Thermona PT59X User manual

PT59X

Room thermostat with the option to regulate domestic hot

water (DHW) and remote control by mobile telephone for

boilers with OpenTherm communication

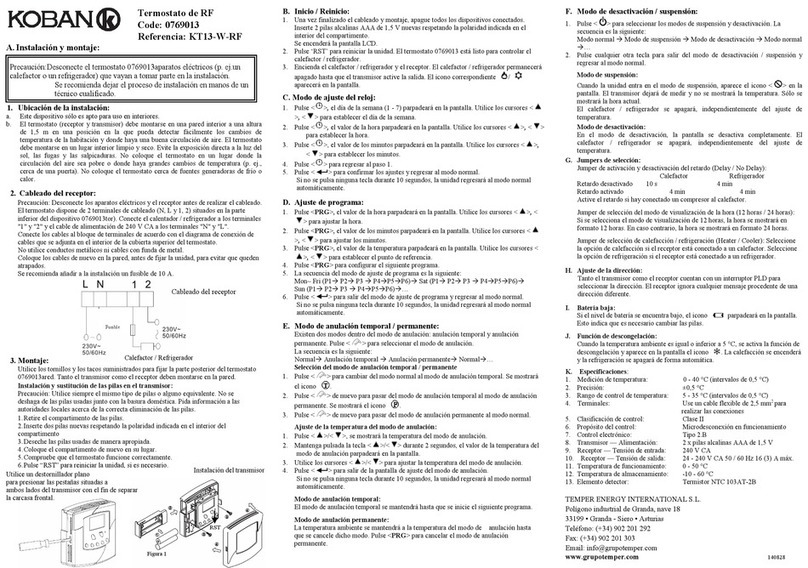

- opening the main menu

-ESC(escape)=return one step back

- browse through the main menu (view)

- browse in the “Parameters” mode

- in the “Setting program” browse between time intervals

- browse (view) information by pressing ” “

-ENTER= acknowledgement= typing changes

- quick change of the requested temp.

(short-term in the mode “Auto”,

permanent in the “Manual” mode)

- change in the adjusted value

- Press the button “LCD” to select the appearance of the introductory display of information on the display

01.01.13 21:45 Thuesday

AUTO prog:1 per.:1

IN:19.0°C DHW:50.0°C OT+

22.4°

C

Temp. DHW: 57°C OT+ Temp. DHW: 57°C OT+

actual

IN: 22.4°C

UT: 42.0°C

OUT: 8.0°C

required

IN: 19.0°C

CH: 0.0°C

DHW: 50.0°C

Actual temp. : 22.5°C

required IN : 19.0°C

required DHW : 50.0°C

outdoor: 8.0°C

- press “ “ for view following information ---------->>>>> by TURNING “ “ button next information

(about the heating system, the supply of hot service water, servicing, the outside temperature etc.)

- serves for fast copy of days in the “ Setting program” mode

- entrance/leaving into/from the service mode, press the button during about 5 s in the introductory display.

- Press the button to open the browse menu and the change the actual requested room temperature and the

automatic or manual mode

Turn the button “ “ to change the actual value of the requested temperature (in automatic mode up to the

further time section) or select another programme.

