thermastor Quest PowerDry 4800D DRY 150 Pro LP Manual

Installation, Operation and Maintenance Instructions

– Read and Save These Instructions –

This manual is provided to acquaint you with

the 4800D so that installation, operation

and maintenance can proceed successfully.

Ultimate satisfaction depends on the quality

of installation and a thorough understanding

of this equipment. This unit is built around

tested engineering principles and has passed

a thorough inspection for quality of workman-

ship and function.

Installation, Operation and Maintenance Instructions

4201 Lien Rd. Phone 608-237-8400

Madison, WI 53704 Toll-Free 1-866-933-7486

www.QuestProtect.com sales@QuestProtect.com

– Read and Save These Instructions –

Specications subject to change without notice. TS-650/651

08/17

1

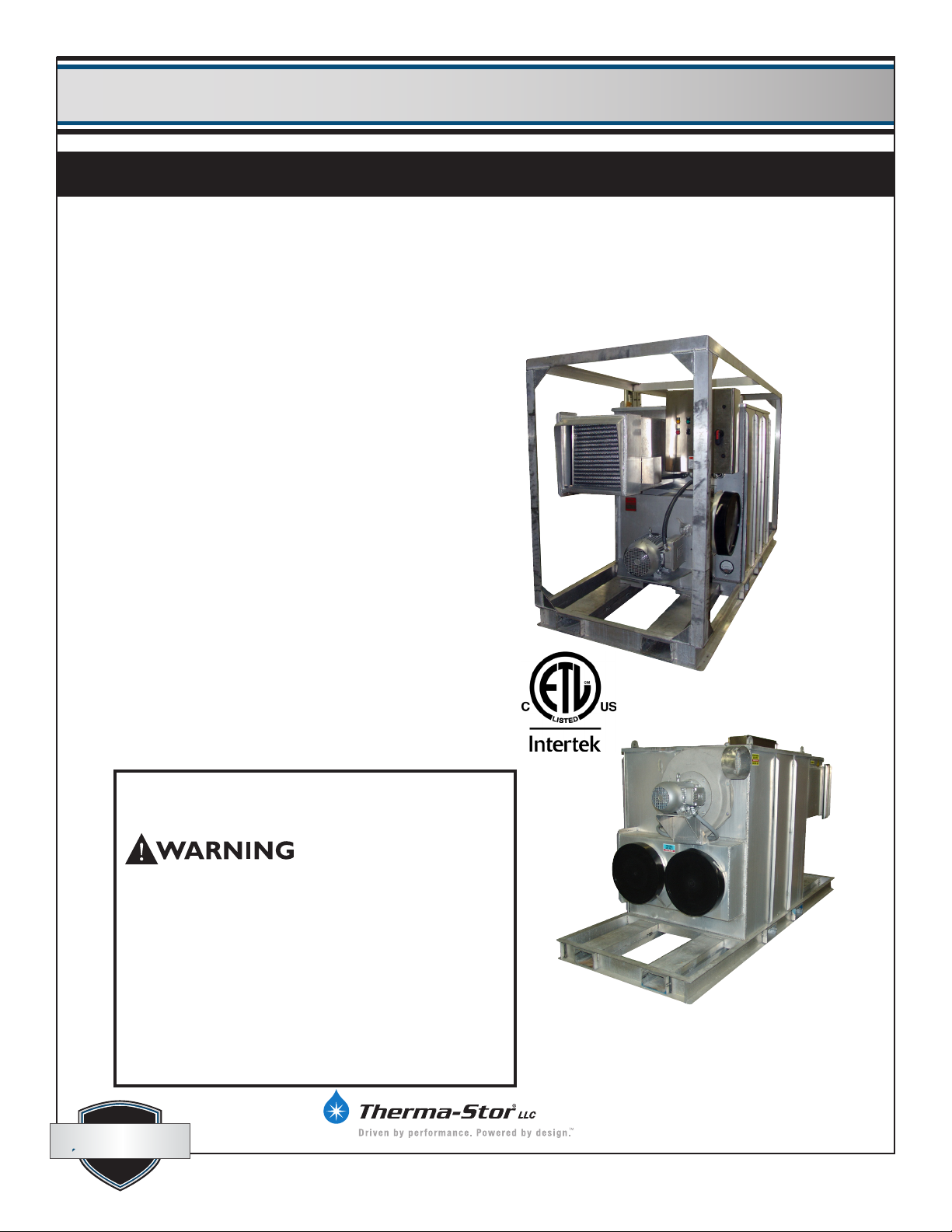

Quest PowerDry 4800D Pro LP/NG:

• 3032 Pints/day AHAM

• 4800 CFM process airow

• Dries in temperatures to 140°F

• Reaches dew points as low as -40°F

• 48”W x 120”L x 74”H

• 1600 lbs. (Standard machine weight only)

• 240 volt, 70 amp single phase

• Propane or Natural Gas Fired

Quest DRY150Quest PowerDry 4800D Pro LP/NG

Quest PowerDry 4800D

Pro P/N

(with Frame)

PN 4028204 Propane

PN 4030630 Nat Gas

Quest PowerDry 4800D

Pro P/N

(without Frame)

PN 4029194 Propane

PN 4030640 Nat Gas

FOR YOUR SAFETY: DO NOT store or use

gasoline or other ammable vapors and liquids in the

vicinity of this or any other appliance.

Improper installation, adjustment, alteration, service

or maintenance can cause injury or property damage.

Refer to this manual. For assistance or additional

information, call a qualied installer, service agency or

the gas supplier.

