THERMOROSSI SlimQuadro 11 Installation and operating instructions

THERMOROSSI

PELLET, WOOD & SUN TECHNOLOGIES

INSTALLATION, USE AND

MAINTENANCE GUIDE

READ!

Model:

SlimQuadro 11

IMPORTANT

INFORMATION FOR

SAFE AND CORRECT

OPERATION

Page 2

Installation, use and maintenance guide

Page 3

Installation, use and maintenance guide

INDEX

“EC” DECLARATION OF CONFORMITY.................................................................................................0

1 - INTRODUCTION...................................................................................................................................0

1.1 GENERAL GUIDELINES.................................................................................................................................. 0

1.2 SAFETY GUIDELINES ..................................................................................................................................... 0

1.2.1 RECOMMENDATIONS.............................................................................................................................................................0

1.2.2 GENERAL WARNINGS............................................................................................................................................................0

1.4 TRANSPORTATION AND STORAGE.............................................................................................................. 0

2 – TECHNICAL CHARACTERISTICS*.....................................................................................................0

3 – GENERAL DESCRIPTION...................................................................................................................0

3.1 OPERATING TECHNOLOGY........................................................................................................................... 0

3.2 THE PELLET..................................................................................................................................................... 0

3.3 THE FEEDBOX................................................................................................................................................. 0

4 - INSTALLATION....................................................................................................................................0

4.1 APPLIANCE LOCATION .................................................................................................................................. 0

4.2 UNPACKING THE APPLIANCE....................................................................................................................... 0

4.3 GLUING THE GLASS PANES TO THE FRONT PANEL................................................................................. 0

4.4 CONNECTING THE APPLIANCE TO THE FLUE OUTLET............................................................................. 0

4.5 REMOUNTING THE FRONT PANEL............................................................................................................... 0

4.6 HANDLE............................................................................................................................................................ 0

4.7 WALL MOUNT INSTALLATION ....................................................................................................................... 0

5 – DESCRIPTIONS OF CONTROLS........................................................................................................0

5.1 DESCRIPTION OF THE CONTROL PANEL AND BACK PANEL .................................................................. 0

5.1.1 DESCRIPTION OF THE CONTROL PANEL............................................................................................................................0

5.1.2 RH SIDE PANEL OF THE HEATER..........................................................................................................................................0

5.2 DAY AND TIME SETTING............................................................................................................................... 0

5.3 ON/OFF PROGRAMMING .............................................................................................................................. 0

5.3.1 ON-OFF PROGRAMMING DISPLAYS ....................................................................................................................................0

5.4 OPERATING LEVEL SETTING........................................................................................................................ 0

6 – USE OF THE APPLIANCE ..................................................................................................................0

6.1 SWITCHING ON THE APPLIANCE.................................................................................................................. 0

6.2 COMBUSTION AND VENTILATION ADJUSTMENTS..................................................................................... 0

6.3 INFRARED REMOTE CONTROL..................................................................................................................... 0

6.4 OPERATION OF THE WHITE HANDHELD RADIO CONTROL THERMOCOMFORT (OPTIONAL)............ 0

6.4.1 INDICATORS OF THE HANDHELD RADIO CONTROL.......................................................................................................... 0

6.5 CHANNELLING................................................................................................................................................. 0

7 - ADDITIONAL ROOM TEMPERATURE THERMOSTAT (not supplied) ADDITIONAL

CHRONOTHERMOSTAT - MODEM (not supplied)..................................................................................0

7.1 OPERATING WITH THE ADDITIONAL ROOM TEMPERATURE THERMOSTAT (not supplied)................. 0

7.2 OPERATING WITH THE ADDITIONAL CHRONOTHERMOSTAT (not supplied)........................................... 0

8 - CLEANING AND MAINTENANCE........................................................................................................0

8.1 FOREWORD..................................................................................................................................................... 0

8.2 CLEANING AND MAINTAINING THE APPLIANCE......................................................................................... 0

8.3 AIR FILTER....................................................................................................................................................... 0

8.4 CHARGING THE BATTERY OF THE THERMOCOMFORT HANDHELD RADIO CONTROL (optional) ....... 0

8.5 BATTERY REPLACEMENT FOR INFRARED REMOTE CONTROL.............................................................. 0

Page 4

Installation, use and maintenance guide

8.6 REPLACING THE BUFFER BATTERY OF THE CONTROL PANEL ..............................................................0

9 – SMOKE DISCHARGE TUBE AND VENTILATION OF THE ROOMS.................................................. 0

9.1 FOREWORD.....................................................................................................................................................0

9.2 ROOM VENTILATION ......................................................................................................................................0

9.2.1 VENTILATION FROM ADJOINING ROOMS.............................................................................................................................0

9.3 SMOKE OUTLET..............................................................................................................................................0

9.3.1 CHIMNEY TYPES.....................................................................................................................................................................0

9.3.2 FLUE OUTLET / FLUE SYSTEM COMPONENTS ....................................................................................................................0

9.3.3 CONTROLS PRIOR TO INSTALLING THE APPLIANCE..........................................................................................................0

10 – ALARMS............................................................................................................................................ 0

11 - ELECTRICAL WIRING....................................................................................................................... 0

12 - INFORMATION FOR THE SKILLED TECHNICIAN........................................................................... 0

12.1 MAIN COMPONENTS AND THEIR OPERATION..........................................................................................0

12.2 REQUIREMENTS NECESSARY FOR CORRECT INSTALLATION AND OPERATION...............................0

12.3 TROUBLESHOOTING CAUSE-SOLUTION...................................................................................................0

13 - SPARE PARTS .................................................................................................................................. 0

13.1 SPARE PARTS SLIMQUADRO 11 PAGE 1/3................................................................................................0

13.2 SPARE PARTS SLIMQUADRO 11 PAGE 2/3................................................................................................0

13.3 SPARE PARTS SLIMQUADRO 11 PAGE 3/3................................................................................................0

Page 5

Installation, use and maintenance guide

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

“EC” DECLARATION OF CONFORMITY

Page 6

Installation, use and maintenance guide

1 - INTRODUCTION

1.1 GENERAL GUIDELINES

This installation, use and maintenance guide is an integral and essential part of the product and must be kept by the user. Before

commencing with the installation, use and maintenance of the product, carefully read all the instructions contained in this booklet.

All local, national and European regulations regarding the installation and use of the appliance must be met. The Manufacturer

recommends carrying out all the maintenance operations described in this manual.

This appliance must only be used as intended by the manufacturer. Any other use is considered incorrect and therefore hazardous;

consequently, the user shall be totally liable for the product if used improperly. Installation, maintenance and repairs must be carried

out by professionally qualified personnel, professionally certified according to Decree no. 37 of 22 January 2008 and in compliance

with current regulations and in accordance with the instructions provided by the manufacturer of the appliance. In case of repairs

only original spare parts supplied by the manufacturer must be used. Incorrect installation or poor maintenance could injure or

damage people, animals or things; in this case the manufacturer shall be relieved of all responsibility. Before beginning any

cleaning or maintenance operation switch off the appliance, turn the switch installed at the back of the appliance to the OFF position

and disconnect the plug from the electrical power socket. The product must be installed in locations suitable for fire-fighting and

furnished with all the services (power and outlets) which the appliance requires for a correct and safe operation. Any repairs or

actions carried out on any systems, components or internal or external parts of the appliance, or on any of the accessories supplied

with it, that are not specifically authorised by Thermorossi S.p.A, will automatically void the warranty and the manufacturer's

responsibility, pursuant to D.P.R. 224 of 24/05/1988, art. 6/b. Keep this manual in a safe place that is easily accessible to all users:

if the manual is lost or deteriorated contact the manufacturer for a replacement copy. If the appliance is sold or transferred to

another user ensure that the guide is handed over with it. If this manual is lost and/or damaged it is mandatory to ask the

manufacturer for a replacement copy.

