Thermo Electron Forma POWERFREEZE 840 Operating instructions

Forma®POWERFREEZE™

Ultra Low Temperature Freezer

Operating and Maintenance Manual

Manual Number 7000840 Rev. 1

FORMA

PowerFREEZE

ULT Freezer

Manual Number 7000840

1 23014 11/29/05 Changed circuit breaker (revised parts list) for 120V units aks

-- -- 6/14/05 Updated contact information aks

0 -- 9/29/04 Modified 89002416-d for Forma brand aks

Revision ECN/ECR Date Description By

Forma®POWERFREEZE™

Ultra Low Temperature Freezer

Operating and Maintenance Manual

Manual Number 7000840 Rev. 1

Thermo Electron Corporation

Packing List

(1) POWERFREEZE freezer

(1) Operating and maintenance manual 7000840

(1) Ice scraper 86000542

(1) Fuse 26387029

(1) 9 point connector adapter 86001821

(2) Door keys

(2) Anti-skid pads for leveling feet 85241913

(1) 17/19 spanner (wrench) for leveling feet 26178039

(1) Door opening limiter 51245425

(1) 8/10 spanner (wrench) for door opening limiter 26178026

(1) Back spacers 85230074

iii Forma®POWERFREEZE™Thermo Electron Corporation

Preface

Thermo Electron Corporation Forma®POWERFREEZE™ivThermo Electron Corporation

Preface

Caution Read this instruction manual. Failure to read, understand and

follow the instructions in this manual may result in damage to the unit,

injury to operating personnel, and poor equipment performance. V

Caution All internal adjustments and maintenance must be performed by

qualified service personnel. V

Important Refer to the serial tag on the back of this manual. V

Note The material in this manual is for information purposes only. The

contents and the product it describes are subject to change without notice.

Thermo Electron Corporation makes no representations or warranties with

respect to this manual. In no event shall Thermo be held liable for any

damages, direct or incidental, arising out of or related to the use of this

manual. V

Important operating and/or maintenance instructions. Read the

accompanying text carefully. V

Potential electrical hazards. Only qualified persons should perform

procedures associated with this symbol. V

Equipment being maintained or serviced must be turned off and locked

off to prevent possible injury. V

Hot surface(s) present which may cause burns to unprotected skin, or to

materials which may be damaged by elevated temperatures. V

Always use proper protective equipment (clothing, gloves, goggles, etc.) V

Always dissipate extreme cold or heat and wear protective clothing. V

Always follow good hygiene practices. V

Each individual is responsible for his or her own safety. V

Thermo Electron Corporationv Forma®POWERFREEZE™Thermo Electron Corporation

Preface

Warranty

The Warranty Period starts two weeks from the date your equipment is

shipped from our facility. This allows for shipping time so the warranty

will go into effect at approximately the same time your equipment is

delivered. The warranty protection extends to any subsequent owner

during the warranty period.

During the first two years of the warranty period, component parts proven

to be non-conforming in materials or workmanship will be repaired or

replaced at Thermo's expense, labor included. The freezer has an additional

two year warranty on the compressors, parts only, F.O.B. factory.

Installation and calibration is not covered by this warranty agreement. The

Technical Services Department must be contacted for warranty

determination and direction prior to any work being performed.

Expendable items, i.e., glass, filters, pilot lights, light bulbs and door

gaskets are excluded from this warranty.

Replacement or repair of component parts or equipment under this

warranty shall not extend the warranty to either the equipment or to the

component part beyond the original two year warranty period. The

Technical Services Department must give prior approval for the return of

any components or equipment.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER

WARRANTIES, WHETHER WRITTEN, ORAL, OR IMPLIED. NO

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE SHALL APPLY. Thermo shall not be liable for

any indirect or consequential damages including, without limitation,

damages relating to lost profits or loss of products.

Your local Thermo Sales Office is ready to help with comprehensive site

preparation information before your equipment arrives. Printed instruction

manuals carefully detail equipment installation, operation, and preventive

maintenance.

If equipment service is required, please call your Technical Services

Department at 1.888.213.1790 (USA and Canada) or 1.740.373.4189.

We're ready to answer your questions on equipment warranty, operation,

maintenance, service, and special applications. Outside the USA contact

your local distributor for warranty information.

