ThermoControl HRT 6015-50 User manual

ThermoControl Temperature Controller

Electronic temperature controller with timer (clock controller) for flush mounting and for smart

function (this function sets the time at which the comfort temperature should be reached)

Universal controller HRT 6015-50 for optional

use as

Floor temperature controller 10 to 60 °C,

Room temperature controller 5 to 30 °C

Room temperature controller 5 to 30 °C

with floor temperature monitoring

Room temperature controller 5 to 30 °C

Floor temperature controller 10 to 40 °C

The room temperature controllers can also be used as cooling controllers (see “Commissioning”).

Smart operation is activated on all controller types.

Also available as master controller (option) for connecting clockless bi-metal and/or electrical controllers as

satellites.

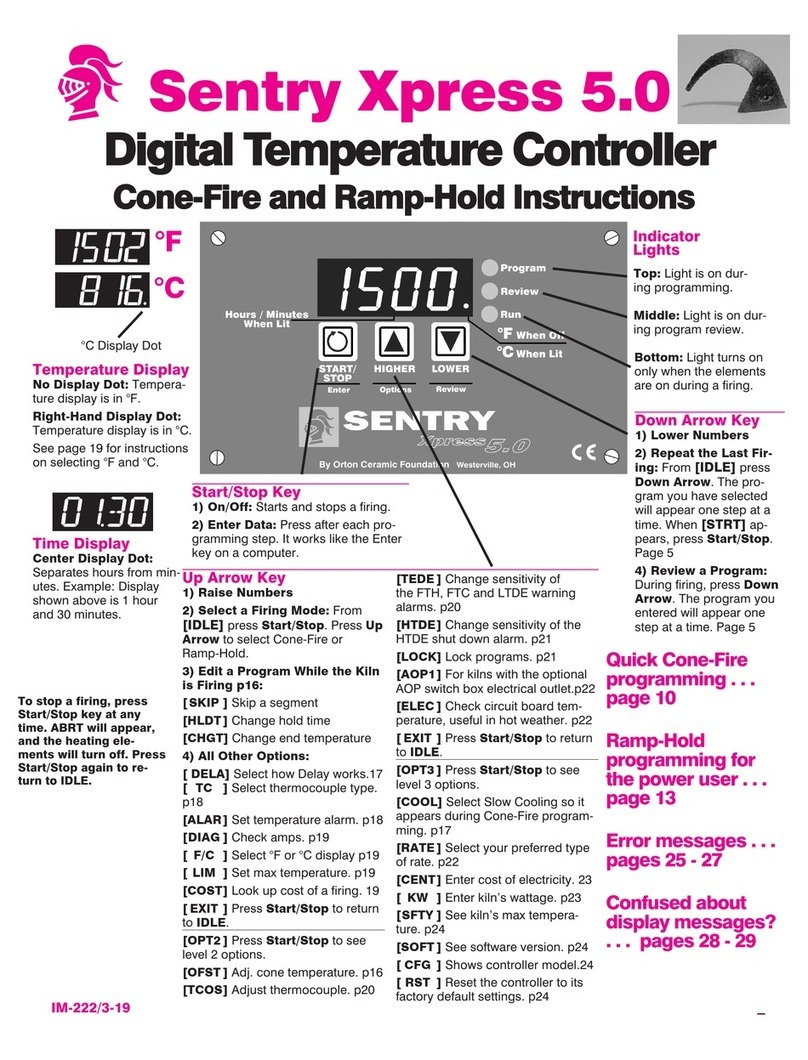