Thermorossi S.p.A. retains copyright on theses service instructions. These instructions may not be reproduced or communicated to

third parties or used in any other way without the necessary authorisation.

1.2 SAFETY GUIDELINES

PERSONAL INJURY

This safety symbol identifies important messages throughout the manual. Read the information

marked by this symbol carefully as non-observance of this message can cause serious injury to

persons using the appliance.

DAMAGE TO PROPERTY

This safety symbol identifies messages or instructions that are fundamental for the appliance and

system to function well. To avoid serious damage to the appliance adhere strictly to these

instructions.

INFORMATION

This symbol indicates important instructions for good functioning of the appliance.If this information

is not correctly observed, the performance of the appliance will not be satisfactory.

NORMATIVE REFERENCES :

complies with the legislative provisions transposing the following Directives:

2004/108/CE (EMC Directive)

2006/95/CE (Low voltage directive)

89/106/CEE (Construction Products Directive) and subsequent amendments

and that all the standards and/or technical specifications listed below were applied

EN 55014-1 EN 55014-2 EN 61000-3-2 EN 61000-3-3 EN 60335-1 EN 60335-2-102 EN 62233 EN 14785

1.2.1 RECOMMENDATIONS

Before using the appliance, carefully read every section of this instruction manual as knowledge of the information

and the regulations contained in it are essential for a correct use of the appliance.

The entire operation concerning the connection of the electric panel must be carried out by expert personnel; no

responsibility will be accepted for damages, even to third parties, if the instructions for installation, use and

maintenance of the appliance are not followed scrupulously. Modifications made to the appliance by the user or on

his behalf, must be considered to be under his complete responsibility. The user is responsible for all the operations

required for the maintenance of the appliance before and during its use.

1.2.2 GENERAL WARNINGS

Page 7

Installation, use and maintenance guide

Caution: the appliance must be connected to a system provided with a PE conductor (in compliance with the

specifications of 73/23/EEC, 93/98/EEC, concerning low voltage equipment).

Before installing the appliance check the efficiency of the earth circuit of the power supply system.

Caution: the power supply line must have a section which is suitable for the power of the equipment. The cable section must in any

case be no less than 1.5 mm². The appliance requires powering with a voltage of 220-240 V and 50 Hz. Voltage variations greater

than 10% of the nominal value can cause irregular operation or damage the electrical device. Position the appliance so that the

electric power plug is easily accessible. Ensure that a suitable differential switch is installed upstream from the equipment.

Your appliance has obtained the CE marking and has been made to run for 1 hour to check that it functions correctly.

The product must not be used by children, by persons with physical or mental impairments, by persons who are not familiar with the

instructions for use and maintenance of the product (the instructions are found in this booklet).

CAUTION: Before each use make sure that the burner is clean and positioned correctly in its lodging, check that the ash pans are

clean and shut tight and check that the firebox door is locked.

WARNING: the door must always remain shut tight when the heater is operating. It is strictly forbidden to open the door while the

appliance is in operation. While the appliance is in operation the smoke exhaust pipes and the appliance itself can reach extremely

high temperatures: do not touch them! Do not expose your body to hot air for long, do not overheat the room in which the appliance

is installed, as these actions could cause health problems. Do not expose plants or animals directly to the hot air flow as this could

have noxious effects on them. The appliance must light up automatically as designed and described in this installation, use and

maintenance booklet; the appliance must light up automatically as designed and described in this installation, use and maintenance

booklet; in this regard, it is strictly prohibited to pour pellets (or other material) directly into the brazier. Do not place non-heat

resistant or inflammable or combustible objects in the vicinity of the appliance: keep them at a suitable distance. Do not place wet

clothing to dry on the appliance. When using a clothes horse, keep at a suitable distance. It is strictly prohibited to disconnect the

appliance from the electrical power mains during normal operation.

Warning: do not wet the appliance and do not touch the electrical parts with wet hands. Never vacuum hot ash : this

could damage the vacuum device. All the cleaning operations described in this manual must be carried out when the

appliance is cold.

Caution! Warning for Swiss users

Refer to the local cantonal regulations imposed by the Fire Department (Mandatory signalling and safety distances )

and the Note concerning installation of heaters issued by the Association of Cantonal Fire Agencies (VKF - AEAI).

1.4 TRANSPORTATION AND STORAGE

TRANSPORTATION AND HANDLING

The appliance must always be in a vertical position when handled and exclusively by means of trolleys. Take special care to protect

the electric panel, the glass, and all the fragile parts from mechanical impact which could damage them and their correct

functioning.

STORAGE

The appliance must be stored in a humid-free environment and sheltered from the weather; do not place the appliance directly on

the floor. The Company denies all responsibility for damage caused to wood floors or floors made from any other material.

It is inadvisable to store the appliance for long periods of time.

Page 8

Installation, use and maintenance guide

1109

USCITA

FUMI

USCITA FUMI

69

854

69

854

CANALIZZAZIONE

CANALIZZAZIONE

CANALIZZAZIONE

418.3

571.7

487.2

857

768.4

219.6

157.9

422.8

908

992.5

769.8

769.9

300

USCITA FUMI

366.5

258.5

343

PRESA ARIA

O

50

O

80

O

80

CANALIZZAZIONE CANALIZZAZIONE

2 – TECHNICAL CHARACTERISTICS*

* All the data are based on the heater fuelled with standards UNI EN 14961-2 A1 and A2 type-approved pellets.

** It is important to take into consideration the fact that the heatable volume is greatly influenced by the insulation of the

house (energy class of the building) and by the position of the appliance in the planimetry of the house, therefore the

indicated values may vary, even significantly.

SLIM

QUADRO 11

Height (mm) 993

Depth (mm) 300

Width (mm) 1109

Weight (Kg) 160

Min/Max firebox power (KW) 2.98 / 10.2

Min/Max rated power (KW) 2.5 / 9.2

Min/Max consumption (Kg/ h) 0.70 / 2.3

ΦSmoke exhaust pipe (mm) 80

Min. draught at rated power (Pa) 12

Min. draught at reduced power (Pa) 10

Tank capacity (Kg) Approx. 17

Average smoke temperature at

rated power (°C) 180

Average smoke temperature at

reduced power (°C) Not detected

Smoke flow at rated power (g/sec) 5.5

Smoke flow at reduced power

(g/sec) Not detected

Efficiency at rated power (%) 90.2

Efficiency at reduced power (%) 84.2

CO concentration in exhaust gas

with 13% O2 at rated power

(mg/m

3

)

188

CO concentration in exhaust gas

with 13% O2 at reduced power

(mg/m

3

)

Not detected

Power supply voltage and

frequency 220 V 50 HZ

Max electrical consumption 1.17 A – 270

W

Min electrical consumption 0.34 A – 70

W

Room heating capacity cubic

metres 210 **

Legenda Key

Canalizzazione Channelling

Uscita fumi Smoke outlet

Presa aria Air intake

Page 9

Installation, use and maintenance guide

3 – GENERAL DESCRIPTION

3.1 OPERATING TECHNOLOGY

Your appliance has been built to fully satisfy all your heating and practical requirements. Top-grade components and functions

managed with microprocessor technology guarantee high reliability and optimal performance.