Forma®POWERFREEZE™viThermo Electron Corporation

Table of Contents

Packing List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Use and Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

General Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Freezing System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Storing System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Inner Chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Outer Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Casters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Outer Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Chamber Gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Storage Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

CO2Backup System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Back Spacer Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Door Opening Limiter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Positioning the Leveling Feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Optional Recorder Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Changing the Recorder Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Installing Chart Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Calibrate Chart Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Section 1

Section 2

vii Forma®POWERFREEZE™Thermo Electron Corporation

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Inner Dimensions/ Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Chamber Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Packaging Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Operating Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Instruction for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Temperature Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Fault Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

High Temperature Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Communication Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Service Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Discarding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Cleaning the Condenser Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Service and Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

Door Seal Defrosting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

Chamber Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

Table of Contents

Section 3

Section 4

Section 5

Section 6

Section 7

General Presentation

Forma®POWERFREEZE™1-1Thermo Electron Corporation

Section 1 Use and Function

POWERFREEZE™ ULT Freezers are designed to freeze samples from

ambient temperature and to maintain them at a temperature as low as

-86°C. At -70°C, the metabolism of most biological samples is virtually

stopped.

These samples can be stored several months or years without altering their

properties.

The Forma POWERFREEZE freezers are designed to optimize thermal

transfer from the sample to guarantee their optimal storage conditions. The

POWERFREEZEdesign is a unique combination of a freezing system and

storage system which places a cooling coil in the top of each compartment.

FORMA

PowerFREEZE

ULT Freezer

Figure 1-1. Location of Main Components

Display

Handle

Optional

temperature

recorder

Control panel

Condenser filter access grille

Grille

Safety and

communication

devices

Electrical

connection

Power switch-

mains disconnect

General Description

Outer Door

Inner Chamber

Storing System

Insulation

Freezing System

1-2 Forma®POWERFREEZE™Thermo Electron Corporation

Section 1

Use and Function

The freezing system contains:

• Material: anodized aluminum (upper plate)

• Concept: plain upper plate, perforated bottom plate

• Cooling coils inserted in the sandwich shelf

The storing system contains:

• 4 independent compartments closed by 4 insulated inner doors

• Material: painted steel; insulation: polyurethane, thickness 0.39 inches

(10 mm)

• Magnetic closing system and “easy opening” knob

The insulation construction consists of the following material:

• Concept: 5 blocks of polyurethane 0%CFC; thickness 4.7 inches

(120 mm)

The inner chamber has the following characteristics:

• Stainless steel

• Access for CO2back-up injection

• Access for probe of 7-day recorder or extra monitoring sensor.

• Single outer door.

• Insulation thickness: 3.5 inches (90 mm)

• Insulation material: Polyurethane

• Door opening limiter located on the top left of the door. The freezer

is delivered without door opening limiter installed. After unpacking

unit, install door opening limiter to avoid damaging door hinges.

Forma®POWERFREEZE™1-3Thermo Electron Corporation

Section 1

Use and Function

• Two lip, easily changed chamber gasket

• Material: high flexibility silicone

• Material: powder coated painted steel

• Low-force single-handed operation handle

• Lock and keys (2)

• 4 rotating casters

• 2 leveling feet with anti-skid pads to prevent freezer from moving

Chamber Gasket

Outer Body

Handle

Casters

Options and

Accessories Options and accessories for the POWERFREEZE ULT freezer include

storage systems, CO2backup and seven day chart recorder.

The following table gives the dimensions, the catalog numbers and the

capacity of the freezer for each type of rack.

