13

14 41

15 42

16 11 43

22 23 52

17 51

202

18

203

46

47

48

49

11

24

50

44

45

12

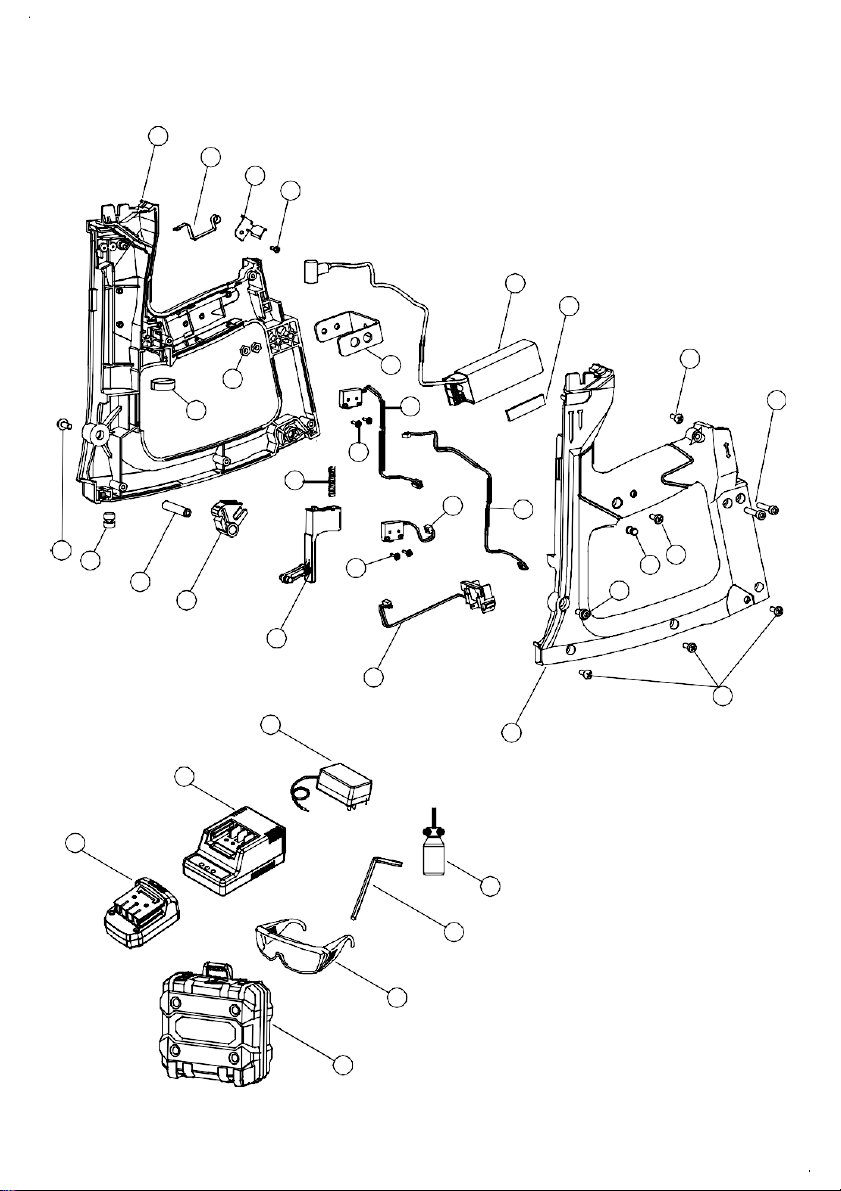

EXPLODED DRAWING AND PARTS LIST

GAS INSULATION NAILER

MODEL: IP50D

53

54

55

56

57

58

63 59

61

62 64 60

70 71

72

73

65

66

67

68

65 69 59

70

74

75

59

501

502

503

504

505

506

507

76

13

PART LISTGSN50D

Note: Wearing parts

No.

Parts Name

Qty

1

Grille

1

2

Filter

1

3

ScrewM5 x30

4

4

Cap

1

5

Fuel Cell Door

1

6

Cap Shaft

1

7

Washer d=5

2

8

O-Retaining Ring 3.5 x2

2

9

Fuel Rubber

1

10

Fuel Dosing Lever

1

11

Screw M4x10

3

12

Retaining Ring d0=24

1

13

Motor Assembly

1

14

Anti-dust Plate

1

15

Motor Rubber Gasket

1

16

Motor Sleeve

1

17

Spark Plug

1

18

Cylinder Head

1

19

O- Ring φ59.92 xd3.53

1

20

Fan Blade Assembly

1

21

Screw M4 x5

1

22

Bracket

1

23

Fuel Cell Adaptor

1

24

Air Dam

1

25

Combustion Chamber Assembly

1

26

Parallel Pinφ 4 x60

2

27

Lock Bar

1

28

Rubber Stop

2

29

Retaining Ring d0=62

1

30

Piston Ring 60 x0.8

2

31

Piston Assembly

1

32

Bumper

1

33

O-Ring 70 x d3.53

1

34

Cylinder

1

35

Cylinder Assembly

1

36

Screw M5 x12

4

37

Muffler Cover

1

38

Muffler

1

39

Reed Valve

1

40

Reed Plate

1

41

Exhaust Baffle

1

42

Cage Sleeve

1

43

Spring Washer 0.5mm

1

44

Cage Spring d=1.6mm

1

45

Cage

1

46

Guide Sleeve

1

47

Fastener Guide Support

1

48

Screw M5 x20

4

49

Fastener Guide

1

50

Nut M18

1

No.

Parts Name

Qty

51

Nut M5

4

52

Housing

1

53

Right Side Handle

1

54

Trigger Spring Plate

1

55

Wire Clip

1

56

Screw ST2.9x8

1

57

Spark Unit Assembly

1

58

Sponge Bumper

1

59

Screw ST4.2 x20

5

60

Screw M5 x25

2

61

Nut M5

2

62

Fuel Cell Bumper

1

63

Hanger

1

64

Fan Switch Assembly

1

65

Screw ST2.2 x11

4

66

Trigger Spring

1

67

Ignition Switch Assembly

1

68

Motor Connection Wire Assembly

1

69

LED Light

1

70

Screw M5x10

2

71

Rubber Column

1

72

Rotating Shaft

1

73

Rotating Block

1

74

Trigger

1

75

Power Circuit Assembly

1

76

Left Side Handle

1

201

Cap Label

1

202

Specification Label

1

203

Logo Label

1

501

Charger Adaptor

1

502

Charger Base

1

503

Battery Pack

2

504

Iubricating Oil

1

505

Wrench M5

2

506

Safety Glasses

1

507

Blow Case Assembly

1

FOR WARRANTY INFO, TOOL REPAIR, OR GENERAL QUESTIONS

Contact us at:

(web) www.thermalgriptools.com

(email) [email protected]

(phone) 616-454-3100

Table of contents