THOR GH100-P User manual

Thor Gas Oven

Installation and Operation Instructions

Model: GH100-P, GH100-N, GH101-P, GH101-N, GH102-P, GH102-N, GE 42-P, GE 42-N,

GE 43-P, GE 43-N, GE 44-P, GE 44-N

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For Warranty

Service and/or parts, this information is required.

Model Number Serial Number Date Purchased

WARNING: For your safety, do not store or use asoline or other flammable vapors or

liquids in the vicinity of this or any other appliances. Keep the area free and clear of

combustible.

WARNING :Improper installation, adjustment, alteration, service or maintenance can

cause property dama e, injury, or death. Read the installation operatin and maintenance

instructions thorou hly before installin , or servicin this equipment.

WARNING:Instructions must be posted in a prominent location. All safety precautions

must be taken in the event the user smells as. Safety information can be obtained from

your local as supplier.

15 Bad ally Road, Campbelltown

NSW 2560

Operation Manual 26052015

Contents

Introduction

............................................................................................. 2

Specifications

........................................................................................... 3

General

Pack Contents

Gas Supply Requirements

Dimensions

................................................................................................ 4

Installation

................................................................................................

Installation Requirements

Unpackin

Location

Clearances

Assembly

Gas Connection

Low Flame Settin

Commissionin

Operation

.................................................................................................10

