Thermo Electron 8600 Series User manual

7998600 Rev. 4

ii

The material in this manual is for information purposes only. The contents and the product it describes

are subject to change without notice. Thermo Electron Corporation makes no representations or

warranties with respect to this manual. In no event shall Thermo be held liable for any damages, direct

or incidental, arising out of or related to the use of this manual.

MANUAL NO. 7998600

4 FR-1789 6/27/05 Revised VRP troubleshooting section for Release 3 aks

3 22216 3/22/04 Added 120V 23 cu. ft. units aks

2 22179 2/24/04 Revised electrical schematic, start capacitor part number aks

-- 8/21/03 Door gap, high stage revisions aks

-- 8/13/03 Revised compressor information page B-1 aks

-- 6/27/03 Revisions per A. Thomas aks

1 21605 5/29/03 Wrong power alarm modifications aks

0 3/21/03 New manual aks

REV ECR/ECN DATE DESCRIPTION BY

iii

Table of Contents

Section 1 – General Operation

1.1 Initial Start Up......................................1-1

1.2 Equipment Explanation.........................1-1

1.3 Operating Pressure

“High and low stage systems”...............1-1

Section 2 – Troubleshooting Charts

2.1 Probe 1,2,3, and 4 failure alarm

(Single) ...............................................2-1

2.2 Probe 1,2,3, and 4 failure alarm

(All probes)..........................................2-1

2.3 Unit will not communicate with alarm

system .................................................2-2

2.4 Display/Keyboard not functioning .......2-3

2.5 Door ajar alarm....................................2-4

2.6 No door access ....................................2-5

2.7 Low battery alarm................................2-6

2.8 Noise ...................................................2-6

2.9 Hot condenser alarm ............................2-7

2.10 High stage system failure alarm ...........2-8

2.11 Power failure alarm..............................2-9

2.12 Wrong power.......................................2-10

2.13 Low Temperature.................................2-10

2.14 High temperature alarm or system not

maintaining temperature ......................2-11

2.15 Troubleshoot compressor.....................2-13

2.16 Voltage Compensation Failure.............2-14

Section 3 – Charts and Schematics

3.1 Analog Output Reference Table.............3-1

3.2 RTD Temperature vs. Resistance ...........3-2

3.3 Pressures vs. Cabinet Temperature.........3-3

3.4 Refrigeration Schematics.......................3-4

3.5 Electrical Schematics ............................3-6

3.6 Micro Board ..........................................3-8

3.7 High Voltage Board...............................3-8

Section 4 -Hidden Functions

4.1 Hidden Test...........................................4-1

4.2 Hidden Calibration ................................4-2

Appendix A - Glossary

Glossary of terms ........................................A-1

Appendix B

Compressor Information..............................B-1

1 - 1

General Operation

1.1 Initial Start Up

1. Power Switch on.

2. Cabinet temperature 0.5°C or warmer than set point.

3. Fans 1 and 2 turn ON.

4. High stage compressor turns ON, after ten seconds delay.

5. Low stage compressor turns ON when:

A. Thirty seconds after high stage starts and heat exchanger probe reads

–41°C or colder or

B. Five minutes after high stage starts and heat exchanger probe reads

between –33°C to –40°C.

If heat exchanger probe warms-up to –20°C or warmer, the low stage

compressor shuts down until either condition 5A or 5B is met. After thirty

minutes, if condition 5A or 5B is not met, the high stage system failure will be

activated.

6. Once the cabinet temperature reaches –50°C, the*expansion tank solenoid is

opened (de-energized). The vacuum relief heater and mullion heater on double

door units, are energized and operate continuously until the cabinet is warmer

than –50°C.

7. Set point achieved, fans and compressors cycle off.

8. Steps 2 though 7 repeat (cycle).

*Items or functions unique to this system

1.2 Expansion Tank Assembly and Solenoid Valve

Location: Suction side of low stage system.

Purpose: Tank assembly increases low stage system refrigeration

capacity. Prevents excessive low stage pressures at

temperatures warmer than –50°.

Operation: The tank assembly solenoid valve is normally open. The

solenoid valve is energized (closed) when the control probe

senses temperature warmer than –50°C. The solenoid valve is

de-energized (open) when the control probe senses

temperature colder than –50°C.

1.3 Operating Pressure “High and low stage systems”

The suction side pressure for both systems typically runs in a vacuum. Prior to

opening a system for a pressure reading, always purge your lines according to the

manufacturer’s recommended procedure. For further information, call Thermo Forma

Service Department.

230 Volt Freezers

Only the compressors require 230 volts. The remaining high voltage components

operate using 115 volts.

