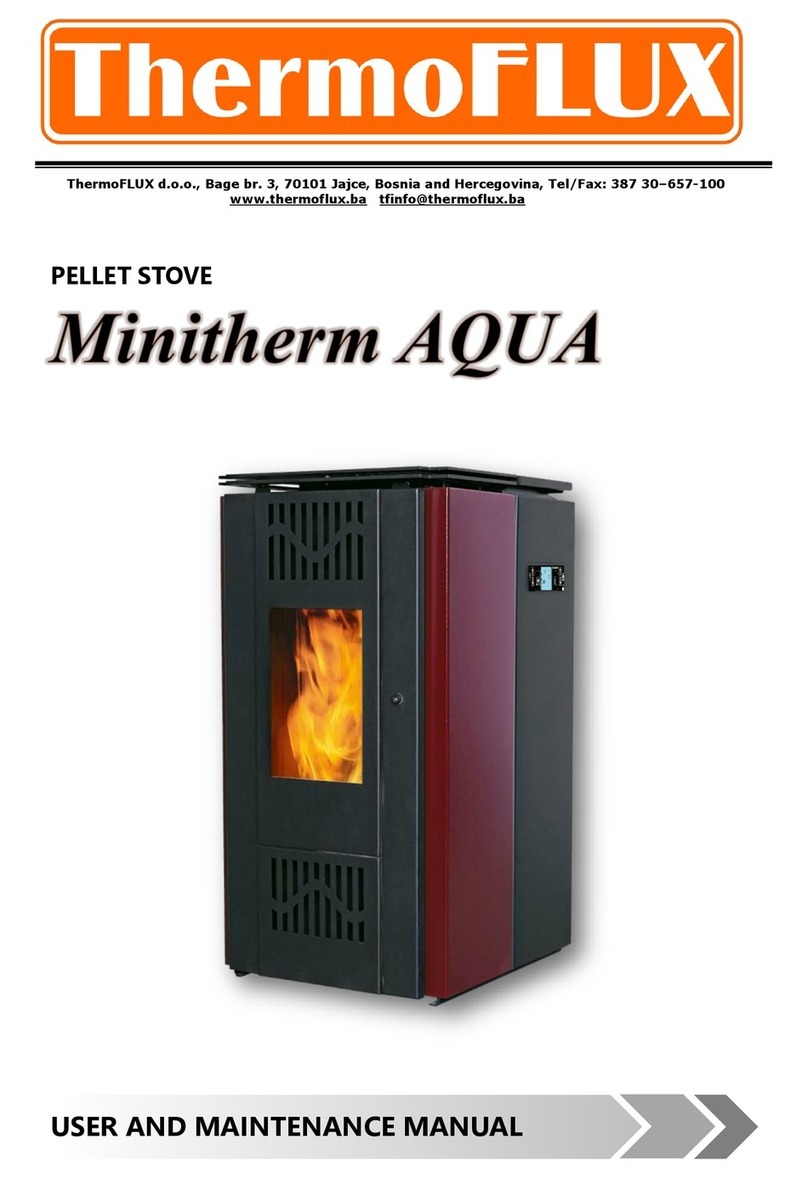

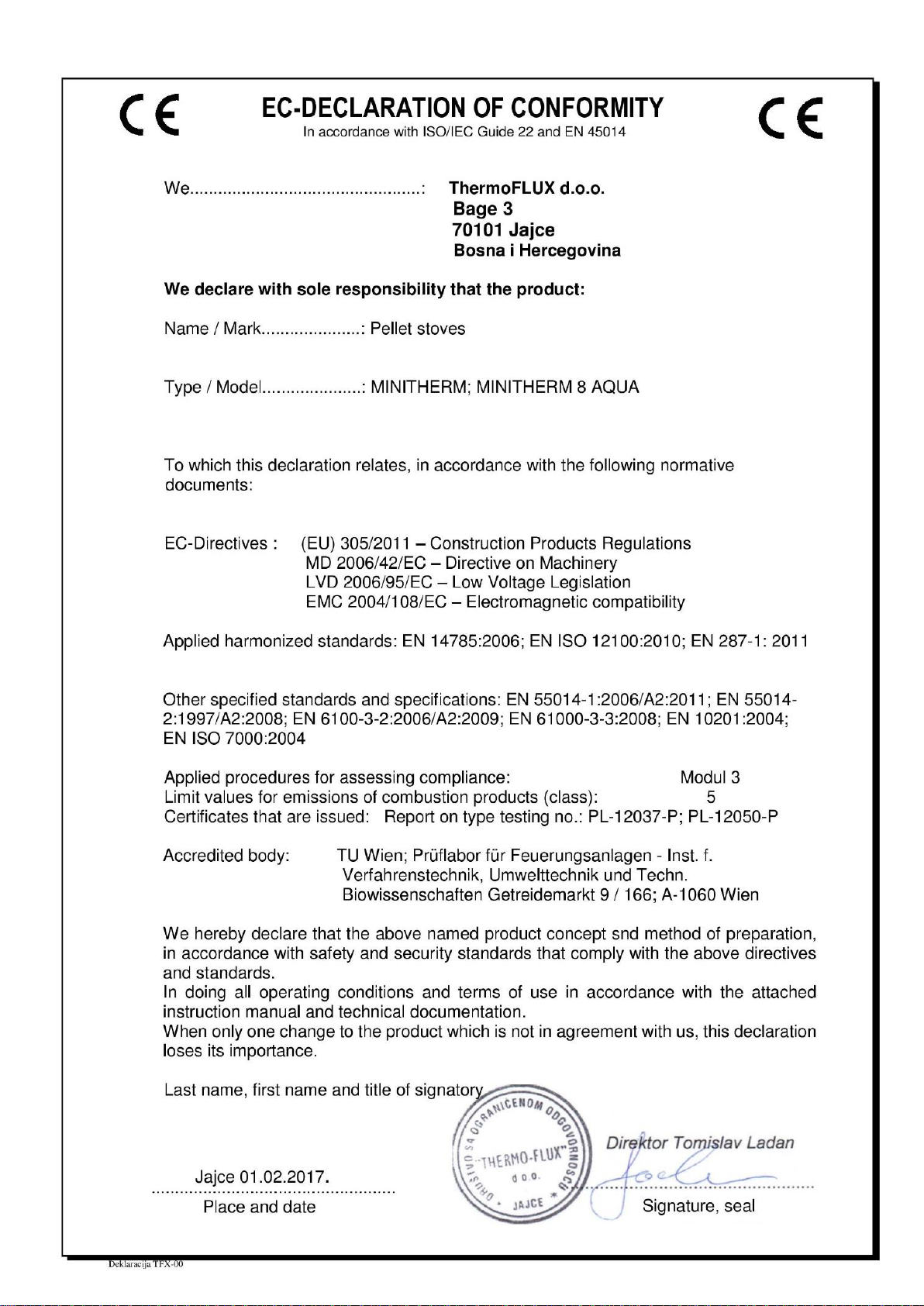

ThermoFLUX Minitherm Operating instructions

2

3

ThermoFLUX

Minitherm -

Content:

Content: .......................................................................................... 3

1Notes on the manual .................................................................... 5

1.1 Introduction .......................................................................................................5

1.1.1 Easy and safe operation....................................................................................5

1.1.2 Reading the manual .........................................................................................5

1.1.3 Technical changes............................................................................................5

1.1.4 Copyright .......................................................................................................5

2Safety notes ................................................................................ 6

2.1 Proper use .........................................................................................................6

2.1.1 Basic principles ...............................................................................................6

2.1.2 Using the stove ...............................................................................................6

2.1.3 Permissible fuel for the Minitherm - stoves...........................................................6

2.1.4 Recommended wood pellets ..............................................................................6

2.2 Warnings and safety symbols used.........................................................................7

2.3 Other risks of the side effects................................................................................8

2.4 Duty to inform....................................................................................................8

2.5 Safety devices....................................................................................................8

3Installation and commissioning of the stove .................................... 9

3.1 Conditions .........................................................................................................9

3.2 Chimney and flue gas pipes ..................................................................................9

3.3 Minimum distances of the stove from wall and objects............................................. 10

4Functional description ................................................................. 11

4.1 General overview .............................................................................................. 11

4.2 Technical data:................................................................................................. 12