Turn the button “ “ to switch between the temperature and the programme

LCD COPY

1

2

3 4 5 6

7

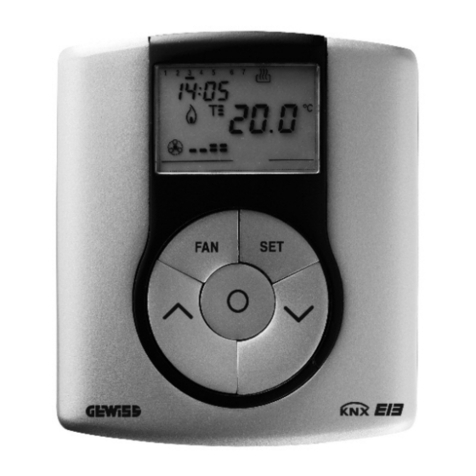

Control elements Button function - PRESSING Button function - TURNING

1

2

3

4

5

6

7

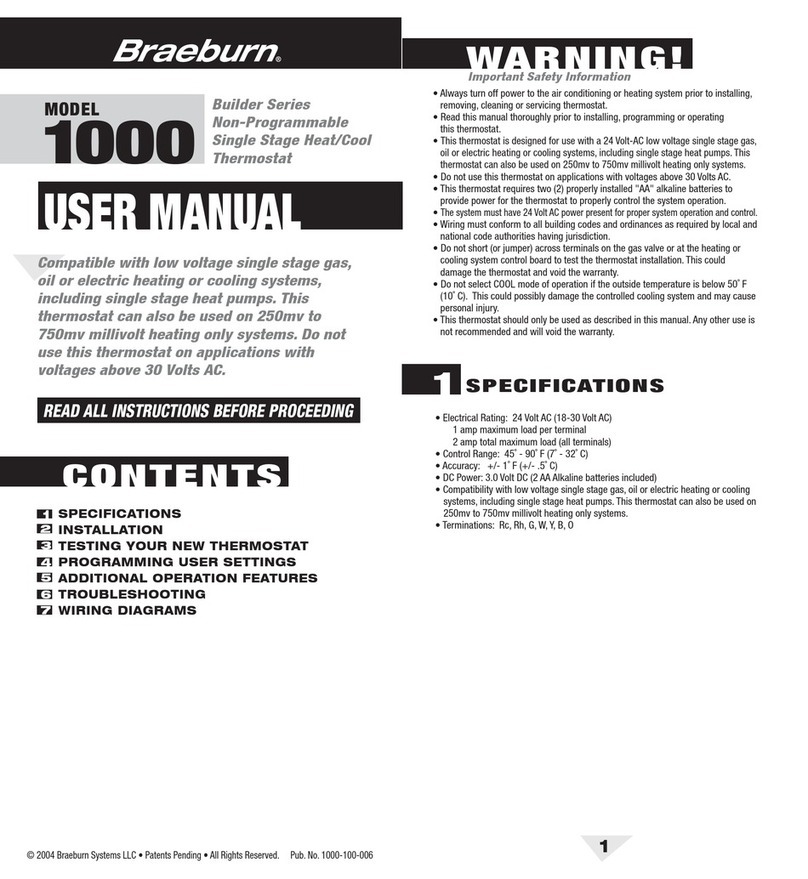

01.01.13 21:45 Thuesday

AUTO prog:1 per.:1

01.01.13 21:45 Thuesday

AUTO prog:1 per.:1

Required CH= calculated central heating according

to he selected equitherm curve, according to the

weather) irrespective of min. and max, potential temper-

ature of CH, the data in brackets is the requested temp.

with respect to the adjusted min. and max. CH temper-

ature (see pages 6, 7 – constants No. 6 and 7)

Actual CH = actual temperature of heating water

Modulation = modulation output of the boiler in %

Flow= information about the flow of DHW in litres per

minute for boiler СХ and ТСХ

Required temp. DHW= required DHW temperature

Operating hours CH and DHW= reset by ”LCD”button

Temp. measured= statistics value, reset by ”LCD”button

Works boiler inspector= service telephone (see page 5)

Required temp. in AUTO/MANU mode= change by

“ “, short-term in “Auto”, permanent in “Manual” mode

Outdoor temp.= temperature on the outside temperature

sensor connected to the boiler

Required temp. in premature switching mode=

constant No. 3

- Display backlight (after pressing any button the display is automatically backlit for about 2 s.)

LCD

COPY

DESCRIPTION

UT

sign for heating on

1

On the last line is further information, for example, the outside temperature

A) B) C)

The thermostat is installed in a suitable place where it cannot be affected by the flow of hot air from the heater, solar radiation and other

heat sources. The installation height should be about 1.5 m above the ground. Install the thermostat into what is known as the reference

room (e.g. a bedroom).

The installation of PT59X must only be done by a

properly qualifi ed person!

Work procedure:

1. Remove from the device РТ59Хreal panel (Fig. No. 1).

2. Remove plastic piece in the middle of the rear cover with the size of the

hole for the supply of the communication link.

3. Fix the rear cover on the installation box or the wall (Fix No.2).

4. Put the communication link from the boiler through the created hole in

the rear panel and connect it to the terminal box according to the

diagram.

5. Connect the thermostat to the rear panel.

Note.: After connecting the leads to initialize the processor (LCD flickers), so

appropriate to start with programming at least 10 minutes after the connection.

OPERATION

Auto (set in production)

The thermostat works according to the previously set program.

Main menu

Manual

The thermostat keeps a constantly adjusted temperature.

Auto off

disconnection of the boiler up to the time for the change of

temperature stated by the program.

Manual off

Permanent disconnection of boiler.

Holiday (Auto)

Keeps a constant temperature up to the set day of return from

vacation, and is then transferred into AUTOMATIC MODE (the last

selected program before the vacation). It is not possible to set the

Summer mode (setting values, constant No. 4)!

Setting

Selection of user modes

Press the “ “ button, by turning ” “ select the Auto mode,

confirm by “ “ button. A quick change of the requested

temp. is performed by pressing the “ “ or “ “ button

(cannot be set when in the OFF mode or the

Summer mode).

Press the “ “, button, by turning” “ select the Manual mode,

confirm by “ “ button.

The quick change of the requested temperature is performed

similarly as when in automatic mode.

Press the “ “ button, by turning ” “ select the

Auto off mode, confirm by “ “ button.

(Mode “OFF in automatic “ is cancelled by selection of

another mode).

Press the “ “ button, by turning ” “ select the

Manual off mode, confirm by “ “ button.

(Mode “ OFF in manual“ is cancelled by selection of

another mode).

Press the “ “ button, by turning the ” “ select mode

Holiday (Auto), confirm by “ “ . Set the date and time of return

from vacation and the temperature which the thermostat must main-

tain during the vacation. Turn the “ “ button to change the value

and press ” “ button. After expiration of the set period of vaca-

tion, the thermostat returns to the automatic mode. The heating

of DHW is always disconnected.

(The set value always flashes, turn the “ “ to browse

between data, press ” “ button to return back to the

menu. In the case of early return from vacation, cancel the

mode “Holiday in AUTO“ so that you select another mode).

The following text is displayed:

“ Holiday to 1.1.09 15:00”

New informotion showed:

“ Requested temp. in holiday ”

the text ” Off “ is displayed

ASSEMBLY

LCD COPY

Fig No.1

Fig No.2

Instal. diagram:

PT59X

BOILER

*

OpenTherm – communication

link, length max.50 m,

without polarity

*for exact electric connection,

see the instructions for the

boiler used

2

Connection outside sensor (see page 6) (not included)

1, for measurement of temp. in other place than is thermostat placed

2, as a floor sensor

3, for DHW regulation

GST1

Transfer of data through RS232 – the

cable is part of delivery GST1, length 1.1 m

Connecting the MS2 (not included)

when error messages are normally closed

relay switches MS2, to which may be

connected to another light or acoustic

element.

