Thermo GasTech HS-95 Manual

95 Series

Operator’s Guide

Personal Portable Gas Monitor

HS-95, CO-95, OX-95

ii 71-0011 — REV E

PROPRIETARY STATEMENT

Thermo GasTech owns proprietary rights in the information disclosed within. By

receiving this document, the recipient agrees that neither this document nor the

information disclosed within nor any part shall be reproduced or transferred to other

documents or used or disclosed to others for manufacturing or for any other purpose

except as specifically authorized in writing by Thermo GasTech.

COPYRIGHT STATEMENT

Information contained in this document is protected by copyright. No part of this

document may be photocopied, reproduced, or translated to another program or

system without prior written authorization from Thermo GasTech., © 2001,

Thermo GasTech.

TRADEMARK STATEMENT

Protected through use and/or registration in the United States and many foreign

countries are the trademarks and service marks of Thermo GasTech. The use of the

® symbol indicates registration in the United States only; registrations may not

have been issued at present in other countries. All other product names and logos

are trademarks of their respective owners.

GASTECH®is a trademark of Thermo GasTech and is registered with the U.S.

Patent and Trademark Office.

DISCLAIMER

Under no circumstances will Thermo GasTech be liable for any claims, losses, or

damages resulting from or arising out of the repair or modification of the equipment

by a party other than Thermo GasTech or its authorized service representatives, or

by operation or use of the equipment other than in accordance with the printed

instructions provided by Thermo GasTech or if the equipment has been improperly

maintained or subject to neglect or accident. Any of the foregoing will void the

warranty.

EXPORT STATEMENT

Export of the information and products in this manual from the U.S.A., or re-export

from another country, may require written authorization from the U.S. Department

of Commerce. Printed in the U.S.A.

REVISIONS TO MANUAL

All information contained in this manual is believed to be true and correct at the

time of printing. However, as part of its continuing efforts to improve its products

and their documentation, Thermo GasTech reserves the right to make changes at

any time without notice. Any revised copies of this manual can be obtained by

writing Thermo GasTech.

71-0011— REV E iii

WARNING

NOTATION CONVENTIONS

Notices are used in this operator’s guide to alert you to hazardous

conditions to person or instrument and to notify you of additional

information. This operator’s guide uses the following notices:

WARNING

Notifies you of potential danger of personal injury.

CAUTION

Notifies you of potential damage to equipment.

NOTE

Notifies you of additional or critical information.

T

HIS

INSTRUMENT

IS

DESIGNED

TO

DETECT

ONE

OR

MORE

OF

THE

FOLLOWING

:

FLAMMABLE

VAPORS

,

OXYGEN

CONTENT

,

AND

/

OR

TOXIC

GAS

AND

TO

GIVE

WARNING

BEFORE

THEY

REACH

HARMFUL

CONDITIONS

.

IN

ORDER

TO

ENSURE

THAT

IT

WILL

WARN

OF

DANGEROUS

CONCENTRATIONS

,

IT

IS

ESSENTIAL

THAT

THE

INSTRUCTIONS

IN

THIS

MANUAL

,

PARTICULARLY

THOSE

CONCERNING

START

UP

,

OPERATION

,

CALIBRATION

,

AND

MAINTENANCE

,

BE

READ

,

UNDERSTOOD

,

AND

FOLLOWED

.

iv 71-0011 — REV E

SERVICE POLICY

Thermo GasTech maintains an instrument service facility at the

factory as well as authorized service facilities around the world.

Shouldyourinstrumentrequireservice,youmaycontactustollfree

at1-877-GASTECH(427-8324)forUSonlyor1-510-745-8700,

orvisitourwebsitewww.thermogastech.comforauthorizedservice

locations.

For warranty ornon-warranty repairs,call us to complete a Return

Material Authorization (RMA) form, obtain billing and shipping

informationandtellusthenatureoftheproblem.Fornon-warranty

repairs, you will need to provide a purchase order number. If you

needtosetalimittotherepairscosts,statea“NottoExceed”figure.

If you need a quotation before you can authorized the repair costs,

so state, but understand this will incur additional costs and may

delay processing of the repair.

Youmaysendtheunit,prepaid,to:ThermoGasTech,8407Central

Ave., Newark, CA 94560-3431, Attn.: Service Department.