Table 1-1. Rack Specifications

1-4 Forma®POWERFREEZE™Thermo Electron Corporation

Section 1

Use and Function

Storage Systems

920015 Standard rack for 2" boxes, no boxes 5.3 x 10.875 x 16.5 16

820015 Standard rack for 2" boxes, with boxes 5.3 x 10.875 x 16.5 16

920018 Standard rack for 2" boxes, no boxes 5.3 x 10.875 x 22 16

820018 Standard rack for 2" boxes, with boxes 5.3 x 10.875 x 22 16

920198 Standard rack for 2" boxes, no boxes 5.3 x 10.875 x 28 16

820198 Standard rack for 2" boxes, with boxes 5.3 x 10.875 x 28 16

920009 Standard rack for 3" boxes, no boxes 5.3 x 10.875 x 16.5 16

820009 Standard rack for 3" boxes, with boxes 5.3 x 10.875 x 16.5 16

920017 Standard rack for 3" boxes, no boxes 5.3 x 10.875 x 22 16

820017 Standard rack for 3" boxes, with boxes 5.3 x 10.875 x 22 16

920197 Standard rack for 3" boxes, no boxes 5.3 x 10.875 x 28 16

820197 Standard rack for 3" boxes, with boxes 5.3 x 10.875 x 28 16

920094 Drawer-style rack for 2" boxes, no boxes 5.5 x 11.9 x 16.6 12

820094 Drawer-style rack for 2" boxes, with boxes 5.5 x 11.9 x 16.6 12

920096 Drawer-style rack for 2" boxes, no boxes 5.5 x 11.9 x 22 12

820096 Drawer-style rack for 2" boxes, with boxes 5.5 x 11.9 x 22 12

920090 Drawer-style rack for 2" boxes, no boxes 5.5 x 11.8 x 26.3 16

820090 Drawer-style rack for 2" boxes, with boxes 5.5 x 11.8 x 26.3 16

920095 Drawer-style rack for 3" boxes, no boxes 5.5 x 11.9 x 16.6 12

820095 Drawer-style rack for 3" boxes, with boxes 5.5 x 11.9 x 16.6 12

920097 Drawer-style rack for 3" boxes, no boxes 5.5 x 11.9 x 22 12

820097 Drawer-style rack for 3" boxes, with boxes 5.5 x 11.9 x 22 12

920091 Drawer-style rack for 3" boxes, no boxes 5.5 x 11.8 x 25.8 16

820091 Drawer-style rack for 3" boxes, with boxes 5.5 x 11.8 x 25.8 16

830012 Multi-drawer rack 11.2 x 11.5 x 11 1 per shelf 1 per shelf 1 per shelf

830030 Storage container 7 x 5.3 x 18.1 24 24

830032 Storage container 7 x 5.3 x 22.6 24

820030 30 position deepwell microplate rack 5.3 x 9.5 x 22 16 16

820036 36 position deepwell microplate rack 5.3 x 12 x 22 16 16

820066 66 position microplate rack 5.3 x 9.6 x 22 16 16

820002 2" cardboard box

820003 3" cardboard box

820064 64 cell divider

820081 81 cell divider

820100 100 cell divider

Dimensions (inches)

Part No. Description W x H x F-B 840/841 842/843 844/845

Forma®POWERFREEZE™1-5Thermo Electron Corporation

Section 1

Use and Function

CO2back-up (Part Number 195814 Qualified Installation 115V, 195815

Qualified Installation 208V)

The CO2back-up system is designed to maintain the sample temperature

below -60°C for several hours by injecting CO2into the freezer chamber.

The CO2back-up must be installed by qualified personnel.

7-day temperature recorder (Stock Number 201276 Qualified Installation,

201277 Factory Installed)

Available for the POWERFREEZE is a 7-day temperature recorder with

independent probe. The temperature recorder must be installed by

qualified personnel.

Replacement recorder chart paper can be purchased from Thermo

Electron. Order stock number 17020 - 6 inch, 7 day, -100°C to +38°C

circular chart paper.

Replacement pens are also available. Order stock number 245231 - Short

length red fiber tip pen and 245232 - Medium length blue fiber tip pen.

CO2Backup System

Recorder

Forma®POWERFREEZE™2-1Thermo Electron Corporation

Section 2 Installation

Due to the weight of the freezer, all lifting and transporting must be done

by trained personnel using proper handling equipment that complies with

current regulations.

The freezer must be supported from underneath. If it has to be transported

without its pallet, for example on a staircase, professional handling is

required.

1. Remove the straps and the cling film. Remove the plank located on the

top of the freezer. Unscrew the nuts and remove the side bar by tilting

the machine slightly.

2. Place the plank sideways in contact with the pallet and in line with the

wheels of the machine. Remove the freezer from the pallet by rolling it

down the plank.

Note Two people are needed for this operation. V

Figure 2-1. Unpacking

Unpacking

Plank

Straps

Nuts

Side bar

Pallet

Plank

Back Spacer

Installation

2-2 Forma®POWERFREEZE™Thermo Electron Corporation

Section 2

Installation

Install the back spacers as shown below to allow proper air circulation at

the back of the freezer when positioned against a wall.

Figure 2-2. Back Spacers Installed

1. Never transport the freezer on its side.

2. Check that no accessories or printed material are left in the packaging.

3. Install the freezer in a suitable environment :

a. To ensure proper ventilation of the refrigeration system and

guarantee correct functioning of the freezer, it is extremely

important not to place any object within 8 inches of the front,

back or side ventilation grilles (see Back Spacer Installation).

b. The room should be well ventilated and include mechanical air

exhaust if the optional CO2back-up is in use. The environment

must be non-corrosive and the floor must be level.