MS2

Holiday (Manual)

Keep a constant temperature up to the day of return from the vacation,

then switch to the MANUAL mode (the last selected program before

departure). It is not possible to set the Summer mode (setting values,

constant No. 4!

Press the “ “ button to select Holiday (Manual), confirm

by “ “ button. Use the similar setting as in Auto mode. After

expiration of the set period of vacation, the thermostat returns to

the manual mode. DHW is always disconnected.

Main menu Setting

Programming and

setting parameters

Setting clock

setting the actual time and date.

Setting program (factory setting prog:1)

Setting programs for CH and DHW.

The thermostat can set 9 weekly programs for heaiting and 6

thermal changes per day. Programs No. 8 and 9 are designed

for automatic changes in even and odd weeks.

During selection of permanent CH temperature (4. Regulation

mode “3“ Permanent CH temperature) output temperature from

the boiler or the cascade is always set.

Press the “ “ button, by turning ” “ select the mode

Setting clock, confirm by “ “ button. Turn the “ “ to

change the values and confirm the selected values by pressing

” “ button (Symbols above the set parameter always

flash. Turn “ “ to browse between data, press the but

ton “ “ to return to menu).

Press the “ “, button and turn the” “ to select

Setting program mode, confirm by “ “. Turn the

“ “ to select the program and confirm by ” “

button. Select the requested day in the same manner.

First, select the time of the change and then the

requested room temperature. Proceed in such manner

up to the last terminal. If you know that the following day

will be the same, press the button “ COPY“. The

program is copied. The text “COPY“ flashes on the

right upper side

(the set data always flashes, turn the “ “ button

to browse between the data, press the” “ button to

go back one step back in programming).

When programming DHW, proceed in a similar manner, set

the time sections for the heating of DHW.

Program CH Program DHW*

*Control DHW: When connecting an external sensor (see diagram on page 2), No.17 constant setting to "for DHW" and

location of the sensor in the tank, there is regulation DHW according to set program (with a hysteresis of ± 5 ° C according

to location of the sensor in the tank).

Parameters

Setting the regulation parameters and the heating system.

2. Min. program. temper. (factory setting 5°C)

Temperature limit - it is not possible to set the room

temperature below this limit when programming.

Select within the range from 2 °C to 10°C (by 0.5°C).

3. Max. program. temper. (factory setting 39°C)

Temperature limit - it is not possible to set the room

temperature above this limit when programming.

Select within the range from 15 °C to 39°C (by 0.5°C).

4. Mode (factory setting 0)

Status of the mode in which the thermostat will work.

0 - Required temper.regulation, the thermo-

stat heats for requested temp. at the stated time.

1 - Premature switching (PS), during two day of opera

tion, the thermostat ascertains thermal constants

of the reference room and then switches the

heating with requested advance (for restriction of

advance, see constant No. 5 below).

2 - Summer mode, the thermostat does not heat,

only controls the heating of DHW.

3 - Permanent temp. CH, the thermostat keeps

temperature of heating water within the limits of the set

time and the constant 6 (MIN. TEMP. CH) and 7 (MAX.

TEMP. CH).

5. Start-up sooner max. (factory setting 2 hours)

When PS is activated! The thermostat may

activate the heating at the set number of hours in

advance.

Optional range 0.5 to 6.0 hours (by 0.5 hours).

Press the “ “ button, by turning the button ” “ select the

Parameters mode. Confirm by pressing the “ “.

Turn the “ “ button to browse through the constants.

Turn the “ “ button to set the minimum adjustable

temperature and confirm with ” “ button.

Constant No. 3 automatically appears.

Turn the “ “ button to set maximum adjustable

temperature and confirm with ” “ button.

Constant No. 4 automatically appears.

Turn the “ “ set the maximum time in hours to show

the time in advance it is possible to activate the heating

so that the temperature reaches the requested value by

the stated time. Confirm by ” “ button.

Constant No. 6 automatically appears.

Constants

1. Cesky (factory setting Cesky)

Selection of language.

Turn the “ “ to select and press the ” “ button.

Constant No. 2 automatically appears.

3

Select program

Program: > 1 < Monday

1. 6:00 22.0°C

2. 9:00 19.0°C

3. 14:00 22.0°C

4. 16:30 24.0°C

5. 21:30 19.0°C

6. 21:30 19.0°C

Select program

Program: > DHW < Monday

1. 0 - 24 45.0°C

2. 24 - 24 45.0°C

3. 24 - 24 45.0°C

The last program is reserved for the management of DHW. For

boilers with flow heating, it is possible to set 3 time sections with

various temperatures (from 35 °C to 60 °C ). For boilers with

tanks, the temperature of DHW is set on the boiler and on

PT59X ; setting the temperature only enables activation of the

boiler for heating the boiler.

Turn the “ “ button to select the required regulation

mode and confirm with ” “ button.

In the case of selection of the mode “ 0 ” the constant No. 5

is skipped and the constant No. 6 is immediately appeared.

In the case of selection of mode “1“ , constant No.5 auto-

matically appears (in the list of information , the text

“required temperature in premature switching“ appears).

In the case of selection of mode “2”, constant No. 5 is

skipped and constant No. 6 immediately appears (on the

introductory screen the text “Summer mode” appears).