EnclosethecopyoftheRMA(ReturnMaterialAuthorization)that

was previously faxed to you. Pack the instrument and all its

accessories (preferably in its original packing) and any special

instructions.

Repairs are warranted for 90 days from the date of shipment.

Sensors have individual warranties.

NOTE

Thermo GasTech assumes no liability for work performed by

unauthorized service facilities.

71-0011— REV E v

WARRANTY STATEMENT

Thermo GasTech (the “Company”) warrants that the Products will

operate substantially in conformance with the Company’s published

specifications, when subjected to normal, proper, and intended usage by

properly trained personnel, for a period of one (1) year after shipment to

Customer (the “Warranty Period”). The Company agrees during the Warranty

Period, provided it is promptly notified in writing upon the discovery of any

defect and further provided that all costs of returning the defective Products to

the Company are prepaid by Customer, to repair or replace, at the Company’s

option, defective products so as to cause the same to operate in substantial

conformance with said specifications. Replacement parts may be new or

refurbished, at the election of the Company. All replaced parts shall become

the property of the Company.

Lamps, pump diaphragms/valves, batteries, fuses, bulbs, and other expendable

items are expressly excluded from the warranty.

The Company’s sole liability with respect to equipment, materials, parts, or

software furnished to the Company by third party suppliers shall be limited to

the assignment by the Company to Customer of any such third-party

supplier’s warranty, to the extent the same is assignable. In no event shall the

Company have any obligation to make repairs, replacements, or corrections

required, in whole or in part, as the result of (i) normal wear and tear, (ii)

accident, disaster, or event of force majeure, (iii) misuse, fault, or negligence

of or by Customer, (iv) use of the Products in a manner for which they were

not designed, (v) causes external to the Products such as, but not limited to,

power failure or electrical power surges, or (vi) use of the Products in

combination with equipment or software not supplied by the Company.

ANY INSTALLATION, MAINTENANCE, REPAIR, SERVICE,

RELOCATION, OR ALTERATION TO OR OF, OR OTHER TAMPERING

WITH, THE PRODUCTS PERFORMED BY ANY PERSON OR ENTITY

OTHER THAN THE COMPANY WITHOUT THE COMPANY’S PRIOR

WRITTEN APPROVAL, OR ANY USE OF REPLACEMENT PARTS NOT

SUPPLIED BY THE COMPANY, SHALL IMMEDIATELY VOID AND

CANCEL ALL WARRANTIES WITH RESPECT TO THE AFFECTED

PRODUCTS.

THE OBLIGATION TO REPAIR OR REPLACE A DEFECTIVE

PRODUCT SHALL BE THE SOLE REMEDY OF CUSTOMER IN THE

EVENT OF A DEFECTIVE PRODUCT. EXCEPT AS EXPRESSLY

PROVIDED IN THIS SECTION, THE COMPANY DISCLAIMS ALL

WARRANTIES, WHETHER EXPRESS OR IMPLIED, ORAL OR

WRITTEN, WITH RESPECT TO THE PRODUCTS, INCLUDING

WITHOUT LIMITATION ALL IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR

PURPOSE. THE COMPANY DOES NOT WARRANT THAT THE

PRODUCTS ARE ERROR-FREE OR WILL ACCOMPLISH ANY

PARTICULAR RESULT.