3.2 THE PELLET

The appliance is fuelled by pellets, that is, cylinders of compressed sawdust; this allows you to fully enjoy the heat of the flame

without having to manually stoke the combustion.

The pellets have a 6 mm diameter and a maximum length of 15 mm. They have a maximum moisture content of 8%; thermal value

4000/4500 Kcal/Kg and density of 620-630 Kg/m³, less than 0.7% ash content.

It is strictly forbidden to use any pellet type other than that specified above. (UNI EN 14961-2 A1 and A2). The use of fuel

that does not comply with the above specifications not only immediately invalidates the warranty for the appliance but can

also create dangerous situations. Do not use the appliance as an incinerator, at the risk of voiding the warranty.

IMPORTANT: shut off the appliance before loading the pellets.

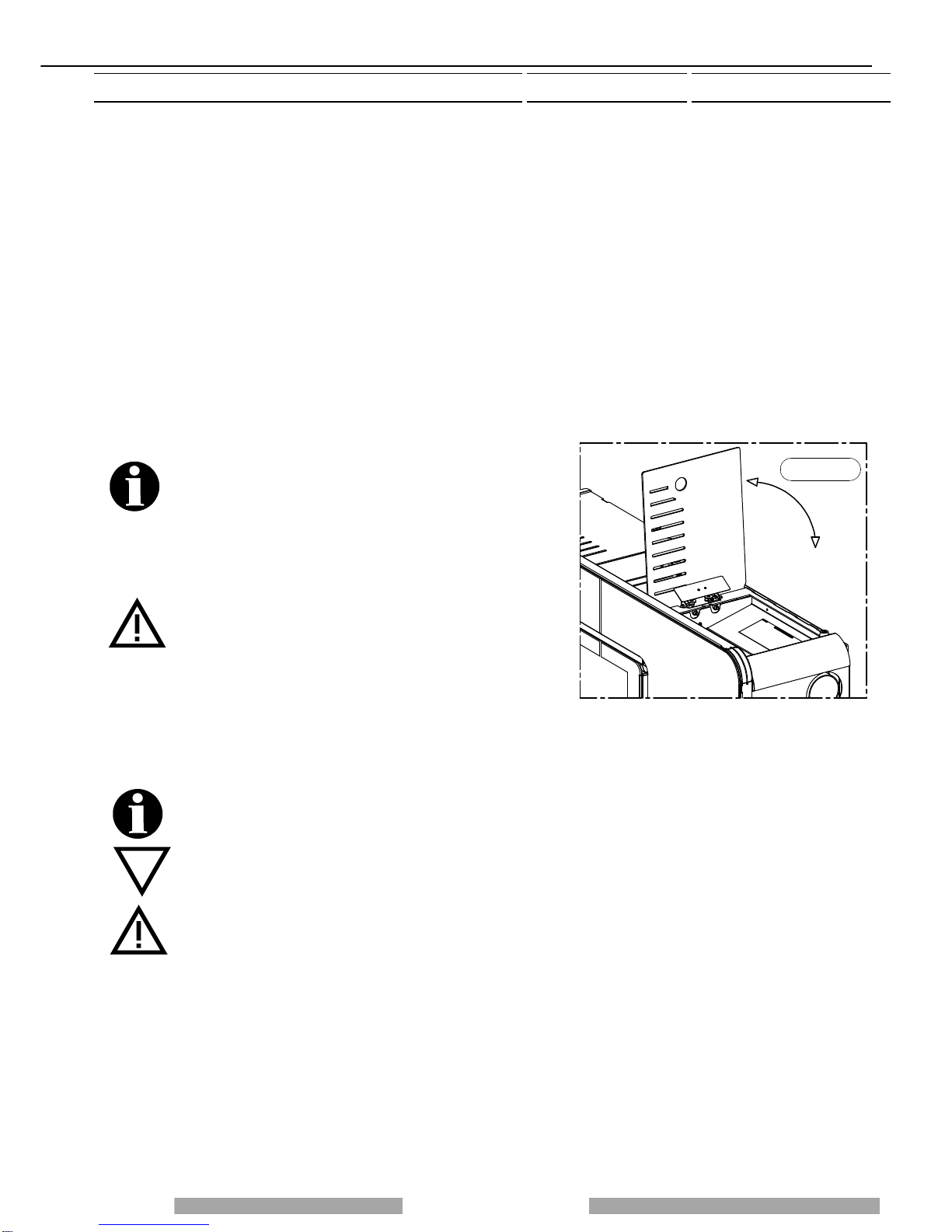

3.3 THE FEEDBOX

The feedbox is situated in the top part of the appliance. The load

capacity specified in the technical data can vary according to the

specific weight of the pellets.

Take special care when loading the tank of the screw feeder at

its base. Take care when topping up with fuel as the loading

area can get very hot.

Only pellets that comply with the specifications listed above

must be fed into the tank;

Never insert foreign objects into the tank. To access the feedbox

firstly remove the tank cover as illustrated in Figure 1.

Attention: when loading the pellets into the tank take care not to

drop any in the inner parts of the appliance, as this could cause

live flames inside the appliance. The manufacturer recommends

emptying the tank and vacuuming the screw feeder zone once a

month and during the summer period. The appliance is

designed to run on pellet fuel. Use of other combustible

materials in the tank and/or combustion chamber is strictly

prohibited.

4 - INSTALLATION

4.1 APPLIANCE LOCATION

Follow the general guidelines set out in paragraph 1.1 to the letter. Keep in mind that the flooring of the room in which

the appliance is to be installed must withstand the combined weight of the appliance and the pellets contained in the

tank.

CAUTION: The appliance must be installed in a room with adequate ventilation. The appliance must be positioned at

a minimum safe distance from walls and furnishings. If inflammable items are positioned near the appliance

(matchboarding, furniture, curtains, wall hangings, sofas, etc...), this gap must be increased considerably. The

recommended minimum distances are illustrated in Figure 1. If the flooring is made of wood or any other combustible

material, it is recommended to install a fireproof floor protector plate between the appliance and the floor. Installation

in the vicinity of heat-sensitive materials is only permitted if suitable insulating and fireproof protection is placed

between the object and the appliance (ref. Uni 10683). Failure to observe this instruction will immediately invalidate

the warranty.

The installer must issue a certificate of conformity for the installation which includes the design plans and the

following documents:

a) Report containing the type of materials utilised.

b) Project as defined in Article 5 of Ministerial Decree n°37 22 January 2008.

c) Drawing of the finished installation.

d) References to existing partial or previous declarations of conformity (e.g. electrical wiring).

e) Copy of the certificate of recognition of the professional technical qualifications.

Figura 1

Page 10

Installation, use and maintenance guide

These documents must, by law, be kept together with the

use and maintenance guide. The customer is responsible

for verifying, directly or indirectly, that the installation has

been carried out to perfection in accordance with relevant

regulations in force. Do not install the appliance in

unsuitable rooms such as bedrooms, bathrooms, garages

and/or lock-ups. It is forbidden to place the appliance in

environments with an explosive atmosphere.

ATTENTION , the stove is not simply a household

appliance: if the instructions set out in this booklet are not

followed and/or if installation of the appliance is not

executed perfectly and/or the provisions in force are not

strictly complied with, dangerous conditions could arise for

both objects and persons. It is the user’s responsibility to

verify the presence, in the room, of a vent necessary for

supplying oxygen to the generator.