In the case of selection of the mode “3“ the constant No. 5

is skipped and the constant No.6 is immediately appeared.

On the introductory screen the text “required IN“ and at this

mode the stated actual value of required-permanent

temperature of heating watter is appeared.

6. Min. temp. heating watter (factory setting 30°C)

States the lower limit of the requested temperature for

heating water calculated by the thermostat for when

the heating can start. This constant prevents

redundant activation of the boiler.

Optional range from 5.0 °C to 50.0°C (by 1.0°C).

7. Max. temp. heating watter (factory setting 70°C)

States the upper limit of the requested temperature of the heating

water calculated by the thermostat which the boiler must not

exceed. Difference between the minimum and ten maximum

temperature must be greater than 8°C.

Optional range from 13.0 °C to 85.0°C (by 1.0°C).

Turn the “ “ button to set the minumum temperature

of the heating water and confirm with the ” “ button.

Constant No. 7 automatically appears.

Turn the “ “ button to set the maximum temperature

of the heating water and confirm with the ” “ button.

Constant No. 8 automatically appears.

Programming and

setting parameters

Main menu Setting

4

Constants

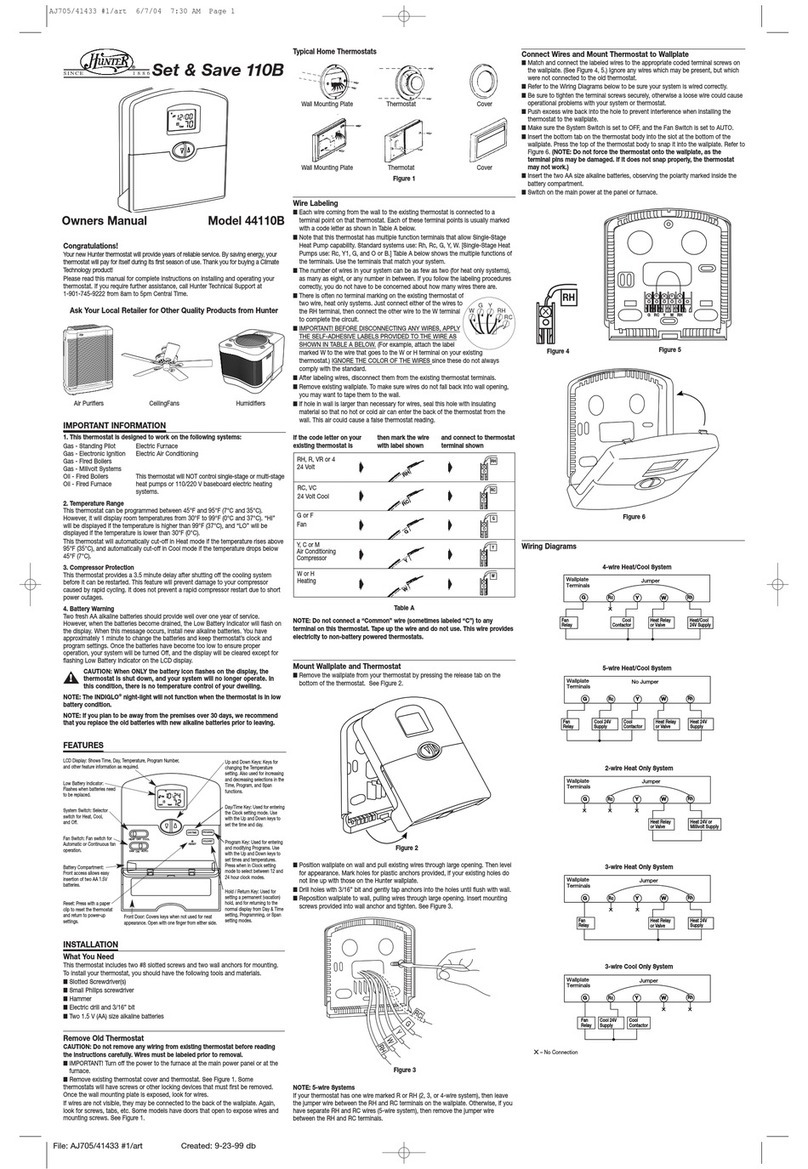

8. Number heating curve (factory setting “Room control”)

Selection of the type of regulation.

Room control = PI regulation (according to the

inside temperature). The thermostat heats up

depending on the temperature in the reference room.

It is necessary to set constants 11 and 12!

1 - 60 = equithermal regulation, number 1 to 60

corresponds to the requested heating curve (see below)

It is recommended to select equithermal regulation for large buildings where it is not possible to select a reference room. The principle of

equithermal regulation is optimising the temperature of the water for the heating system depending on the outdoor temperature.

The mentioned equithermal curves express this dependence (for a requested room temperature of20°C), according to which it is possible to select the

requested temperature of the water in the heating system. The thermostat calculates the temperature of heating water according to the selected

equithermal curve which is consequently sent to the boiler. Then the boiler regulates the temperature of heating water to the requested value.

It is necessary to select the slope of the curve according to the heating system to prevent permanent over or under heating of the building.

The selection of the correct curve for the stated system is a long-term issue and it is necessary to test the system at various outdoor temperatures! It is

recommended to modify the indoor temperature in the rooms, e.g. regulation by thermostat heads. The water temperature in the heating system is

restricted by minimum and maximum limits which are set in constants No. 6 and 7! During this regulation, the outdoor sensor must always be

connected to the boiler!