vi 71-0011 — REV E

71-0011 — REV E vii

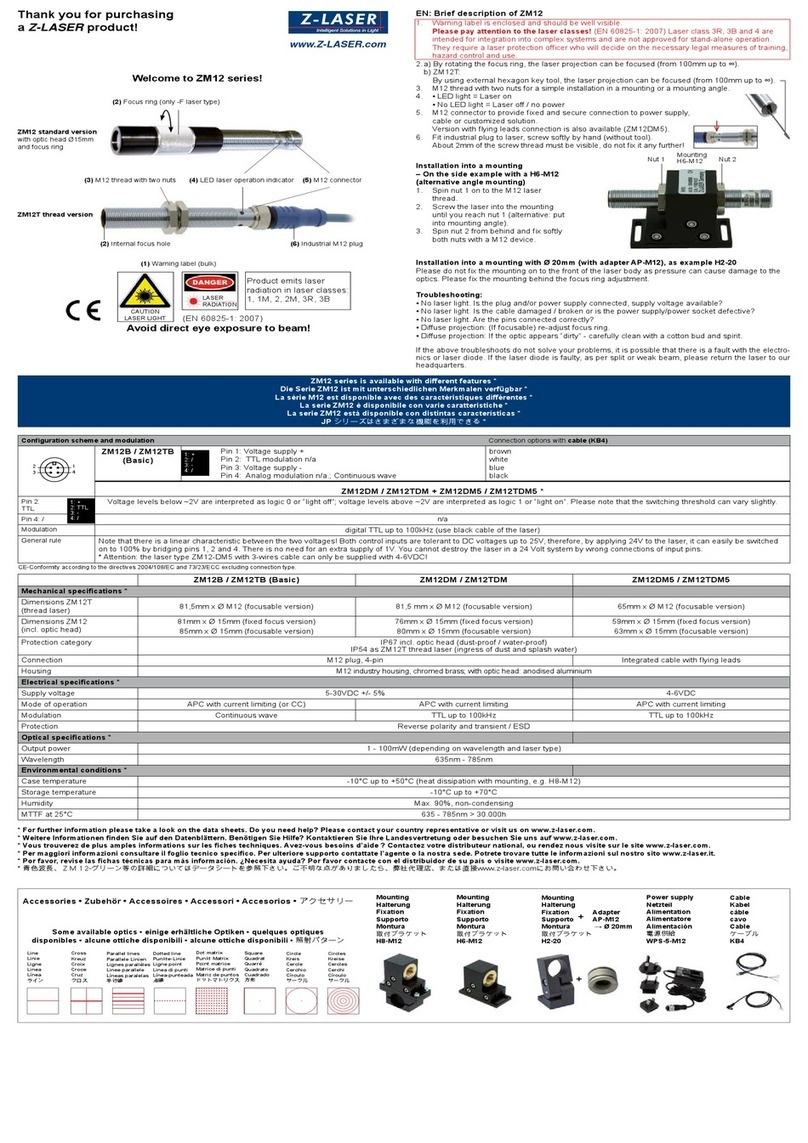

TABLE OF CONTENTS

Chapter 1 INTRODUCTION............................................. 1-1

OVERVIEW ............................................................ 1-1

DESCRIPTION........................................................ 1-1

SPECIFICATIONS..................................................1-2

Chapter 2 PHYSICAL DESCRIPTION........................... 2-1

OVERVIEW ............................................................ 2-1

PHYSICAL DESCRIPTION...................................2-1

Electronics Assembly .........................................2-3

Buzzer.................................................................2-4

Housing/Housing Gasket.................................... 2-4

Sensor ................................................................. 2-5

Battery Compartment.......................................... 2-5

Chapter 3 START UP & OPERATION ........................... 3-1

OVERVIEW ............................................................ 3-1

START UP...............................................................3-2

INSTRUMENT OPERATION ................................3-3

Alarm Indications ............................................... 3-3

Low or Dead Battery Indications........................3-4

Weak or Failed Sensor Indications.....................3-5

INTERFERENCE CHARTS ...................................3-6

OPTIONAL ACCESSORIES..................................3-8

Hand-aspirated Sample-draw Adapter................3-8

Earphone............................................................. 3-9

Vibrating Alarm.................................................. 3-9

viii 71-0011 — REV E

Chapter 4 CALIBRATION & MAINTENANCE............ 4-1

OVERVIEW ............................................................ 4-1

TEST KIT ................................................................4-2

Test Gas Cylinders..............................................4-2

H2S Regulator (for HS-95).................................4-2

Dispensing Valve (for CO-95 and OX-95)......... 4-2

Flowmeter (for CO-95 and OX-95).................... 4-3

Test Cup..............................................................4-3

Tubing................................................................. 4-3

Test Kit Instruction Sheet................................... 4-3

CALIBRATION PROCEDURES............................4-3

Preparing for Calibration (all models)................ 4-4

How to Use the Control Buttons.........................4-4

Calibration (HS-95, CO-95) ...............................4-6

Calibration (OX-95)............................................ 4-7

If Calibration Fails..............................................4-8

Switch to Default Zero (OX-95)......................... 4-9

Return to Normal Operation.............................4-10

MAINTENANCE ..................................................4-11

How to Open and Close Your Monitor............. 4-11

Troubleshooting Guide..................................... 4-12

Changing Alarm Setpoints................................4-13

Changing the Alarm Delay...............................4-14

Replacing Defective Components .................... 4-14

FRUs AND ACCESSORIES LIST........................4-19

71-0011 — REV E 1-1

INTRODUCTION

OVERVIEW

This Operator’s Guide provides information on the proper

set-up, use, calibration, and maintenance of the 95 Series of

single-gas monitoring instruments.