4. Check that the mains voltage corresponds to the freezer’s voltage.

5. After locating the instrument, install non-skid pads.

Installation

Door Opening Limiter To install the door opening limiter:

1. Align the holes of two plastic washers and two spacers with those on

the body of the freezer and the door.

2. Position the limiter as shown in Figure 2-3 and secure in place with the

two bolts and washers, using the box spanner (wrench).

3. Check that the limiter slides easily.

Figure 2-3. Door Opening Limiter

Forma®POWERFREEZE™2-3Thermo Electron Corporation

Section 2

Installation

Bolt

Plastic

washer

Washer

Spacer

Limiter

Door

Body

2-4 Forma®POWERFREEZE™Thermo Electron Corporation

Section 2

Installation

If the freezer has an optional 7-day recorder, a power cable must be

connected before use. To connect power to the recorder:

1. Disconnect power to the freezer.

2. Open the condenser filter access grille located at the lower front of the

freezer (see Figure 1-1).

3. Locate the cable extending from the recorder and connect to the cable

secured to the bottom of the compressor compartment (mate-n-lock

connection).

4. Replace the front grille.

Optional Recorder

Connection

There are two leveling feet located at the front of the freezer.

1. Unscrew the leveling feet.

2. Place an anti-skid pad beneath each one (2 anti-skid pads are

provided).

3. Using the 19 mm spanner provided with the freezer, continue to

unscrew the leveling feet until the front of the freezer is lifted about

one millimeter.

4. Check the stability of the freezer by opening the door, then watching it

close. Adjust the height of the feet accordingly.

Positioning the

Leveling Feet

Figure 2-4. Leveling Feet

Installing Chart Paper 1. Open the glass door of the recorder and press button #3 until the pen

begins to move outward.

2. Unscrew the knob at the center of the chart and remove the paper.

3. Install the new chart paper, position the paper to the correct time line

and replace the knob.

4. Remove the cap from the felt pen and press button #3.

The chart recorder contains eight temperature ranges and is factory-

programmed for the freezer.

1. Press and hold button #3 for one second, then let the pen move off the

chart paper.

2. Press and hold for five seconds either button #1 or button #2.

3. Release the button and the green LED will begin to flash. Count the

number of flashes to determine the present program setting.

4. To change the program setting, press the left or right arrows to increase

or decrease the count.

5. When the desired program number is flashing, press button #3 to

bring the pen arm back onto the chart. Recording will begin in the

new program.

Table 2-1. Chart Recorder Program Ranges

Forma®POWERFREEZE™2-5Thermo Electron Corporation

Section 2

Installation

Changing the Recorder

Range

Program From To

1-40 30°C

2 0 60°C

3-100 38°C

4-5 50°C

5 0 100°C

6-100 200°C

7-115 50°C

8-10 70°C

The recorder must be in service for 24 hours before performing the

following calibration procedure.

1. Place an accurate thermometer in the chamber next to the recorder

probe.

2. Temperature probes for the recorder are located in the left front corner

of the freezer chamber (Figure 2-6).

Figure 2-6. Recorder Probe Placement

3. After about three minutes, compare the thermometer reading with the

chart recorder reading.

4. If an adjustment is necessary, press the #1 button to move the pen to

the left or the #2 to move the pen to the right. The button must be

held about five seconds before the pen begins to move. Release the

button when the pen position matches the thermometer.

Note The felt-tip pen on the recorder requires periodic replacement.

Usually the ink will appear to fade before replacement becomes necessary.

Additional pen tips may be purchased. V

2-6 Forma®POWERFREEZE™Thermo Electron Corporation

Section 2

Installation

Calibrate Chart Recorder

Freezer probe Recorder probe

Chamber tube

Start-Up

Power Connection See the serial tag on the side of the unit for electrical specifications. The

freezer should be operated on a dedicated grounded service. Check the

voltage rating on the serial tag of the unit and compare it with the outlet

voltage.

Warning For personal safety, this apparatus must be properly grounded. V

The power cord provided on this unit is equipped with a three-prong plug

which mates with a standard three prong grounding wall receptacle to

minimize the possibility of electric shock hazard. The wall receptacle and

circuit should be checked by a qualified electrician to ensure that the

receptacle can provide adequate current and is properly grounded.