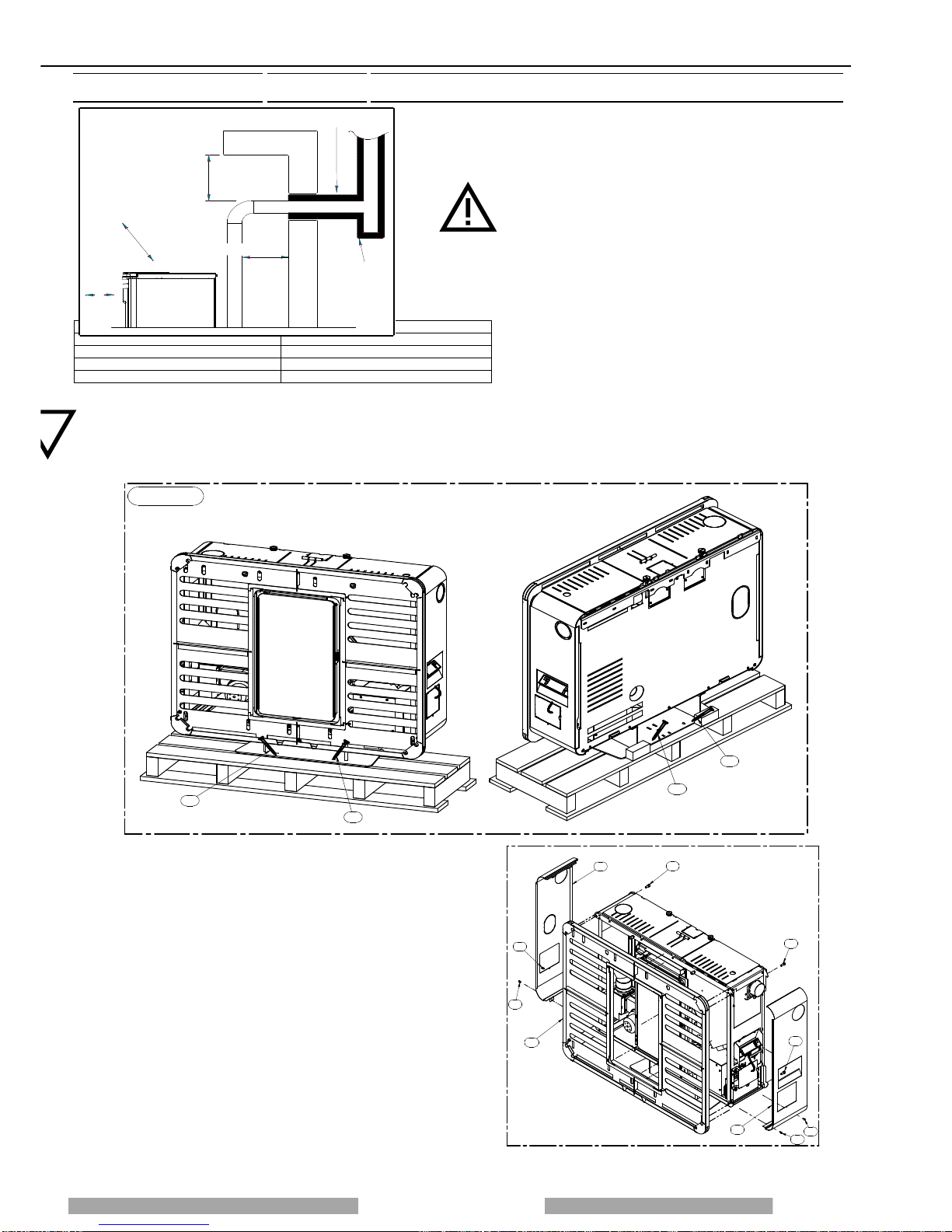

4.2 UNPACKING THE APPLIANCE

To unpack the appliance undo the screws C that fasten the base of the appliance to the pallet (Figure 1).

Figura 1

C

C

C

C

4.3 GLUING THE GLASS PANES TO THE FRONT PANEL

After unpacking the glass panes of the casing, disassemble the

front panel as described below. Prior to beginning any operation,

lay a soft sheet on the floor where you can place the front panel

after removing it from the appliance, in order to prevent damaging

the floor or scratching the paint on the panel.

• Undo screws A and slide out the left protective panel B

• Undo screws C and slide out the right protective panel D

• Undo the two screws E that fix the right side of the front panel

• Undo the two screws F that fix the left side of the front panel

• Remove the front panel by detaching it from the body of the

appliance.

• Lay the front panel on the sheet on the floor.

Legenda Key

Isolante termico Heat insulating material

200 – 450 mm se materiale combustibile 200 / 450 mm if combustible material

T ispezionabile Inspectable Tee element

Figura 1 Figure 1

200mmsematerialecombustibile

450mmsematerialecombustibile

ISOLANTETERMICO

200m

m

sem

ate

rialecom

bu

stibile

450mmsematerialecombustibile

Tispezionabile

Figura 1

A

A

B

CC

D

E

E

F

G

Page 10

lation, use and maintenance guide

SILICONEALTA

TEMPERATURA

AA

C

Figura 1

To glue the panes to the front panel, firstly apply silicone to the surface of the panel as illustrated in Figure 1. The silicone must be

suitable for high temperatures (>200°C). Attention: as highlighted in Detail C, do not apply silicone to the areas where the corners

of the glass cross over. If applied here the silicone could leak out and ruin the look of the product.

Position each glass pane by placing it in an inclined position and using the locators A indicated in Figure 1. When the edges of the

glass abut the locators A, delicately place the entire surface of the pane with the applied silicone and exert uniform pressure with

your hands over the whole surface, while making sure that the pane remains aligned in position. Repeat this procedure for all the

glass panes.

After checking that the panes are aligned with each other and with the front panel secure them in position by applying strips of

paper tape along the edges.

Wait at least 24h for the silicone to cure before handling the front panel. If the room temperature drops below 18°, wait 48 hours for

the silicone to cure completely.

4.4 CONNECTING THE APPLIANCE TO THE FLUE OUTLET

Connection of the appliance to the flue outlet must be carried out in

strict compliance with the instructions contained in this booklet (see

Chapter 9).

The appliance is fitted with the possibility for venting on three sides: top

left, side left and rear left (Figure 3).

Side or rear venting requires the use of a 90°elbow which is not supplied

with the appliance.

Once you have decided on the venting option that you wish to use, remove

the relevant precut shape. For this operation it is recommended to use a

blade for iron to prevent damaging the metal cover.

For instructions on how to install the smoke outlet in the wall, refer to the

technical drawings indicated in the “technical characteristics” in paragraph

2.

4.5 REMOUNTING THE FRONT PANEL

Once the appliance has been installed, the next step is to remount the front panel. Re-attach the front panel G to the body of the

appliance and lightly screw in the screws E (do not tighten). After checking that the front panel is aligned with the door (see the

alignment line in the drawing below) tighten the screws E. Complete the assembly of the heater.

ALLINEAMENTO

EG

G

E

E

ALLINEAMENTO = ALIGNEMENT

SUPERIORE

LATERALE

POSTERIORE

Figura 3

TOP

SIDE

REAR

Page 11

Installation, use and maintenance guide

4.6 HANDLE

Your appliance is supplied with a handle for opening and closing the firebox door to facilitate cleaning (see paragraph 8). The

handle is also designed to be used for regulating the ducting flow rate. When not in use, the handle can be stowed on the side of

the appliance if the hook provided is attached to the stove. (see Figure 4).

Figura 4

1

3

2

MANIGLIA

To mount the hook, remove the right side panel 1 of the heater (see paragraph 4.3), position the hook 2 in the hole and lock with

the nut 3. Replace the side panel 1.