Chapter 2 contains a physical description of your monitor.

Instructions to use and interpret monitor readings are in

Chapter 3, Start Up and Operation. Chapter 4, Calibration

and Maintenance, also contains troubleshooting information

and a list of replacement part numbers.

DESCRIPTION

The 95 Series is a line of three personal, portable gas

monitors that each detect one gas. Each pocket-size

instrument detects either oxygen (O2), hydrogen sulfide

(H2S), or carbon monoxide (CO), and actuates an alarm to

alert you should the measured gas surpass the alarm setting.

Table 1-1 lists specifications for each model.

CHAPTER 1

95 Series Operators Guide

1-2 71-0011 — REV E

SPECIFICATIONS

** In range of ±2% O2from calibration point.

Specifications are subject to change without notice.

Table 1-1 95 Series Gas Monitor Specifications

Model Designation

(Gases Detected) OX-95 (0-30.0% O2in 0.1% increments)

HS-95 (0-100 ppm H2S in 1 ppm increments)

CO-95 (0-500 ppm CO in 1 ppm increments)

Detection Method Diffusion, electrochemical

Response Time

Accuracy

Repeatability

90% in 30 seconds

±5% of reading (±0.2% O2for OX-95**)

±3% of reading (±012% O2for OX-95**)

Gas Alarm Setpoints OX-95: 19.5% vol, decreasing, (programmable)

23.5% vol, increasing, (programmable)

HS-95: 10 ppm, and 15 ppm, (programmable)

CO-95: 25 ppm, 200 ppm, (programmable)

Gas Alarm Delay 3 sec. (programmable to 0, 1, 2, or 3 sec.)

Other Alarm Modes Weak or failed sensor, low or dead battery

Operator Controls - Powerswitch

- ZERO/- button

- SPAN/+ button

Dimensions

Weight 4.5 in. H x 2.5 in.W x 1.0 in. D

6.5 ounces

Battery Life

(approximate) Continuous, non-alarm operation per one 9V

alkaline battery:

OX-95: 3,200 hours

CO-95 and HS-95: 2,500 hours

Standard* and

Optional Accesso-

ries

Operator’s guide*, hand-aspirated sample-draw

adapter, earphone, test kits, vibrating alarm,

*strap.

Operating Tempera-

ture and Humidity -4º F (-20º C) to 113º F (45º C)

