Thinkcar PLD-212 User manual

www.thinkcar.com

1

THINKCAR PLD-212

Automobile Pipeline Smoke Leak Detector

User Manual

V202204

www.thinkcar.com

2

Caution

1) Please read the user manual carefully before using this device.

2) After receiving the device, please check the packing list and parts carefully. If you have any

questions, please contact THINKCAR immediately.

3) Due to product upgrades, minor differences between the user manual and the device will

not be further noticed.

All rights reserved! Without the written consent of THINKCAR Technology Co., Ltd.

(hereinafter referred to as "ThinkCar"), no unit or person may copy or reproduce this user

manual in any form (online, mechanical, video, recording or other forms). The user manual is

designed for ThinkCar PLD-212 only. No responsibility is taken for any consequences of using

this manual to operate other equipment.

ThinkCar is not responsible for damage and loss of equipment due to personal accident or

third parties, misuse and abuse of equipment, unauthorized replacement and repair, or any

operation and maintenance not in accordance with ThinkCar standards.

ThinkCar is not responsible for equipment damage or problems caused by the use of optional

accessories or consumables that are not original ThinkCar products or products that are not

approved by ThinkCar.

Disclaimer: Other product names mentioned in the user manual are mainly used to describe

the use of the device. The registered trademark still belongs to the original company.

This equipment is suitable for professional technicians and vehicle maintenance personnel.

www.thinkcar.com

3

Content

1. Packing list .................................................................................................................................................4

2. Overview ....................................................................................................................................................4

3. Operation tutorial .......................................................................................................................................5

4. General detection steps ............................................................................................................................ 5

5. EVAP leak test (EVAP models only) ......................................................................................................... 7

6. Instructions for use of universal air inlet adapter ......................................................................................7

7. Product Information ................................................................................................................................... 8

8. Others ........................................................................................................................................................ 8

9. Warranty .................................................................................................................................................... 8

www.thinkcar.com

4

1. Packing list

A. Main Unit

B. Power Supply Cable

C. Smoke Hose

D. Standard Cone Adapter

E. Funnel

F. Smoke Test Oil

G. Airbag

H. Hard rubber Hose Plug

I. EVAP Special Connector

J. Screwdriver

(I&J only apply to EVAP Model)

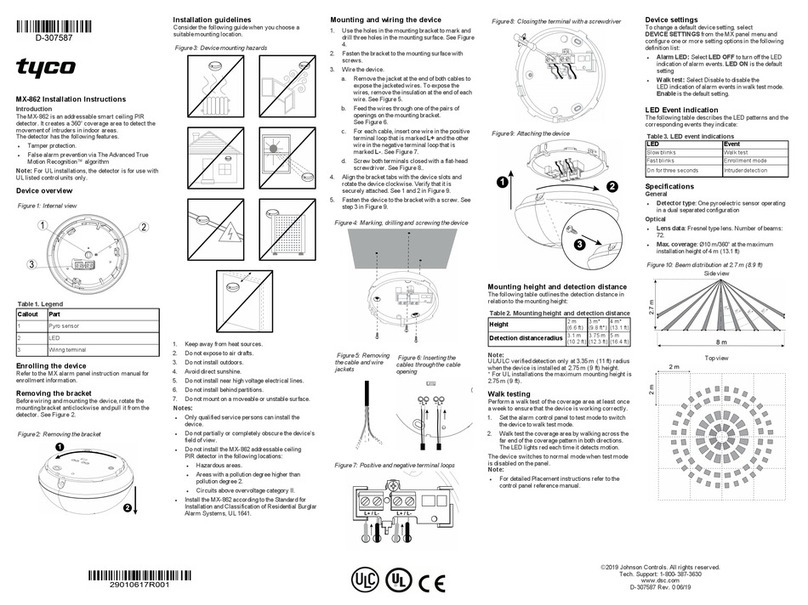

2. Overview

A. Handle

B. Pressure gauge

C. Flowmeter

D. Smoke Mode Indicator

E. Flow adjustment knob

F. Smoke Mode Switch

G. Power on/off indicator

H. Power socket: red to +, black to -

I. Smoke vents

J. Oil filling port

K. Oil level window

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

I

K

J

I

J

www.thinkcar.com

5

PLD-212 is specially designed to detect the leakage of vehicle pipeline system. It can be used

for leakage detection of pipeline system of automobiles, motorcycles, snowmobiles, off-road

vehicles, ATVs, light trucks, speedboats, ships, etc. It has a wide range of applications and is

not subject to Check equipment shape restrictions.

3. Operation tutorial

3.1.Preparations

a) Open the oil filling port, use the aid of the funnel, and fill the smoke oil into the oil tank.

Please make sure that the oil level of the smoke oil does not exceed the Max line.

Note: If the smoke oil is added too much, the equipment will stop working, and the excessive smoke

oil needs to be taken out.

b) Install the smoke pipe to the smoke outlet and fasten it to the connection with clips.

c) Connect the DC12V power supply to the device.

d) The device is ready to use.

Note: Please check the oil level window before use to ensure that the smoke oil is sufficient during

use to avoid equipment failure.

3.2.Operating equipment

a) Connect the DC12V vehicle battery, the power on/off indicator will light up and the

device will start generating air pressure.