Operation Guide

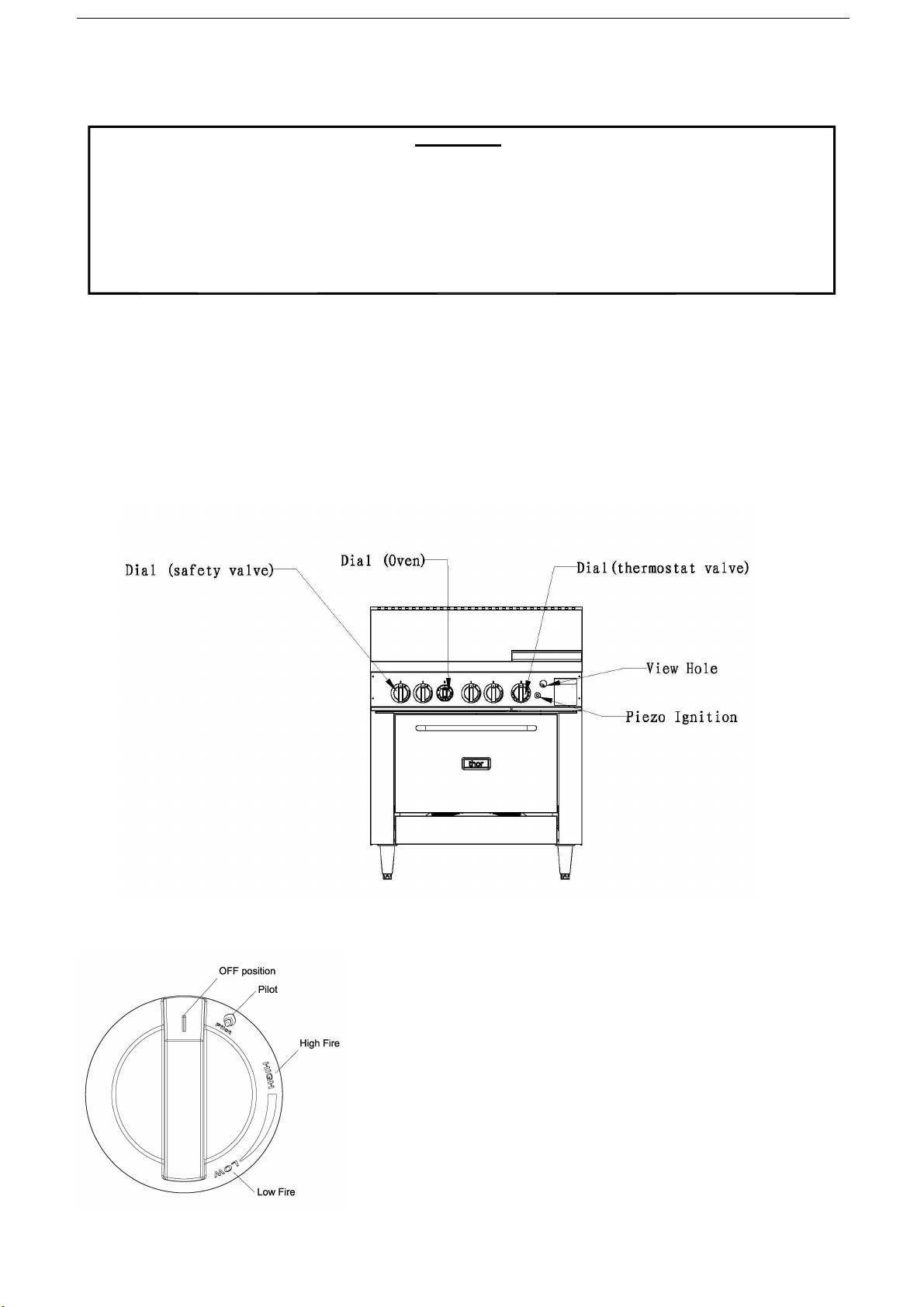

Description of Controls

Li htin the Pilot Burner

Li htin the Main Burner

Cleaning and Maintenance

......................................................................... 13

Routine Maintenance

After Each Use

Daily Cleanin

Weekly Cleanin

Adjustments………………………………………………………………………………………….1

Trouble Shooting

.......................................................................................18

Replacement parts List

........................................................................……24

Explosion Drawing

..............................................................................……2

Spare Parts List

........................................................................................26-29

2

Introduction

We are confident that you will be deli hted with your Thor Gas Oven, and it will become a most valued

appliance in your commercial kitchen.

To ensure you receive the utmost benefit from your new Gas Oven, there are two important thin s you

can do.

Firstly

:

Please read the instruction book carefully and follow the directions iven. The time taken will be well

spent.

Secondly

:

If you are unsure of any aspect of the installation, instructions or performance of your appliance,

contact your dealer promptly. In many cases a phone call could answer your question.

CE Only

:

These instructions are only valid if the country code appears on the appliance. If the code does not

appear on the appliance, refer to the supplier of this appliance to obtain the technical instructions for

adaptin the appliance to the conditions for use in that country.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE PROPERTY

DAMAGE, INJURY OR DEATH.

READ THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS APPLIANCE.

WARNING:

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE USER SMELLS GAS ARE TO BE POSTED IN A PROMINENT

LOCATION. THIS INFORMATION SHALL BE OBTAINED BY CONSULTING THE LOCAL GAS SUPPLIER.

WARNING:

GREAT CARE MUST BE TAKEN BY THE OPERATOR TO USE THE EQUIPMENT SAFELY TO GUARD IT AGAINST RISK OF

FIRE.

•

THE APPLIANCE MUST NOT BE LEFT ON UNATTENDED.

•

IT IS RECOMMENDED THAT A REGULAR INSPECTION IS MADE BY A COMPETENT SERVICE PERSON TO

ENSURE CORRECT AND SAFE OPERATION OF YOUR APPLIANCE IS MAINTAINED.

•

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPOURS OR LIQUIDS IN THE VICINITY OF THIS

OR ANY OTHER APPLIANCE.

•

DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

CAUTION

:

THIS APPLIANCE IS;

•

FOR PROFESSIONAL USE AND IS TO BE USED BY QUALIFIED PERSONS ONLY.

•

ONLY QUALIFIED SERVICE PERSONS ARE TO CARRY OUT INSTALLATION, SERVICING AND GAS CONVERSION

OPERATIONS.

•

COMPONENTS HAVING ADJUSTMENTS PROTECTED BY THE MANUFACTURER SHOULD NOT BE ADJUSTED BY

THE USER/OPERATOR.

•

DO NOT OPERATE THE APPLIANCE WITHOUT THE LEGS SUPPLIED FITTED.

3

Specifications

General

Commercial heavy duty oven.