0-95% relative humidity (RH), non-condensing

Regulatory

Approvals UL classified; CSA classified

Class I, Division 1, Groups A, B, C, and D

DEMKO EEx ia IIB T2

71-0011 — REV E 2-1

PHYSICAL

DESCRIPTION

OVERVIEW

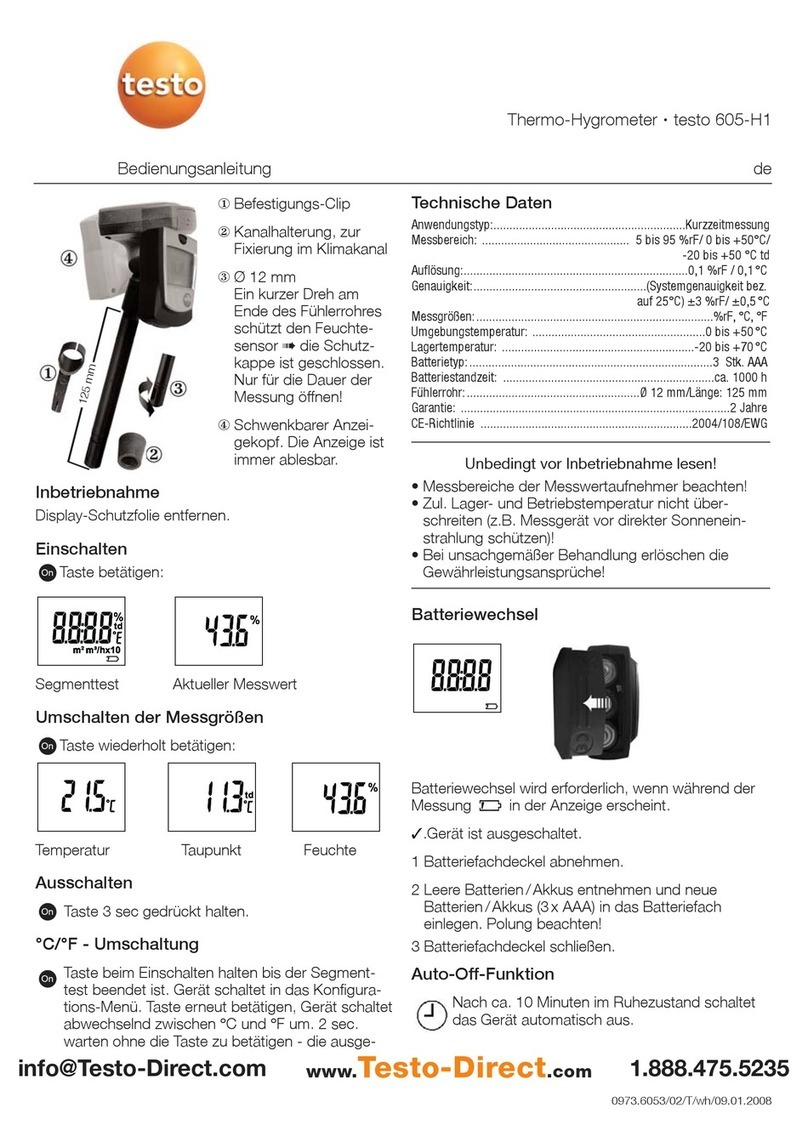

This chapter describes the physical components of your

95 Series gas monitor. For purposes of identification throughout

this guide, the monitor is described as having front and rear

housing halves, as shown in Figure 2-1.

PHYSICAL DESCRIPTION

To open your monitor, loosen the two captive screws on the rear

cover, then separate the two halves.

The components identified in Figure 2-1 are described in this

chapter. The field replaceable units (FRUs) include the housing

gasket, sensor, and battery.

CHAPTER 2

95 Series Operator’s Guide

2-2 71-0011 — REV E

Figure 2-1 Components of the 95 Series Gas Monitor

(Hydrophobic

membrane

behind grille) Sensor Port Buzzer Port

FRONT HOUSING

HOUSING GASKET

Operator Controls Cover

Earphone Jack Cover

ELECTRONICS ASSEMBLY:

Display Board

Display Cable

Main Board

Buzzer

Battery

Compartment

REAR HOUSING

Earphone Jack

Span Button

Power Switch

Zero Button

Plug-in

Sensor

LCD

Physical Description

71-0011 — REV E 2-3

Electronics Assembly

The electronics assembly consists of the main board, operator

controls (power switch, buttons, and earphone jack), display

board with liquid crystal display (LCD), and the display cable. If

any of these components fail, contact the factory for repair.

Main Board

All buttons and operator controls are part of the main board.

Control circuitry for other components is also located on the

main board.

ZERO/- and SPAN/+ Buttons

The ZERO/- button alone is used to zero the sensor and decrease

parameter settings. The SPAN/+ button alone is used to set

sensor span and increase parameter settings.

The ZERO/- and SPAN/+ buttons are pressed together to select

setting modes.

Power Switch

Set to the left position (toward the sensor) to turn the instrument

on. Set to the right position (away from the sensor) to turn the

instrument off.

Earphone/Vibrating Alarm Jack

The earphone or vibrating alarm accessory is connected to this

jack.

95 Series Operator’s Guide

2-4 71-0011 — REV E

Display Board/Display Cable

The display board is attached to the main board by a

nondetachable ribbon cable.

Liquid Crystal Display (LCD)

The LCD panel is visible through the window in the top of the

housing. A red LED is visible through the display panel as a

visual indication of alarm conditions. Display readings are

described in Chapter 3.

Buzzer

The buzzer is mounted on the main board.

Housing/Housing Gasket

The instrument housing is a two-piece plastic case held together

by two captive screws. A mylar gasket covers the operator

controls to keep water and dust away from the internal

components. The case is sealed using a detachable rubber gasket

and two flaps to protect the operator controls and earphone/

vibrating alarm jack.

The letters Z, P, and S on the inside of the flap identify the

position of the ZERO/- button, the power switch, and the SPAN/+

button, respectively. The arrow next to the P indicates the

direction to move the power switch to turn the instrument on and

off.