Turn the “ “ button to select the type of regulation

and press the ” “ button to confirmation.

In the case of selection of equithermal regulation follow

the instructions under the graph with the heating

curves.

If selecting a requested room temperature of other than

20 °C, the thermostat calculates the automatic shift of the

curve according to the following equation where the

coefficient is 1:

shift = (requested temper. - 20) * coefficient

Note.: the most frequently used curve under our conditions

is 9-11 for low-temperature systems and 15-17 for traditional

heating systems.

After selection of the optimal heating curve and the

confirmation, there is a shift to constant No. 9.

In the case of option PI regulation constants No. 9, 10 are

skipped and constant No.11 is automatically displayed for

further setting of the Pl regulation.

9. Parallel displac. h.c.

0.5 to 10.0 =manual correction according to the

coefficient, used if the temperature is not

according to your requirements (by 0.5).

In the case of this regulation, the heating curve is automatically corrected depending on the outdoor temperature, as well as

the actual temperature in the reference room where the thermostat is located. This enables to achieve higher thermal comfort in

the heated area, optimal operation of the heating system and greater savings! During this regulation, the sensor must always be

connected to the boiler and constant No. 9 must be set to „AUTO”!

AUTO= automatic correction, according to the

indoor temperature measured in the reference

room. It is possible to use this option after the

correctly selected equithermal curve!

Example describes the option for equithermal curve No. 13

(pink) and the calculated correction with the coefficient 2.5

(for requested room temperatures of 24 °C and 16 °C). The

optimal setting of the system is achieved when the water tem-

perature of the heating system is regulated according to the

actual outdoor temperature.

In the case of setting the equithermal regulation, it is possible

to select manual correction of the shift of the curve or the

automatic correction according to the indoor temperature.

Turn the “ “ button to set the correction for the curve and

press the ” “ button to confirm.

In the case of manual correction set the shift coefficient

for the heating curve when at various requested tempera-

tures in the reference room, regulation of the heating water

will be reached according to the actual outdoor tempera-

ture (for the formula, see constant No. 8).

After setting and confirmation, there is the automatic

transfer to constant No. 10.

In the case of option automatic correction according

to the indoor temperature, constants No. 10, 11 and

13 must be set.

Omezení max. teploty

vody top. sys. (Konst. 7)

Omezení min. teploty

vody top. sys. (Konst. 6)

external sensor

temperature [°C]

required temperature of

heating system [°C]

external sensor

temperature [°C]

required temperature of

heating system [°C]

designation of curves

13. Reaction speed (factory setting 12)

Active only in the case of selection of equithermal regulation

with automatic correction according to the indoor

temperature! States how fast the requested temperatures

are achieved. Optional range 1 to 16 (by 1).

Turn the “ “ button to select the value and press ” “

button to confirm. Constant No. 14 automatically appears.

At the speed of reaction 1 the requested temperature is achieved

slightly, which prevents possibility of overusing, although the

requested temperature is achieved later. At the speed of reaction

16, in the case of the change of the requested temperature, there

is immediate heating up to the requested temperatures, but

overusing occurs.

Setting

Constants

Programming and

setting parameters

Main menu

5

11. Reg. period in minutes (factory setting 10 min.)

It is selected according to the thermal inertia of the

object. The optimal setting is 10 to 15 min.

Optional range 5 min to 20 min (by 1min).

12. Reg. period in °C (factory setting 2°C)

Only in the case of the option PI regulation (constant 8

= without equitherm). The “zone of proportionality“ from

when the thermostat starts to restrict the CH temp.

(when the PI regulation starts). Optional range

1.5°C to 3.0°C (by 0.1°C).

The principle of PI regulation is based on comparing the

actual temperature of the room with the requested tem-

perature. This regulation depends solely on the indoor

thermostat sensor. Selection of constants 11,12: when

setting the time section, it is necessary to ensure the thermal

inertia of the room. The optimal setting is 10-15 minutes.

If there are frequent thermal deviations in the room it is rec-

ommended to select a shorter time section. Zone of propor-

tionality states from which value the PI regulations will start.

14. Day of service (factory setting 1.1.2029)

Setting the date for servicing the boiler. Notification for the

user regarding the maintenance of the boiler.

Turn the “ “ to set regulation interval and press ” “

button. Constant No. 12 or No. 13 automatically appears (at

the equitherm with automatic balancing).

The length of the interval in minutes influences the oscilla-

tion of the system. The lower this value, then the higher the

risk of oscillations.

If selecting the PI regulation (constant No. 8), it is necessary

to set the further parameter.

Turn the “ “ zone of the proportionality of PI regulation

and press the ” “ button. There is the automatic

appearance of constant No. 14.

In the case of selecting the PI regulation parameters,

orientate according to the PI regulation and follow

instructions shown at the graph.

Turn the “ “ button to consequently set day, month and

year for the revision and confirm each setting by the ” “ .

To speed-up the setting, press the button “COPY“, which

displays the actual date. The revision is cancelled by the change

of the date of revision. After setting constant No. 17 automati-

cally appears (or 15 in service mode).

At the stated date, the text “ revision of the boiler

is required” is shown on the display.

15. Name of technical expert

Display of the name of the service technician. The name of

your service technician appears on the display. Active only

when in service mode.

16. Phone of technical expert

Display of the telephone number of the service technician.

The name of your service technician appears on the display.

Active only when in service mode!

Constants 15 and 16 can be set in service mode!