FOR YOUR SAFETY: If you smell gas: DO NOT

try to light any appliance. DO NOT touch any electrical

switch. IMMEDIATELY call your gas supplier from a

location away from the device. If the gas supplier cannot

be reached, call the re department.

quest

quest

quest

quest 1-866-933-7486

Quest PowerDry 4800D Pro P/N Installation, Operation and Maintenance Instructions

2

www.QuestProtect.com

sales@QuestProtect.com

GENERAL HAZARD WARNING

Failure to comply with the precautions and

instructions provided with this unit can result

in death, serious bodily injury and property loss

or damage from hazards of fire, explosion, burn,

asphyxiation, carbon monoxide poisoning, and/or

electrical shock.

Only persons who can understand and follow the

instructions should use or service this unit.

If you need assistance or unit information such

as an instruction manual, label, etc., contact a

qualified installer, service agency, gas supplier, or

the manufacturer.

Do NOT use this appliance if any part has been

under water. Immediately call a qualified service

technician to inspect the appliance and to replace

any part of the control system and any gas

control which has been under water.

Should overheating occur, or the gas supply fail

to shut off, shut off the manual gas valve to the

appliance before shutting off the electrical supply.

Installation must conform to applicable local codes and/

or the National Fuel Gas Code, ANSI Z223.1, the Standard

for the Storage and Handling of Liquefied Petroleum

Gasses, ANSI/NFPA 58 and the Natural Gas and Propane

Installation Code, CSA B149.1.

Other standards govern the use of fuel gases and heat

producing products in specic applications. Your local

authority can advise you about these.

FIRE, BURN, INHALATION, AND

EXPLOSION HAZARD.

Keep solid combustibles, such as building materials,

paper, or cardboard, a safe distance away from the

unit as recommended by the instructions. Never use

the unit in spaces which do or may contain volatile or

airborne combustibles, or products such as gasoline,

solvents, paint thinner, dust particles or unknown

chemicals.

MISES EN GARDE GENERALES

Le non-respect des mises en garde et des instructions fournies avec

ce radiateur peut entrainer la mort, de graves blessures et des pertes

materielles ou des dommages a la propriete resultant d’un incendie,

d’une explosion, de brulures, d’asphyxie, d’empoisonnement au

monoxyde, de carbone et/ou d’un choc electique.

Seules les personnes aptes a comprendre et a suivre les instructions

devraient se servir de ce radiateur ou le reparer.

Si vous avez besoin d’aide ou d’informations concernant ce radiateur

ou le reparer.

Avertissement

Risque d’incendie, de brulures, d’inhalation et d’explosion.

Garder les combustibles solides, tels les materiaux de

construction, le papier et le carton, a bonne distance de ce

radiateur, comme il est recommande dans les instructions.

ne jamais utiliser cet appareil dans des endroits qui

contiennent ou pourraient contenir des combustibles

volatiles ou en suspension dans l’air tels l’essence, les

solvants, les diluants pour peinture, les particules de

poussieres ou des produits chemiques inconnus.

Quest PowerDry 4800D Pro P/N Installation, Operation and Maintenance Instructions

3

www.QuestProtect.com

sales@QuestProtect.com

quest

quest 1-866-933-7486

Table of Contents

Introduction .......................................................1

1. Specications ..............................................4

2. Operation ...................................................4

2.1 How the Quest Dry

PowerDry 4800D Pro P/N Works ...............5

3. Installation ..................................................5

3.1 Inspection .............................................5

3.2 Location ................................................6

3.3 Set-Up ..................................................6

3.4 Ducting .................................................6

3.5 Avoiding Secondary damage .................7

3.6 Electrical Requirements .........................7

4. Operation Instructions.................................8

4.1 Connect and Start-Up Procedure ...........8

4.2 Cool Down ...........................................8

4.3 Shut Down and Disconnect Procedure..8

5. Control Panel ..............................................9

5.1 Main Disconnect ..................................9

5.2 Standby Light ........................................9

5.3 Selector Switch .....................................9

5.4 Alarm (Light and Horn) .........................9

5.5 Hour Meter .........................................10

6. Maintenance .............................................10

6.1 General Maintenance..........................10

6.2 Cabinet ...............................................10

6.3 Filter ...................................................10

6.4 Blower and Motor ...............................10

6.5 Drive Motor ........................................11

6.6 Rotor Drive Chain ...............................11

6.7 Seals ...................................................11

6.8 Desiccant Media .................................11

7. Wiring Diagram ........................................12

8. Trouble Shooting .......................................16

9. Service Parts ..............................................17

Warranty ...................................................18

Serial No.__________________________________

Purchase Date_____________________________

Dealer’s Name_____________________________

Read the operation and maintenance instructions

carefully before using this unit. Proper

adherence to these instructions is essential

to obtain maximum benet from your Quest

PowerDry 4800D Pro P/N.

quest

quest 1-866-933-7486

Quest PowerDry 4800D Pro P/N Installation, Operation and Maintenance Instructions

4

www.QuestProtect.com

sales@QuestProtect.com

Quest PowerDry 4800D Pro LP/NG Installation, Operation and Maintenance Instructions

4

1. Specications

Part No. 4028204 Propane (with cage)

4030630 Nat Gas (with cage)

Part No. 4029194 Propane (without cage)

4030640 Nat Gas (without cage)

Power 240 volt, 70 amps single phase

Water 3032 pints/day @ AHAM

Removal

Blower 4800 CFM Process Air Flow

2000 CFM Reactivation Air Flow

Operating -10ºF to 140ºF

Range

Filters Process lter size: (2) 20” x 20” x 2”

Reactivation lter size: (1) 20” x 20” x 2”

Duct Options Process inlet/outlet - 18” Heavy Duty PVC minimum, 20” Heavy Duty PVC recommended

Reactivation - 18” Heavy Duty PVC minimum, 20” Heavy Duty PVC recommended

Warranty 1 Year 100% Parts & Labor

Dimensions

Machine only With Cage

Width 48” 48”

Height 66” 72”

Length 120” 120”

Weight 1550 lb 1675 lb

Accessories

4028364 18” x 25’, 6” Pitch, Heavy Duty PVC/Polyester Duct

4029256 18” Lay Flat Duct

4035579 20” x 25’, 4” Pitch, Heavy Duty PVC/Polyester Duct

4027327 External Temperature control

4020175 External Dehumidistat

Air Filter Replacement

4028635 20” x 20” x 2” Filter (3 per unit)

2. Operation

The function of the dehumidier is to remove moisture (in the vapor state) from an air stream. This is

accomplished by exposing the air to an adsorbing media (desiccant) in a sealed air stream (process).

