Thermocell Topper 2413 User manual

Pag.1

OPERATING AND INSTALLATION INSTRUCTIONS

Remote control

Topper Mertik AB

Topper Dungs AB

ten behoeve van Topper Gasblokkenvuren

Applicable to the following Topper models:

2413, 2424, 3613, 4525, 4813 , 6013, 9013, 9513, 12013

Topper Steel:

5015 (1060)

8015 (1061)

10015 (1062)

12015 (1063)

14015 (1064)

GREAT BRITTAN-GB IRELAND-IE

Pag.2

1. General page 3

1.1 Contents of the packaging

2. Safety of the unit page 4

2.1 Safety

3. Remote control (Mertik GV60) page 5

3.1 General

3.2 Manual transmitter

3.3 Screen setup

3.4 Setting the time

3.5 Operation (Remote Control)

3.6 Possible error messages

3.7 Setting the flame size / Extinguishing the fire

3.8 Switching the unit off

3.9 Inserting and replacing the batteries

4. Manual operation page 8

4.1 Igniting the fire

4.2 Extinguishing the fire

4.3 Switching the unit off

5. Instructions for the Mertik Maxitrol GV60 and the Remote Control page 10

6. Technical details for the Mertik Maxitrol GV60 page 11

7. Mertik GV60 Troubleshooting Flow Chart page 13

8. Operating instructions for the Dungs AB combination page 16

8.1 Infra-red remote control and its operation

8.2 Igniting the gas fire

8.3 Basic system components

8.4 Connection of gas regulation block wiring

8.5 Adjusting the gas regulation block

8.6 Connecting to the mains supply

8.7 Chimney

8.8 Warning

9. Electrical and gas connection (Dungs) page 17

9.1 Electrical connection

9.2 Installation order for electrical connections

9.2.1 Basic gas regulation combination

9.3 Secured air supply and combustion gas exhaust system

9.4 Gas connection

9. Gas technical specifications for Topper burners 3613 to 12013 page 22

10. Gas technical specifications for Topper Steel burners 5015 to 14015 page 23

11. Maintenance check list page 24

12. Maintenance activities page 25

13. Installation instructions page 26

13.1 General instructions

13.2 Chimney

13.3 Warning

14. Installing the ceramic wood blocks - Standaard page 27

15. Installing the ceramic wood blocks –De Luxe page 27

16. Installing the ceramic wood blocks (butane) –De Luxe page 27

17. Covering burner 9013 with Basalt / Carrara stones page 28

18. Covering burners 9513 and 12013 with vermiculite, Basalt / Carrara stones page 28

19. Positioning ceramic wood blocks 9513 and 12013 page 28

20. Positioning ceramic wood blocks 5015 to 14015 page 28

21. Positioning pebble set - Topper Steel 5015 to 14015 page 28

22. Positioning the Basalt / Carrara stones - Topper Steel 5015 to 14015 page 38

Illustrations pages 29 - 38

ALL RIGHTS RESERVED.

(2/12042013)

Pag.3

We hope that you enjoy the warmth of your new Topper Burner. Read these instructions carefully before

installing and using the Topper Burner. Keep these instructions in a safe place. Always provide the follow-

ing information if the burner breaks down: model and serial number, which can be found on the unit.

Your receipt of purchase is your proof of warranty.

1. GENERAL

Check the unit immediately after delivery to confirm that it has not been damaged during transport. If it is dam-

aged in any way, please inform your supplier immediately and provide as many details as possible. Your Topper

Burner has been coated with heat-resistant enamel that can withstand extremely high temperatures. Allow the

Topper Burner to burn at the highest setting and ventilate the room thoroughly during the first hours of use. As

the enamel is cured, convection will cause a non-hazardous smell and/or some smoke to be emitted.

Attention

The Topper Burners must be installed, connected and checked by a qualified fitter in accordance with national,

regional, and local standards and regulations. The fitter should verify that the Topper Burner is gas tight for gas

and combustion products and that the various components and functions are operating correctly. The fitter

should furthermore ensure that the identification plate is placed in a prominent position in the immediate vicinity

of the burner. The flue system also needs to comply with the applicable regulations.

Warning

Topper burners become hot during use. Therefore you should take care, for example, by keeping children and

those requiring help away from the immediate vicinity of burning fires. Furthermore, the Topper Burners should

not be placed on or against flammable materials (curtains, etc.).

1.1. PACKAGE CONTENTS

The TOPPER and TOPPER STEEL gas fires are supplied disassembled.