Opening service mode: twice press the ” “ button re-

turn to the introductory menu in the same manner and then

press the button „COPY“ for 5 s. Entrance into the service

mode is indicated by the text “SR“ in the right lower corner

of the display.

Press the “ “ button, select the “Parameters“ mode,

confirm by pressing the “ “. Turn the “ “ button select

the constant No. 15. Turn the “ “ button and set the tech-

nician name, each letter confirm by ” “.

Proceed in the same manner as when setting the telephone

number.

Termination of service mode (output from SR):

In the introductory menu, press the button „COPY“ for 5 s.

Do not make any changes and you are in the introductory dis-

play, there is automatic termination of the service mode within

4 minutes.

10. Building insulation

The speed of the change of temperature in the room during

frequent deviations of outdoor temperature depends on the

construction and insulation of the building. With this constant, it

is possible to take into consideration the speed of the change of

temperature according to the type of heated building (only in the

case of equithermal regulation.

badly = uninsulated building, responds quickly to a change in

the outdoor temperature

medium = insulated building, responds slowly to a change in

the outdoor temperature

well = well insulated building, responds slower to the

changes in the outdoor temperature

Turn the “ “ button to select the type of the building

according to the kind of insulation and press the ” “

button. There is the automatic appearance of constant

No. 14 (during manual correction) or No. 11 (during

automatic correction).

If stated, a new item appears in the information, for

examples SERVICE TECHNICIAN).

If stated, a new item appears in the information.

Example: Service technician

VASILEV

89876543210

Preset temperature

Proportional

band

Heating on at

100 % of the

working cycle

25. Version (reset of the factory setting)

Only for information regarding the firmware version of

the thermostat. Option to reset the factory setting

- reset.

Setting

Constants

Programming and

setting parameters

Main menu

6

17. Temper. 2nd sensor (factory setting “not used”)

Option to use the external room sensor (not the outdoor

temperature sensor).

Disconnect = external sensor is not connected, if connected,

it functions as an indoor sensor and regulation is according to

the temperature measured on the connected sensor.

For DHW = external sensor is placed in water tank and

regulate DHW (temper.program select for DHW see

page3).

15.0°C to 80.0°C = external sensor is used to restrict the

maximum temperature (e.g. heated floor, etc).

18. Use GSM (factory setting NO)

Option to use GST1 module for remote control of the

thermostat by mobile telephone.

NO = modul GST1 module is not connected

YES = modul GST1 is connected, the following

constants No. 20 and 21 must be set and the module

must be connected according to the respective manual!

19. Phone No. 1

Entering the telephone number in an international

format (79876543210), to which SMS are sent

back regarding the status of the thermostat.

79876543210

22. Pin

Setting the PIN code for the SIM card which is

inserted into the GST1 module.

* * * *

The version number of the firmware appears with the text

“COPY“. With the second pressing of the button „COPY“ (for

about 5 s) there is RESET OF THE FACTORY SETTING (on

the display above this button the text is displayed “reset“). To

return to the main menu use the “ “ button.

If the sensor is connected, the text will appear at the constant “ Sensor connected”. In the introductory LCD the value of

the temperature of the external sensor appears “ External sensor: XX.X°C.

If the sensor is not connected (or the sensor was disconnected) and constant No. 17 is set for the use of this sensor, the

notification “ External sensor error” appears. In information, a new item appears according to the use of the external sensor:

“ Regulation according to the 2nd sensor“/“ Temp.DHW sensor “/ “ Temp. 2nd sensor “.

Turn the “ “ in upward direction and set maximum temper-

ature measured by the external sensor (within the range 15 °C

to 80 °C), at which there is the disconnection of the boiler.

Setting is confirmed by pressing the “ “.

If the temperature measured by the external sensor reaches

the set value, there is the disconnection of UT and

on the display, the text “Disconnected-external sensor

appears“.

After setting, constant No. 18 appears.

Turn the “ “ button to set the option for using the module

GST1and press the button “ ” to confirm. There is the

automatic appearance constant No. 19 (if the module is not

used, constants 19, 20, 21, 22 is automatically skipped).

Turn the button “ “ to gradually set the numbers which

correspond to the telephone number for sending SMS

messages sent from the thermostat. Each number entered

ust be acknowledged by the button “ “. After setting the

last number, constant No.20 automatically appears

1st numeral

The telephone number is entered in the international format

(without “+“ or “00“ at the beginning). In the case that the

telephone number has 10 or 11 digits, an empty place is set on

the last position after entering the last number. Press the button

“ “ to switch to the next constant. In the case that you do not

want to enter the next telephone number, constant No. 20

“Phone No. 2” and No.21 “Phone No. 3” are left empty. When

setting constants No. 20, 21 the procedure is the same!

1st numeral

Individual characters of the PIN are not visible due to the

high level of security against misuse of the SIM card.

Turn the “ “ button to gradually enter the PIN code for the

card, to be inserted into the GST1 module. Each time the

number is entered it must be confirmed by “ “. After enter-

ing the last number PIN code, connect the conductor into the

GST1 module and connect the module into the socket. As

soon as the orange diode lights up, press the button “COPY”

(on the display above this button the following text is displayed

“1st attempt of 3”). Then, there is the testing of the correct

connection of module GST1 and verification of the PIN code.

If the PIN is incorrectly entered, the following text appears “In-

correct PIN“ and “2nd attempt of 3”. In the case of further

incorrect entering of the PIN, the following text appears “ Last

attempt”.

.