After the desiccant has adsorbed moisture, it is exposed to a second air stream at an elevated temperature

(reactivation). This causes the moisture to be driven out of the desiccant preparing it for more moisture

Quest PowerDry 4800D Pro P/N Installation, Operation and Maintenance Instructions

5

www.QuestProtect.com

sales@QuestProtect.com

quest

quest 1-866-933-7486

Quest PowerDry 4800D Pro LP/NG Installation, Operation and Maintenance Instructions

5

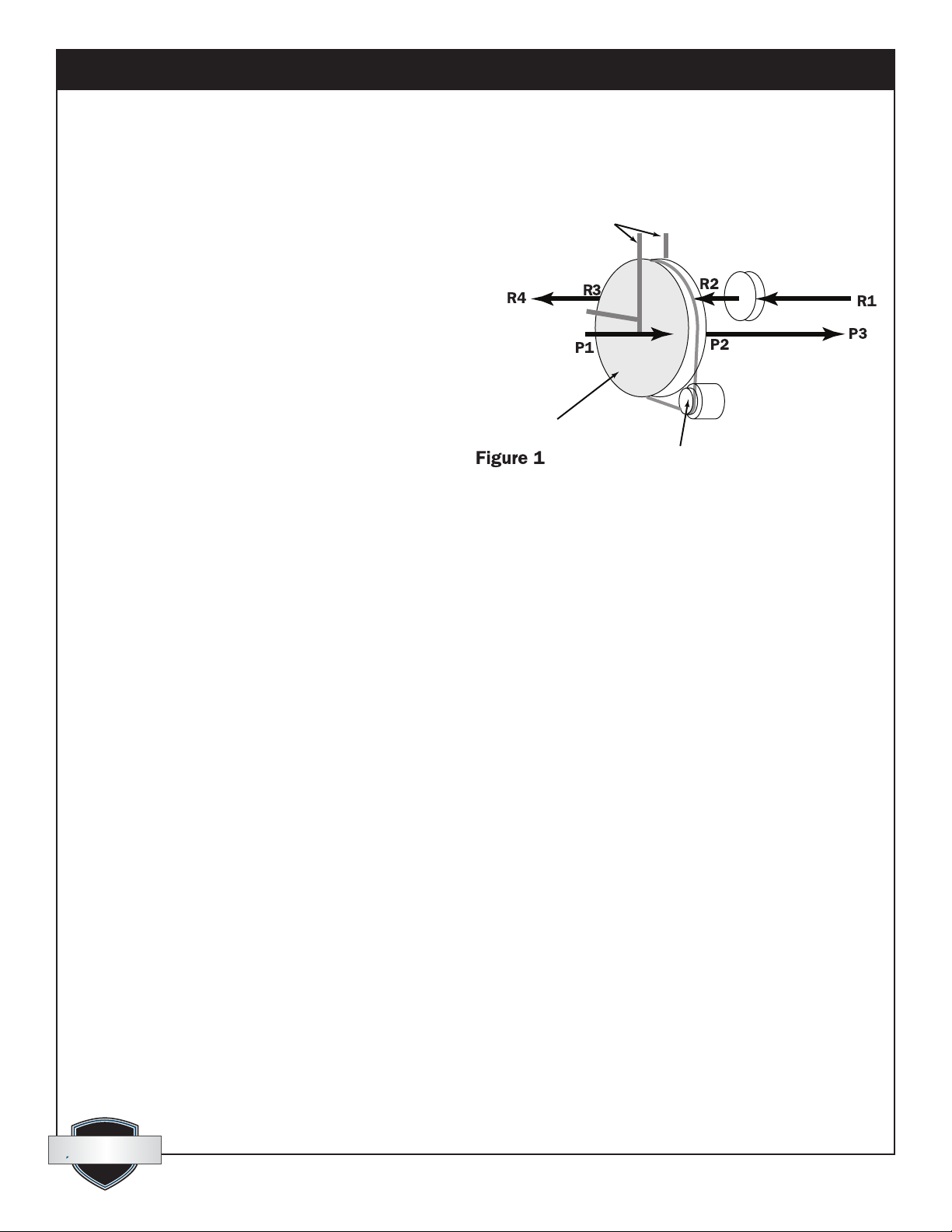

adsorption. This process is done on a

continuous basis, providing a constant drying

process. The two air streams (process and

reactivation) are separated by seals, which

contact the desiccant media. Figure 1 illustrates

the relationship of the seals and airow pattern.

The dehumidier is designed with the two air

streams owing in opposite directions (counter

ow) thereby maximizing the energy efciency

of the equipment.

2.1 How the Quest PowerDry 4800D

Pro P/N Works

The Quest PowerDry 4800D Pro P/N has

two separate air streams that run through it –

Process and Reactivation (Fig. 1).

Process Air Stream:

P1 – 4800 CFM of air enters the machine (Process Air Inlet) and...

P2 – ...water vapor from incoming air is deposited (adsorbed) on the desiccant wheel.

P3 – 4800 CFM of dry air exits the machine (Process Air Outlet).

Reactivation Air Stream:

R1 – 2000 CFM of air enters the machine (Reactivation Air Inlet) and...

R2 – passes over the heater coils.

R3 – Water vapor is picked up (desorbed) from the desiccant wheel by the hot air and...