5Function of stove ....................................................................... 13

5.1 Overview of the controls and display and their basic functions .................................. 13

5.2 Principle of stove operation................................................................................. 15

5.3 Schematic representation of the menu control ....................................................... 16

5.3.1 Clock adjustments ......................................................................................... 18

5.3.2 Adjustments of the programmed on and off mode ............................................... 19

5.3.3 Stove has possibility for programmed on and off mode during a day and this option is

regulated on three ways: .......................................................................................... 19

5.3.4 LANGUAGE OPTIONS...................................................................................... 21

4

ThermoFLUX

Minitherm -

5.3.5 STAND BY mode ........................................................................................... 21

5.3.5.1 STAND BY mode with installed sensor for air temperature ................................. 21

5.3.5.2 STAND BY mode with room thermostat connected............................................ 22

5.3.6 Option Buzzer ............................................................................................... 22

5.3.7 Filling of spiral dispenser................................................................................. 23

5.3.8 STATE OF THE STOVE..................................................................................... 23

5.3.9 Technical settings .......................................................................................... 23

5.3.10 FUEL TYPE................................................................................................. 23

6Ignition and shutting down of stove.............................................. 25

6.1 Ignition ........................................................................................................... 25

6.2 Shutting down of stove ...................................................................................... 26

6.3Stove power adjustments ................................................................................... 26

6.4 Adjustment of air temperature ............................................................................ 27

6.5 Modulation....................................................................................................... 27

6.6 Cleaning of FIRE-POT......................................................................................... 28

7Cleaning and maintenance .......................................................... 29