The different packages contain the following:

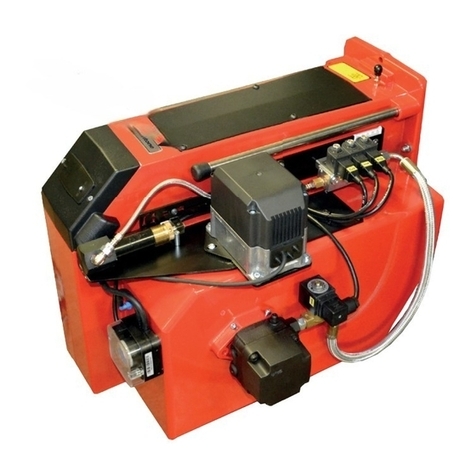

1. Gas regulation:

Complete gas regulation block

Remote control hand-held transmitter (inc. batteries)

Pilot pipe

Pilot flame cover

Instructions

2. Gas fire:

Topper burner in various sizes.

Various 3/8”x 12 mm connections.

Flexible gas pipe incl. 2x radiator connections (only with 9013 Butane model)

Fire-resistant Carrara ornamental pebble stones (only with 9013 model)

Vermiculite glowing embers

Identification plate

3. Decoration set:

Ceramic block set - Standaard or De Luxe.

Ceramic pebble set - Topper Steel 5015 to 14015

Pebble set - Topper Steel 5015 to 14015

Carrara - Topper Steel 5015 to 14015

Pag.4

2. SAFETY DEVICE

The unit is fully safeguarded by means of thermo-electric pilot light protection to prevent unforeseen discharge

of gas from the main burner.

2.1 Safety

Do not place ceramic burner decoration material or logs against the pilot burner. Ensure the pilot light is able to

burn freely over the main burner. Good ignition of the main burner is only guaranteed if this is the case. Not ad-

hering to these instructions can lead to dangerous situations.

The unit, complete concentric flue system and flue terminal need to be cleaned and checked annually by a

recognised gas technician/fitter, so the unit continues to operate safely. For additional instructions, see

Chapter 10: Maintenance.

If, for whatever reason, the pilot light extinguishes, you must wait 5 minutes before igniting the pilot light

again.

The unit may not be operated without the glass panel being in place.

It is not permitted to place flammable materials on the ceramic wood inset.

The layout of the main burner with ceramic burner decoration material and wood inset may under no cir-

cumstances be changed or added to.

Light flammable materials, such as nylon clothing or flammable liquids, may not be placed near the unit.

Ensure children and other persons unaware of the operation of a gas unit, are supervised at all times when

near the unit.

Use a fireguard to protect against burns and protection of the children and persons named above.

Pag.5

3. REMOTE CONTROL

Please note:

Before the device is switched on, the air supply flue gas discharge valve must be opened.

The control knob is located front-right in the unit. If this valve is not open, the unit will not function

3.1 General

* The unit is operated using a radio-controlled remote control. This consists of a manual transmitter and a re-

ceiver. The receiver is connected to the gas control block.

* The receiver and the gas control block are located in the operating box.

3.2 Manual transmitter

* The transmitter uses a radio-controlled signal. The signal code is set at the factory

3.3 Screen setup

* After the batteries have been inserted, press the OFF button and (small) at the

same time to toggle between °F (and 12 hour clock) and °C (and 24 hour clock).

* Wait a moment or press OFF to return to MAN mode.

3.4 Setting the time

* Press (large) and (small) at the same time to go to the SET mode or program-

ming mode.

* The time can be set while the screen is flashing.

* Press to set the hour and minutes.

* Wait a moment or press OFF to return to MAN mode.

Manual transmitter

230 °C

20.59

Pag.6

3.5 Operation (Remote Control)

Igniting the flame

* Open the gas shut-off cock that has been installed in the gas pipe to the unit.

* Press the “O I” switch on the gas control block to the “I” position.

* Turn the operating button on the gas control block into the ON position.

* Press the OFF and (large) switches on the remote control at the same time. A short sound signal will

confirm commencement.

Short sound signals will then follow until the pilot light and main burner are ignited.

Once the main burner is ignited, the flame will adjust to its maximum height automatically.

3.6 Possible error messages

* Long sound signals during ignition: Receiver batteries are almost empty. (After this signal is heard, the unit

may be switched on approximately 10x more).

* 5 seconds of continuous sound signal: Error message. For example: one of the cables is not connected, the

“O I” switch is not in the “I” position.

* 5x short sound signal: The pilot light or main burner are not ignited.

Possible cause: air in the pilot pipes.

Important

If the pilot light is extinguished, wait at least 5 minutes before

repeating the steps above.