HANDLE

Page 12

lation, use and maintenance guide

4.7 WALL MOUNT INSTALLATION

The appliance is supplied standard with a wall mount bracket.

To install the appliance on the wall firstly remove the left, right and front panels (see instructions in paragraph 4.3).

Remove the bracket A by undoing the two screws B which can be accessed by lifting the door C. For instructions on how to fasten

the bracket to the wall refer to the drawing in Figure 8.

Figura 7

Viti

B

Sportellino

C

Staffa

A

C

DETTAGLIO C

D

DETTAGLIO D

50858

Uscita Fumi

Posteriore Presa aria

comburente

C

a

n

a

l

i

z

z

a

z

i

o

n

e

Canalizzazione 213

369 458

86

97

364

O

80

O

80

O

80

600

332

STAFFA

A MURO

1040

LEGENDA KEY

Figura Figure

Viti Screws

Sportellino Door

Dettaglio Detail

Staffa Bracket

Canalizzazione Channelling

Uscita fumi posteriore Rear smoke outlet

Presa aria comburente Combustion air intake

Staffa a muro Wall bracket

Page 13

Installation, use and maintenance guide

14:30

WORK

3

2

5

48

1

76

11

13

12

14

14:30

WORK

Zona del display dove viene visualizzato il giorno

corrente (per esempio 3 pallini = mercoledì).

Indicatore livello

di ventilazione Zona del display

visualizzati fasi di funzionamento, ora....

dove vengono

"Themocomfort On "

ovvero connesso

Indicatore livello

di combustione

Hang the unit on the wall bracket A; once the appliance is suspended, push it firmly against the wall and tighten the screws B.

When carrying out this operation, take care to match up the support hooks (See details C and D in Figure 7).

Once you have completed this operation, remove the base by undoing the 4 screws that fix it to the structure of the appliance. It is

recommended to tighten the screws in the appliance once the base has been removed. Next assemble the front panel and the left

and right side panels.

ATTENTION: considering the weight of the appliance, it is recommended to use anchor bolts suitable for the type of

wall to which the appliance is mounted.

ATTENTION: it is necessary to ensure that the wall plaster and finish can resist a working temperature of 80 °C.

Given the working temperatures of the appliance it is normal for the wall to blacken, particularly if it is a light colour,

after a season of operation.

5 – DESCRIPTIONS OF CONTROLS

There are two main control pushbuttons marked with the ventilation symbol (2) and the symbol of the flame (1).The flame

pushbutton (1) sets the power of the appliance with 5 levels available which are activated as the 5 bars light up in sequence on the

display (7). The off cycle is activated when all power bars are turned off. The fan button (2) controls the ventilation of the appliance.

It is activated when the smoke, detected by the smoke probe, reaches a temperature over 60°C.

The fan can be set to any of 6 speed levels displayed by the 6 bars progressively coming on on the display (7): when the appliance

is on the ventilation cannot be switched off.

5.1 DESCRIPTION OF THE CONTROL PANEL AND BACK PANEL

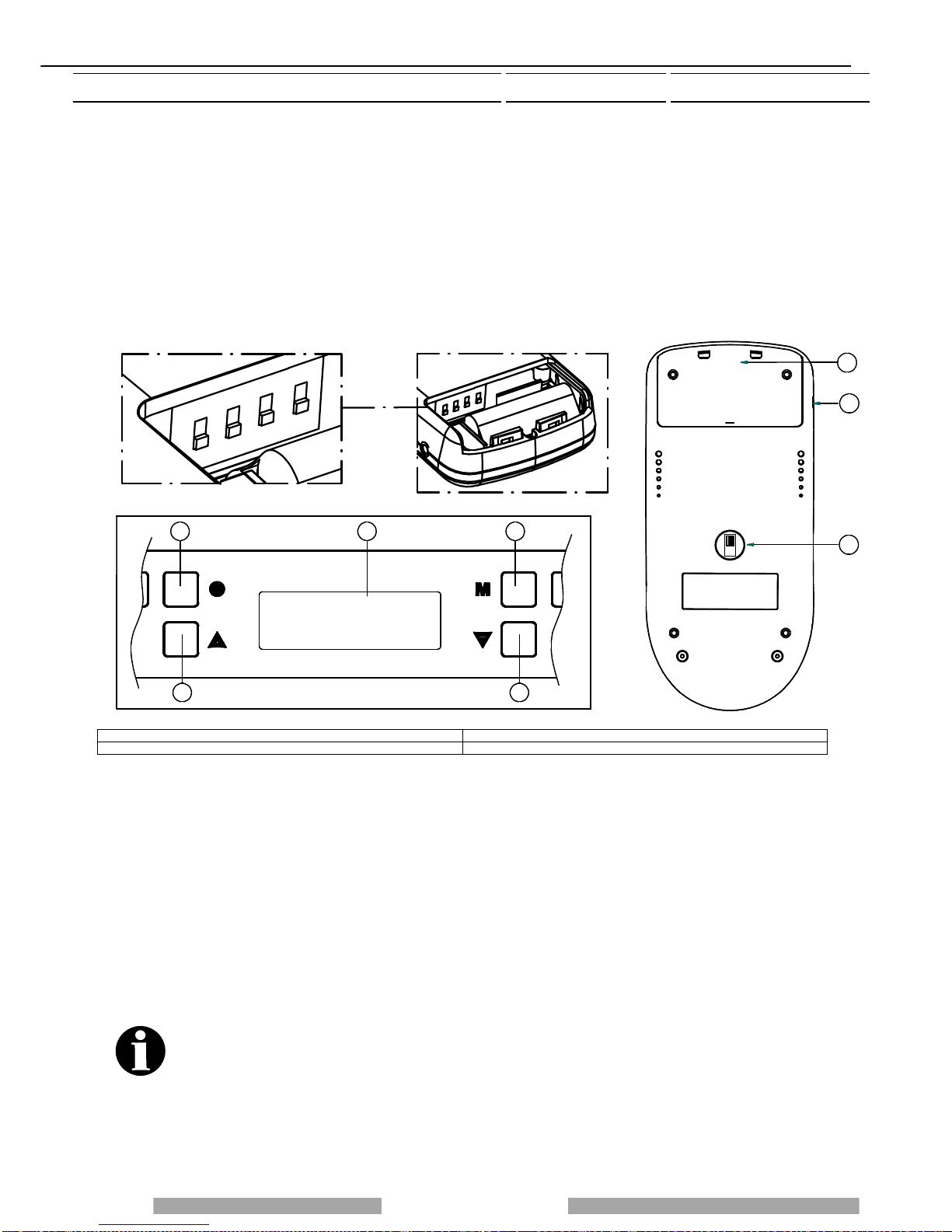

5.1.1 DESCRIPTION OF THE CONTROL PANEL

All controls and indicators are presented here below:

(1) Appliance on/off and flame adjustment button When you press

this button the appliance switches to START/WORK/ OFF

(appearing on the display 7). Press repeatedly to activate up to 5

bars on the display (7)

(2) Ventilation setting button Press this button to set the desired

level of ventilation: you can select up to a maximum of 6 speeds,

acknowledged by the corresponding bars lighting on the display (7).

One bar is always lit up even in OFF status.

(3) (4) Auxiliary setting buttons

Keys (3) and (4) are operating buttons necessary when on-off cycles

are programmed, for operative levels, clock setting, etc..

(5) Programming Enable / Disable / Chrono Reset buttons

(6) “MENU” selection button To access the main menu press the

button marked with 6. Press button 6 repeatedly to scroll the various

windows: date, programming setting,...

