Final notes

•A HIGH END PRINTER IS NOT REQUIRED, I printed all parts on a £200 TEVO Tarantula with

a 0.4mm nozzle and 0.2mm layer height.

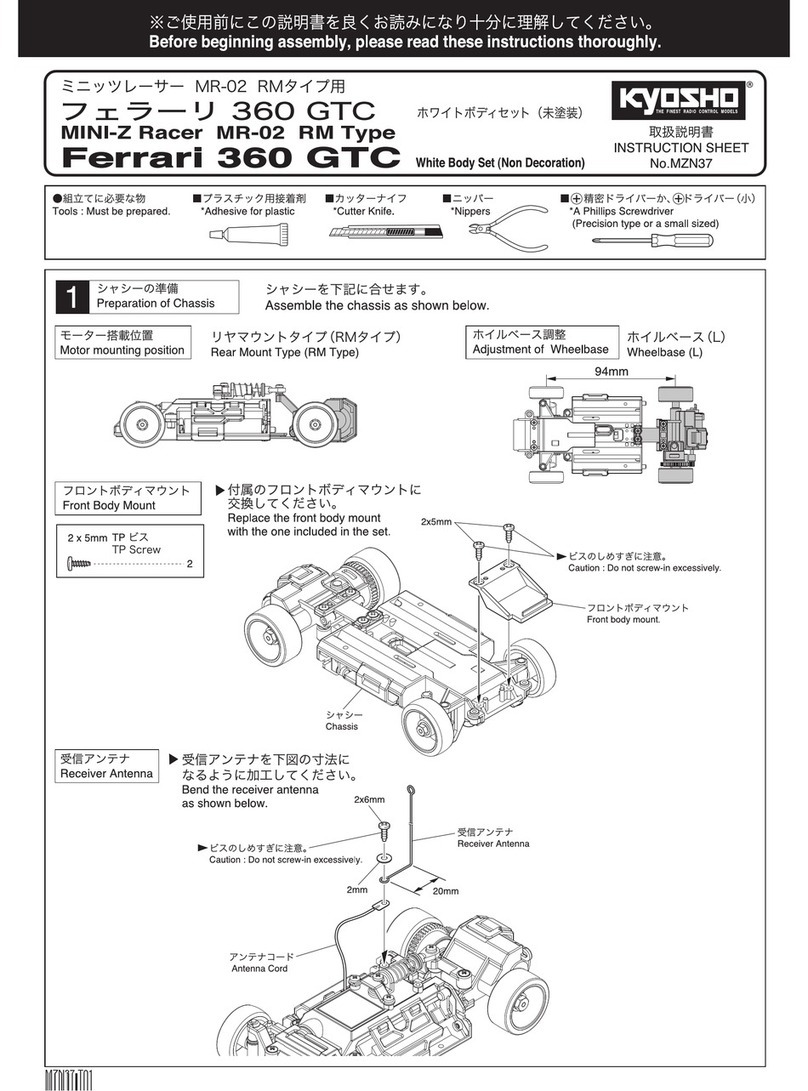

•If parts are difficult to print, or break easily, try different print orientations. The front end

is tilted back by 15°, and so are many of the stl files. If a part is not lying flat when sliced,

try a rotation of 15°.

•The all plastic dogbones don't work very well in PLA, the friction causes them to soften

and break quickly. The metal-pin ones work fine in PLA.

•The pinion gear and transmission drive gears also don't work well in PLA with a brushless

motor, I had good results with PETG for these. However, PLA works fine for non-brushless

use. The actual differential gears work fine in PLA in my tests, and they should be greased

to reduce friction. Vaseline (petroleum jelly) works well.

•The spur gear and transmission drive gear must be a VERY TIGHT fit on the shaft (I needed

to press the shaft in with a vice). If there is any slipping, it will generate heat and soften

the parts. I had this problem with some old gears and it heated up enough to melt the

gear from the inside.

•Don't buy bad quality bearings like I initially did, the small amount of play in them caused

the gears to wear excessively.

•If the motor gets too hot with the 10-tooth pinion, switch to the 8-tooth pinion.

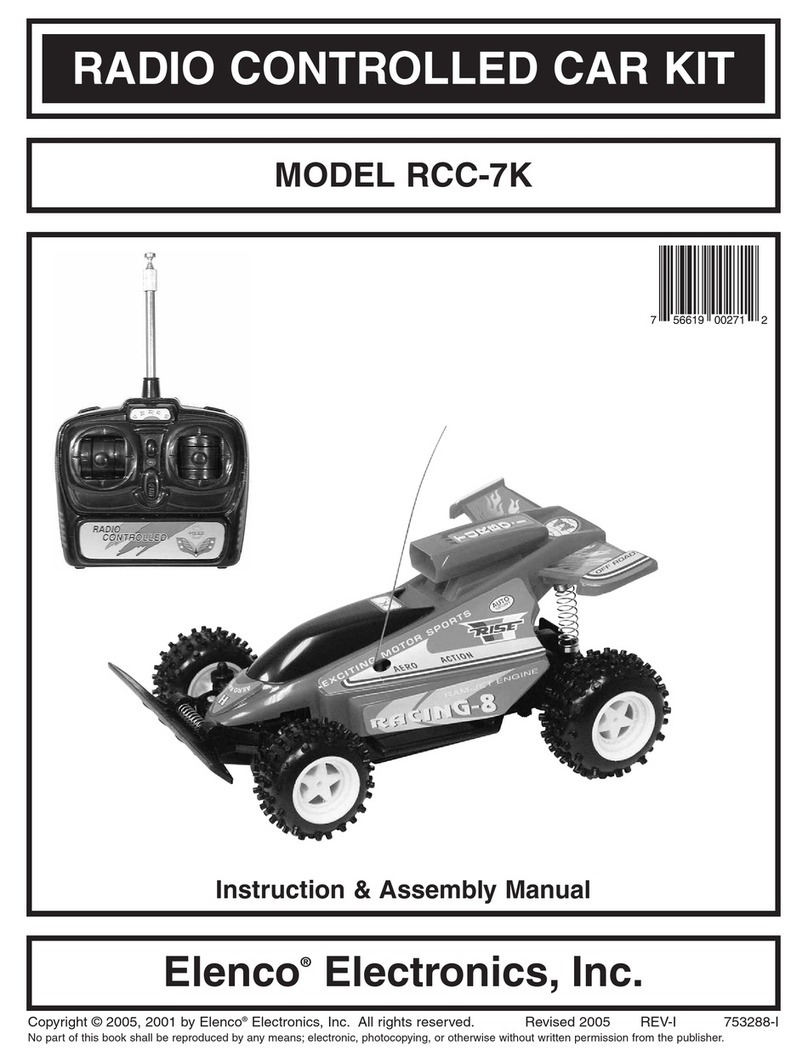

•I recommend using standard 1/16 scale oil filled RC car shocks at the front and rear for

optimal handling.

•Print the tyres with low infill (~8%) and few outer shells to make them softer for more

traction.

•If the 3D printed rear tyres don't give enough traction, standard 1/16 buggy wheels fit the

rear hubs.

•Use blue threadlocker on any screws that are used as pivots to stop them working loose.