Piëzo Ignitter

(Manual) Manual knob Main valve knob

Microswitch

“O I” Switch 8 Wire Receiver Jack

Combination Control, Cover

Pag.7

3.7 Setting the flame height / extinguishing the flame

* After the burner is ignited, the flame size will adjust to its maximum height automatically.

* Press the button (small) on the image of the flame to reduce the height and to switch the burner off.

(Extinguishing the flame: “STAND BY”). (Press the key for a short time to gradually reduce the flame.)

* Press the (large) button to increase the flame height. (Press the button briefly to gradually increase the

flame height)

3.8 Switching the unit off.

* Press the (small) button to reduce the flame height and to switch the burner off (“STAND BY”).

* Then press OFF to switch off the entire unit, including the pilot light.

* If the unit is out of use for a long period, set the “O I” switch on the gas control block to the “O” position

to save the batteries.

* In this case, it is also recommended you close the gas shut-off cock in the supply line.

Breakdowns:

* If the receiver is not receiving signals from the manual transmitter effectively, this could be caused by:

1. Flat batteries: replace the batteries.

2. An electronic problem: press “RESET” on the receiver.

3. Contact your fitter if the unit switched off regularly.

Important: If, for whatever reason, the pilot light goes out, you must wait 5 minutes before reigniting it.

3.9 Inserting and replacing the batteries

* The manual transmitter and receiver batteries have a life span of approximately one year. The use of alka

line batteries is recommended.

* The batteries need to be replaced when:

1. Manual transmitter: BATT appears on the display.

2. Receiver: long sound signals can be heard during ignition.

1. Manual transmitter:

* Open the small cover on the back.

* Carefully remove the 9V square battery and remove the battery from the contact holder. Do not pull the

wires!

* Connect the new battery and place the whole unit back. Close the cover.

2. Receiver:

* Carefully remove the entire receiver from the holder.

* Slide the small cover open.

* Remove the batteries from the battery holder.

* Place 4 new 1.5V batteries (type LR6 or AA) in the battery holder as shown. The spring must always be

against the negative (-) pole of the battery.

* Close the cover and place the receiver back into the holder.

If the batteries are not inserted correctly, the electronics of drive mechanism could be damaged irreparably.

Replace the batteries only when the unit is completely switched off.

Important

Use only non-metallic tools to remove the batteries

Removing batteries with a metal object may cause permanent damage to the electronic control.

Pag.8

4.0 MANUAL OPERATION (in case of emergency, only if remote control is not working)

The unit may be operated by hand if there is a defect in the remote control. To do so, the ignite (piezo)cable of

the receiver must first be removed and carefully slid into the piezo connector on the gas control block.

4.1 Igniting the fire

* Open the gas shut-off cock that has been installed in the gas pipe to the unit.

* Press the “O I” switch, on the gas control block, in the “I” position.

* Turn the motor button, on the gas control block, completely to the right. The button will make a "click”

sound.

* Turn the operating button on the gas control block, into the “MAN” position. A metal circle in the

operating button will become visible.

* Push the metal circle inwards. For example, with a pen. Gas will now flow to the pilot flame.

* While keeping the metal circle pressed down, press the (square) piezo button (along the “O I” switch)

several times to ignite the pilot flame. You will be able to see whether the pilot flame is burning through

the glass window.

* If the pilot flame is alight, keep the metal circle pressed down for another 10 seconds and then let go.

Important: If the pilot light extinguishes, one should wait at least 5 minutes before repeating the

aforementioned steps.

* Turn the operating button to the ON position. The burner may or may not ignite, depending on the position

of the motor button.

* By turning the motor button to the required setting to the left, the burner will ignite and the flame size can

be adjusted.

4.2 Extinguishing the fire

Turn the motor button, on the gas control block, completely to the right. The button will make a "click” sound.

The burner will turn off. The pilot flame continues to burn.

4.3 Switching the unit off

Press the "O I” switch, on the gas control block, in the “O” position. The pilot flame will extinguish.

If the fireplace is not used for an extended period of time, we recommend closing the gas shut-off cock in the

supply line.

Important: If, for whatever reason, the pilot light extinguishes, you must wait 5 minutes before

igniting the pilot light again.

Piezo Button

Piezo connector

(With manual operation) Control button Motor button

(in the maximum setting)

Microswitch

“O I” switch 8-pole receiver cable

connection

Small metal circle for

manual operation of the

ignition

(Control button in Manual position)

Page.9

5. INSTRUCTIONS FOR THE MERTIK MAXITROL GV60 AND REMOTE CONTROL:

Ensure that the fuel supplied to the unit is clean and free from particles and moisture.

Before a gas supply pipe (new or existing) is connected to the main gas pipe at the gas meter and to the gas

control block of the unit, clean and dry compressed air should been blown through it.