23. Legionella function (factory setting NO)

Ensures the control of the TUV tank for the minimum

temperature of 60°C, which kills all potential Legionella

bacteria.

NO = the function is not active

YES = the function is active, the value in the bracket is the

number of days, which remain to the automatic heating (always

by 5 days, if the temperature of the TUV does not exceed 60°C)

Turn the “ “ button to set the option and press the ” “

button to confirm. Constant No. 25 automatically appears.

Conditions for the correct function:

There must be information about the temperature of the DHW

from the boiler or the 2nd sensor must be in the function for

„HSW“!

The automatic heating always takes place at midnight.

20. Phone No. 2

Entering the telephone number in the international

format (79988776543) - not obligatory.

21. Phone No. 3

Entering the telephone number in the international

format (79988776543) - not obligatory.

When setting telephone numbers 2 and 3, the function is as follows:

1, SMS “ Info” will be sent from tel. numbers 2nd or 3rd, answer will be

sent to tel. number 2nd or 3rd;

2, SMS “Temp xx” will be sent from tel. numbers 2nd or 3rd, answer will

be sent to tel. number 1st;

3, If an error status is reported, an SMS is sent to tel. no. 1, 2 and 3;

4, If an SMS is sent from other tel. number, the reply is always sent only

to tel. number 1st.

5, SMS “Call” will be sent, the call is only on tel. number 1

!If the PIN is incorrectly entered three times, disconnect the module

and restart the thermostat. Remove the SIM card and insert it into the

telephone and activate the SIM card by entering the PIN. Then enter

the PIN again!

7

REMOTE CONTROL BY MOBILE TELEPHONE

FORMAT OF SENT MESSAGES

Info

Off

Temp xx

Call

information on the status of the heating system

disconnection of the heating system (in the AUTO mode - short-term, in the MANU mode - per-

manent), use to cancel the function to use the message Temp xx

change in the requested temperature (only integers can be entered and these must be within

the range of permitted minimum and maximum temperatures – constants No. 2 and 3)

back calling

xx = value of temperature in °C (always a 2-digit number, e.g. 15)

Attention: To send and receive back messages, any type of mobile telephone can be used! If the telephone

has the option to set the size (format) of the font, always use MEDIUM size (option for three font sizes) or

LARGE size (option for two font sizes).

!

Require: xx.x

Act: xx.x

On

Sig: x

Requested temperature (entered by the user)

Actual room temperature

Activated heating system (On)

states the value of the signal in the place of the location of the module where x

are values within the range 0 to 5:

0..cannot be determined or no signal is detected

1..the worst signal level

5..the best signal level

FORMAT FOR BACK MESSAGES FROM PТ59X

Off Deactivated heating system (Off)

AUTO The thermostat is in automatic mode

MANU The thermostat is in manual mode

Noakcept! Signals an error (incorrectly entered SMS, etc.)

xx.x = temperature in °C

Note: In the case of exceeding the min./max. temperature in the room (set constants 2 and 3) a

"WARNING " SMS is automatically sent in the Info form.

Specify the conditions for sending messages with your operator. We recommend using the services of

the mobile operator with the best connection.

BACK MESSAGES ARE SENT WITHIN 3 MINUTES!

DÁLKOVÉ OVLÁDÁNÍ MOBILNÍM TELEFONEM

pomocí modulu GST1

HOLI the thermostat is in vacation mode, keeps the constant temperature up to the stated date

Sens 2: xx.x Absolute temperature of the external sensor, if connected (see pages 2,6)

Out: xx.x Actual temperature of the outdoor sensor which is connected to the boiler

CH Indicates that heating is to CH

DHW Indicates that the heating is to DHW

E xxx Error message where xxx is the indication of error 001 to 255 (see page 8)

Power supply Through the OT communication link from the boiler

Communication link double link

polarita without polarity

length up to 50 m

Type of communication Bi-directional OpenTherm

Hysteresis DHW ±5°C

Range of adjustable temperatures 3 to 39°C

Range of adjustable CH temp. 5 to 85°C

Range of adjustable DHW temp. 35 to 65°C

Precision of measurement ±0,5°C

Protection IP20

Relative humidity < 85% RH

Working temperature 0°C to +40°C

TECHNICAL PARAMETERS

CERTIFICATE OF GUARANTEE

(guarantee period for the product amounts to 2 years)

product No.: date of sale:

stamp of shop:

examined by:

In case of guarantee or post-guarantee

service, send the thermostat to

the manufacturer’s address.

v souladu s RoHS

LEAD FREE

ERROR MESSAGES

Warranty rules: If a defect occurs in the product during the warranty period caused by a manufacturing defect or

a defect to the material, it will be removed free of charge. To apply the warranty, the purchaser must submit a

valid warranty certificate.

The warranty period is stated:

a. on the package of the product

b. in the manual for the product

The warranty does not apply to defects caused by:

1. unprofessional use (in variance with the User

Manual)

2. poor handling

3. penetration of other substances into the product

4. natural disasters

5. mechanical damage caused by the user

6. non-functioning of equipment caused by error

installation

The warranty certificate must contain

1. stamp, signature and address of the seller

2. day, month and year of the sale

3. exact indication of the product (model) and

the serial number of the boiler to which the prod-

uct applies

The warranty looses validity

1. if the warranty certificate is not correctly or

only partially completed

2. in the vase of self made changes to the war-

ranty certificate

3. in the case of not keeping to the intended

manner of use and maintenance of the product

4. intervention by unauthorized persons into the

product

5. unprofessional repair of the product

The OpenTherm protocol enables to send important error messages from the boiler into the thermostat.