Where a standard two-prong wall receptacle is encountered, it is the

personal responsibility and obligation of the user to have it replaced with a

properly grounded three-prong wall receptacle. Do not under any

circumstances cut or remove the third (ground) prong from the power

cord. Do not use a two-prong adapter plug.

Note Colors of wires in mains cable: black 1 = Line , white 2 = Neutral,

Earth/Ground = yellow; green. V

Before turning on the freezer, install the fuse located at the back of the

freezer.

Turn on the freezer by activating the power switch located in the back of

the unit. On start-up of the freezer, the display shows the chamber

temperature and the visual and audible alarms are activated. During

temperature stabilization, the audible alarm may be temporarily silenced

by pressing the mute key.

During the cooling procedure, the freezer displays the chamber

temperature.

It takes about 6 hours to cool down the freezer from +20°C to -80°C.

Forma®POWERFREEZE™2-7Thermo Electron Corporation

Section 2

Installation

This manual suits for next models

5

Table of contents

Other Thermo Electron Freezer manuals

Popular Freezer manuals by other brands

Matsui

Matsui MUF48W13E instruction manual

Frigidaire

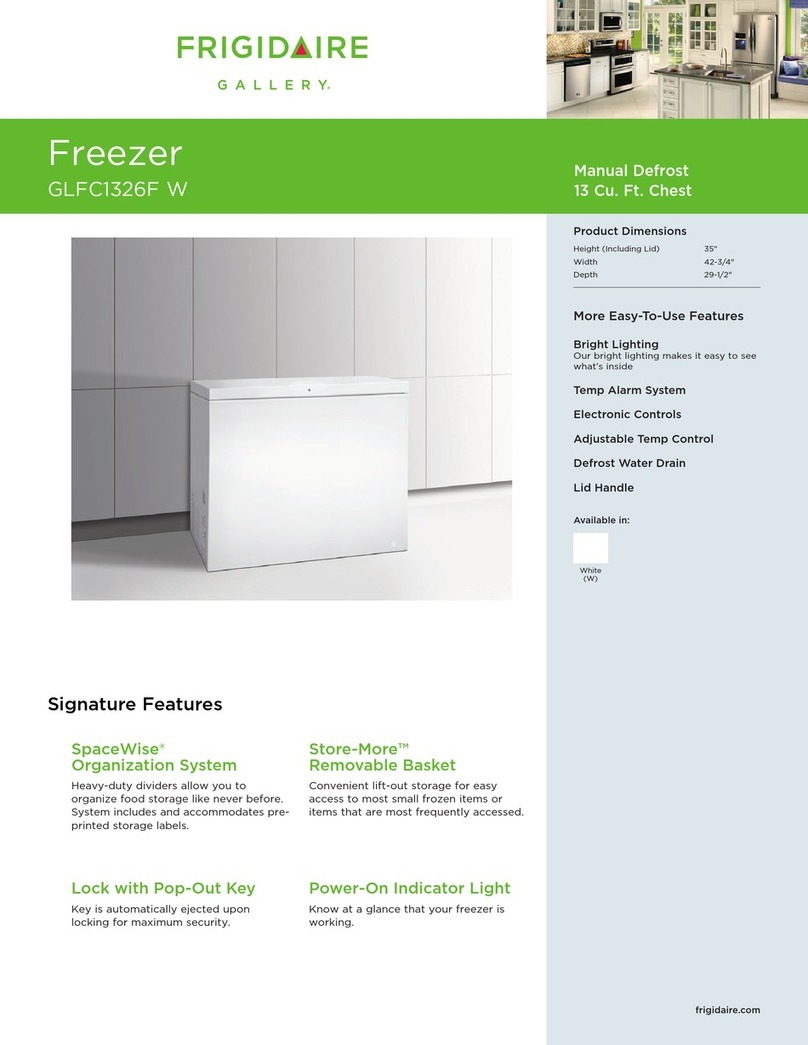

Frigidaire GLFC1526FW - 14.8 cu.ft. Manual Defrost Chest... Features & dimensions

AEG

AEG SANTO 70322 KG operating instructions

Campingaz

Campingaz Smart Cooler Electric 20 l Instruction leaflet

Veripart

Veripart VRIEZER VPVR144NFE user manual

Bosch

Bosch GIN81H Series INFORMATION FOR USE