Cut copper pipes as well as aluminium pilot pipes must be deburred and blown clean before they are con

nected. The dust filter at the connection to the gas control block will only filter out the coarsest dirt from

the system. Fine particles are still able to reach the inside and may damage and/or adversely affect regula-

tion in the gas control block.

Heat, moisture and dust are a threat to all electronic components

Protect the electronic gas control until all construction, plastering and paintwork has been completed. If

such work cannot be avoided, then protect the control against dirt and moisture penetration by using, for

example, plastic film.

Warning

Electronic components will become permanently faulty when exposed to temperatures higher than 60°C.

Standard AA batteries will crack open at temperatures >54°C and the battery contents will damage the

electronic switches located underneath. Batteries last longest at <25°C. At >50°C the life span is around 23

weeks, this makes the use of the gas fire unnecessarily expensive.

Only install the gas control block and receiver as pre-installed at the factory

Remember that components may have to be replaced or that repairs may have to be performed at a later

date. This may be more difficult if the control is installed using a method that is different from the instruc-

tions provided here.

Please note:

Only place the batteries after wiring to the receiver, gas control block and pilot set is connected.

Premature connection to the energy source may damage the control’s CPU (central processor).

Ensure that the ignition cable is not near the antenna wire and that they do not cross each other.

The high voltage released at ignition may damage the sensitive receiver circuit.

This may mean that the unit becomes less responsive or not responsive at all to handset commands. (See