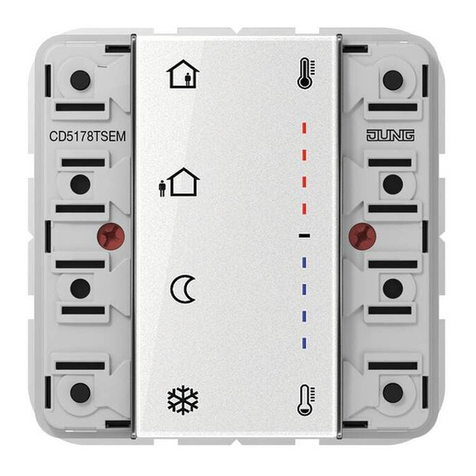

Device view

Figure 1

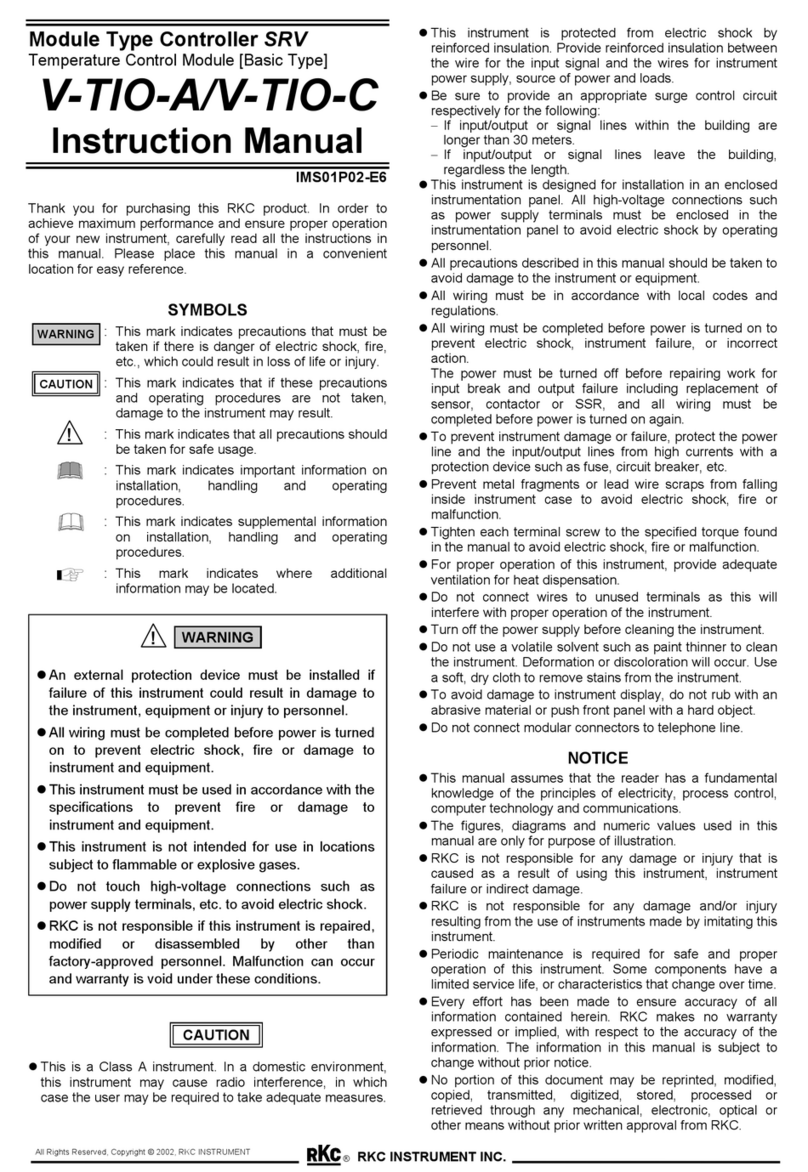

Safety instructions

Only authorised electricians are permitted to work on a 230 V mains voltage. The safety regulations

of the VDE and the local electrical utility company must be observed

The connection work stated in these instructions must not be carried out when the mains voltage is

switched on.

A 30 mA residual current circuit-breaker must be used in humid areas (such as bathrooms) in

accordance with VDE 0100.

The mains supply must be protected by means of a miniature circuit-breaker (16 A).

A terminal cross-section of 2.5 mm2 must be used for a heating output of 3 kW or higher.

Description/application range

The electronic temperature controller with timer control is designed for controlling the floor

temperature and/or the room temperature in individual rooms.