2 - 1

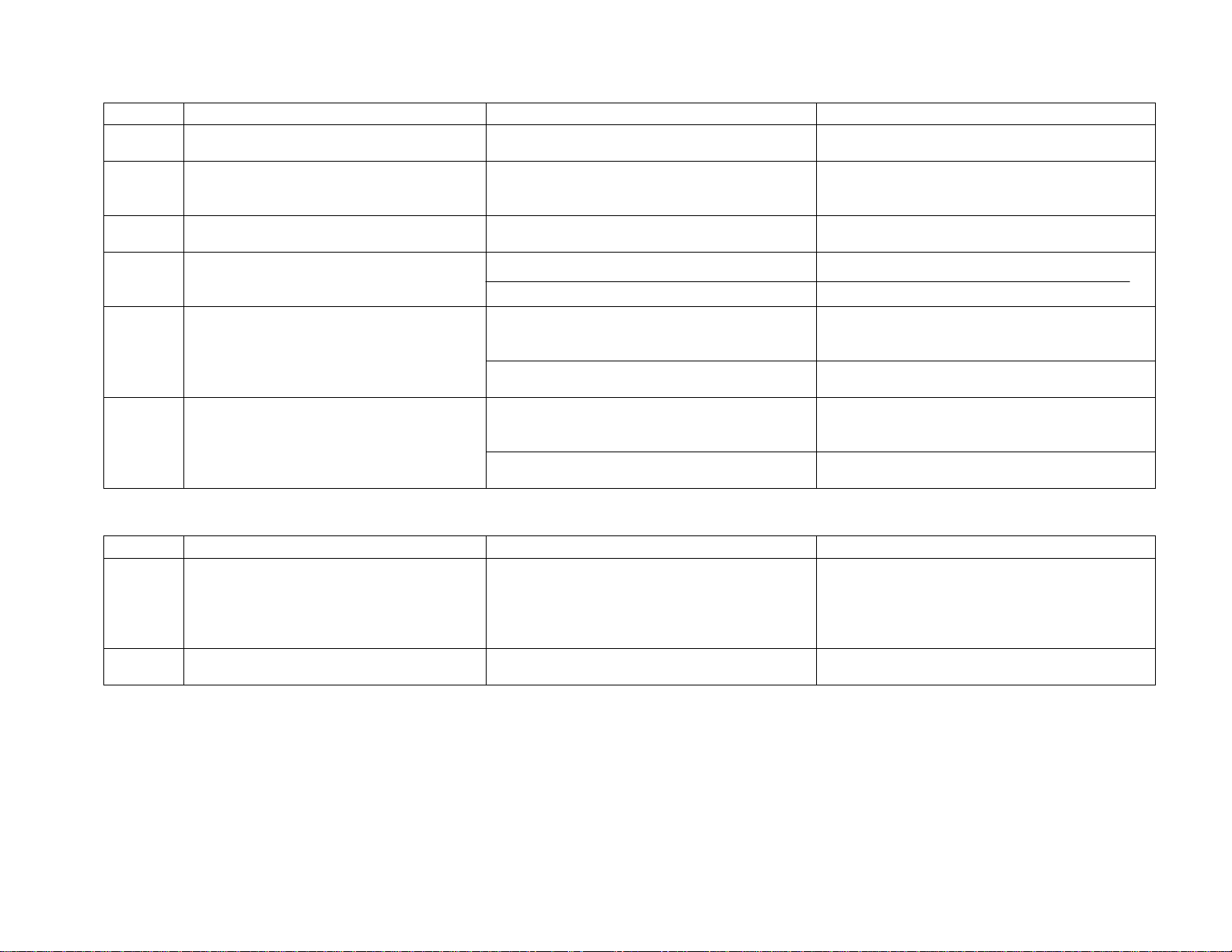

2.1 Symptom: Probe 1, 2, 3, or 4 Failure Alarm - SINGLE PROBE FAILURES

Order Possible Cause Verification Action

Probe

Unplugged. Re-seat connector. Re-seat all connections.

1

Not fully seated Verify wires are fully seated in connectors and

connectors are seated together

Replace probe if necessary.

Bad probe

Short.

Open. Display reads 99. Verify probe resistance. See

Temperature vs. Resistance Chart (Page 3-2).

Replace probe.

2

Wrong value. Verify probe resistance. See Temperature vs.

Resistance Chart (Page 3-2).

Replace probe.

3 Micro board.

Temporarily switch suspect probe with control or

heat exchanger probe.

If the same error exists, replace micro board.

2.2 Symptom: Probe 1, 2, 3, and 4 Failure Alarm – (ALL PROBES FAIL)

Order Possible Cause Verification Action

Re-seat connector.

1 Control probe not installed.

Startup only.

Verify wires are fully seated in connectors and

connectors are seated together.

Reinitialize (re-start) unit.

Reseat all connections.

Replace probe if necessary.

Bad control probe Display reads 99. Bad control probe will also

cause a high temperature alarm and lock both

compressors on.

2

Short.

Open.

Wrong value.

Verify probe resistance with Temperature vs.

Resistance Chart (page 3-2).

Replace probe.

3 Micro board.

Temporarily switch control probe with heat

exchanger probe.

If the same error exists, replace micro board.

4 Micro board EEPROM Problem still exists after re-initializing unit. Re-initialize eeprom in test mode. If problem

remains, replace the micro board. Note: all

calibration, set points and configuration are set to

default.

2 - 2

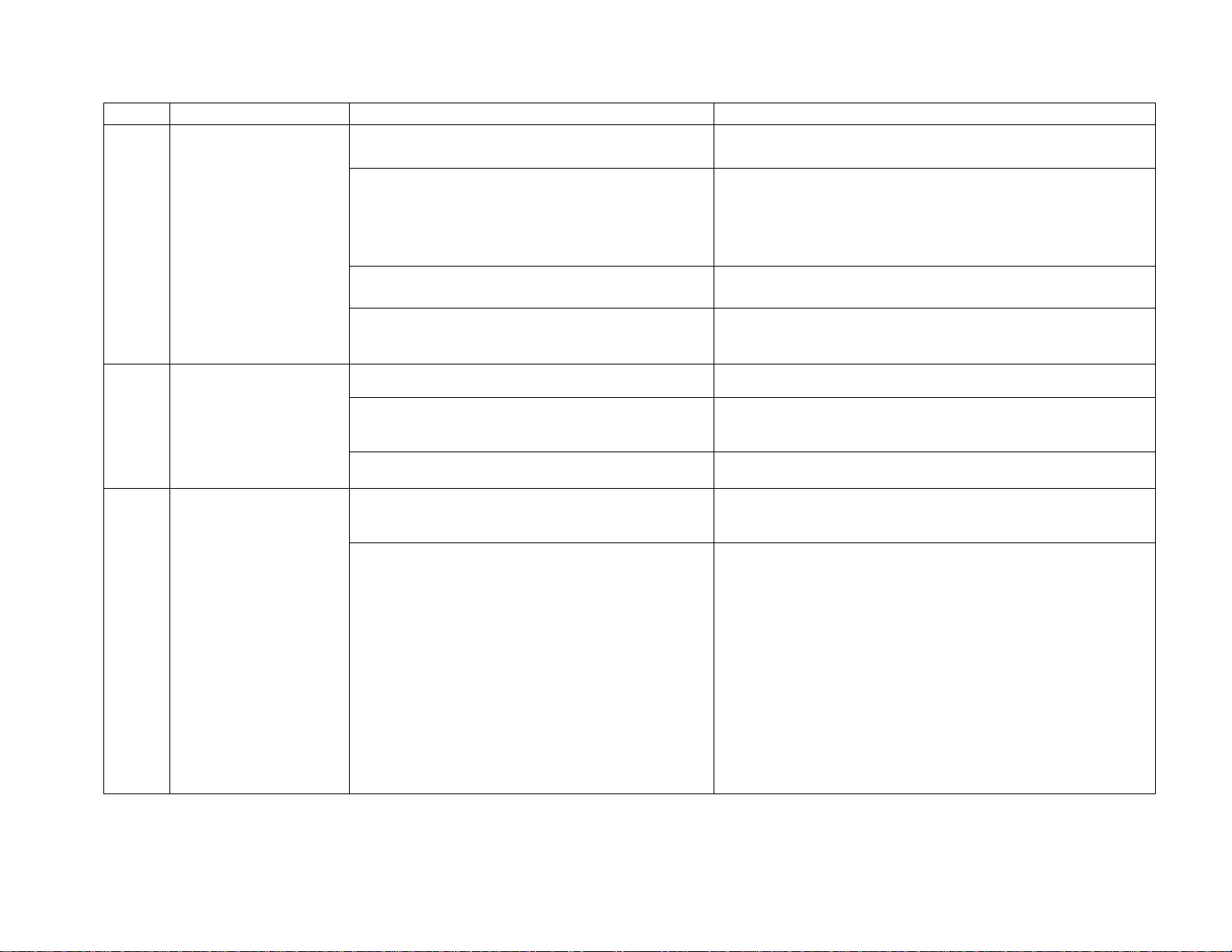

2.3 Symptom: Unit will not communicate with alarm system (Remote Alarm Contacts/Analog

System/Serial communication)