R4 – ... 2000 CFM of wet air exits the machine (Reactivation Air Outlet).

3 Installation

Proper installation is critical to the performance of the Quest PowerDry 4800D Pro P/N. Follow the

guidelines below to maximize service life and performance.

3.1 Inspection

Thoroughly inspect the machine to insure no damage has occurred during shipping or on the job site.

The hose assembly shall be visually inspected prior to each use of the heater. If it is evident there is excessive

abrasion or wear, or the hose is cut, it must be replaced prior to the heater being put into operation. The

replacement hose assembly part is listed in the service parts list.

Cabinet Divider

and Seals

Reactivation Air Outlet

Process Air Inlet

Heater

Principle of Operation

Process Air Outlet

Desiccant Wheel

Desiccant Wheel

Drive and Chain

Reactivation Air Inlet

quest

quest 1-866-933-7486

Quest PowerDry 4800D Pro P/N Installation, Operation and Maintenance Instructions

6

www.QuestProtect.com

sales@QuestProtect.com

3.2 Location

Note the following precautions when locating the Quest PowerDry 4800D Pro P/N:

The Quest PowerDry 4800D Pro P/N must be located outdoors with reactivation outlet pointed away

from open windows or building fresh air inlets. Position unit for shortest, straightest duct run to structure.

Provisions for adequate combustion and ventilation air must be provided in accordance with section 5.3 of

the National Fuel Gas Code ANSI Z223.1.

Always ensure the Quest PowerDry 4800D Pro P/N is located with the reactivation outlet pointed such that

the reactivation air exhausts to the atmosphere in an unoccupied area and can NOT be drawn into any

nearby structure. Do not exhaust reactivation air across walkways or towards buildings, openable windows,

or building openings. Do not allow the reactivation outlet to become obstructed by snow, construction

debris, etc. Maintain a minimum 4’ clearance around electric and gas meters, regulators, and relief

equipment. Locate device a minimum of 10’ from combustible constructions. Be aware that reactivation

air contains ue gasses that, over time, can degrade some building materials. Do not connect device to a

chimney ue serving a separate appliance designed to burn solid fuel.

Do not direct process or reactivation air streams toward any Propane-gas container within 20’ (6m).

3.3 Set-Up

When conditions warrant the use of a desiccant dehumidier, use one of the setups described below to

achieve efcient drying, while avoiding secondary damage. Review Section 2.1 to understand the desiccant

drying process. Always ensure that the Reactivation Outlet duct is vented to the outdoors to minimize the

possibility of secondary damage.

Neutral Pressure Setup

Many drying applications require neutral pressure operation. In this setup, the Process Air Inlet pulls air

from the affected area (drying chamber) and returns dried, processed air to the affected area via the Process

Air Outlet.

Positive Pressure Setup

For Positive Pressure operation, the Process Air Inlet pulls air from outside the drying chamber, while the

Process Air Outlet is ducted into the chamber.

3.4 Ducting

The duct requirements of the Quest PowerDry 4800D Pro P/N are much more critical than those of

refrigerant-based dehumidiers. ALL SUPPLY AND RETURN AIR DUCTING FOR THE Quest PowerDry

4800D Pro P/N MUST BE AIR AND VAPOR TIGHT. This is extremely important for proper performance.

Ensure that reactivation discharge air does not enter the process or reactivation inlets.

Using excess duct length signicantly reduces air ow volume through duct. This is true in any application. If

the job at hand needs a short length of duct, cut a section to the appropriate length. If air ow is restricted by

excess length, performance will suffer. The same can be said of excess bends in the ducting.

Multiple duct sizes are used on the Quest PowerDry 4800D Pro P/N (see below). All ducting materials are

available from Therma-Stor LLC

(see accessories list in Section 1).

Quest PowerDry 4800D Pro P/N Installation, Operation and Maintenance Instructions

7

www.QuestProtect.com

sales@QuestProtect.com

quest

quest 1-866-933-7486

Process inlet: 18” ex duct.

To attach ex ducts to the process air intake, push the wire of the rst few loops beyond the 2 holes in the

duct collar. Push the metal rod through the duct and duct collar piercing the duct in two places. Tape or a

hose clamp can be used to create an airtight seal. Alternatively, the duct wire can be pushed past the weld

beads on the duct collar and the duct can be secured with hose clamps or ratcheting straps. If using only

one inlet connection, the other can be left closed.

Process outlet: 18” ex or lay at plastic duct.

To attach ex ducts to the process air outlet, push the wire of the rst few loops beyond the 2 holes in the

duct collar. Push the metal rod through the duct and duct collar piercing the duct in two places. Tape or a

hose clamp can be used to create an airtight seal. Alternatively, the duct wire can be pushed past the weld

beads on the duct collar and the duct can be secured with hose clamps or ratcheting straps.

When using 18” lay at ducting, slip over the outlet collar and zip-tie or duct tape in place.

Reactivation outlet: 10” ex duct or lay at.

To attach ex duct to the reactivation air outlet, push the wire of the rst couple of loops beyond the weld

beads on an outlet collar. Secure with hose clamp.

3.5 Avoiding Secondary Damage

The Quest PowerDry 4800D Pro P/N is a powerful tool capable of removing a great deal of water from

most environments. Care must be taken to avoid secondary damage of over-drying and or unexpected

condensation.

The Quest PowerDry 4800D Pro P/N removes vapor water from the incoming process air stream and

transfers it to the outgoing reactivation air stream. The reactivation exhaust air is hot and wet.

Take care to prevent the reactivation exhaust air stream from causing secondary damage due to

condensation. Always ensure the Quest PowerDry 4800D Pro P/N is located with the reactivation outlet

pointed such that reactivation air will NOT be drawn back into the structure.

The Quest PowerDry 4800D Pro P/N does not produce liquid water internal to the machine. There is no

condensate pump and no drain hose.