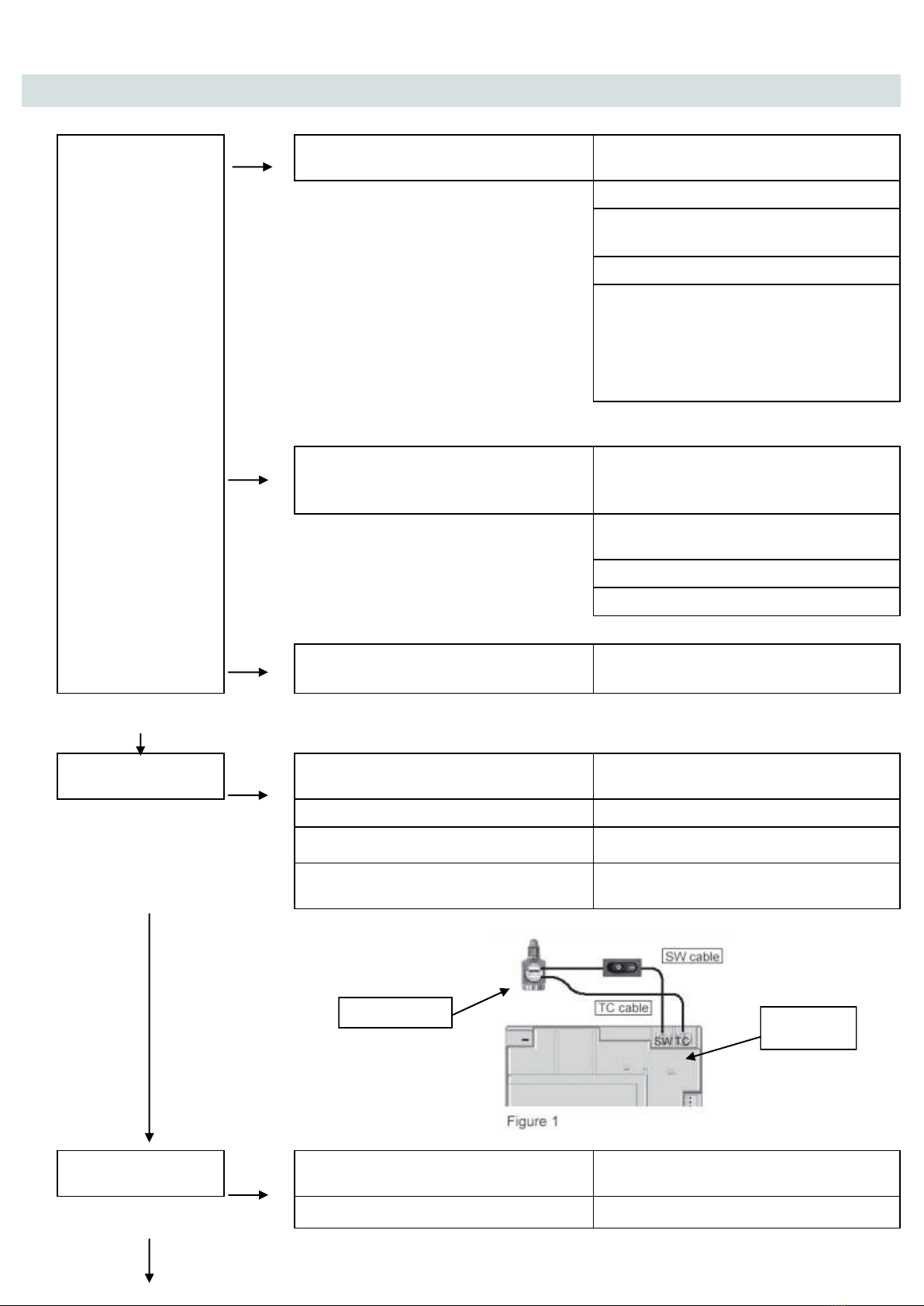

photograph 1 on page 16)

Loosen the antenna wire from the terminals on the receiver box

Direct the antenna wire away from the ignition cable and in the direction of the control box door.

Ensure there is no contact with metal components. Ensure there is no damage to the connection to elec-

tronic components or to the wire itself. (See photograph 1 on page 16)

Connect the wires correctly to the contact breaker behind the gas control block.

The shortest wire runs immediately back to the 1/0 switch and can be found nearest to the back of the gas

control block. The longest wire runs to one of the two connections on the receiver box and only fits on one

of the screws.

Do not tighten the contact breaker and the thermocouple connection too tightly on the gas control

block or to each other.

It is sufficient to tighten by hand and add a half a turn with an open-end spanner. Tightening too much will

break the connection to the magnetic coil below and/or the insulation around the aluminium contact pin

in the contact breaker. This may lead to the magnetic coil not opening the gas supply to the pilot and the

unit not working.

Page.10

Do not extend the thermocouple supplied to the pilot set

Extending the thermocouple beyond its limit will lead to a reduction in voltage. This may, in turn, lead to the

magnetic coil not being activated.

Prevent leakage of the ignition spark to parts of the installation other than the ignition rod at the pilot.

Ensure the ignition cable is not in contact with the shell or other metal parts. If a cable extension is used, ensure

that connections are additionally insulated using silicone.

The receiver and the control units on the gas control block should be switched on to ensure automatic start

-up through the manual transmitter.

The oval disk on the gas control block should be turned to the ON position. The I/0 switch should be set to 1. See

photograph 2. The ignition cable should be connected to the SPARK connection point on the receiver box. See

photograph 1.

The manual transmitter has to communicate with the receiver. This has to be ‘learnt’.

Press the RESET button using a blunt object. (See photograph 3.) Continue to press this button until you hear a

short beeping sound, followed immediately by a long beeping signal. Release the button. Direct the manual trans-

mitter towards the receiver and press the arrow down until you hear a long beeping sound. The gas control button

will now move for a short period.

The manual transmitter has now learned the setting with regard to the receiver and the unit can now be ignited

using the remote control.

The system’s thermostat sensor is in the manual transmitter.

The manual transmitter operates best at a distance of 2 or 3 metres from the unit. Although communication oc-

curs via short wave radio signals, it is recommended to place the hand transmitter in view of the gas apparatus in

a place where the user wishes to experience a pleasant temperature. Do not place the manual transmitter in direct

sunlight or other warm location. The thermostat measures the temperature and regulates the flame size of the gas

unit accordingly.

Only remove batteries using non-metallic tools.

Removing batteries with a metal object may damage the electronic control permanently.

Photo 2

Photo 3

Photo 1

40 mm

Page.11

6. TECHNICAL DETAILS GV60

Gas block type : Mertik GV60 M1-C5D3KL-0001

Automat type : G6R-R4Ax

Ignition : Distance operation and Piezo ignition

Gas connection : 3/8" (Internal) A=Gas intake B=Gas exhaust C=Thermocouple connection

D=Pilot burner connection

Unit category : C11-C31-C91

Pilot flame : SIT 3 flames

Combustion gas discharge

and Combustion air supply : Concentric: Ø100 / 150 mm

D= Pilot burner

connection

A=

=B C= Thermocouple

connection

B

A

C

D

Page.12

Page.13

7. Mertik GV60 Troubleshooting Flow Chart

No ACTION Possible problem/cause Solution

1. Option: wall switch START:

press ON button > wall switch

works.

NO Bent pin on switch, or cable not

operating properly. Straighten pin, replace wall switch

or cable.

1. Manual transmitter START: press

both buttons to start ignition

sequence.

Beep will occur each second

NO Manual transmitter battery low. Replace battery, 9V quality

alkaline!

Receiver batteries low. Replace batteries, 1.5V AA quality

alkaline!

Optional mains adapter not

operating properly. Check mains adapter.

Check coding of transmitter and

receiver. Learn in new code, see instructions

and label on receiver.