Note: The red clip is connected to the positive pole +, and the black clip is connected to the negative

pole -.

b) Turn the flow adjustment knob to the maximum, the flow meter will indicate the flow.

c) Cover the mouthpiece on the cigarette pipe with your finger, the pressure gauge will

display the output pressure value in real time.

d) Press the smoke mode switch, the smoke mode indicator will light up and the device will

start producing smoke.

4. General detection steps

4.1. Turn off the vehicle.

www.thinkcar.com

6

4.2. Remove the air filter and throttle.

4.3. Clean the corresponding connections to avoid dirty or sharp objects.

4.4. Put the inlet adapter cone (or universal inlet adapter) into the opening, as shown below:

4.5. Wait about 2 minutes for the device to pressurize.

4.6. Observe the indication scale of the flow meter and pressure gauge. As shown below:

1

2

3

4

5

6+

LEA K SI ZE

D

es

i

r e

d

P res sur e

1

2

3

4

5

6+

LEA K SIZE

Des ired

P res sur e

1

2

3

4

5

6+

LEA K SIZE

D

es

i

re

d

P res sur e

NO LEAK S MALL LEAK M ASSIVE LEAK

4.7. Determine the size of the leak according to the flow meter and pressure gauge.

4.8. If there is a leak in the system, turn on the smoke mode and the device will start

generating smoke.

4.9. Unplug the cigarette holder and plug it back in when there is obvious smoke coming out

of the cigarette holder.

4.10. The system will be ready within 2 minutes, a bright flashlight or work light can be used

to assist with leak checking.

4.11. After leak detection, use Velcro to tuck up the power cord and pipe, clean and store

the intake adapter cone (or universal intake adapter).

Tips:

a) If the whole is leak tested, the cover plugs can be used to close the remaining openings.

b) The cover plug can also be used to block the air inlet, and the smoke nozzle also supports

connection to the site to be inspected through other available openings.

c) The smoke method cannot be used to test for leaks from oil-sensitive parts such as lamp

www.thinkcar.com

7

shades.

d) Only 12V vehicle battery is allowed to power the machine.

5. EVAP leak test (EVAP models only)

General OBD EVAP related codes: P0443~0457/P0465~0469.

5.1. Locate the EVAP access opening (green cap inside the engine compartment).

5.2. Use the screwdriver Value Tool to remove the Schrader valve.

Tip: The valve is left-hand thread.

5.3. Installing the EVAP Service Port Adapter.

5.4. Connect the smoke nozzle to the EVAP service port adapter and turn the flow knob to

maximum, check the status of the pressure gauge and flow meter for leaks.

5.5. If there is a leak in the system, turn on the smoke mode and the device will start

generating smoke.

5.6. Unplug the cigarette holder, when the cigarette holder emits obvious smoke, plug it back

in again.

5.7. Determine the size of the leak according to the flow meter and pressure gauge.

5.8. After the leak test, collect the power cord and smoke pipe with Velcro and clean the intake

adapter cone (or universal intake adapter) before storage.

6. Instructions for use of universal air inlet adapter

6.1. Before installing the adapter, please clean the throttle valve air inlet to avoid scratching

the adapter.

6.2. Close pressure relief valve (A) next to hand pump (B).

6.3. Put the rubber assembly (C) into the air inlet.

A

B

D

C

www.thinkcar.com

8

6.4. Press the hand pump (B) to inflate the rubber assembly (C) until the air inlet is sealed

tightly.

6.5. Insert a smoke nozzle into the nozzle (D) to introduce air/fume into the system.

6.6. After testing, pull out the cigarette holder and open the pressure relief valve (A) next to

the hand pump (B) to release the air in the rubber assembly.

6.7. Clean the adapter after testing and avoid contact with corrosive liquids.

7. Product Information

Power supply: 12V car battery

Flow: about 8-15L/Min

Test pressure: 13-16 Psi(Turbo)/10-16inch H2O(2.5-4KPa)(Evap)

Flow Control: 360 Degree Flow Dial

High temperature protection: yes

8. Others

It is recommended to use special smoke test oil.

Spill: Turn the unit upside down to drain some oil.

9. Warranty

This warranty applies only to users and distributors who purchase THINKCAR products

through normal procedures. Within one year from the date of delivery, THINKCAR warrants its

electronic products for damages caused by defects in materials or workmanship. Damages to

the equipment or components because of abuse, unauthorized modification, use for

non-designed purposes, operation in a manner not specified in the instructions, etc. are not

covered by this warranty. The compensation for dashboard damage caused by the defect of

this equipment is limited to repair or replacement. THINKCAR does not bear any indirect and

incidental losses. THINKCAR will judge the nature of the equipment damage according to its

prescribed inspection methods. No agents, employees or business representatives of

THINKCAR are authorized to make any confirmation, notice or promise related to THINKCAR

products.

Table of contents

Popular Security Sensor manuals by other brands

FIREGUARD GLOBAL

FIREGUARD GLOBAL FG-BD100 Product introduction

Interlogix

Interlogix TX-2413-03-1 Installation sheet

CST/BERGER

CST/BERGER Magna-Trak Series Original instructions

Rotech

Rotech FJC-DL001 user manual

DMP Electronics

DMP Electronics 1161 installation guide

Chamberlain

Chamberlain LM21AFCB owner's manual