Physical Description

71-0011 — REV E 2-5

Sensor

Each model has a dedicated, detachable sensor that plugs into the

main board. Ahydrophobic (waterproof) membrane on the inside

of the case sensor opening is held down by a gasket. The

membrane permits diffusion of the surrounding atmosphere to

the sensor.

When sufficiently exposed to the target gas, the electrical output

of the sensor causes a reading on the display. Readings are in

parts per million (PPM) for H2S and CO, or percent (%) by

volume for O2.

Battery Compartment

The battery compartment houses a standard 9V alkaline battery.

95 Series Operator’s Guide

2-6 71-0011 — REV E

71-0011 — REV E 3-1

START UP &

OPERATION

OVERVIEW

This chapter describes the normal operation of your 95 Series gas

monitor, and how to respond to abnormal operation. Normal

operation is any time that start up has been completed, and the

monitor is not indicating an alarm, fault, or low battery condition.

This chapter also contains interference charts listing other gases

that can affect the sensor in the HS-95 or CO-95 monitor, and

procedures to use the optional accessories available for your

monitor.

CHAPTER 3

95 Series Operator’s Guide

3-2 71-0011 — REV E

START UP

Perform the following steps to start up your monitor. Refer to

Figure 2-1 as needed.

CAUTION

Perform start up only in a fresh air environment.

1. Flip open the housing gasket flap that covers the operator

controls, and move the power switch toward the sensor to

turn the monitor on. The unit should sound a single audible

tone, and display the installed version of software. A

number will then be displayed. Allow a few seconds for the

reading to stabilize, then check the display. If your HS-95 or

CO-95 shows a reading of 0 PPM, or your OX-95 a reading

of 20.9%, proceed to Step 4. If the reading is anything other

than this, perform Step 2 or 3, as appropriate.

2. Zero the HS-95 or CO-95 by pressing the ZERO/- button

until the PASS message appears (about 5 seconds).

3. Span the OX-95 by pressing the SPAN/+button until the

PASS message appears (about 5 seconds).

4. Close the operator controls flap. Your monitor is ready for

use.

Start Up & Operation

71-0011 — REV E 3-3

INSTRUMENT OPERATION

In normal operation, your instrument monitors the environment

and displays the current gas concentration. The instrument

displays alarms to indicate gas concentrations outside preset

limits. Low and dead battery as well as weak and failed sensor

conditions are also indicated.

NOTE

Momentary small negative gas readings are not abnormal with

the HS-95 and the CO-95. The instrument automatically corrects

itself.

Alarm Indications

When a gas concentration reaches the alarm setpoint, the alarm is

indicated by the buzzer pulsing, the red alarm light flashing, and

the gas reading blinking, all in unison. For the HS-95 and the

CO-95, the gas alarm is a pulsing audible tone with a blinking

reading for the low level alarm, and a steady audible tone with

pulsing display for the high level alarm. For the OX-95, you can

tell whether the alarm is a high or low alarm by the gas reading.

A high O2alarm shows a reading above the high setpoint, and is

signified by a pulsing audible tone. A low O2alarm shows a

reading below the low setpoint, and is signified by a steady

audible tone.

NOTE

Preset alarm setpoints conform to current OSHA standards, but

can be adjusted. See Chapter 4 for alarm adjust procedures.

95 Series Operator’s Guide

3-4 71-0011 — REV E

Recommended Action:

When an alarm occurs, follow the established procedure for an

alarm condition. If no procedure is in place, please establish one

that is appropriate for your application.

The alarm circuit is self-resetting. When the instrument is moved

from the suspect environment, the alarm ceases, and the

instrument returns to normal operation. However, this does not

mean that the danger has passed.

Low or Dead Battery Indications

Low Battery: When your monitor senses that the battery has

approximately 8 hours remaining, the word LOBAT blinks on the

LCD. In addition, the buzzer emits a short chirp and the red

alarm light flashes every 30 seconds.

Dead Battery: When the battery is past the point of useful

operation, LOBAT appears steadily on the LCD. In addition, the

buzzer sounds continuously and the red alarm light is on steady.

When these indications occur, the instrument is not operable.

Recommended Action:

Replace a dead battery immediately or a low battery as soon as

possible, following the procedure in Chapter 4.

Table of contents