The Quest PowerDry 4800D Pro P/N desiccant dehumidier will continue to remove water from already dry,

cold air. It is possible to over-dry objects and or structures.

Care must be taken to avoid secondary damage due to over-drying.

3.6 Electrical Requirements

A 240 volt, single phase power source is required to operate the Quest PowerDry 4800D Pro P/N.

All local and state codes must be strictly adhered to and good electrical practices should be followed to

achieve the best installation possible. The Quest PowerDry 4800D Pro P/N must be properly wired to an

adequate power source. The electrical grounding of the appliance shall be in compliance with the National

Electrical Code, ANSI/NFPA 70, or the CSA C22.1, Canadian Electrical Code, Part I. Serious damage to the

motors and controls can occur if incorrect voltage is applied.

(See Electrical Schematic drawing in the back of this manual for internal wiring.)

quest

quest 1-866-933-7486

Quest PowerDry 4800D Pro P/N Installation, Operation and Maintenance Instructions

8

www.QuestProtect.com

sales@QuestProtect.com

4 Operating Instructions

Refer to the Operating Instructions label located next to the control panel of your Quest PowerDry 4800D

Pro P/N.

User-supplied power cord, cord grip, and branch protection appropriate for the electrical load must be

supplied. See device for FLA rating.

The Quest PowerDry 4800D Pro P/N dehumidier comes complete and ready for operation. All that is

required is to provide the proper power source, propane or natural gas supply, and duct connections

(described above).

4.1 Connect and Start-Up Procedure

1. STOP! Read the safety information on unit label.

2. Turn off all electric to this appliance - Selector Switch turned to STAND BY position. Main Disconnect

turned to OFF position.

3. Connect gas source.

• Propane: Connect propane gas source (5-20 psig) to hose attached to the regulator (located next to

the process blower, below reactivation inlet duct).

• Natural gas: Connect natural gas source (4-11” water column) to hose located on reacivation inlet

duct.

4. Open gas supply shut off valve.

5. Open appliance shut off valve.

6. Energize power source and turn Main Disconnect switch to ON.

7. Turn Selector switch to RUN.

8. Set process damper to obtain a maximum of 1.5” water column pressure as read on pressure gauge.

9. If the appliance will not operate, follow the instructions “To Turn Off Gas To Appliance” and call your

service technician or gas supplier.

4.2 Cool Down

1. Set Selector Switch to OFF.

2. COOL DOWN light will come on for 5 minutes.

3. When COOL DOWN light is off, Main Disconnect can be switched to OFF.

Failure to follow COOL DOWN PROCEDURE may result in damage to unit due to overheating. ALWAYS

follow COOL DOWN PROCEDURE before shutting unit down.

4.3 Shut Down & Disconnect Procedure

1. Verify COOL DOWN light is not illuminated and cool down procedure has been followed.

2. Close appliance shut off valve.

Quest PowerDry 4800D Pro P/N Installation, Operation and Maintenance Instructions

9

www.QuestProtect.com

sales@QuestProtect.com

quest

quest 1-866-933-7486

3. Close gas supply shut off valve.

4. Turn main disconnect switch to OFF.

5. Disengage power source.

6. Lock out power source.

7. Disconnect power cable.

8. Disconnect propane or natural gas source.

5 Control Panel

5.1 Main Disconnect

The main disconnect switches power from the source to the panel. Power must be disconnected at the

source prior to accessing control panel. Access to the control panel with power applied is ONLY by

qualied service personnel with the appropriate personal protective equipment Power is present up to

disconnect even in OFF position. Disconnect power at the source before opening panel.

5.2 Standby Light

The STANDBY indicator lamp illuminates to indicate that power is supplied to the control panel.

5.3 Selector Switch

When the selector switch is moved to the “RUN” position, the Quest PowerDry 4800D Pro P/N starts

dehumidifying. The machine will continue to dehumidify in all conditions until the power is turned off.

No dehumidistat is provided to monitor process inlet air condition (see over-dry warning section 3.5). An

external control (dehumidistat, thermostat or other contact) can be wired in place of the jumper across

terminals 100 and 3070. The external control must be designed to operate a 24 VAC circuit.

5.4 Alarm (Light and Horn)

The alarm indicator lamp illuminates (and horn sounds) to indicate that a fault condition exists. All ashing

faults ash for only 5 minutes after the fault occurs:

• No ash - An immediate alarm sounds after turning the unit on. This can be due to any pressure switch

being closed on start-up.

• 1 ash - Combustion Blower fault. Blower is not developing enough pressure differential (airow) to

support proper combustion.

• 2 ashes - Differential pressure between reactivation and process ducts too great. May be indicative of

blocked process inlet ducting.

• 3 ashes - Failure to ignite after 3 trials for ignition. Check gas supply. Ignitor failure may also produce

this fault.

• 4 ashes - Reactivation or process blower motor overload relay tripped.

• 5 ashes - High reactivation temperature. Temperature approaching the desiccant wheel may be

in excess of 325°F. Air ow through the reactivation section may be restricted. Ensure proper gas is

supplied to the unit.

An external alarm can be wired to relay output terminals 4440 and 4442. Relay contacts are rated 5A

resistive/2A inductive at 12/24 V AC/DC, 5A resistive/3A inductive at 115/120/230/240 VAC

quest

quest 1-866-933-7486

Quest PowerDry 4800D Pro P/N Installation, Operation and Maintenance Instructions

10

www.QuestProtect.com

sales@QuestProtect.com

5.5 Hour Meter

The hour meter will run whenever the Quest PowerDry 4800D Pro P/N is operating. This hour meter

measures the cumulative time of operation in one-tenth hour increments. This meter is often used to verify

hours on a job or to schedule maintenance.

