Minitherm AQUA

15

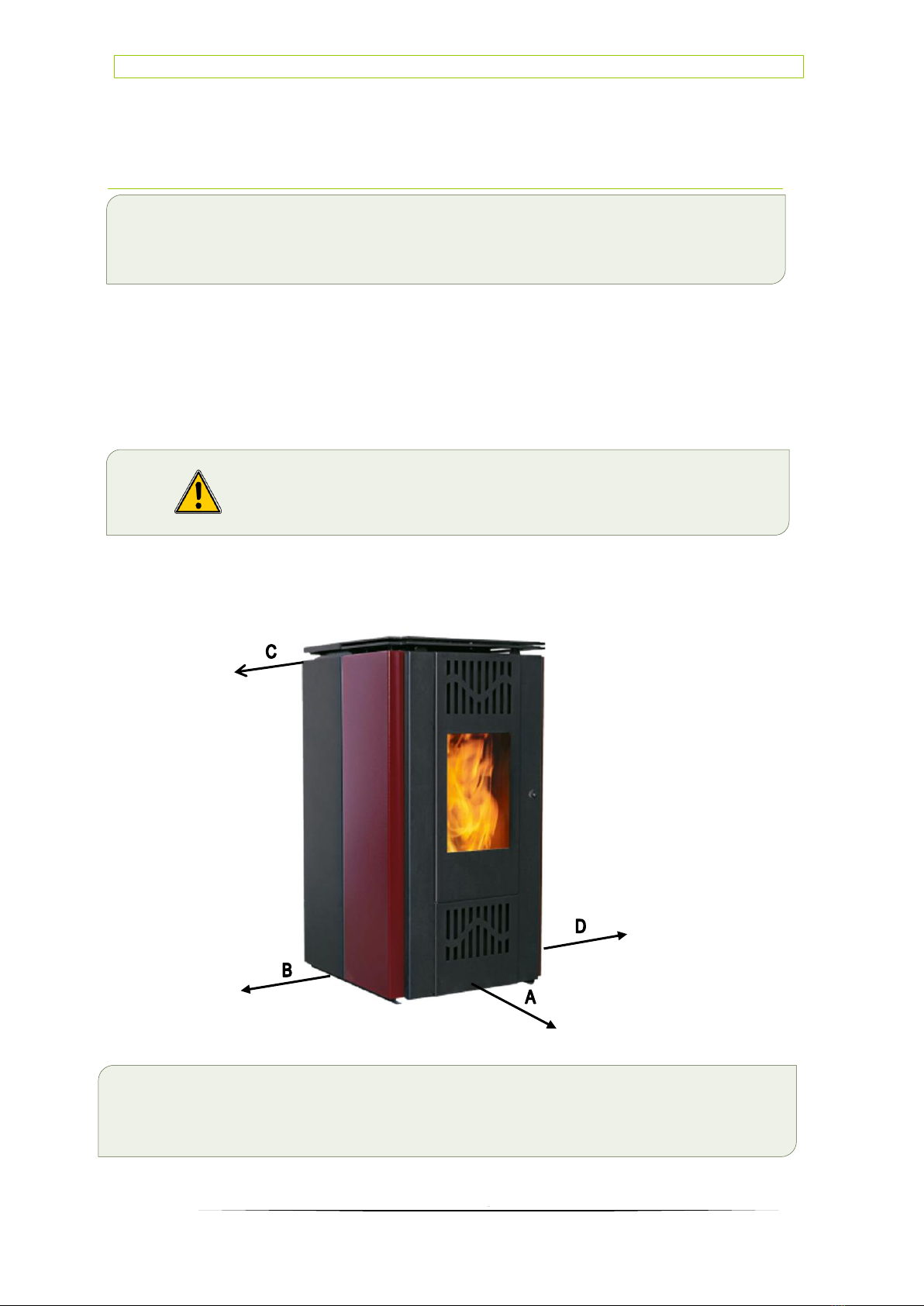

The following conditions must be fulfilled before the system is put into operation. Turn

OFF power supply.

Check mechanical connections

Check that all components are properly connected

Check that all mechanical components are securely attached

Check whether combustion chamber (pot) is properly seated.

Check hidraulical connections

Check whether the circulation pump and the mixing valve is properly connected.

Check whether the safety equipment properly connected.

4.2 Chimney and flue gas pipes

The chimney should be calculated and constructed in accordance with the EN

13384-1 standard.

The venting of flue gas must be done in accordance with all applicable laws including

those related to dimensions of the chimney and materials used for its production. Flue

gas channel should be made of adequate materials, such as steel tubes, with various

sealing. In any case, materials that could potentially catch fire, e.g. wooden planks,

beams, cloth, should be adequately protected with non-combustible material. For the

sake of parity of dimensions, chimneys that are round in shape of the inner part should

have an advantage over the rectangular-shaped chimneys. Too small inner zone can

cause irregular flow from the stove to the top which could lead to poor stove

performance and excessive exhaust gas production that discharges the exhaust gas to

the environment. Gas flue pipe should be permanently installed and it would be good

to make safety door which would enable the cleaning of inner parts, especially the

horizontal parts. Smoke pipe should be installed fixed. It would be good to leave safety

gates that could do the Minitherm -r cleaning, especially in their horizontal parts. You

should avoid as much as possible horizontal mounting parts. Horizontal parts must

have a slope of at least 3% upwards. Length of the horizontal part should be minimal

and in any case not more than 3 meters.

ALL PARTS OF THE FLUE GASN PIPE NEED TO BE SECURED AND REPLACEABLE

IN ORDER FOR INTERNAL CLEANING. AVOID MULTIPLE HORIZONTAL

DEVIATION AND ANGLES.

The internal cross-section of the exhaust pipes should be smoth and all connections

must be hermetically sealed. Avoid as much horizontal mounting as possible.

Horizontal parts should have a slope of at least 3% upwards. The length of the

horizontal part of the saddle shall be minimum and in any case not more than 2 meters

with the possibility of cleaning and removing the accumulated ash. The connection to

the chimney should be made with a maximum of two exhaust pipes.

For stove operation, a constant negative pressure is required. At reduced power, the

flue gas temperature is low and condensation may occur. It is therefore important that

the chimney is well insulated. The flue pipes should be made of non-combustible

materials that are suitable and resistant to combustion products and their possible

condensation. In any case, the parts or zones that are flammable, must be properly

protected, such as wooden boards or beams.

FOR SMOKE PIPES, DO NOT USE METAL-FLEXIBLE CABLES. ALL PARTS

OF THE SMOKE PIPE SHOULD BE SAFE AND REMOVABLE TO CLEAN

CLEANING. AVOID HORIZONTAL DEVIATIONS.