The thermostat displays these messages on the last line of the display:

-E xxx , where xxx can be from 001 to 255. This type of error can be changed according to the model of the boiler (see

technical sheet) or according to the form of the connection of thermostat PT59X to the driving boiler in the cascade; therefore,

a service technician may need to be called. These are errors, e.g. bad exhausting of burnt gases, error in the outdoor

temperature sensor, etc. In the case of a cascade connection, there may be an interruption to the connection between individual

boilers in the cascade.

- Error in measurement of UT temperature = the inside sensor is damaged, contact a service technician.

- Error OPT - UT temperature = no information received from the boiler for the actual UT temperature.

Note: error xxx is displayed, the first line of the display starts to flash (date and time) to highlight the error status!

In the case of disconnection or interruption of a communication link between the thermostat and the boiler, the text ”Connect

the link”is displayed (during the first connection, the thermostat must be connected with the boiler through the link for about

30 minutes).

The advantage of this thermostat is an extremely long period for running the backup of the data and time module

(i.e. it is not necessary to set them again) – for more than 10 days from the date of disconnection from the source!

If the breakdown of the communication link is extremely long, it is necessary to set the date and the time, although the con-

stants and programs remain kept in the thermostat!

In this case, on the last line of the display, there is the notification „Set the date and the time“.

www.thermona.cz

Pb

f.w. - PT59X - V11.11Т

This manual suits for next models

1

Table of contents

Popular Thermostat manuals by other brands

Gemtech

Gemtech GT5020 Operation manual

Honeywell

Honeywell RTH7400 series installation guide

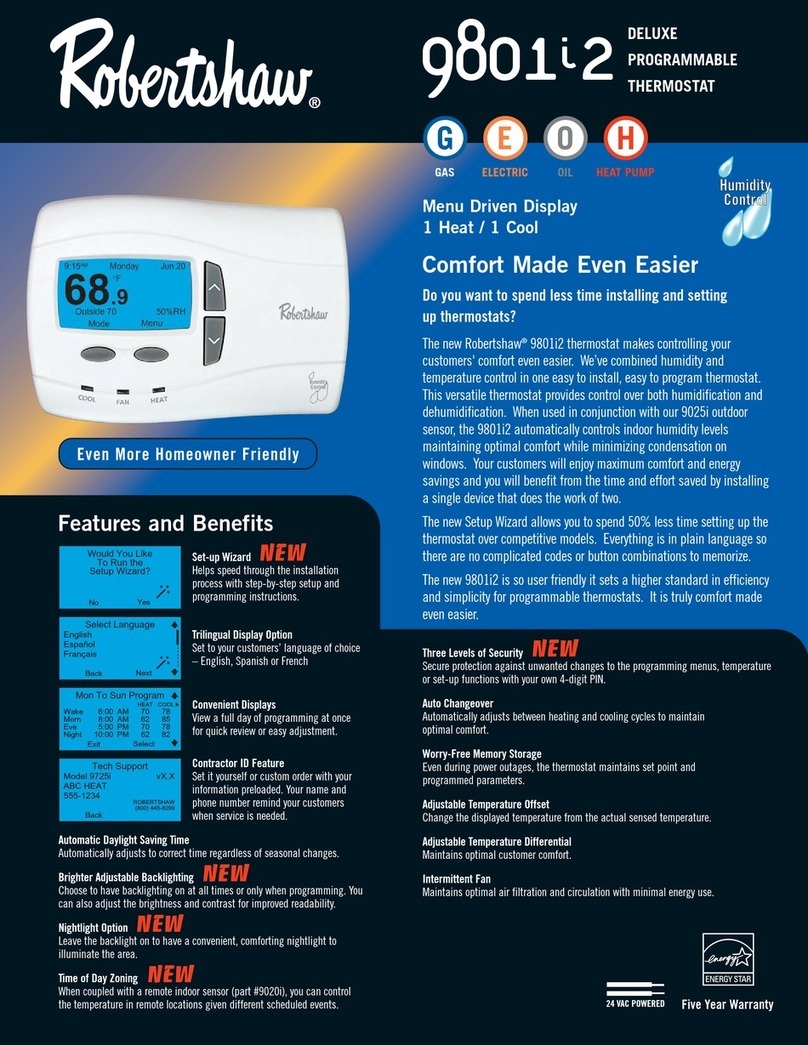

Robertshaw

Robertshaw 9801i2 Specifications

Venstar

Venstar T1070 Owner's manual and installation instructions

White Rodgers

White Rodgers 1F87-0261 Installation and operating instructions

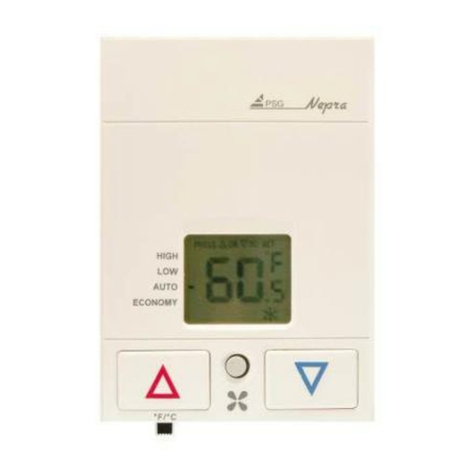

PSG

PSG NPK-4120U-1 Installation and operating instructions