Order Possible Cause Verification Action

Check that all connections are tight and properly

wired. Missing wires?

Tighten and / or correct wiring.

1 Remote Alarm Contacts

Measure continuity of alarm contacts between

pins 6 & 7 and 6 & 8 while toggling in test mode

(pin 6 is common).

Replace micro board if contacts do not change

state.

Verify the setting is correct in hidden calibration

and corresponds to the dip switch settings on the

micro board per the electrical schematic.

Make changes so the dip switch settings and hidden

calibration settings match.

Measure output. Compare with Analog Output

Reference Table (page 3-1).

Call the factory service department 888-213-1790.

See section 4.2.p Analog Calibration (page 4-3).

2 Analog Output

Check that all connections are tight and properly

wired. Missing wires?

Tighten and / or correct wiring.

Verify address is correct in configuration menu

and matches the 1535 address.

Change so that the unit address of the freezer

matches the 1535 address.

Verify the setting is correct in hidden calibration

and corresponds to the dip switch settings on the

micro board per the electrical schematic.

Make changes so that the dip switch settings and

hidden calibration settings match.

Check that all connections are tight and properly

wired. Missing wires?

Tighten and / or correct wiring.

Tighten and / or correct wiring.

3 Serial Communication

Verify that the cable is a DB9 (straight through)

extension cable.

Replace cable if necessary.

2 - 3

2.4 Symptom: Display / Keyboard Not Functioning

Order Possible Cause Verification Action

1 Turned battery on before AC power is

applied.

(initial start up issue only)

Ask customer/end user. Turn unit power off. Turn battery off. Reapply AC power

before the battery is turned on.

2 No AC power and no battery power. Verify supply AC voltage is present.

Supply correct line voltage.

+14VDC on switching power supply.

If not, replace switching supply.

+14VDC on micro board at connector

labeled DC power from HV board (pins 1

and 6).

Check connector seating on ribbon cables. Replace if

required.

3 Micro board -

Micro LED LD1 on micro board not

functioning.

Is unit operating (fans, compressors)?

If no, replace micro board.

If yes, continue to step 4.

Turn unit off, then turn unit back on.

Miscellaneous characters displayed. Replace display board.

4 Micro board - Micro LED LD1

functioning / no display LED LD2.

Check connection of 25 pin D sub cable

at both ends.

Waiting Comm is displayed. Replace micro and/or display as

needed.

Display -

Missing segment Visual. Replace display board.

Keys not responding

Check continuity for buttons on overlay. Replace overlay.

LEDs not functioning

Ohm out LEDs.

Replace overlay.

5

No Alarm Press any key on overlay. If no audible, replace display board.

2 - 4

2.5 Symptom: Door Ajar Alarm

Order Possible Cause Verification Action

1 No magnet Visually inspect for magnet in door handle. Replace magnet as required.

2 Worn door handle

Inspect inside of door latch for signs of metal

(aluminum) wear (wobbly handle).

Replace latch if necessary and verify vacuum relief

port operation, as well as the door alignment.

Improper connection

Wires loose from door switch connector.

Verify wires are properly seated in connector.

If required, re-seat the wire connection.

Door switch connector not seated to board

connector.

Verify connectors are seated together.

Re-seat connection.

3

Installed in wrong connector Verify the plug is in the correct receptacle.

Re-seat plug in correct receptacle.

4 Improper door alignment Verify door gap. Single door .600”

Double door .700”, both measured from the hinge

side.

Make adjustment as required.

5 Bad door switch

Verify continuity on door switch by opening and

closing door.

If no continuity of switch during opening and

closing of door, replace door switch.

6 Defective micro board. Short out door switch connector. If alarm does not clear replace micro board. Or else

repeat starting at Step 1.

2 - 5

2.6 Symptom: No Door Access

Order Possible Cause Verification Action

1 Door locked. Check to ensure door is not locked. Unlock door.

2 Vacuum relief assembly is frozen over.

Visually inspect vacuum relief port for any

restrictions. Clean as necessary. Follow routine maintenance

instructions in user’s manual to periodically clean

the port.

Check voltage at J7 on the display board for +14V

+0.5?

YES (+14V): unplug heater harness from PCB and

measure resistance across heater leads. Heater

resistance should be between 9 and 30 Ohms.

If not between 9 and 30 Ohms, replace VRP

assembly.

3 Release 3 unit: Vacuum relief not

functioning.

Release 3 units(built after 6/2005 have

vacuum relief port in door.

NO: Check and reseat connections on heater harness.

Measure DC voltage at the switching power supply.

On the 6 pin connector, measure between pins 1 and

6 (+14V + 0.5V)

Check and reseat connectors between switching

power supply and high voltage board. Also check

and reseat connections between high voltage

board and micro board.

Verify unit is colder than –50°C. Cabinet temperature must be colder than –50°C to

activate vacuum relief heater.

90-130VAC at heater?

YES: Ohm out heater. Heater to be 1037-1210 Ohms Replace heater if required.

Release 1 unit: Vacuum relief not

functioning.

Release 2 units built between May 2003

and June 2005 do not use a heated vacuum

relief assembly.

NO: Check connections Re-seat connection(s). If problem still exists,

continue troubleshooting.

Blown fuse Check fuse. Ohm out fuse, replace fuse as required.

Micro board Check voltage between U16-13 and J11-1 on micro

board. If voltage is greater than 10VDC, replace micro

board.

High voltage board. Check DC voltage across D15 on high voltage. If voltage is less than 10VDC, replace high

voltage board.

2 - 6

2.7 Symptom: Low Battery Alarm

Order Possible Cause Verification Action

1 New battery / new unit or freezer just placed

into service?