It can be used, for example, for electrical direct heating (floor or convectors), supplementary heating

for floor background heating in bathrooms, electrical perimeter heating or warm water heating with

control valves. The controlled variable is either the room temperature using an integrated room

temperature sensor or the floor temperature using the supplied floor temperature sensor at the level

of the heating mat.

AC 230V normally closed control valves are used for the control of warm water heating systems.

Technical data

Colour alpine white

Degree of protection IP 30

Protection class II

Mains voltage 230 V +/- 10%, 50 Hz

Room controller versions 5 to 30 °C

Floor controller version 10 to 40 °C

Max. switching current 12 (4 ) A floor controller

Max. switching capacity 2.7 kW floor controller

Switch temperature differential 0.7 K

Switch contact Opens on overtemperature

Temperature sensor NTC to DIN 44574

Temperature sensor cable 4 m length, max. 8 mm

Directives/Standards/Approvals EMC Directive 89/336/EEC

EU Low-Voltage Directive 73/23/EEC

Ambient temperature -10 to + 40 °C

Energy class IV = 2.0%

Installation instructions - Mounting options

Installing the floor temperature sensor

Install the floor sensor in a separate protective tube at the heating mat level centrally between the

heating cables.

ATTENTION: Apart from when only room temperature control is required, a floor temperature sensor

must always be connected. Failure to do so will turn off the heater.

With room temperature control systems with floor heating, it must be ensured that the floor is not

overheated. With the universal controller it is possible to implement a temperature monitor function

(floor temperature monitoring) by using the floor sensor (default setting). The floor limit temperature

that is not to be exceeded can be set in the controller.

(see “Changing controller options”)

Installing temperature controllers

Installation in standard conduit box. When using additional intermediate terminals

the use of a deep conduit box is recommended.

Mounting height: Approx. 1.5 m above floor.

Avoid exposure to water.

When used as a room temperature controller, ensure that normal room air reaches the controller

without obstruction. The controller should not be mounted in shelf walls, under curtains or on outdoor

walls.

External heat from sunlight and draughts from windows and doors impair the accuracy of the

controller and should be avoided.

The frame can be exchanged for switch frames (if required with intermediate frame) from Busch-

Jaeger, Berker or similar, in order to adapt the controller to different switch systems

Preparation for installation in the conduit box

Figure 2

-

+

C

~

~

~

1

25

4

3

20 4 6 8 10 12

12 16 20 22 24

1814

50 mm

50 mm

80 mm

80 mm

Step 4: Remove round cover

Open out from bottom left to top right

Step 3: Remove cover

Step 1: Carefully remove the

adjustment dial with a screwdriver

Step 2: Undo screw

Deph 42 mm

Mounting depth in conduit box 25 mm

Electrical connection

Figure 3 and 4

L N PE

T

A

F

F

N

L

1

N

L

Heating

NTC

230V~

mains supply

Floor temperature sensor

Master output

(optional)

L N PE

T

A

F

F

N

L

1

N

L

NTC

230V~

mains

Floor temperature sensor

Heating mat

Master output

(optional)

Figure 5

Commissioning

If a room temperature controller is to be used as a cooling controller, remove jumper 1 (figure 7) with

a long nose pliers and fit it in the two upper sockets. To deactivate the smart function remove jumper

2 (figure 7) and fit it into the two sockets on the right.

The universal controller is factory set as a floor temperature controller (10 to 60°C).

For changes see “Changing controller options”. If you have moved a jumper or changed the rotary

switch setting on the universal controller, the Reset button must be pressed after the und cover is

fitted and the mains voltage is switched on.

Then set the Heating On/Off switch on the controller to the

position (Figure 1). Setting the time and weekday (see “Programming”)

Move the switch to the required position.

= Continuous operation (heating system controls a constant heating temperature)

= Timed operation, the preset heating program no. 1 is now active.

Mon ... Fri Sat, Sun Type

No. 1 06.00 ... 08.00 07.00 ... 09.00 Bath

19.00 ... 22.00 20.00 ... 23.00 room

The display shows the current heating program

and the current time. The bar corresponding to

this time flashes at the same time.

For other heating programs see

“Programming”

Long bars = Heating temperature

Short bars = Setback temperature

The controller switches to heating operation at the indicated times (long bars).