OK Transmitter/receiver range

limited. 1. Move antenna cable, see

instructions.

2. Replace receiver.

Optional wall switch / cabling not

operating properly. Replace wall switch / cabling.

Receiver fuse blown (in older

versions only). Replace receiver.

2. Magnet unit in gas valve is

energised (audible click) NO

No beep Impulse magnet not operating

properly. Replace gas valve.

NO 3 short beeps Receiver batteries low. Replace batteries, 1.5V AA quality

alkaline!

NO 1 long beep ON/OFF switch on gas valve in

OFF position Set switch to ON.

8-wire cable between receiver and

gas valve defective / poor contact. Check cable, especially in case of

plug connection.

OK Switch cable disconnected. Check switch cable, see fig. 1 on

page 18

Motor not operating properly. Replace gas valve.

Micro switch on gas valve not

operating properly. Replace gas valve.

Page.14

No ACTION Possible problem/cause Solution

3. NO Ignition components not operating properly. Check connection between cable & IGN

electrode.

Check IGN electrode spark gap.

Check IGN electrode for discharge to ground

(break in ceramic).

Check IGN cable for damage

Increase distance between IGN cable and all

metal parts. Check that spark does not

discharge to ground at location of spark plug

connection. Shorten cable if possible. If

applicable, provide extra insulation with silicon

hose etc.

Spark will occur each

second.

NO IGN sequence stops, no pilot flame.

No reaction to transmitter command (receiver

does not react).

Press RESET button, see instructions.

Add ground wire between pilot burner and gas

valve.

Do not coil the IGN cable.

Shorten IGN cable if possible.

NO IGN sequence stops, no pilot flame.

Transmitter command is possible. IGN sequence stops, no pilot flame.

Transmitter command is possible.

OK

4. Pilot lit. NO

TC and SW cable reversed. Check connection of cable to receiver and

interrupter, see fig. 1.

Impulse magnet not operating properly. Replace gas valve.

Short between interrupter and SW cable. Check connection to interrupter.

OK No gas (magnet unit drops after 30 second

audible count). Check gas supply to gas valve.

5. Sparking stops after pilot

is lit NO Short between interrupter and TC cable. Check connection to interrupter, see fig. 1

OK Electronic measuring amplifier defective. Replace receiver.

Interrupter Receiver

Page.15

No ACTION Possible problem/cause Solution

6. NO Resistance in thermo

current circuit too high. Check cables and connections in

thermo current circuit.

Magnet unit drops

(audible click) Not enough heat on

thermocouple. Check position of pilot to

thermocouple and intensity of pilot

flame.

Motor turns to main gas

and pilot stays lit. Low voltage from

thermocouple. Check connections and, if necessary,

replace thermocouple. Do not

overtighten the connections!

Short because

thermocouple end is

damaged.

Replace thermocouple, do not

overtighten the connections!

NO IGN sequence stops. No

reaction to transmitter

command (receiver does

not react).

Press RESET button, see

instructions.

Add ground wire between pilot

burner and gas valve.

OK Do not coil the IGN cable.

Shorten IGN cable if possible.

7. Main burner is lit. NO Gas valve manual knob in

“MAN” position. Turn knob to “ON” position.

OK

8. Main burner stays lit. NO Too much / too little air

flow / draft at pilot, blows

out or is smothered.

Check whether restriction plate has

been correctly applied in unit, see

instructions.

Poor flue location, check correctness

of layout and connections.

OK

9. Magnet unit drops while

motor turns.

3 beeps

NO Receiver batteries low. Replace batteries, 1.5V AA quality

alkaline!

System can be switched

OFF via remote control.NO System can be

switched OFF via

ON/OFF switch.

NO Short between TC and SW

cable. Check connection to interrupter

block.

YES YES

OK OK Replace gas valve.

Page.16

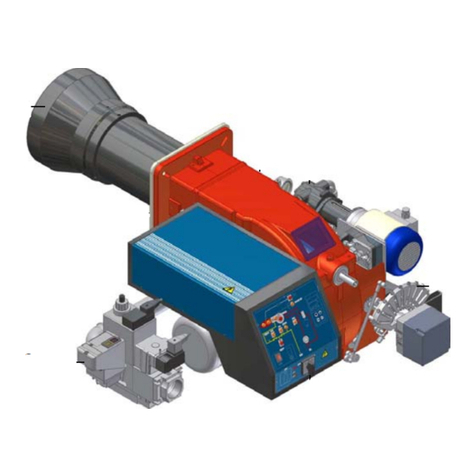

8. OPERATING INSTRUCTIONS DUNGS GAS REGULATORCOMBINATION AB

This regulator is fitted with a complete infra-red control system. This means that you can ignite the unit, smoothly

adjust the flame height and extinguish the unit using the remote control.