Ask customer/end user.

Complete steps 2,3, & 4.

If yes, batteries required 36 hours for charging.

If no, continue to step 5.

2 Missing battery Visually look for battery. Install battery.

3 Battery switch turned off. Verify switch is “on”.

Turn switch on after AC power is applied.

4 Connection –

Wires making connection.

Battery wired backwards.

Ensure connections are tight at the battery,

battery switch, and micro board. Verify the red

wire is connected to the positive terminal.

Tighten and change wiring as needed.

5 Battery switch defective. Verify continuity with multimeter. Replace switch.

6 Battery Calibration Measure voltage at the battery and compare to

the value displayed in hidden calibration.

Match values.

7 Battery voltage < 12.1 during battery test. Check voltage at the battery during battery test

after 2 days (48 hours) of operation.

If voltage < 12.1, replace battery and continue to

step 8.

8 Micro board –

Battery test circuit.

Battery charging circuit

Disconnect battery and measure voltage at the

battery wires.

If 13.5 - 13.8 VDC is present, replace battery.

If not present replace micro board and battery.

2.8 Symptom: Noise

Order Possible Cause Verification Action

1 Loose screws on panels or compressors. Ensure all screws and bolts are tightly secure. Tighten as needed.

2 Missing or no sound insulation.

Remove side panels to ensure insulation is

present. Inspect the bottom of cabinet to verify

insulation is present.

Add foam panels if necessary.

3 Start capacitor on compressor.

Ensure capacitor is not touching the compressor

body and capacitor bracket securely holds the

capacitor.

Adjust as needed.

4 Electrical cover on compressors.

Ensure cover is tight.

Tighten as needed.

5 Vibrating refrigeration lines.

Inspect for lines that are touching. Adjust as necessary.

6 Solenoid Ensure that the solenoid base sits on presstite tape

and is tie wrapped to the freezer base.

Replace presstite tape and tie wraps, if necessary.

2 - 7

2.9 Symptom: Hot Condenser Alarm

Order Possible Cause Verification Action

1 High ambient.

Measure ambient temperature.

Is ambient above 33°C?

Alarm will cycle with compressors. If ambient is

above 37°C, alarm is on constantly.

Move to cooler location / lower ambient.

Educate customer.

Check filter. Change / clean filter.

Check for condenser blockage. Remove blockage.

Verify clearance specifications of 5 inches are

met.

Install stand-offs.

2 Restricted / reduced airflow.

Check for open front panel.

Close front panel.

Confirm High stage is on (fans should be running) Start unit to continue, if off.

Identify problem fan(s) Method ( tie wrap…)

If no voltage, check voltage between U13-10 and

J11-1, U16-10 and J11-1 on micro board. If less

than 10VDC, replace micro board. Else if DC

voltage across D11 and D14 on high voltage board

is less than 10VDC, check ribbon cable. If ribbon

cable OK, replace high voltage board.

3 Fan(s) not running.

Confirm voltage to each fan by verifying voltage

at pins J29-1 to J29-7 and J29-2 to J29-8 on the

high voltage board.

If voltage exists, measure Ohms for fans at

connector that plus into J29 on high voltage board.

First column of black wires for fan in front of high

stage, second column of black wires for fan in front

of low stage. Ohms should be 130 to 145 in 23°C.

Replace fan(s) with improper Ohms.

4 Defective probe. See: Probe 1,2,3, or 4 failure alarm

troubleshooting chart. Condenser probe plus into

J4 of micro board.

2 - 8

2.10 Symptom: High Stage System Failure Alarm

Order Possible Cause Verification Action

1 Clear HS System Failure Alarm in Configuration

Mode.

2 Fan(s) not running.

See procedure for troubleshooting fans under “Hot

Condenser” alarm.

High stage compressor not starting or not running.

Inadequate power at the customer’s

site.

Check voltage at the wall and monitor for large

voltage drop during start-up.

If voltage drops below 90V for 120V units or 180V for 230V

units, contact customer.

No voltage at compressor. LD2 and LD4, on high

voltage board, are not on.

Line voltage is within specified limits

For LD2 measure voltage between U13-12 and J11-1, for LD4

measure voltage between U13-14 and J11-1, on micro board. If

voltage is less than 10VDC, replace micro board.

If voltage is greater than 10VDC, for LD2 measure voltage from

right side of D3 to right side of D4, for LD4 measure from right

D7 & right side of D8 on high voltage board. If voltage is less

than 10VDC, check ribbon cable. Ribbon cable OK, replace

high voltage board.

No voltage at compressor, LD5 (HS) on high

voltage board is on.

Check connections: enclosure, high pressure cutout switch. Ohm

out pressure switch. Switch to be closed. Switch OK, measure

voltage between pins 4 and 5 of J30. If no voltage, replace high

voltage board.

Switch defective; jumper around switch and continue to test.

No voltage at compressor LD5 (HS) is off and

should be on.

If voltage between U13-15 and J11-1, on micro board, is less

than 10VDC, replace micro board.

Else, if DC voltage across D12 on high voltage board is greater

than 10VDC, check ribbon cable. If ribbon cable OK, go to

previous verification.

Else, if D12 voltage less than 10VDC, replace high voltage

board.

AC power to high stage compressor.

If required, go into test mode; turn

both fans and high stage compressor

on.

Voltage at compressor Check continuity of compressor thermal switch.

Check winding resistance of compressor.

See Appendix B

Check compressor-starting hardware. Replace parts as needed.

3

HS compressor cycles on high-

pressure cutout.

Install pressure gauges on high stage and verify

that high-pressure cutout is functioning normally.

Replace defective high-pressure cutout.

4 HX probe reading incorrectly.

Compare T/C reading on interstage heat exchanger

to resistance of HX probe and display value. See

Resistance to Temperature Chart (page 3-2).

If T/C differs from resistance and displayed value, defective

probe. If displayed value differs from T/C and resistance value,

replace micro board.

2 - 9

2.10 Symptom: High Stage System Failure Alarm (continued)

Order Possible Cause Verification Action

5 Restriction in high stage capillary

tube.

Measure the temperature at the heat exchanger.

If a restriction exists, the heat exchanger will be

warmer than normal.

Recondition high stage.

2.11 Symptom: Power Failure Alarm

Order Possible Cause Verification Action

1 Unplugged line cord.

Check that line cord is properly seated in wall

connection and relay enclosure.

Re-attach line cord and install strain relief per

user’s manual, if required.