(7) Display

(8) Infrared remote control sensor

LEGENDA KEY

Zona del display dove viene visualizzato il giorno corrente (per esempio 3

pallini = mercoledì) Display area in which the current day is displayed (for example, 3 dots =

Wednesday)

Indicatore livello di ventilazione Ventilation level indicator

Zona del display dove vengono visualizzati fasi di funzionamento, ora… Display area in which the operation steps are displayed, time...

Indicatore livello di combustione Combustion level indicator

“Thermocomfort On” ovvero connesso "Thermocomfort On" i.e. connected

5.1.2 RH SIDE PANEL OF THE HEATER

A description of the functions of the buttons and LEDs on the rear panel:

(11) Main switch 0-1

(12) Electrical power outlet 220-240V 50 Hz.

(13) Overtemperature reset thermostat button cap

In the event of overtemperature this safety thermostat stops the loading of

pellets. To restart the appliance you need to wait until it cools down, then

verify the cause for the overheating, remove the cause, unscrew the

protective cap and press the button (13).

(14) Feed motor test indicator light When the pellet screw feeder is set

in motion the light must come on.

LEGENDA KEY

Riarmo Reset

Spia motoriduttore Ratio motor led

Page 14

lation, use and maintenance guide

DAYS

DATA MON

2

3

5

4

76

1

8

00 : 00

5.2 DAY AND TIME SETTING

The appliance must be energised and the rear

switch in position "1". The words START or WORK

or OFF could be present on the display (7). To set

the time and the day of the week carry out the

procedures described below. Press button (6) once;

the word DATA will appear on the display followed

by the words illustrated in the figure on the left. To

set the day press arrow button (3) and/or (4)

repeatedly until the desired day appears: (MON and

one dot for Monday -- TUE and two dots for Tuesday -- WED and 3 dots for Wednesday -- THU and 4 dots for Thursday -- FRI and

5 dots for Friday -- SAT and 6 dots for Saturday -- SUN and 7 dots for Sunday). Then confirm the day by pressing the key (1). The 2

digits representing the hours will start flashing in the display: it is possible to select the present hour using the arrow keys (3) and/or

(4), the selection must be confirmed by pressing key (1). The 2 digits indicating the minutes will start flashing: it is possible to select

the present minutes using the arrow keys(3) and/or (4), the selection must be confirmed by pressing the key (1). The day and time

setting is now completed.

5.3 ON/OFF PROGRAMMING

The generator must be energised and the rear switch in position "1". The words START or WORK or OFF could be present on the

display (7).

DAYS

CRONO MON

3

2

5

48

1

76

DAYS

CRONO MON

3

2

5

48

1

76

00: 00

ON 1

It is possible to carry out the weekly programming by setting up to 3 on/off cycles for each day from Monday to Sunday. To program

the heater press button (6) twice until the word CRONO appears followed by the words illustrated in the figure above on the left.

Now you can begin programming the first day of the week - Monday - by pressing button (1). Press the arrow button (3) and/or (4)

to choose another day to be programmed, to confirm the selection press button (1) again. The words ON1 will appear on the display

followed by 2 blinking digits indicating the hours (figure above right). Press button (3) and/or (4) to enter the hour of the first cycle

start time. To confirm the selection press the button (1). The 2 digits indicating the minutes will start flashing. Press button (3)

and/or (4)to enter the minutes of the first cycle start time. To confirm the selection press button(1).The first start up time for the

selected day has now been set. Then the inscription OFF1 will appear in the display and the two digits representing the hours will

turn on. When the (3) and/or (4) button is pressed the hour of the first off-cycle is entered. To confirm the selection press the button

(1). The 2 digits indicating the minutes will start flashing. By pressing the button (3) and/or

(4) the minutes for the first off-cycle will be entered. To confirm the selection press the button (1). This concludes the setting of the

first on-off cycle for the selected day. Later, it is possible to set the second on-off cycle (e.g. Monday) (shown with the display of

ON2 and OFF2) and the third Monday’s on-off cycle (shown with the display ON3 and OFF3). Next the display appears as

illustrated in the figure above on the left. Press the arrow button (3) and/or (4) to choose another day to be programmed, to confirm

the selection press button (1) again.

If you wish to copy all the on-off programs, for example the Monday settings, to the other days of the week, proceed as follows:

press button(6) until the word "CRONO" appears followed by the screen illustrated in the figure below on the left. Next press button

(2) and the display appears as illustrated in the figure below on the right: the program for Monday has been copied to Tuesday.

Press button (2) again to copy the program to Wednesday, Thursday ....

In the programming menu if you wish, for example, to edit the programming for Sunday press button (3) and/or (4) to go to Sunday

and then press button (1) . If the second on-off cycle is not required simply set the ON2 time as 00:00 and the OFF2 time as 00:00 .

DAYS

CRONO MON

348

2

576

1

DAYS

CRONO TUE

Copy

348

2

576

1

Page 15

Installation, use and maintenance guide

348

2

576

1

LEVEL 1

The programming procedure ends when you confirm the last data entered by pressing button (6) or when you exit the programming

menu. During the START or WORK or OFF phases press button (5) to enable / disable the programming (Enabled = CR.ON

appears momentarily on the display together with the fixed presence of the chrono symbol on the right of the display - see picture

below). Disabled: message CR.OFF temporarily displayed and, at the same time, the chrono symbol on the right side of the display

is not present (see figure below): this function is useful if you wish to disable the established weekly program setting. Moreover, you

can reset, or delete, all the programmings by holding down (in OFF or START or WORK phase) button (5) for approximately 8

seconds; the word "RESET CRONO" appears momentarily in order to indicate deletion of all the programmings previously set. With

the programming active, the operating conditions at the start-up (combustion power – ventilation speed) are the same as set-up

before the last off-cycle of the appliance: this is the case if the off-cycle has been done through the

programming and not through a manual action. Manual shut down can only be carried out with the programming disabled.

After shut down, by re-enabling the programming, at the next start up controlled by the programming the appliance will be set at the

first combustion power position and first ventilation speed.

In the event of a programmed cycle on always ensure that the brazier is clean and seated correctly in its

lodging: failure to clean the brazier can reduce and/or affect the life of the spark plug as it would be

subjected to high temperatures due to poor cooling. When the programming is enabled (CR.ON appears

momentarily together with the fixed presence of the chrono symbol on the bottom of the display) any

additional chronothermostats (see para. 7.2) are disabled.

WORK

14:30 14:30

WORK

Programmazione abilitata Programmazione disabilitata

Legenda Key

Programmazione abilitata / disabilitata Programming enabled / disabled

5.3.1 ON-OFF PROGRAMMING DISPLAYS

To view the programmings press button (6) 5 times until the words "Show Chrono" appear.

After a few seconds the display appears as illustrated in the figure below on the left. Press button (3) repeatedly to scroll the

programmings for all the days of the week (see figure below on the right) : press button (6) to exit.

Caution: the on-off programmings cannot be modified from the "SHOW CRONO" menu,

this menu is used only for viewing the programs that have been entered and/or edited through the "CRONO menu".

5.4 OPERATING LEVEL SETTING

The appliance must be energised and the rear switch in position

"1".

The words START or WORK or OFF could be present on the

display (7).