7.1 Daily cleaning................................................................................................... 29

7.2 Weekly cleaning................................................................................................ 29

7.3 Cleaning the tube heat exchanger........................................................................ 30

7.4 Cleaning the flue gas chamber ............................................................................ 31

8Connection options..................................................................... 33

8.1 Scheme for electric connection ............................................................................ 33

9Alarms...................................................................................... 34

10 Instruction about safety removal and proper disposal of stove ...... 36

10.1 Disposal .......................................................................................................... 36

11 Guarantee .............................................................................. 37

11.1 Guarantee period .............................................................................................. 37

11.2 Guarantee terms............................................................................................... 37

11.3 Exemption from the guarantee ............................................................................ 37

12 Technical personal................................................................... 38

13 EU Label ................................................................................ 39

5

ThermoFLUX

Minitherm -

1Notes on the manual

1.1 Introduction

1.1.1 Easy and safe operation

This manual contains important information for proper and safe operation of the

Minitherm - stoves. Following these instructions you will avoid danger and repair

costs, and also increase the operational life of the stove.

1.1.2 Reading the manual

This manual must be read and applied by everyone who operates or works on the

Minitherm - stove.

1.1.3 Technical changes

ThermoFLUX continuously develops and improves its stoves. The information in this

version is correct at the time of going to press. All details in this manual on

standards and regulations should be checked before use and should be compared

with the installed stove. We reserve the right to make changes which may then

deviate from the technical details and illustrations in this manual.

1.1.4 Copyright

Written agreement is required from Thermo FLUX d.o.o. for any reprints,

storage in a data–processing system or transmission by electronic, mechanical

or any other means, for copies and publications, in whole or in part.

6

ThermoFLUX

Minitherm -

2 Safety notes

2.1 Proper use

2.1.1 Basic principles

Minitherm stove was built in accordance with safety regulations. However, its use can

result in the injury or death of the user and/or third part and in impairments to the

stove itself or to other material goods.

2.1.2 Using the stove

Use the stove only when it is in perfect condition. Use it properly, as described in this

manual. Stay aware of the safety and of the dangers involved. Have any faults which

can impair safety immediately fixed.

The stove was designed to burn wood pellet and wood. The manufacturer will accept

no responsibility for any damage resulting from improper use. Proper use includes

maintaining the installation, operation and maintenance specified by the

manufacturer. The user may only enter or change the operating values specified in

this manual. Any other entries will affect the stove's control program and operation,

which can lead to a malfunction.

2.1.3 Permissible fuel for the Minitherm - stoves

Only wood pellets and wood are permissible as fuel for the stove. Wood pellets are

pressed into a cylindrical shape. They consist of untreated sawdust from the wood

processing industry as well as unprocessed forestry waste. They have a standardized

diameter and length and very low air content.

2.1.4 Recommended wood pellets

Thermo FLUX d.o.o. recommends wood pellets with a diameter of 6 mm and a

length of 10 - 30 mm.

Other requirements on the fuel result from either standard O-Norm M 7135,

DIN plus 51731,

UNI CEN/TS 14961

Pay particular attention to the wood pellet quality.

7

ThermoFLUX

Minitherm -

2.2 Warnings and safety symbols used

DANGER OF ELECTRIC SHOCK.

Work on areas marked with this symbol may only be done

by a qualified electrician.

WARNING!

Warning about a dangerous location. Work on areas marked

with this symbol can lead to serious injuries or to extensive

material damage.

CAUTION!

Hand injuries. Work on locations marked with this symbol

can lead to hand injuries.

CAUTION!

Hot surface. Work on locations marked with this symbol can

lead to burns. .

CAUTION!

Danger of fire. Work on locations marked with this symbol can

lead to a fire.

CAUTION!

Frost danger. Work on locations marked with this symbol can

lead to frost damage.

Notes on disposal.

8

ThermoFLUX

Minitherm -

2.3 Other risks of the side effects

Despite the precautions taken there are also certain risks of side effects:

DANGER OF CARBON MONOXIDE.

If the stove is running during cleaning time may occur

transmission of CO through the open door. Do not open the

door longer than necessary.

2.4 Duty to inform

Reading the manual

Everyone who works on the stove must have read the Use and maintenance manual

before starting work and, in particular, have read the second chapter „Safety notes“.

This holds especially true for persons who only occasionally work on the stove e.g.

when cleaning or maintaining the stove. This manual must be kept ready to hand at

the stove's installation location.

Pay particular attention to the applicable local standards and guidelines.

2.5 Safety devices

Stove is equiped with safety devices that in case of unexpected situations

stop the power supply and thereby stop the operation stove.

Stove electronic regulation: operates directly and stops the operation of the stove

until it cools down.

* In case of the suction fan failure, failure of the motor for auger (doser), black out

(if the blackout was longer than 10 seconds), an unsuccessful firing.