Pack Contents

The followin is included:

Thor Gas Oven

2pcs racks

4pcs Feet

Instruction Manual

Gas Supply

Requirements

Natural Gas Propane

GH100-N

GH101-N

GH102-N

GH100-P

GH101-P

GH102-P

Single burner Heat Input

32.5 MJ 32.5 MJ 32.5 MJ 32.5 MJ 32.5 MJ 32.5 MJ

Oven burner

26.5MJ 26.5MJ 26.5MJ 28MJ 32.5 MJ 32.5 MJ

Heat Total

156.5 MJ 221.5 MJ 189MJ 158 MJ 227.5 MJ 195MJ

Burner Operating

1.0 kPa 2.75 kPa

Supply Pressure

1.0 kPa 2.75 kPa

Gas Connection

¾” BSP Male ¾” BSP Male

Natural Gas Propane

GE 42-N

GE 43-N GE 44-N

GE 42-P GE 43-P

GE 4 -P

Single burner Heat Input

32.5 MJ 32.5 MJ 32.5 MJ 32.5 MJ 32.5 MJ 32.5 MJ

Oven burner

26.5MJ 26.5MJ 26.5MJ 28MJ 32.5 MJ 32.5 MJ

Heat Total

91.5 MJ 156.5 MJ 124MJ 93 MJ 162.5MJ 130MJ

Burner Operating

1.0 kPa 2.75 kPa

Supply Pressure

1.0 kPa 2.75 kPa

Gas Connection

¾” BSP Male ¾” BSP Male

The burner operatin pressure is to be measured at the as control valve outlet test point with two burner

operatin at ‘Hi h’ settin . The operatin pressure is ex-factory set, throu h the appliance re ulator and not

to be adjusted, apart from when carryin out as conversion, if required. (Refer to the ‘Gas Conversion’

section for details).

Minimum input of burner: Open burner: 23MJ for NG

‘U’ burner: 21MJ for NG

Size of the pan: The smallest pan for open burner is 100mm;

The bi est pan for open burner is 300mm.

The hi hest temperature of riddle plate is 290℃(thermostat valve)

The hi hest temperature of riddle plate is 390℃(safety valve).The burner operatin pressure is to be

measured at the as control valve outlet test point with one burner operatin at ‘Hi h’ settin . The operatin

pressure is ex-factory set, throu h the appliance re ulator and not to be adjusted.