Verify switch / circuit breaker (power switch) by

continuity or test for line voltage on high voltage

board where wires from switch are connected to

board.

Replace if required.

2 Unit circuit breaker (power switch).

Verify switch / circuit breaker does not trip below

amperage rating.

Replace if required.

If trips above rating, go to step 5.

3 Loose wires

Circuit Breaker/ Power switch.

High voltage board.

Switching power supply.

Verify line voltage connection from circuit

breaker/power switch to high voltage board inputs

and ribbon cable connection from high voltage

board to DC switching power supply.

Seat or replace as required.

4 Defective switching power supply.

Verify input line voltage and output voltage,

+14 VDC, is present at switching power supply.

Replace if required.

5 Damaged components or wiring. Inspect relay enclosure for damaged components

and wiring.

Replace as required.

6 Defective starting hardware or

compressor(s).

Check both stages for L.R.A.

If compressor attempts to run and draws L.R.A.,

check start relay for proper operation and values on

start and run capacitors. Ohm compressor windings

and compare to nominal values (Appendix B).

Dedicated circuit and correct rating? Advise customer.

7 Facility Wiring

Circuit breaker

Wire. Connections, gauge size, and length. Try a different circuit. Fix as required.

2 - 10

2.12 Symptom: Wrong Power

Order Possible Cause Verification Action

1 Sequence that battery and power switch was

turned on (start-up only)

Was battery switch turned on before power switch

was turned on?

Turn both switches off. Turn power switch on, then

turn battery switch on.

2 Facility wiring incorrect.

230V receptacle 115 supply

Proper line voltage. Need correct operation voltage.

3 Wrong line cord set.

Verify correct line cord plug : P5-15 (120V,15A),

P5-20 (120V,20A), P6-15 (230V,15A).

Contact manufacturer.

4 Ribbon cable connection between high

voltage and micro board.

Cables properly seated.

Ribbon cables damaged.

Reseat connections.

Replace cable(s).

Measure AC voltage between left side F1 and left

side of R9. Voltage should be between .25 and .95

VAC.

If incorrect voltage, replace high voltage board.

5 High voltage board failure.

Measure frequency between pins 4 and 5 of U1. Frequency is not twice the frequency of wall outlet.

Replace high voltage board.

Measure AC voltage across R40 on micro board.

Voltage should be between .25 and .95 VAC.

No voltage: replace ribbon cable.

Good voltage: replace micro board.

6 Micro board failure.

Measure frequency between pin 10 of U14 and

pin 8 of U28..

No measurement, check ribbon cable. If ribbon

cable is ok, replace micro board.

2.13 Symptom: Low Temperature Alarm

Order Possible Cause Verification Action

1 Relays on high voltage board not being

turned off.

Verify that LEDs (LD5 and LD6) on the high

voltage board are illuminated and voltage across

D12 and D13 is greater than 10VDC.

IF LD5 and LD6 on and voltage is greater than

10DC, replace micro board. If LD5 and LD6 are

off and voltage is less than 10VDC, replace high

voltage board.

2 Wrong probe value Verify probe resistance with Temperature vs.

Resistance Chart (page 3-2).

Replace as required.

2 - 11

2.14 Symptom: High Temperature Alarm or System is not maintaining temperature

Order Possible Cause Verification Action

Inspect gasket for ice or excessive frost.

Clear ice or frost from door and gasket.

Check door adjustment: fit and gasket

compression.

Adjust door to restore uniform gasket compression.

1 Door

Frequency and duration of door openings and

product loading (size of load and temperature of

introduced product. If customer usage is high or

suspected as high, then verify actual performance

with a datalogger.

Work with customer to communicate effects of

loading.

2 Load – evaluate customer usage. Install thermocouple at control sensor and verify

control RTD temperature is accurate.

Troubleshoot control probe with “Probe 1,2,3 & 4

failure procedure”.

3 Defective control probe

See procedure for troubleshooting probes “Probe

1,2,3 or 4 Failure (Single Probe).

4 Normal relay(s) on high voltage board LD 2 and LD 4 on high voltage board are not lit

120v units: Line voltage 105 - 140

230V/60Hz units: Line voltage 210 - 260

230V/50Hz units: Line voltage 190- 230

Line voltage is within specified limits

For LD2 check voltage between U13-12 and J11-1

on micro board, for LD4 measure between U13-14

and J11-1, if voltage is less than 10VDC, replace

micro board.

If voltage is greater than 10, then check DC voltage

from right side of D3 to right side of D4 (LD2),

from right D7 & right side of D8 (LD4) on high

voltage board. If is less than 10VDC, check ribbon

cable. If ribbon cable OK, replace high voltage

board.

2 - 12

2.14 Symptom: High Temperature Alarm or System is not maintaining temperature (continued)

No voltage at compressor, LD6 (LS) on high

voltage board is on.

Check connections: enclosure, high-pressure cutout

switch. Ohm out pressure switch. Switch to be

closed. Switch OK, measure voltage between pins

1 and 2 of J30. If no voltage, replace high voltage

board.

Switch defective; jumper around switch and

continue to test.

No voltage at compressor LD6 (LS) is off and

should be on.

If voltage between U13-16 and J11-1, on micro

board, is less than 10VDC, replace micro board.

If voltage greater than 10, check DC voltage across

D13 on high voltage board is less than 10VDC,

check ribbon cable. If ribbon cable OK, go replace

high voltage board

If D13 voltage greater than 10VDC, . Go to

previous verification, LD6 maybe defective.

AC power to low stage compressor.

Voltage at compressor Check continuity of compressor thermal switch.

Check winding resistance of compressor.

See Appendix B

Check compressor-starting hardware. Replace parts

as needed.

5

LS compressor cycles on high-pressure

cutout.

Install pressure gauges on low stage and verify

that high-pressure cutout is functioning normally.

Replace defective high-pressure cutout.

6 High stage refrigeration system failure Verify interstage heat exchanger temperature is

above –33°C.

Troubleshoot with “Troubleshooting Compressor”.

7 Low Stage refrigeration system failure Verify interstage heat exchanger temperature is

below –33°C.

Troubleshoot with “Troubleshooting Compressor”.

2 - 13

2.15 Symptom: Troubleshoot compressor

Order Possible Cause Verification Action

Verify compressor starts and run continuously.

If yes, install gauges and go to next step.

If no, go to order 3 of “Compressor starting problem”.

Verify suction pressure is above:

High Stage – 0 psig

Low Stage – 10” vac

If suction pressure is “ok”, proceed to next step.