6 Maintenance

6.1 General Maintenance

A denitive time schedule should be established for inspecting all rotating parts and components. Inspection

requirements depend on the frequency of operation, transport, and operating conditions. Periodically check

the condition of the air lter, rotating parts, and fasteners to ensure they are secure and in proper working

order. Periodically check airow to make sure there are no obstructions to airow in outlet or inlet ductwork.

Recommended minimum inspections:

• Upon installation

• After 1 week of operation.

• Annually thereafter or upon loss of performance.

6.2 Cabinet

Disconnect power before removing access panels.

Remove panel fasteners and panels from unit to access internal components. The condition of the cabinet

gaskets should be observed during inspection and servicing to insure a good seal. Any leaks must be sealed

and panels securely fastened for proper dehumidier operation.

6.3 Air Filters

The maintenance interval for the lter depends directly on the cleanliness of the air entering the

dehumidier. It is suggested that a program be established to assure that the lters are replaced or cleaned

prior to becoming clogged to the point they create a system problem.

Three aluminum (20”x20”x2”) air lters must be checked regularly. Two lters are located near the process

air inlet. The other one is located near the reactivation air inlet.

Wash the lters with fresh water. Clean the lter from the downstream side, forcing debris toward the lter

inlet. Dry the lters completely before installing them in unit. Replacement lters can be ordered from the

factory or purchased locally if available.

DO NOT operate the unit without the lters or with less effective lters as the desiccant wheel inside the

unit will become clogged and require disassembly to clean.

6.4 Blower and Motor

Blower and motor bearings are permanently lubricated and do not require maintenance. Blower wheel

- inspect wheel blades for accumulation of dust and dirt. Clean thoroughly with compressed air and or

vacuum. The wheel should not strike the housing or the inlet ring. Make sure wheel is rotating in the proper

direction.

Quest PowerDry 4800D Pro P/N Installation, Operation and Maintenance Instructions

11

www.QuestProtect.com

sales@QuestProtect.com

quest

quest 1-866-933-7486

6.5 Drive Motor

The media drive motor is permanently lubricated and requires no maintenance.

6.6 Rotor Drive Chain

A spring loaded tensioner keeps the chain sufciently tensioned. Check the chain for signs of excessive

wear. Replace as necessary. If additional tension is required, simply tighten the nuts on the tension springs as

required.

6.7 Seals

High temperature seals separate the process and reactivation compartments. Normally, the seals will not

require service or replacement. However, should damage occur, or if poor performance as the result of an

air leak is suspected, the following inspection must be performed to determine whether the seals should be

replaced:

Inspection:

1) Turn the unit off and remove the access covers.

2) Visually inspect for gaps between the desiccant media

and the seals.

3) If signicant gaps, wear, or damage are observed,

the seal needs to be replaced.

6.8 Desiccant Media

The silica gel desiccant media supplied with the dehumidier will last indenitely under ideal conditions.

Due to the nature of desiccants they make very good lters. The life of the desiccant is directly related to the

airborne contaminates passed through it. Atmospheric contaminants, exposure to acidic gases/or air streams,

and contact with petroleum based airborne particles can reduce the efciency of the desiccant media.

The preferred method of cleaning is to blow dust out with compressed air. Proper ltration and preventing

contact with chemicals will greatly improve the life of the desiccant. Inspect the face of the media to see that

no surface damage has occurred. If damage is noticed, please contact Therma-Stor at 1-800-533-7533 x8459

for assistance. The rotor should turn smoothly upon the shaft, if not check the support bearings.

Servicing the Quest PowerDry 4800D Pro P/N with its high voltage circuitry presents a health hazard

which could result in death, serious bodily injury, and/or property damage. Only qualied service people

should service this unit.

ELECTRICAL SHOCK HAZARD: Electrical power must be present to perform some tests; these tests should

be performed only by a qualied service person.

quest

quest 1-866-933-7486

Quest PowerDry 4800D Pro P/N Installation, Operation and Maintenance Instructions

12

www.QuestProtect.com

sales@QuestProtect.com

STAND BY

STAND

BY

RUN

STAND

BY

STAND

BY

RUN

3440

200

200

3090

3110

3130

3420

200

3150

4380

4440

4442

GND

GND

GND

200

100

100

100

100

1

200

3210

----

S1

S2

1

100

3070

4060

Quest PowerDry 4800D Pro P/N Installation, Operation and Maintenance Instructions

13

www.QuestProtect.com

sales@QuestProtect.com

quest

quest 1-866-933-7486

quest

quest 1-866-933-7486

Quest PowerDry 4800D Pro P/N Installation, Operation and Maintenance Instructions

14

www.QuestProtect.com

sales@QuestProtect.com

3110

3170

3150

3130

3190

MAIN CHASIS

24VAC INPUTS/RELAY OUTPUTS

230RCO

FROM PREVIOUS PAGE

FROM PREVIOUS PAGE

NEUTRAL24VAC

200

100

START/STOP

3072

3090

DEHUMIDISTAT

100

COMBUSTION BLOWER

PRESSURE SWITCH (PS1)

100

REACTIVATION BLOWER

PRESSURE SWITCH (PS2)

100

HIGH TEMPERATURE

OVERLOAD RELAY

OVERLOAD RELAY

FLAME VERIFICATION

100

3380

3420

3440

230RCO REACTIVATION BLOWER MOTOR

200

RMS

200

200

200

100

PROCESS BLOWER MOTOR

PMS

DESSICANT MOTOR

120VAC 1/50HP 0.33AMPS

RUN PILOT LAMP

GREEN

OX

ONOFF

DEHUMIDISTAT

H

P

PS1

SYSTEM

P

PS2

100

T

TS1

SWITCH (TS1)