Fuse F 4 A 250V : Fast fuse , protects the stove from large voltage changes of

electricity and short circuits inside the stove.

Safety thermo switch (STB) : intervenes by breaking the circuit in the stove

(automatically stops motor of the auger and exhaust gasses fan) if the stove

temperature reaches the limit of 95 °C.

9

ThermoFLUX

Minitherm -

3Installation and commissioning of

the stove

Commissioning system in the operation is performed by personnel

authorized by ThermoFLUX Ltd or autorized seller.

Commissioning includes referral to operation with the basic operations and

maintenance of the stove. Authorized service for the first start, must control the

functioning of the stove at least during one full operating cycle.

Danger from material and body due to improper

commissioning. If the commisioning is performed by

unautorished personel, it may cause damage to the stove

and heating system.

3.1 Conditions

The following conditions must be fulfilled before the system is put into

operation.

Turn OFF electrical power.

Check mechanical connections

Check that all components are properly connected

Check that all mechanical components are connected.

Check whether combustion chamber properly seated

Check hidraulical connections

Check whether the circulation pump and the mixing valve is properly

connected.

Check whether the safety equipment properly connected.

3.2 Chimney and flue gas pipes

The chimney should be calculated and constructed in accordance with the EN

13384-1 standard.

The venting of flue gas must be done in accordance with all applicable laws

including those related to dimensions of the chimney and materials used for its

production. Flue gas channel should be made of adequate materials, such as steel

tubes, with various sealing.

10

ThermoFLUX

Minitherm -

In any case, materials that could potentially catch fire, e.g. wooden planks,

beams, cloth, should be adequately protected with non-combustible material. For

the sake of parity of dimensions, chimneys that are round in shape of the inner

part should have an advantage over the rectangular-shaped chimneys.

Too small inner zone can cause irregular flow from the stove to the top which

could lead to poor stove performance and excessive exhaust gas production that

discharges the exhaust gas to the environment. Gas flue pipe should be

permanently installed and it would be good to make safety door which would

enable the cleaning of inner parts, especially the horizontal parts.

Smoke pipe should be installed fixed. It would be good to leave safety gates that

could do the Minitherm -r cleaning, especially in their horizontal parts.

You should avoid as much as possible horizontal mounting parts. Horizontal parts

must have a slope of at least 3% upwards.

Length of the horizontal part should be minimal and in any case not more than 3

meters.

ALL PARTS OF THE FLUE GASN PIPE NEED TO BE SECURED AND REPLACEABLE

IN ORDER FOR INTERNAL CLEANING.

AVOID MULTIPLE HORIZONTAL DEVIATION AND ANGLES.