8.1 Infra-red remote control and its operation

The infra-red remote control allows you to comfortably control

the AB system. When in direct line of sight with the infra-red

receiver, the remote control has a range of approximately 15m

To start the system, press the buttons “ON” and “OFF” together

for at least 3 seconds. The start-up process is indicated by a se-

ries of three short tones. After the flame has lit, it can be in-

creased to the maximum height by pressing the “UP” button.

Pressing the “DOWN” button reduces the flame to its minimum

height. Pressing the “OFF” button for at least one second

switches off the system and places the unit in “Stand By" mode.

In the event of a fault in the unit (a red LED lamp lights on the

receiver), the system can be reset by pressing the “ON” and

“OFF” buttons at the same time for at least 3 seonds which will return it to the “STAND BY” mode. The

“Automod” button starts automated adjustment of the system. When automated adjustment is selected, the power of

the unit automatically reduces from approximately 80% to 20% and then increase from 20% back to 80% again

within a set time interval. This function can be stopped by pressing the “Automod” button again or by pressing the

“UP” or “DOWN” buttons. Depending on the individual specification of the unit, the FOCContact knob can be

used. Pressing the button engages a transistor that enables external units with their own power supply to be switched

on or off.

8.2 Igniting the gas fire.

Open the gas shut-off tap that has been fitted in the gas pipe leading to the unit. Now follow the steps described

above in “Infra-red remote control and its operation.”

Systeem "OFF"

AUTO mod / Aan / Uit

FOCContact / Aan / Uit

Led Vlamhoogte / "UP"

Vlamhoogte / "DOWN"

Systeem "ON"

8.3 Basic system components (See page 21)

1: Modu box 4: Gas control block

2: Transformer (24 V) 5: Remote control

3: IR receiver 6: Wire harness

8.4 Connection to the gas regulation block wiring

1: Blue / Blue

2: Black / Black

3: Red / Red

4: Yellow-green

8.5 Adjusting the Gas regulation block (See adjustment values

on pages 22 and 23)

Setting the flow rate - Low setting

A Connect manometer to pressure measuring point (9)

B Ignite the fire

C Set the flow rate by turning adjustment screw 11 with a screw

driver.

- turn clockwise, to reduce "-"

- turn anti-clockwise, to increase "+"

Setting the flow rate - High setting

A Connect manometer to pressure measuring point (9)

B Ignite the fire

D Set the flow rate by turning adjustment screw 12 with a screw

driver.

- turn clockwise, to reduce "-"

- turn anti-clockwise, to increase "+"

123

9

11

12 13

mBar

- +

1 2 3

5

4

Page.17

After completing any work: Test for leaks and check operation.

8.6 Connecting to the mains supply

The regulation equipment is fitted with an electronic control. Take into account the length of the cable

when connecting to a power socket.

7.7 Chimney

If it is connected to a chimney that had previously been connected to a wood-fuelled fire, than the flue

should be thoroughly and professionally cleaned as dirt can still become dislodged from the chimney when

used with gas. The chimney will need to be cleaned again after a couple of months.

8.8 Warning.

* Only install the unit in a well-ventilated room.

* The gas unit is only suitable for installation in a non-flammable, fire resistant mounting.

* This is an open fire so you should not place any light flammable articles nearby: care should be taken with ny

lon clothing.

* The exhaust gas outlet should have a minimum diameter that corresponds to the size of the connection.

* Protect all pipes (electric/gas) through a wall duct using a pvc tube and so forth.

* If there is a valve or slider in the exhaust gas outlet that allows the outlet to be fully or partially closed, this

should be locked in an open position using a protector connected to the control.

9. ELECTRICALAND GAS CONNECTION

9.1 Electrical connection.

The regulator is composed of various components which should be fitted in the

correct manner. You need to provide the following:

* 230 V AC, 50 Hz power supply positioned near to the gas block fire.

* The plug and the power socket should be within reach at all times. Position the main components, namely the

control cabinet and the gas regulator combination in a place that is easily accessed. The maximum permitted

ambient temperature for all of these components is 60° C. The regulation box is simple to mount, for instance

on a wall. Remove the cover plate from the regulation box by unscrewing the 2 cover plate screws. The regu

lation box can be positioned on the assembly slots in the bottom of the regulation box.

9.2 Order of installation: electrical connections.

* Connect according to local regulations.

* Determine the position for the control box and the gas regulation combination (pay attention to the maximum

length of the wire harness).

* Check that the wire harness from the gas block is connected to the Modu box.