In other words, heating will be activated until the heating temperature set on the dial is reached, when

it is then kept constant by the controller. At the other times, the device regulates the temperature to

the setback temperature value, i.e. the heating is switched back on if it goes below the defined

setback temperature (default 15 °C).

For changing the setback temperature, see “Changing the setback temperature”

Setting the required setback temperature with the adjustment dial (Figure 1)

With floor temperature control 10 to 60 °C (numbers on the adjustment dial 1 to 6)

1 = approx. 10 °C ; 2 = approx. 20 °C etc.

With room temperature control 5 to 30 °C (numbers on the adjustment dial 1 to 6)

1 = approx. 5 °C ; 2 = approx. 10 °C etc.

Note The heating temperature cannot be shown on the display.

:

18

35

0

2

4

8

10

12

24

22

20

18

16

14

12

6

1

Heating program Mo-Fr

Programming

Remember when programming that any changes are accepted automatically after

10 seconds!

A change, for example between time and date is not possible in this time.

The device automatically switches to operating status.

Setting the time

Note: The Time and date are automatically set and reset if a flush mounted radio clock is connected.

Manual time and date setting is not necessary.

Set the switch to the Sun symbol (all bars are now long on the display). Hold down the C

button and press the + button. You can now release the C button and set the time with the + or –

buttons. Holding the button down for a long time first changes the setting slowly and then increasingly

faster.

:

18 35

0 2 46810 12

2422

20

1816

12 14

Example with time setting

18 : 35

Summer/winter time changes must be carried out manually.

Weekday setting

Leave the switch at the Sun position. Hold down the C button and press the –button. You can now

release the C button and set the current weekday with the + or –buttons.

1 = Monday, 2 = Tuesday, ... 7 = Sunday.

Examples:

2

0246810 12

12 14 16 18 20 24

22

Weekday

Example

2 = Tuesday

Programming

Other heating programs

Set the switch to the Clock position. Hold down the C button and select one of the four preset

programs or the personal 'E' user program by pressing the + button several times as required. The

program number is shown on the left of the display, and shows 'Sa, So' (= Saturday, Sunday) for

weekend programs

Mon ... Fri Sat, Sun Type

No. 1 06.00 ... 08.00 07.00 ... 09.00 Bath

19.00 ... 22.00 20.00 ... 23.00 room

No. 2 06.00 ... 08.00 08.00 ... 22.00 Children's

14.00 ... 22.00 room

No. 3 05.30 ... 07.30 07.00 ... 23.00 Employees

17.00 ... 23.00

No. 4 06.00 ... 23.00 06.00 ... 23.00 Standard

No. E your personally created program

Creating an 'E' user program

Call up the 'E' user program (default setting: all bars short). Select the bar to be changed (now

flashing quickly) by pressing the + or - button. Change the bar by pressing the C button. The next bar

will then flash and can likewise be changed. In this way, all the bars can be switched from setback to

heating temperature and vice versa. The completed program will be automatically saved and

activated as a user program 10 seconds after the last actuation. It can be changed at any time if

required. On a weekday, the user program applies to all weekdays. If you wish to create an 'E' user

program for the weekend, hold down the + button and press the - button once. The user program is

now displayed for the weekend (default: all bars short), and 'Sa,So' appears on the left of the display.

Now create the user program for the weekends in the described manner. The program is saved 10

seconds after the last button actuation and the controller returns to weekday operation. (A personal

program for weekdays can likewise be created on weekends).

Programming

Changing the setback temperature

(default setting 15 °C)

Set the switch to the Sun symbol (all bars are now long on the display).

Set the new setback temperature required with the adjustment dial (see Figure 1).

Hold down the + button and press the –button once.

The new setback temperature is now saved and is shown briefly on the display for control purposes.

It is retained when the program is changed.

Turn the adjustment dial back to the required heating temperature and if necessary move up the slide

switch to the clock position.