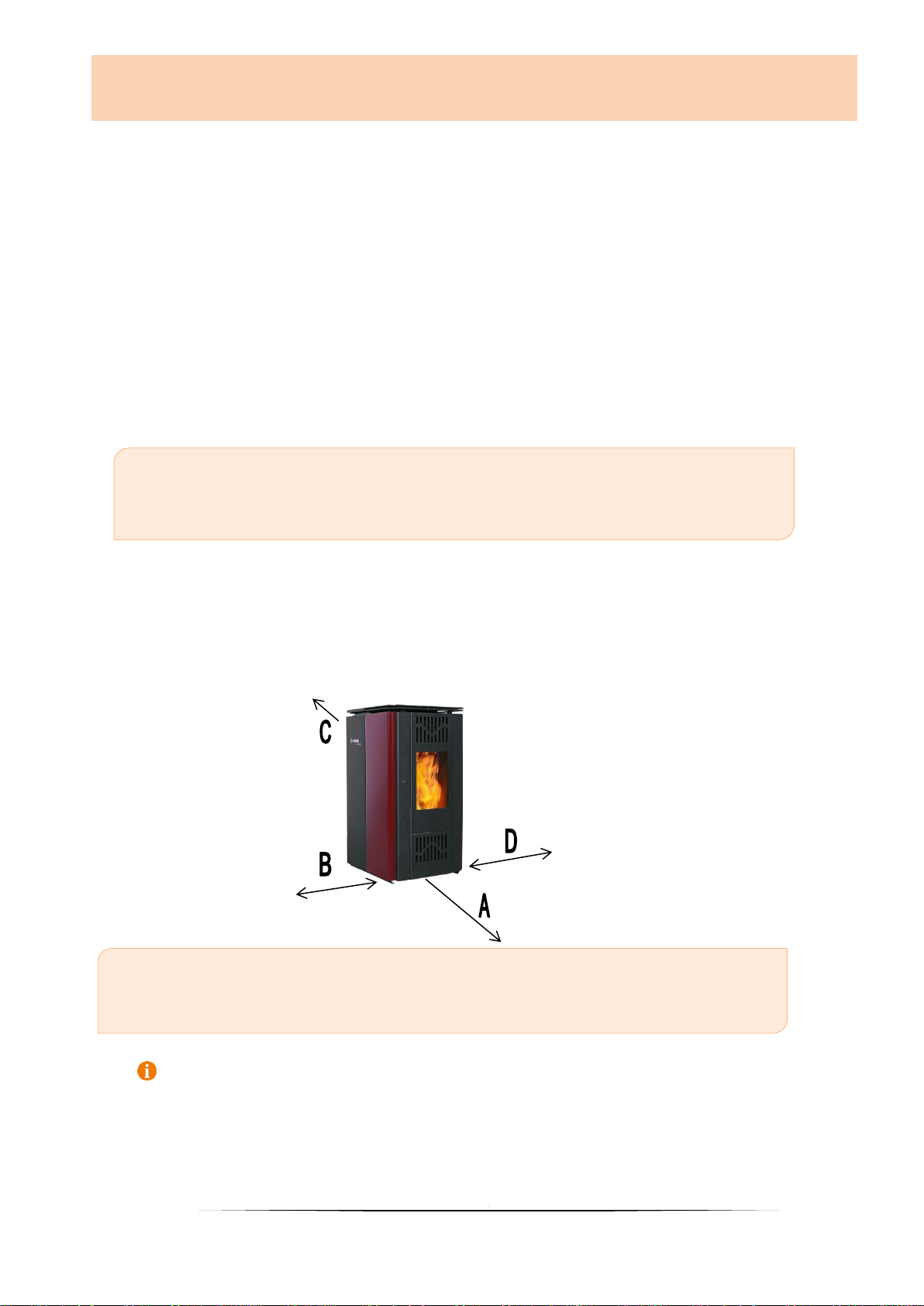

3.3 Minimum distances of the stove from wall

and objects

A –minimum distance front - 100 cm

B –minimum distance from side - 20 cm

C –minimum distance back side- 20 cm

D –minimum distance from side - 20 cm

ThermoFLUX leaves itself the right to later perform changes without notice.