100 OLR-R

100 OLR-P

REACTIVATION BLOWER MOTOR

PROCESS BLOWER MOTOR

RMS

3400

PMS

3382

3402

M

120VAC

1

G

RUN

M

200

HOUR METER

120VAC

3210

1

FROM FENWALL

MV1

100

REMOVE YELLOW JUMPER

TO USE OPTIONAL

EXTERNAL DEHUMIDISTAT

3070

200 COMBUSTION BLOWER

120VAC 107W 0.9AMPS

HM

CONTINUED NEXT PAGE CONTINUED NEXT PAGE

YELLOW

I3

I8

I7

I6

I5

I4

I2

I1

Q2

Q4

Q3

Q1

VAC

VAC

VAC

VAC

Quest PowerDry 4800D Pro P/N Installation, Operation and Maintenance Instructions

15

www.QuestProtect.com

sales@QuestProtect.com

quest

quest 1-866-933-7486

EXPANSION MODULE

4 24VAC INPUTS/4 RELAY OUTPUTS

DM8 24R

FROM PREVIOUS PAGEFROM PREVIOUS PAGE

NEUTRAL24VAC

200100

SPARE

SPARE

SPARE

100

4380

4420

4442

DM8 24R

FENWALL CONTROLLER

200

100

COOL DOWN PILOT

YELLOW

ALARM BUZZER

PULSATING

ALARM PILOT

RED

4400

1

200

G

COOL DOWN

4440

H

R

ALARMS

200

200

200

FENWALL CONTROLLER

1

1

SUPPLY POWER/IGNITOR

HEAT REQUEST

EXTERNAL ALARM

CONTACTS

100

L1 L2

W MV1

3210

S1 S2

TO IGNITOR

120VAC

DRY CONTACT

8 AMPS MAX.

120VAC

4060

100 PS3

PROCESS BLOWER

PRESSURE SWITCH (PS3)

GAS

I11

I12

I10

I9

Q6

Q8

Q7

Q5

VAC

VAC

VAC

VAC

quest

quest 1-866-933-7486

Quest PowerDry 4800D Pro P/N Installation, Operation and Maintenance Instructions

16

www.QuestProtect.com

sales@QuestProtect.com

8 Troubleshooting

9 Troubleshooting

Trouble Probable Fault Probable Cause Corrective Action

1. Main power off Check main power and cable

2. Main disconnect open Close or replace disconnect

3. Selector switch open Close or replace switch

Unit Stopped

(fan off, no

heater)

Power/Control

Failure

4. Dehumidistat Repair or replace

1. Motor circuit breaker or

overload tripped

Reset circuit breaker or

overload

2. Contactor failure Repair or replace

3. Motor winding failure Repair or replace

Fan off

(Rotor turns)

Power/Mechanical

Failure

4. Fan motor failure Repair or replace

1. Excessive unconditioned make-

up air

Reduce make-up air

2. Leaking ducts or air handling

equipment outside controlled

area

Seal leaks

3. Access opening to area not

sealed

Close and seal

Excessive

infiltration of

humid air into the

controlled area

4. Area not vapor tight Seal with paint or vapor barrier

1. Dehumidistat needs

adjustment

Re-adjust

2. Improper settings Re-adjust

Faulty humidity

controls

3. Defective Replace

1. Dirty filter Clean or replace

2. Obstruction at inlet, outlet or

ducting

Remove obstruction

Inadequate air flow

3. Clogged desiccant media

(high pressure differential

across media)

Remove and replace media

rotor

1. Element failure

Check elements – repair or

replace

2. Low / no voltage

Correct power supply /

breakers

Inadequate or no

reactivation heat

3. Control elements failure

Control set point / repair or

replace

1. Air leaking into dehumidifier

Replace access door gaskets

Air seals and

gaskets

2. Air bypassing media or leaking

seals

Check media position, replace

seals

1. Chain

Repair or replace

2. Motor/gear box

Repair or replace

3. Damaged desiccant rotor

Repair or replace

Unit running

but humidity

rises

Ineffective

desiccant media

4. Contaminated or damaged

desiccant

Replace desiccant rotor

Inadequate or no 1. No Fuel Check for fuel in tank, verify

reactivation heat valves open

2. No power to ignition module Watch for igniter glow through

inspection window, verify power

to transformer and ignition

module

3. Overtemp switch failure Check continuity of overtemp

switches

4. Igniter failure If ignition module has power,

watch for igniter glow through

inspection window

5. Gas Valve Failure With gas valves OFF,

power on the device and check

for voltage at the gas valve

6. Ignition control failure Check power to ignition module,

replace if igniter outputs are

never energized and LED never

blinks (allow several minutes to

verify)

9 Troubleshooting

Trouble

Probable Fault

Probable Cause

Corrective Action

1. Main power off

Check main power and cable

2. Main disconnect open

Close or replace disconnect

3. Selector switch open

Close or replace switch

Unit Stopped

(fan off, no

heater)

Power/Control

Failure

4. Dehumidistat

Repair or replace

1. Motor circuit breaker or

overload tripped

Reset circuit breaker or

overload

2. Contactor failure

Repair or replace

3. Motor winding failure

Repair or replace

Fan off

(Rotor turns)

Power/Mechanical

Failure

4. Fan motor failure

Repair or replace

1. Excessive unconditioned make-

up air

Reduce make-up air

2. Leaking ducts or air handling

equipment outside controlled

area

Seal leaks

3. Access opening to area not

sealed

Close and seal

Excessive

infiltration of

humid air into the

controlled area

4. Area not vapor tight

Seal with paint or vapor barrier

1. Dehumidistat needs

adjustment

Re-adjust

2. Improper settings

Re-adjust

Faulty humidity

controls

3. Defective

Replace

1. Dirty filter

Clean or replace

2. Obstruction at inlet, outlet or

ducting

Remove obstruction

Inadequate air flow

3. Clogged desiccant media

(high pressure differential

across media)

Remove and replace media

rotor

1. Element failure

Check elements – repair or

replace

2. Low / no voltage

Correct power supply /

breakers

Inadequate or no

reactivation heat

3. Control elements failure

Control set point / repair or

replace

1. Air leaking into dehumidifier

Replace access door gaskets

Air seals and

gaskets

2. Air bypassing media or leaking

seals

Check media position, replace

seals

1. Chain

Repair or replace

2. Motor/gear box

Repair or replace

3. Damaged desiccant rotor

Repair or replace

Unit running

but humidity

rises

Ineffective

desiccant media

4. Contaminated or damaged

desiccant

Replace desiccant rotor

ELECTRICAL SHOCK HAZARD: Electrical

power must be present to perform some tests;

these tests should be performed only by a

qualied service person.