If suction pressure is below limits, conduct equalization test: if

equalization test fails – blocked cap tube; recondition refrigeration

system.

If equalization test passes, warm unit, go order 2 “unit at room

temp, heat exchanger at room temp”.

Verify discharge pressure is below 175 psig – conduct

efficiency test.

Suspect bad compressor (values): replace compressor…recondition

refrigeration system.

1 Low suction pressure

problem

If discharge pressure is above:

LS 175 psig

HS 250 psig

Suspect non-condensables: recondition the refrigeration system in

question.

Verify static pressures are acceptable. Recondition low stage (suspect partial restriction in cap tube).

Compare high stage static and low stage static

pressures. Are the static pressures on high and low

stages identical?

Yes, replace interstage and recondition both the high and low

stages.

No, go to next verification.

2 Unit at room temperature,

heat exchanger at room

temperature

Static pressure unacceptable. Suspect under- or overcharge. Recondition refrigeration system for

system in question.

Measurements of wall voltage

Unit off

Unit at start-up.

If unacceptable, work with customer to correct.

If acceptable, go to next step.

3 Compressor Starting

Problem

Verify compressor attempts to start (draws L.R.A. or

turns over briefly).

If no attempt to start –

Check voltage to compressor

No voltage at compressor LD5 (HS) or LD6 (LS) is on.

No voltage at compressor LD5 (HS) or LD6 (LS) is

off.

If compressor attempts to run and draws L.R.A., check start relay

for proper operation and values on start and run capacitors.

If voltage at compressor, isolate compressor. Ohm compressor

windings at compressors and compare to nominal values (Appendix

B).

Check connections: enclosure, high pressure cutout switch. Ohm

out pressure switch. Switch to be closed.

Voltage between U13-15 (HS) or U13-16 (LS) and J11-1 on micro

board is less than 10VDC, replace micro board. Else if DC voltage

across D12 (HS) or D13 (LS) on high voltage board is less than

10VDC, replace high voltage board.

2 - 14

2.15 Symptom: Troubleshoot compressor continued

Order Possible Cause Verification Action

Verify if compressor tripping on high pressure switch

and confirm that discharge is reaching 375 psig (+ 25

psi).If tripping on pressure switch and discharge

pressure is high, then troubleshoot why discharge

pressure is high.

If tripping on high pressure switch and pressure is not running at

375 psig (+25), then replace pressure switch.

3

Verify if compressor is tripping on thermal switch. If yes, recondition low stage.

If no, troubleshoot high voltage board (board turning compressor

off).

2.16 Symptom: Voltage Compensation Failure

Turn unit off, and then back on. If unit goes into

Boost (LD2 & LD3) or Buck (LD1 & LD4), unit

does not function and then goes into Normal mode

(LD2 & LD4).

Check wiring between transformer(s) and high voltage board

Check transformer

Check relay contacts. Restart unit. Take following readings

when LD1 or LD3 should be on.

LD1: Line voltage should be read between J5 and J22

Replace high voltage board as required

1 Voltage Compensation Failure

Unit will operate normally

Turn unit off, and then back on. If unit goes into

Boost (LD2) or Buck (LD4), unit does not function

and then goes into Normal mode (LD2 & LD4).

LD1 or LD3 does not turn on.

For LD3, measure voltage between U13-11 and J11-1, for LD1

measure between U13-13 and J11-1, on micro board. If voltage

is less than 10VDC, replace micro board.

If voltage was greater than 10VDC, for LD1 measure voltage

from right side of D1 to right side of D2, for LD3 measure

voltage from right D5 & right side of D6 on high voltage board.

If the voltage is less than 10VDC, check ribbon cable. If ribbon

cable is OK. Replace high voltage board. If voltage between

diodes was greater than 10VDC, go to previous verification,

LD1 or LD3 maybe defective.