11

ThermoFLUX

Minitherm -

4Functional description

4.1 General overview

Accompanying material

Tools for the pipeline and firebox cleaning

Door key

Power supply cable

Instructions booklet

Guarantee

12

ThermoFLUX

Minitherm -

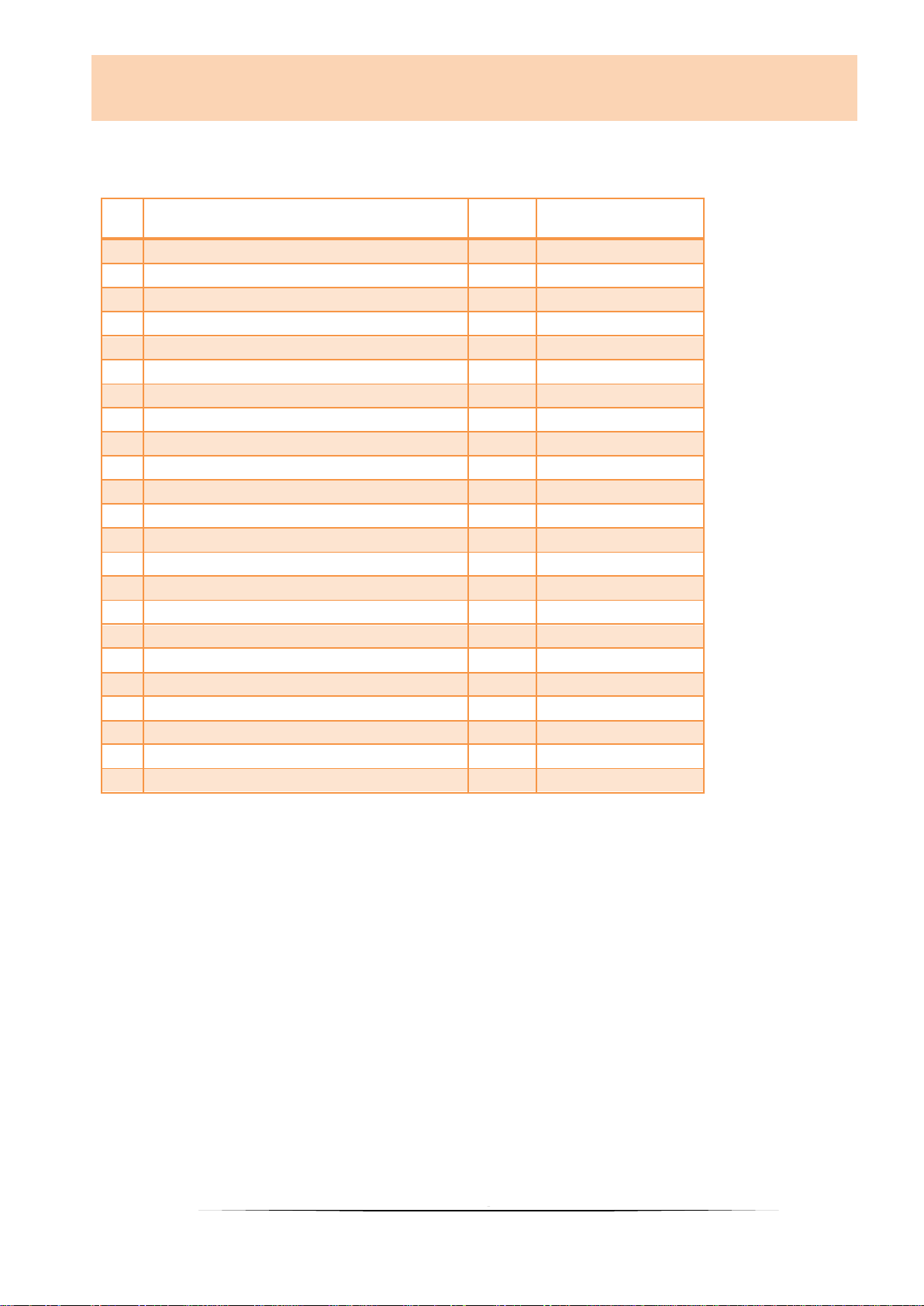

4.2 Technical data:

RB

J.M

Minitherm -

1.

Power range

kW

3 - 8,5

2.

Heat transfer to the air

kW

6,5

3.

Heat in room

kW

2

4.

Air content

L

23

5.

Recom. draught ratio

mbar

0,05/0,1

6.

Air conection return / out

inch

3/4''

7.

Flue gas max.temperature

oC

cca160

8.

Max working temperature

oC

85

9.

Max working pressure

bar

2,5

10.

Height to center of flue pipe

mm

198,5

11.

Depth

mm

575

12.

Width

mm

480

13.

Height

mm

945

14.

Color

red / black

15.

Flue pipe diameter

mm

80

16.

Out / Return height

mm

321 / 321

17.

Pellet storage cappacity

kg

18

18.

Electrica consumption nominal/max

W

80 / 330

19.

Min/max air temperature

oC

55 / 85

20.

Glass dimensions

mm

330x220x4

21.

Min/max pellet consumption

kg/h

0,6 –1,7

22.

Fuel

-

Pellet

23.

Flue pipe direction

back

820mm

13

ThermoFLUX

Minitherm -

5Function of stove

5.1 Overview of the controls and display and

their basic functions

Button

Description

1-

Increasing temperature and program functions

(adjusting days, time...)

2-

Decreasing temperature and program functions

(adjusting days, time...)

3-

Changing –accepting program

4-

ON / OFF, program exit

5 -

Decreasing power, navigate through the menu

6 -

Increasing power navigate through the menu

1

2

1

3

4

5

6

7

8

9

10

14

ThermoFLUX

Minitherm -

Display

8

Info

9

Clock

10

Air temperature indicator

Regulation on the stoves ''Minitherm'' is most important electronic

component. It is consisted of key controling modul set under the cover of the

stove and controling unit with display set on the front side of the stove. With

controling unit it is possible to control functions of the stove and also to check

information about present state of the stove.

Due to the possibilty to work in 5 (five) different powers, regulation can

satisfy needs to increase or decrease heating by automatic adjustment of

power.

If there is a need to increase power, this is registered by regulation and

regulation gives a signal to increase power by adding more pellet as well as

proportional increase of air flow in the burning basket.

When desired temperature is reached (need for heating energy is satisfied)

regulation is decreasing power ( modulates ), or when room thermostat gives

signal that set temperature is reached, stove then goes into SHUT DOWN mode

(if mode STAND-BY is ON )