Your appliance is delivered with an excellent program installed

that favours combustion yield; the program is called

LEVEL 1. If you are using pellets with an out-of-standard

incidence of residues after combustion in the brazier, alternative

levels may be selected:

DAYS 10:45

MON

348

2

5 7 6

1

DAYS 10:45

MON

348

2

576

1

ON 1 11:15

OFF 1 13:45

Page 16

lation, use and maintenance guide

LEVEL 2: this program increases the smoke suction unit speed acceleration (program Level 2 increases air delivery to the burner

which promotes the combustion of tightly compacted pellets: this program reduces combustion efficiency).

LEVEL 0: when using too long pellets and/or flue outlets with very high vacuum, over 2 Pascal. When operating at LEVEL 0 the

burner becomes dirty very easily. The pellet consumption value is not affected by the operating level settings. Select the required

level by acting as follows:

press button (6) three times until the word LEVEL appears on the display after which the level set will appear (LEVEL 1 or LEVEL 2

or LEVEL 0). In order to change the operating level as key (3) is kept pressed, press the key (4). By holding down button (3) and

pressing button (4) repeatedly the level changes in the following sequence: LEVEL 2... ...LEVEL 0 ... LEVEL 1.

If the change is made while the appliance is running the difference in the flame will be apparent. It is

mandatory to pay particular care when selecting the most appropriate operating cycle for your

installation. After the selection of the operating cycle a thorough cleaning of the brazier is mandatory.

For the entire procedure to be confirmed and to move back to the appliance status display, key (6) must

be repeatedly pressed.

6 – USE OF THE APPLIANCE

Your appliance has obtained the CE marking and has been made to run for 1 hour to check that it functions correctly. It has also

undergone numerous tests as detailed in the test check sheet supplied with the generator. The product must not be used by

children, by persons with physical or mental impairments, by persons who are not familiar with the instructions for use and

maintenance of the product (the instructions are found in this booklet). CAUTION: Before each use make sure that the burner is

clean and positioned correctly in its lodging, check that the ash pans are clean and shut tight and check that the firebox door is

locked. WARNING: the door must always remain shut tight when the heater is operating. It is strictly forbidden to open the door

while the appliance is in operation. While the appliance is in operation the smoke exhaust pipes and the appliance itself can reach

extremely high temperatures: do not touch them! Do not expose your body to hot air for long, do not overheat the room in which the

appliance is installed, as these actions could cause health problems. Do not expose plants or animals directly to the hot air flow as

this could have noxious effects on them. It is strictly forbidden to use any type of fuel (liquid, solid...) to light the appliance : the

appliance must light up automatically as designed and described in this installation, use and maintenance booklet; in this regard, it

is strictly prohibited to pour pellets (or other material) directly into the brazier. Do not place non-heat resistant or inflammable or

combustible objects in the vicinity of the appliance: keep them at a suitable distance. Do not place wet clothing to dry on the

appliance.

When using a clothes horse, keep at a suitable distance. It is strictly prohibited to disconnect the appliance from the electrical

power mains while it is in operation.

6.1 SWITCHING ON THE APPLIANCE

Before using the appliance check that all the movable parts are in place; also remove any labels and stickers from the glass to

avoid having permanent traces remain on the surfaces. Always ensure that the brazier is clean and seated correctly in its lodging

(see para. 8).

Turn the switch installed on the back of the appliance to position "1" (= ON). Press button (1) to start the start up phase.When key

(1) is repeatedly pressed, the desired combustion level can be set and it will be active at the end of the ignition stage. The electrical

heater will start to overheat and after a few minutes the first lot of pellets will start dropping into the brazier. This occurs because the

screw feeder has to fill up because it is completely empty. The first time the appliance is started up the start up phase will have to

be carried out twice for this very reason.

CAUTION: The start up phase (the word START appearing on the display) continues until the word

START .remains lit.Once this phase has ended the word WORK appears on the display. The fan will

begin operating as soon as the combustion smoke reaches a suitable temperature. During the work

stage it is then possible to adjust combustion and the ventilation:

The combustion can be adjusted by 5 bars through button (1)), the ventilation setting can be set on 6 levels indicated by the

sequential lighting up of the corresponding bars on the display (through button (2)).

To turn the appliance on it is necessary for the inscription OFF to be present on the display: if it is not present, the key

(6) must be repeatedly pressed until the inscription OFFappears.

Page 17

Installation, use and maintenance guide

8R

9R

10R

3R

2R 4R 1R

6R

7R 5R

11R

12R

13R

6.2 COMBUSTION AND VENTILATION ADJUSTMENTS

The heating capacity is adjusted by pressing key (1) or on the remote control provided. Act on this command to adjust the quantity

of pellets fed to the firebox. Maximum combustion power is achieved when all 5 leds are lit.

Caution: the room fan starts up as soon as the temperature of the combustion smoke reaches a suitable threshold. The

fan setting is expressed visually by means of 6 different positions represented by 6 bars: press button (2) repeatedly to

regulate it. A slight vibration of the appliance is quite normal when it is running. One bar is always present on the display

even in OFF status.

6.3 INFRARED REMOTE CONTROL

A practical infrared remote control is supplied with the heater: adjust the ventilation level by means of the left button, whereas use

the right button to start the appliance, to adjust the power and combustion level and to switch off the appliance. If the appliance is

supplied with a white radio control (optional) the infrared control only works when the MANUAL setting is set on the white handheld

radio control.

6.4 OPERATION OF THE WHITE HANDHELD RADIO CONTROL THERMOCOMFORT (OPTIONAL)

INTRODUCTION

The Thermocomfort handheld radio control is the instrument that allows you to optimise both consumption and

functions. Keep in mind that radio wave transmissions can be affected by the surrounding environment: the presence

of thick walls can reduce the transmission that normally extends to 6-7 metres.

CAUTION: to guarantee optimal data transmission it is advisable to always place the radio control in its support in

a vertical position.

The following operations must be carried out the first time the appliance is started up:

• Turn the switch (11R) to ON (see drawing below)

• Connect the radio control to the mains power supply by means of the supplied battery charger. The radio control

must be recharged for at least 5 days, as the rechargeable batteries could be partially or completely empty.

Repeat the same procedure every time the radio control batteries discharge.

The appliance must be energised and the rear switch turned to position "1".

CAUTION: the Thermocomfort function is disabled when the remote control is OFF. To enable it, in the START,

WORK, OFF phases, repeatedly press button (6) on the appliance's control panel until the word

"THERMOCOMFORT" appears on the display (7) followed by the words Thermocomfort Off". To activate the

Thermocomfort function simply press the button (3) on the appliance's control panel: " Thermocomfort On". To

return to the original operating function simply press the button (6) again on the appliance's control panel. At the

end of the winter season, in order to preserve the life of the batteries, it is mandatory to recharge the batteries

and switch off the radio control completely by means of the switch located on the back (11R). The batteries are

guaranteed for 6 months. When the batteries are exhausted dispose of them safely. It is normal for the

temperature sensor to detect temperatures which are slightly different to the real ones: variations caused by the

environment in which the radio control is positioned and by the tolerance of the thermostat.

6.4.1 INDICATORS OF THE HANDHELD RADIO CONTROL

(1R) Flame selection button

(2R) Ventilation selection button

(3R) (4R) Auxiliary buttons

(5R) “Room temperature detected by the radio control's sensor” indicator

(6R) "Ventilation" indicator

(7R) “Combustion” indicator

(8R) “Room temperature setting” indicator: this is the room temperature

that you wish to reach by means of buttons 3R and 4R.

(9R) Area of the display where the operating program is displayed

(10R) Battery charge level

(11R) Switch 0-1 radio control power

(12R) Battery charger connection

(13R) Code selector and batteries compartment cover

Page 18

lation, use and maintenance guide

The Thermocomfort radio control can be used with 4 different operating programs:

• Manual (MANUAL appears in area (9R) of the display).