Min. set-back temperature on floor temperature controller: 10 °C

Min. set-back temperature on room temperature controller: 5 °C

Changing the controller options of the universal controller

Figure 6

Figure 7

Step 4:

Set the required controller option here

J1 (Jumper)

Heating / cooling

J2 (Jumper)

Smart mode

-

+

C

~

~

~

1

2

5

4

3

2

0

4

6

8

10

12

12

16

20

22

24

18

14

Step 3: remove cover

Step 1: carefully remove adjustment dial

with a small screwdriver

Set 2: undo screw

Changing the controller options of the universal controller with rotary switch

Position 0 Floor temperature controller 10 to 60 °C

In this position the room temperature controller is switched off

Position 1 Room temperature controller 5 to 30 °C

In this position the floor temperature controller is switched off

Room temperature controller 5 to 30 °C with optional

floor limit temperature

Position 2 28 °C for sensitive parquet flooring or laminate

Position 3 31 °C optional intermediate value

Position 4 34 °C optional intermediate value

Position 5 44 °C to DIN 44 576 for electrical floor direct heating

(default setting)

Position 6 55°C to DIN 44 576 for electrical perimeter heating

Position 7 Reserve

Attention!

The Reset button must be pressed after a controller option is changed.

The change is activated automatically after approx. 60 to 90 secs. If necessary reset the personal 'E'

user program and the set-back temperature.

Reset button

Pressing the Reset button sets the controller back to the default setting.

•The user program E is deleted

•Set-back temperature = 15 °C

•Date/ time is unchanged

•The set controller option is unchanged

Limiting the temperature range

The temperature setting range can be mechanically limited by reducing the rotation range of the

adjustment dial. To do this, proceed as follows:

Remove the adjustment dial carefully with a screwdriver.

Pull out the range limit stop pin from the housing cover using a long nose pliers. Rotate the wheels to

limit the rotation angle as required.

Insert the stop pin and then refit the adjustment dial back in position.

Figure 8

-

+

C

~

~

~

1

2

5

4

3

2

0

4

6

8

10

12

12

16

20

22

24

18

14

Stept 1: Carefully remove the adjustment dial with

screwdriver

Stop pin

Mains supply failure

The heater switches off in the event of a mains supply failure and the upper bar of the

display flashes. The device resumes its previous operation if the mains voltage is restored within

approx. 1 to 1 ½ days. If the mains supply failure is longer, the time and weekday must be reset and

the 'E' user program may have to be re-entered. The set-back temperature must also be

reprogrammed if this was altered.

Short-circuit or interruption in the sensor line: The heating system is disconnected and the LED

flashes. CAUTION: In the event of a fault, the mains voltage may still be present on the sensor line

Special master controllers for connecting satellites

All controllers listed can be supplied as master controllers for connecting satellites. The TA output can

be used to connect virtually any number of clockless temperature controllers, e.g. commercially

available bimetal controllers with their L set-back input TA as satellites. If the master controller with its

timer switches to set-back operation, all satellites do the same.

Troubleshooting

Diagnosis

Possible cause

Solution

No display visible

Heating system not switched on

Heating system does not switch

on, the entire display flashes

Heating system does not switch

on, LED flashes

Device is not working correctly

Mains voltage not connected

Device possibly on setback mode or

floor monitor has responded

Mains supply failure

Floor temperature sensor faulty

Device fault caused by lightning or

overvoltage

Switch on mains voltage

Check setback mode or wait until

the floor has cooled down

Check mains voltage

Replace floor temperature sensor

Press Reset button, reset the

device

Your personal 'E' user program

Mon ... Fri Sat, Sun

No. E ......................... .........................

Reservation of right

Subject to technical modifications.

Compensation cannot be claimed on account of modifications, errors or print errors.

Table of contents

Popular Temperature Controllers manuals by other brands

Tekmar

Tekmar Mixing Control 361 Data brochure

Elotech

Elotech R4000 Description and operating manual

BAPI

BAPI BA-WTH-SO Installation and operation instruction

Jung

Jung KNX 5178TSM-01 Series operating instructions

dixell

dixell XW60K Installation and operating instructions

Pentair

Pentair Raychem RTD-200 installation instructions