7

When mark is visible

Clock

programmed ignit. active

Heater

heater active

Pelet dosage

auger active

Smoke fan

fan active

Primary air fan

fan active

Circulating pump

pump active

Alarm

alarm active

7

15

ThermoFLUX

Minitherm -

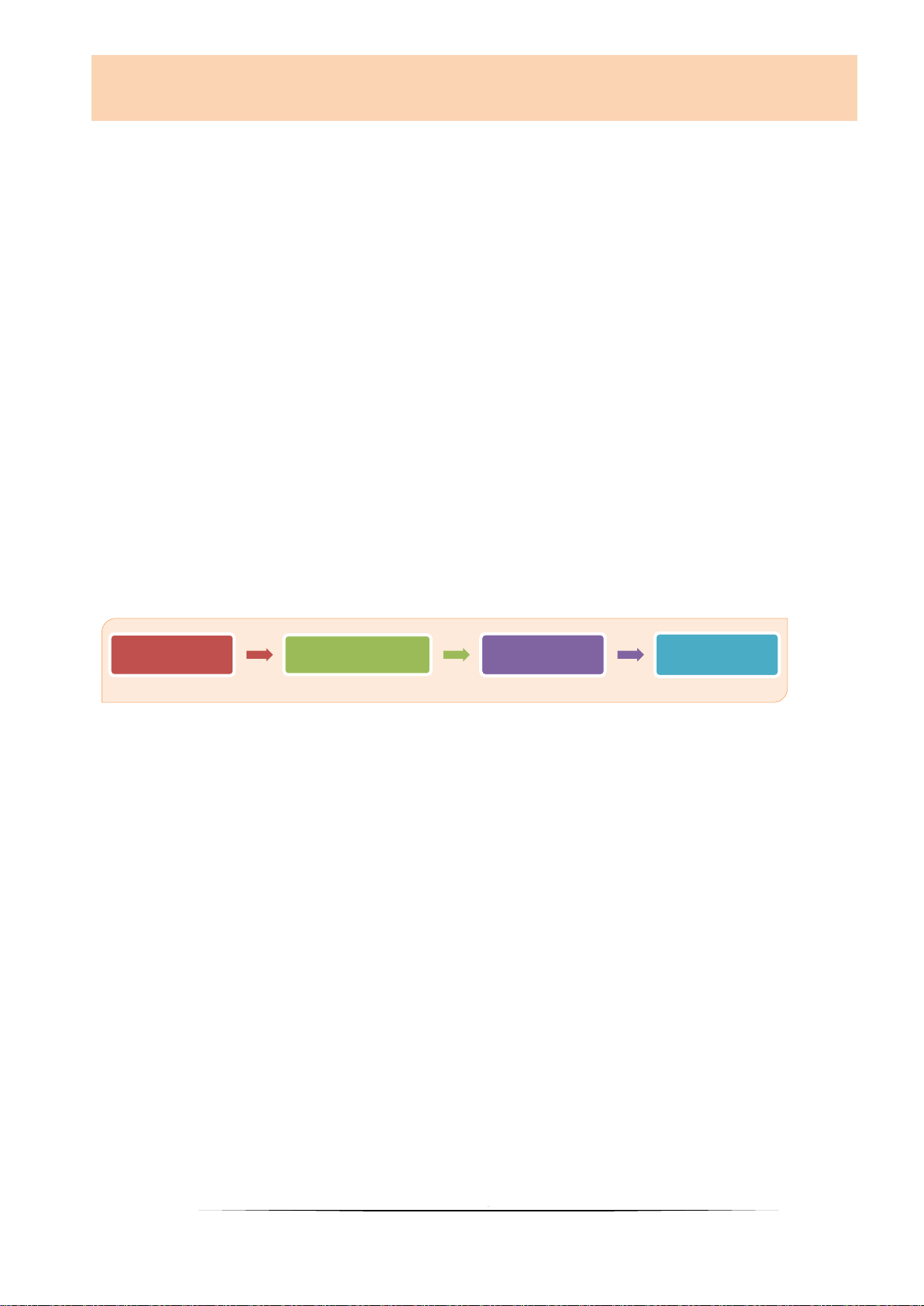

5.2 Principle of stove operation

Principle of the stove operation is very simple.

When button for start is pressed stove goes into IGNITION MODE. START is

displayed, and after that PELLET IGNITION. Usually this phase lasts for 5-15 minutes

depending on type of the stove and pellet quality. At that point dosing system is

activated, igniter and suction fan. Dispenser is making initial dosing of pellet into

burning basket. At the same point igniter starts to ignite pellet and suction fan is on

and is making necessary underpressure needed for combustion. When temperature

sensor for flue gasses detects that temperature in the chimney has reached

necessary value, regulation then changes working mode of the stove into FLAME

STABILIZATION.

This phase (FLAME STABILIZATION) lasts for 2-3 min. (depending on the type of the

stove and in this phase igniter goes off. After flame stabilization, stove goes into the