* The ignition cable should be passed through separately on its own. (excess sparking)

* Determine the position of the infra-red receiver (the lens should remain visible to the remote control)

* Insert the power cable into the wall socket.

* If used, connect the open position protector or GTP as shown in the wiring diagram. (See page 16).

* Ensure that the ground wire is properly connected. Without this connection, ionization current protection is

not possible.

9.2.1 Basic Gas regulation combination

* For connections and attachments for the basic gas regulation combination (See page 21).

Page.18

BASIC DIAGRAM

Page.19

9.3 Optional protected air supply and combustion gas flue system for type II gas-fired block fires in natu

rally and mechanically ventilated homes.

* You can additionally connect an air supply and combustion gas flue system. The protection system is used

in existing or newly installed type II block fires in open hearths which are set up in mechanically ventilated

homes.

* The combustion gas is extracted mechanically by means of a protected exhaust ventilator.

This ventilator is fitted with current protection which in the event of insufficient flow in the exhaust vent inter

venes in the gas supply to the unit.

* The air supply comes directly from outside the home through the exterior walls or by means of an air pipe

through the ventilation cavity. The air supply should be locked in an open position. Gas can only be supplied

to the unit if the supply grill is fully open. Ask your supplier about the options.

Protected air supply and combustion gas flue system for type II gas-fired block fires in naturally and

mechanically ventilated homes. Exhausto EFC21 (See page 17)

* You can additionally connect an air supply and combustion gas flue system. The protection system is used

in existing or newly installed type II block fires in open hearths which are setup in mechanically ventilated

homes.

* The combustion gas is extracted mechanically by means of an EFC21 exhaust ventilator. This ventilator is

fitted with current protection which in the event of insufficient flow in the exhaust vent intervenes in the gas

supply to the unit.

* The air supply comes directly from outside the home through the exterior walls or by means of an air pipe

through the ventilation cavity. The air supply should be locked in an open position. Gas can only be supplied

to the unit if the supply grill is fully open. See the instructions provided with the EFC21.Ask your supplier

about the options.

Page.20

Operation using control knobs. (See pages 16 and 21)

Three buttons are required for operation: - “UP” button – “DOWN” button – “RESET” button To start the system,

press the “UP” en “DOWN” buttons together for at least three seconds. The start-up process is indicated by a se-

ries of three short tones. After the flame has lit, it can be increased to the maximum height by pressing the “UP”

button. Pressing the “DOWN” button reduces the flame size to its minimum height. Pressing the “UP” and

“DOWN” buttons again for at least three seconds switches off the unit. In the event of a fault in the unit, the sys-

tem can be unlocked by pressing the “RESET” button and reset to the “STAND BY” state.

9.4 Gas connection Mount the gas regulation combination in an accessible place near to the gas block fire (take

account of the length of the connection cables). Use a 1/2“ gas tap with a connector. Topper Steel: Fit a (ø12mm)

flexible gas pipe between the gas regulation combination and the Topper burner. For model 9013 burner (B / P),

mount the flexible gas pipe using the accompanying radiator connection and nosepiece by first exchanging the

flare fitting for the accompanying nosepiece. Remaining Topper burners: use between gas regulation combination

and burner a copper connecting pipe diameter 12x1mm., maximum length 1500mm.

Connect the pilot pipe and the ignition cable to the Oxy stop pilot flame. Also ensure that the gas pipe is free from

dirt or sand. You should ensure that the various connection points are accessible. Ensure

that the control equipment does not become twisted during installation and that there is no

excessive tension during connection. After installation, check that the connections are gas

tight. Position the pilot flame cover as shown after the pilot flame burner has been assem-

bled. The pilot flame cover is not used on the 4525 and 9013 models.

COMBINATION DIAGRAM

Dungs / Exhausto EFC 21

Waakvlamkap

Cover

This manual suits for next models

16

Table of contents

Popular Burner manuals by other brands

Riello

Riello 556T40 Installation, use and maintenance instructions

Wayne

Wayne MSR-DC manual

Riello

Riello 554T40 Installation, use and maintenance instructions

Riello

Riello 521T80 Installation, use and maintenance instructions

Bentone

Bentone LMO14.113C2E Installation and maintenance instruction

Beckett

Beckett CF1000 Setup guide

Bentone

Bentone B 55-2 FAME Installation and maintenance instruction

MARANA Forni

MARANA Forni GENIUS MRN operating manual

Conrad Electronic

Conrad Electronic DJ061 operating instructions

EcoSmart Fire

EcoSmart Fire AB8 quick start guide

Unigas

Unigas HP60 manual

Riello

Riello F20 Installation, use and maintenance instructions