Refer to section 5.4 regarding interpeting flashing faults.

Quest PowerDry 4800D Pro P/N Installation, Operation and Maintenance Instructions

17

www.QuestProtect.com

sales@QuestProtect.com

quest

quest 1-866-933-7486

9 Service Parts

Item Part No. Description

1 4020175 Humidity Control

2 4028010 Magnehelic Gauge

3 4028013 Thermostat, 350°F

4 4028015 Ignition Module

5 4028016 Hot Surface Ignitor

6 4028033 Inspection Window Glass 6x6

7 4028559 Inspection Window Glass 4x4

8 4028626 Process Blower

9 4028627 Reactivation Blower

10 4028635 Washable Air Filter 20x20x2

11 4029107 Duct Cover

12 4029314 Duct Cover Retainer

13 4031199 Gas supply hose, 15 ft

quest

quest 1-866-933-7486

Quest PowerDry 4800D Pro P/N Installation, Operation and Maintenance Instructions

18

www.QuestProtect.com

sales@QuestProtect.com

Warrantor:

Therma-Stor LLC

4201 Lien Rd

Madison, WI 53704

Telephone: 1-866-933-7486

Who Is Covered: This warranty extends only to the original end-user of the Quest PowerDry 4800D Pro

P/N and may not be assigned or transferred.

First Year Warranty: Therma-Stor Products warrants that, for one (1) year the Quest PowerDry 4800D

Pro P/N will operate free from any defects in materials and workmanship, or Therma-Stor Products will,

at its option, repair or replace the defective part(s), free of any charge.

End-User Responsibilities: Warranty service must be performed by a Servicer authorized by Therma-

Stor Products. If the end-user is unable to locate or obtain warranty service from an authorized Servicer,

he should call Therma-Stor Products at the above number and ask for the Therma-Stor Products Service

Department, which will then arrange for covered warranty service. Warranty service will be performed

during normal working hours.

The end-user must present proof of purchase (lease) upon request, by use of the warranty card or

other reasonable and reliable means. The end-user is responsible for normal care. This warranty does

not cover any defect, malfunction, etc. resulting from misuse, abuse, lack of normal care, corrosion,

freezing, tampering, modication, unauthorized or improper repair or installation, accident, acts of

nature or any other cause beyond Therma-Stor Products’ reasonable control.

Limitations and Exclusions: If any Quest PowerDry 4800D Pro P/N part is repaired or replaced, the

new part shall be warranted for only the remainder of the original warranty period applicable thereto

(but all warranty periods will be extended by the period of time, if any, that the Quest PowerDry

4800D Pro P/N is out of service while awaiting covered warranty service).

UPON THE EXPIRATION OF THE WRITTEN WARRANTY APPLICABLE TO THE Quest PowerDry

4800D Pro P/N OR ANY PART THEREOF, ALL OTHER WARRANTIES IMPLIED BY LAW, INCLUDING

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, SHALL ALSO EXPIRE. ALL

WARRANTIES MADE BY THERMA-STOR PRODUCTS ARE SET FORTH HEREIN, AND NO CLAIM

MAY BE MADE AGAINST THERMA-STOR PRODUCTS BASED ON ANY ORAL WARRANTY. IN NO

EVENT SHALL THERMA-STOR PRODUCTS, IN CONNECTION WITH THE SALE, INSTALLATION,

USE, REPAIR OR REPLACEMENT OF ANY Quest PowerDry 4800D Pro P/N OR PART THEREOF

BE LIABLE UNDER ANY LEGAL THEORY FOR ANY SPECIAL, INDIRECT OR CONSEQUENTIAL

DAMAGES INCLUDING WITHOUT LIMITATION WATER DAMAGE (THE END-USER SHOULD TAKE

PRECAUTIONS AGAINST SAME), LOST PROFITS, DELAY, OR LOSS OF USE OR DAMAGE TO ANY

REAL OR PERSONAL PROPERTY.

Some states do not allow limitations on how long an implied warranty lasts, and some do not allow the

exclusion or limitation of incidental or consequential damages, so one or both of these limitations may

not apply to you.

Legal Rights: This warranty gives you specic legal rights, and you may also have other rights which

vary from state to state.

Quest PowerDry 4800D Pro P/N

This manual suits for next models

1

Table of contents

Popular Dryer manuals by other brands

Vivog

Vivog SC2600V Instructions for Use, Maintenance and Safety

Warner Howard

Warner Howard EL600 user guide

Fisher & Paykel

Fisher & Paykel AeroCare DG7027P2 Installation instructions and user guide

aeolus

aeolus Mango H-901MT owner's guide

CTA

CTA MPF140 instruction manual

Hoover

Hoover DYH 9913NA1X Instruction book

Maytag

Maytag BRAVOS MGD6600TQ0 Use & care guide

Grundig

Grundig GTP5824BN user manual

Electrolux

Electrolux EDC 5368 operating instructions

Alliance Laundry Systems

Alliance Laundry Systems Drying Tumbler Operation and programming manual

Electrolux

Electrolux SAGQ7000FS0 installation instructions

Beko

Beko DH 9519 GU user manual