3 - 1

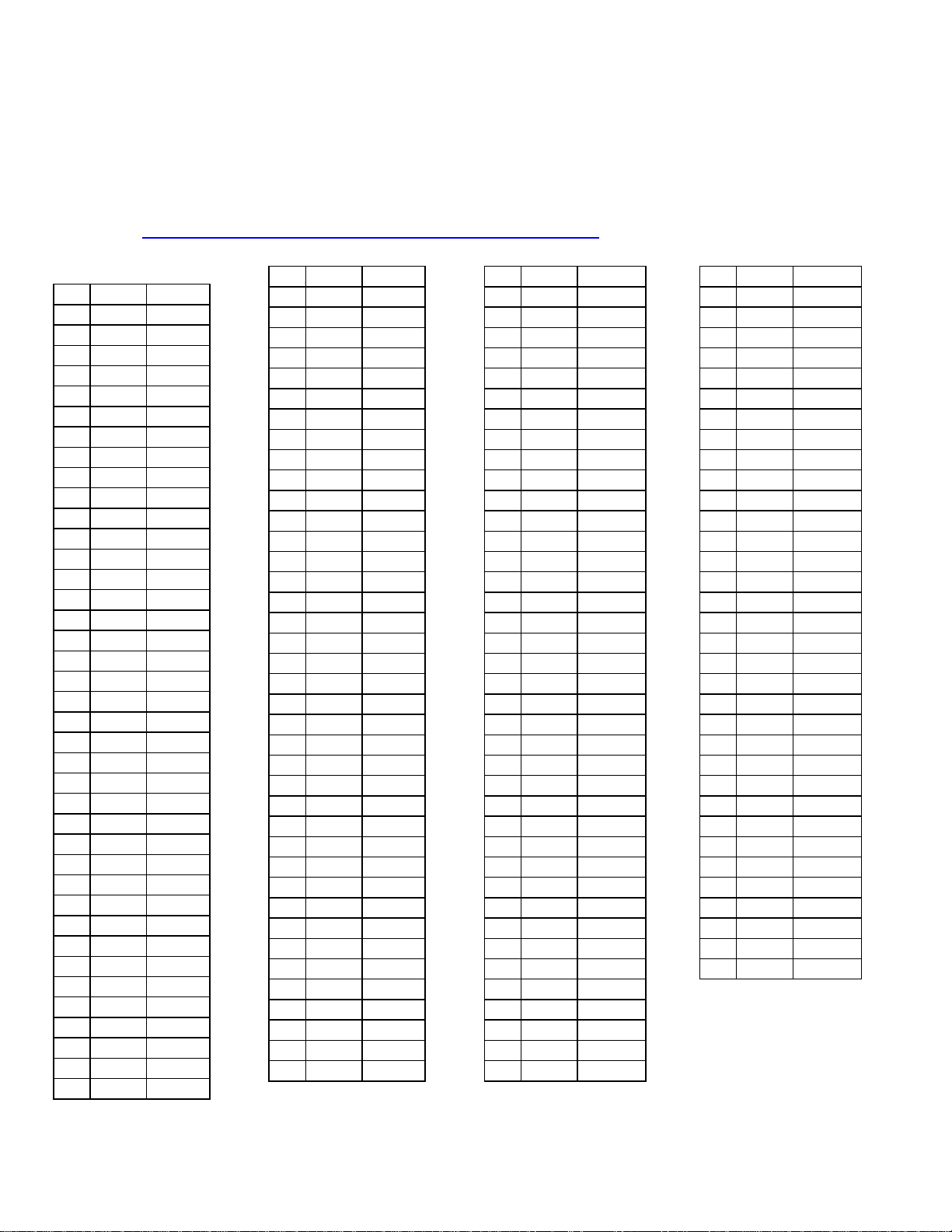

Temp°C 4-20

mA

4-0mA

with

250

Ohm

resistor

0-1V 0-5V

50 20.000 5.000 1.000 5.000

49 19.893 4.973 0.993 4.967

48 19.787 4.947 0.987 4.933

47 19.680 4.920 0.980 4.900

46 19.573 4.893 0.973 4.867

45 19.467 4.867 0.967 4.833

44 19.360 4.840 0.960 4.800

43 19.253 4.813 0.953 4.767

42 19.147 4.787 0.947 4.733

41 19.040 4.760 0.940 4.700

40 18.933 4.733 0.933 4.667

39 18.827 4.707 0.927 4.633

38 18.720 4.680 0.920 4.600

37 18.613 4.653 0.913 4.567

36 18.507 4.627 0.907 4.533

35 18.400 4.600 0.900 4.500

34 18.293 4.573 0.893 4.467

33 18.187 4.547 0.887 4.433

32 18.080 4.520 0.880 4.400

31 17.973 4.493 0.873 4.367

30 17.867 4.467 0.867 4.333

29 17.760 4.440 0.860 4.300

28 17.653 4.413 0.853 4.267

27 17.547 4.387 0.847 4.233

26 17.440 4.360 0.840 4.200

25 17.333 4.333 0.833 4.167

24 17.227 4.307 0.827 4.133

23 17.120 4.280 0.820 4.100

22 17.013 4.253 0.813 4.067

21 16.907 4.227 0.807 4.033

20 16.800 4.200 0.800 4.000

19 16.693 4.173 0.793 3.967

18 16.587 4.147 0.787 3.933

17 16.480 4.120 0.780 3.900

16 16.373 4.093 0.773 3.867

15 16.267 4.067 0.767 3.833

14 16.160 4.040 0.760 3.800

13 16.053 4.013 0.753 3.767

12 15.947 3.987 0.747 3.733

11 15.840 3.960 0.740 3.700

10 15.733 3.933 0.733 3.667

9 15.627 3.907 0.727 3.633

8 15.520 3.880 0.720 3.600

7 15.413 3.853 0.713 3.567

6 15.307 3.827 0.707 3.533

5 15.200 3.800 0.700 3.500

4 15.093 3.773 0.693 3.467

3 14.987 3.747 0.687 3.433

2 14.880 3.720 0.680 3.400

1 14.773 3.693 0.673 3.367

0 14.667 3.667 0.667 3.333

Temp°C 4-20

mA

4-20mA

with

250

Ohm

resistor

0-1V 0-5V

-1 14.560 3.640 0.660 3.300

-2 14.453 3.613 0.653 3.267

-3 14.347 3.587 0.647 3.233

-4 14.240 3.560 0.640 3.200

-5 14.133 3.533 0.633 3.167

-6 14.027 3.507 0.627 3.133

-7 13.920 3.480 0.620 3.100

-8 13.813 3.453 0.613 3.067

-9 13.707 3.427 0.607 3.033

-10 13.600 3.400 0.600 3.000

-11 13.493 3.373 0.593 2.967

-12 13.387 3.347 0.587 2.933

-13 13.280 3.320 0.580 2.900

-14 13.173 3.293 0.573 2.867

-15 13.067 3.267 0.567 2.833

-16 12.960 3.240 0.560 2.800

-17 12.853 3.213 0.553 2.767

-18 12.747 3.187 0.547 2.733

-19 12.640 3.160 0.540 2.700

-20 12.533 3.133 0.533 2.667

-21 12.427 3.107 0.527 2.633

-22 12.320 3.080 0.520 2.600

-23 12.213 3.053 0.513 2.567

-24 12.107 3.027 0.507 2.533

-25 12.000 3.000 0.500 2.500

-26 11.893 2.973 0.493 2.467

-27 11.787 2.947 0.487 2.433

-28 11.680 2.920 0.480 2.400

-29 11.573 2.893 0.473 2.367

-30 11.467 2.867 0.467 2.333

-31 11.360 2.840 0.460 2.300

-32 11.253 2.813 0.453 2.267

-33 11.147 2.787 0.447 2.233

-34 11.040 2.760 0.440 2.200

-35 10.933 2.733 0.433 2.167

-36 10.827 2.707 0.427 2.133

-37 10.720 2.680 0.420 2.100

-38 10.613 2.653 0.413 2.067

-39 10.507 2.627 0.407 2.033

-40 10.400 2.600 0.400 2.000

-41 10.293 2.573 0.393 1.967

-42 10.187 2.547 0.387 1.933

-43 10.080 2.520 0.380 1.900

-44 9.973 2.493 0.373 1.867

-45 9.867 2.467 0.367 1.833

-46 9.760 2.440 0.360 1.800

-47 9.653 2.413 0.353 1.767

-48 9.547 2.387 0.347 1.733

-49 9.440 2.360 0.340 1.700

-50 9.333 2.333 0.333 1.667

Temp°C 4-20

mA

4-0mA

with

250

Ohm

resistor

0-1V 0-5V

-51 9.227 2.307 0.327 1.633

-52 9.120 2.280 0.320 1.600

-53 9.013 2.253 0.313 1.567

-54 8.907 2.227 0.307 1.533

-55 8.800 2.200 0.300 1.500

-56 8.693 2.173 0.293 1.467

-57 8.587 2.147 0.287 1.433

-58 8.480 2.120 0.280 1.400

-59 8.373 2.093 0.273 1.367

-60 8.267 2.067 0.267 1.333

-61 8.160 2.040 0.260 1.300

-62 8.053 2.013 0.253 1.267

-63 7.947 1.987 0.247 1.233

-64 7.840 1.960 0.240 1.200

-65 7.733 1.933 0.233 1.167

-66 7.627 1.907 0.227 1.133

-67 7.520 1.880 0.220 1.100

-68 7.413 1.853 0.213 1.067

-69 7.307 1.827 0.207 1.033

-70 7.200 1.800 0.200 1.000