normal working mode and changes power from power 1 to set power. On display is

written WORK. On the right side set power is displayed and in the last

Start PELLET IGN. Flame

stabilization WORK

16

ThermoFLUX

Minitherm -

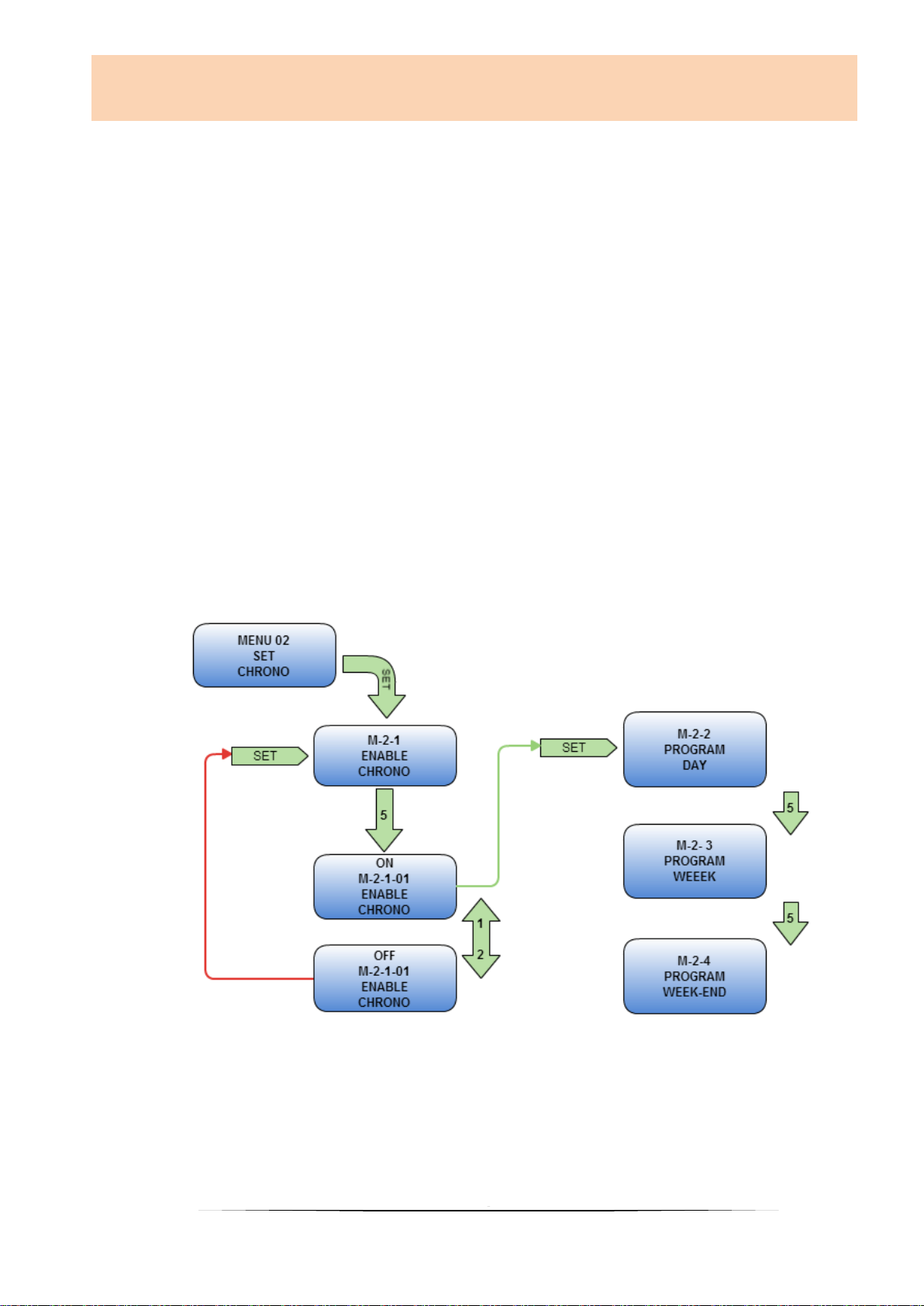

5.3 Schematic representation of the menu

control

By pressing button SET we enter general menu.

17

ThermoFLUX

Minitherm -

18

ThermoFLUX

Minitherm -

5.3.1 Clock adjustments

Clock adjustments can be done on following way:

19

ThermoFLUX

Minitherm -

5.3.2 Adjustments of the programmed on and off

mode

5.3.3 Stove has possibility for programme d on and off mode

during a day and th is o ption is regulated on three ways:

1. DAY PROGRAM, in this mode we can set 2 (two) different times

for ignition and shutting down of the stove.This applies to all

days in the week.(Scheme 2)

2. WEEK PROGRAM, in this mode we can set 4 (four) different

times for ignition and shutting down. In this mode, we can

choose day in the week (MON-SUN) in which we want stove to

work for each program (Scheme 3)

3. SUN-SAT PROGRAM, in this mode we can set 2 (two) different

times forignition and shutting down, but onl for SATURDAY and

SUNDAY. (Scheme 4)

Sheme1.

20

ThermoFLUX

Minitherm -

Shema 2. Shema 3. Shema 4.

Table of contents

Other ThermoFLUX Pellet Stove manuals

Popular Pellet Stove manuals by other brands

Enviro

Enviro Maxx brochure

Enviro

Enviro EF2 Service manual

Harman

Harman P43 Installation & operating manual

Palazzetti

Palazzetti MULTIFIRE BIO 9 Installation, use and maintenance guide

THERMOROSSI

THERMOROSSI BellaVista R silent Installation, use and maintenance guide

Enviro

Enviro Alliance EF3 Technical manual

Puros

Puros JOB Operating and maintenance manual

Hudson River Stove Works

Hudson River Stove Works Saratoga owner's manual

Palazzetti

Palazzetti ECOFIRE AIR SLIM 7 DESCRIPTION / CLEANING / TECHNICAL DATA

EURO AJPI

EURO AJPI Bernina Use and maintenance manual

klover

klover DEA PLUS manual

Whitfield

Whitfield Profile 20 FS Installation and operation manual