• Automatic 5 (AUTO 5 appears in area (9R) of the display).

• Automatic 3 (AUTO 3 appears in area (9R) of the display).

• Economy (ECONOMY appears in area (9R) of the display).

To change the operating program turn the switch (11R) to "1". Press and hold down button (3R) until the set program begins to blink

on the display (9R). Now release button (3R) and press button (3R) and/or (4R) repeatedly until you select the desired operating

program.

MANUAL program (the "Thermocomfort ON" symbol blinks on the display of the appliance).In the MANUAL program the room

temperature thermostat is disabled. Press button (1R) and the flame symbol begins to blink. Press button (3R) to decrease the

combustion level by lighting up the bars sequentially, vice versa press button (4R)

to increase the combustion level. The combustion level changes every time buttons (3R) and (4R) are pressed. Press button (2R)

and the ventilation symbol blinks. Press button (3R) to decrease the combustion level, vice versa press button (4R) to increase the

combustion level. The ventilation level changes every time buttons (3R) and (4R) are pressed. Caution: it is possible that, due to

radio interference or sending commands too close together, the changes will not be implemented. With this program you can also

use the infrared control supplied. It is normal that in the manual cycle the ventilation is often set at the maximum speed in order to

cool the appliance body more effectively.

AUTO 5 program (the "Thermocomfort ON" symbol is steady on the display of the appliance) In program AUTO 5 the room

temperature thermostat is enabled. The radio control adjusts the ventilation and the combustion automatically in relation to the

target room temperature set in display area (8R). The desired room temperature

appears in area (8R). You can vary the desired room temperature by simply pressing button (3R) and/or (4R) (variation indicated in

area (8R)). The remote control will set the maximum combustion and ventilation levels and modulate them both as the room

temperature (5R) approaches the target temperature (8R). When the target temperature (8R) in the room (5R) is reached, the

combustion level will stabilise on a bar as will the ventilation level.

Caution: it is possible that, due to radio interference, the commands sent to the generator will not be implemented. When using this

program the infrared remote control cannot be used. Caution: the power and the ventilation depend on the preset value, if the

required temperature is too high or not reachable the appliance could operate at maximum power for long periods of time.

AUTO 3 program (the "Thermocomfort ON" symbol is steady on the display of the appliance) In program AUTO 3 the room

temperature thermostat is enabled. The remote control adjusts the ventilation and combustion automatically in relation to the target

room temperature set in display area (8R). The desired room temperature is displayed in area (8R).

You can vary the desired room temperature by simply pressing button (3R) and/or (4R) (variation indicated in area (8R)). The

remote control will set the combustion power at level 3 and the ventilation at level 4 and modulate them both as the room

temperature (5R) approaches the target temperature (8R). When the target temperature (8R) in the room (5R) is reached, the

combustion level will stabilise on a bar as will the ventilation level. Caution: it is possible that, due to radio interference, the

commands sent to the appliance will not be implemented. When using this program the infrared remote control cannot be used.

Caution: the power and the ventilation depend on the preset value, if the required temperature is too high or not reachable the

appliance could operate at maximum power for long periods of time.

ECONOMY program (the "Thermocomfort On" symbol is steady on the display of the appliance) In the ECONOMY program the

appliance always operates at the minimum combustion level and the minimum ventilation level. When using this program the

infrared remote control cannot be used.

CAUTION: THE APPLIANCE MUST ALWAYS BE STARTED UP AND SHUT DOWN FROM THE CONTROL PANEL

OR THROUGH PROGRAMMING.

6.4.2 TRANSMISSION CODES SETTINGS

The appliance must be energised and the rear switch in position "1". The words START or WORK or OFF could be present on the

display (7).

Page 19

Installation, use and maintenance guide

If there are several appliances installed in rooms closely to each other it may be necessary to set different transmission codes as

this type of interference deactivates operation of the optional Thermocomfort radio control. To change the transmission codes

proceed as follows:

-Disable the Thermocomfort function. To disable it, in the START, WORK, OFF phases, repeatedly press button (6) on the

appliance's control panel until the word "THERMOCOMFORT" appears on the display (7) followed by the words Thermocomfort

On". To deactivate the Thermocomfort function simply press the button (3) : "Thermocomfort Off". To return to the original operating

function simply press the button (6) again.

-Switch off the Thermocomfort radio control by pressing the button (11R) on the device.

-To change the transmission codes, open the cover (13R) and act as indicated in the figure below.

-Next switch on the radio control by pressing the button (11R).

-Activate the Thermocomfort function. To enable it, in the START, WORK, OFF phases, repeatedly press button (6) on the

appliance's control panel until the word "THERMOCOMFORT" appears on the display (7) followed by the words Thermocomfort

Off". To activate the Thermocomfort function simply press the button (3): "Thermocomfort On". To return to the original operating

function simply press the button (6) again. The radio control may still not function even after having changed the transmission

codes. If this occurs change the codes once again using the procedure described above.

LEGENDA KEY

Selettore codici per radiocomando palmare gestito via onde radio Code selector for handheld radio control controlled by radio waves

6.4.3 CARE AND MAINTENANCE OF THE RADIO CONTROL

The radio control has been designed and produced to the strictest standards and must be handled with great care. If you observe

the guidelines set out below, the radio control will provide a long trouble-free performance:

• Protect the radio control against humidity! Precipitation, humidity and liquids corrode the electronic circuits. If the radio control is

wet, disconnect it immediately from a power source, remove the battery, open it and allow it to dry at room temperature.

• Do not use or store the radio control in dusty or dirty environments. The dust/dirt could damage the movable parts of the radio

control.

• Do not store the radio control in very hot environments. High temperatures could shorten the life of the electronic devices, damage

the batteries and deform or even melt plastic parts. Do not store the radio control in cold environments. When it heats up (when it

returns to normal operating temperature), humidity could form inside it and damage the electronic circuits.

• Do not drop the radio control, do not hit or bump it and do not shake it. Actions such as these could damage the internal circuits of

the device.

• Do not use corrosive chemical substances, caustic solutions or detergents to clean the radio control.

All the above guidelines apply to the radio control, the battery, the battery charger, and all the accessories. The parts

subject to wear (such as batteries, keypads, lodging compartments, small compartment parts) are guaranteed for 6

months from the purchase date. The guarantee does not apply if the defect is caused by non-conforming use and/or

if the instructions and guidelines described above are not observed to the letter. Devices or parts returned for

replacement become the property of Thermorossi S.p.A. The presence of any irregular black-blue lines on the

display, also present when de-energised and/or battery flat or missing, indicate that the glass screen of the display is

damaged following a fall or impact: in this case the breakage is not covered by the guarantee.

SELETTORE CODICI PER RADIOCOMANDO

P

A

L

M

A

R

E

G

E

S

T

I

T

O

V

I

A

O

N

D

E

R

A

D

I

O

ON

1234

3

1

ON

24

THERMOCOMFORT

3

5

4

7 6

Thermocomfort

On

11R

12R

13R

Table of contents

Other THERMOROSSI Pellet Stove manuals

Popular Pellet Stove manuals by other brands

Quadra-Fire

Quadra-Fire SANTAFE-MBK installation manual

Ravelli

Ravelli Whisper 7 Use and maintenance manual

United States Stove

United States Stove Ashley Heritage 5700 owner's manual

Masport

Masport STM00739 Owners manual instructions

Napoleon

Napoleon Auburn NPS40 Installation and operating insctructions

Olsberg

Olsberg Levana manual