-71 7.093 1.773 0.193 0.967

-72 6.987 1.747 0.187 0.933

-73 6.880 1.720 0.180 0.900

-74 6.773 1.693 0.173 0.867

-75 6.667 1.667 0.167 0.833

-76 6.560 1.640 0.160 0.800

-77 6.453 1.613 0.153 0.767

-78 6.347 1.587 0.147 0.733

-79 6.240 1.560 0.140 0.700

-80 6.133 1.533 0.133 0.667

-81 6.027 1.507 0.127 0.633

-82 5.920 1.480 0.120 0.600

-83 5.813 1.453 0.113 0.567

-84 5.707 1.427 0.107 0.533

-85 5.600 1.400 0.100 0.500

-86 5.493 1.373 0.093 0.467

-87 5.387 1.347 0.087 0.433

-88 5.280 1.320 0.080 0.400

-89 5.173 1.293 0.073 0.367

-90 5.067 1.267 0.067 0.333

-91 4.960 1.240 0.060 0.300

-92 4.853 1.213 0.053 0.267

-93 4.747 1.187 0.047 0.233

-94 4.640 1.160 0.040 0.200

-95 4.533 1.133 0.033 0.167

-96 4.427 1.107 0.027 0.133

-97 4.320 1.080 0.020 0.100

-98 4.213 1.053 0.013 0.067

-99 4.107 1.027 0.007 0.033

-100 4.000 1.000 0.000 0.000

Analog Output Reference Table

3 - 2

°C Ohms Difference

-100 602.60 4.10

-99 606.70 4.10

-98 610.70 4.00

-97 614.80 4.10

-96 618.70 4.10

-95 622.90 4.20

-94 626.90 4.00

-93 631.00 4.10

-92 635.00 4.00

-91 639.10 4.10

-90 643.00 3.90

-89 647.00 4.00

-88 651.10 4.10

-87 655.10 4.00

-86 659.10 4.00

-85 663.10 4.00

-84 667.20 4.10

-83 671.20 4.00

-82 675.20 4.00

-81 679.20 4.00

-80 683.30 4.10

-79 687.30 4.00

-78 691.30 4.00

-77 695.30 4.00

-76 699.30 4.00

-75 703.30 4.00

-74 707.30 4.00

-73 711.30 4.00

-72 715.30 4.00

-71 719.30 4.00

-70 723.30 4.00

-69 727.30 4.00

-68 731.30 4.00

-67 735.30 4.00

-66 739.30 4.00

-65 743.30 4.00

-64 747.30 4.00

-63 751.30 4.00

-62 755.30 4.00

°C Ohms Difference

-61 759.30 4.00

-60 763.30 4.00

-59 767.30 4.00

-58 771.30 4.00

-57 775.20 3.90

-56 779.20 4.00

-55 783.20 4.00

-54 787.20 4.00

-53 791.10 3.90

-52 795.10 4.00

-51 799.10 4.00

-50 803.10 4.00

-49 807.00 3.90

-48 811.00 4.00

-47 815.00 4.00

-46 818.90 3.90

-45 822.90 4.00

-44 826.90 4.00

-43 830.80 3.90

-42 834.80 4.00

-41 838.80 4.00

-40 842.70 3.90

-39 846.70 4.00

-38 850.60 3.90

-37 854.60 4.00

-36 858.50 3.90

-35 862.50 4.00

-34 866.40 3.90

-33 870.40 4.00

-32 874.30 3.90

-31 878.30 4.00

-30 882.20 3.90

-29 886.20 4.00

-28 890.10 3.90

-27 894.00 3.90

-26 898.00 4.00

-25 901.90 3.90

-24 905.90 4.00

-23 909.80 3.90

°C Ohms Difference

-22 913.70 3.90

-21 917.70 4.00

-20 921.60 3.90

-19 925.50 3.90

-18 929.50 4.00

-17 933.40 3.90

-16 937.30 3.90

-15 941.20 3.90

-14 945.20 4.00

-13 949.10 3.90

-12 953.00 3.90

-11 956.90 3.90

-10 960.90 4.00

-9 964.80 3.90

-8 968.70 3.90

-7 972.60 3.90

-6 976.50 3.90

-5 980.40 3.90

-4 984.40 4.00

-3 988.30 3.90

-2 992.20 3.90

-1 996.10 3.90

0 1000.00 3.90

1 1003.90 3.90

2 1007.80 3.90

3 1011.70 3.90

4 1015.60 3.90

5 1019.50 3.90

6 1023.40 3.90

7 1027.30 3.90

8 1031.20 3.90

9 1035.10 3.90

10 1039.00 3.90

11 1042.90 3.90

12 1046.80 3.90

13 1050.70 3.90

14 1054.60 3.90

15 1058.50 3.90

16 1062.40 3.90

°C Ohms Difference

17 1066.30 3.90

18 1070.20 3.90

19 1074.00 3.80

20 1077.90 3.90

21 1081.80 3.90

22 1085.70 3.90

23 1089.60 3.90

24 1093.50 3.90

25 1097.30 3.80

26 1101.20 3.90

27 1105.10 3.90

28 1109.00 3.90

29 1112.80 3.80

30 1116.70 3.90

31 1120.60 3.90

32 1124.50 3.90

33 1128.30 3.80

34 1132.20 3.90

35 1136.10 3.90

36 1139.90 3.80

37 1143.80 3.90

38 1147.70 3.90

39 1151.50 3.80

40 1155.40 3.90

41 1159.30 3.90

42 1163.10 3.80

43 1167.00 3.90

44 1170.80 3.80

45 1174.70 3.90

46 1178.50 3.80

47 1182.40 3.90

48 1186.20 3.80

49 1190.10 3.90

50 1194.00 3.90

RTD Temperature

vs. Resistance Table

For European Curve, Alpha = .00385, ITS-90 1° Celsius Increments

Source: http://www.omega.com/temperature/Z/pdf/z252-254.pdf

Other manuals for 8600 Series

1

Table of contents

Other Thermo Electron Freezer manuals