4

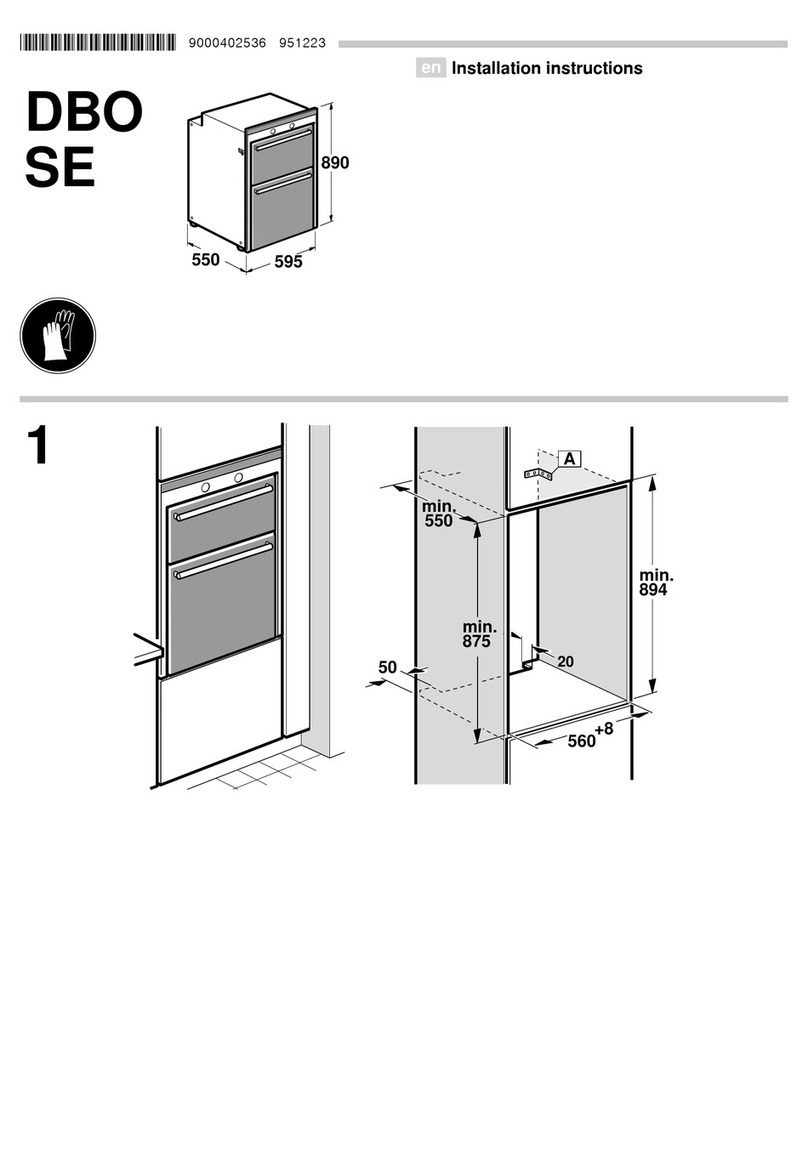

Dimensions

Dimensions for Freestanding Oven

GH104-P / GH104-N

Model Number

Exterior Dimensions (Millime

ters)

A

B

C

D

E

F

H

L

TR-4F

GH100-P / GH100-N

610 835 680 750 1175 940

TR-0-G24F(T)

GE542-P/GE542-N

610 835 610 680 750 510 1175 940

TR-6F

GH101-P / GH101-N

915

835

680

750

1175

940

TR-4F-G12F(T)

GH102-P / GH102-N

915

835

305

680

750

510

1175

940

TR-2F-G24F(T)

GE543-P/GE543-N

915

835

610

680

750

510

1175

940

TR-0-G36F (T)

GE544-P/GE544-N

915

835

915

680

750

510

1175

940

Views

5

Installation

Installation Requirements

NOTE:

•

It is most important that this appliance is installed correctly and that operation is correct before

use. Installation shall comply with local gas, health and safety requirements.

•

This appliance shall be installed with sufficient ventilation to prevent the occurrence of

unacceptable concentrations of substances harmful to health.

Our Gas Ovens are desi ned to provide years of satisfactory service and correct installation is essential to

achieve the best performance, efficiency and trouble-free operation.

This appliance must be installed in accordance with National installation codes and in addition, in accordance

with relevant National / Local codes coverin as and fire safety.

Australia:

AS 5601/AG 601 (to be AS 5601)- Gas Installations

New Zealand:

NZS 5261 - Gas Installation.

United Kingdom:

Gas Safety (Installation and Use) Re ulations 1998

BS 6173-Installation of Caterin Appliances.

BS 5440-1&2 Installation Fluein & Ventilation.

Ireland:

IS 820-Non Domestic Gas Installations.

Installations must be carried out by qualified persons only. Failure to install equipment to the relevant

codes and manufacturer’s specifications shown in this section will void the warranty.

Components havin adjustments protected by the manufacturer are only to be adjusted by an authorized

service a ent. They are not to be adjusted by the installation person.

Step 1: Unpacking

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

All containers should be examined for dama e before and durin unloadin . The frei ht carrier has assumed

responsibility for its safe transit and delivery. If dama ed equipment is received, either apparent or

concealed, a claim must be made with the deliverin carrier.

Apparent dama e or loss must be noted on the frei ht bill at the time of delivery. The frei ht bill must then

be si ned by the carrier representative (Driver). If the bill is not si ned, the carrier may refuse the claim.

The carrier can supply the necessary forms.

A request for inspection must be made to the carrier within 15 days if there is connected dama e or loss

that is not apparent until after the equipment is uncreated. The carrier should arran e an inspection. Be

certain to hold all contents plus all packin material.

6

Installation (Continued)

1. Remove screws and disassemble the top and side wood packa in .

2. Remove plastic wrap and set aside the flue box.

3. Remove the Gas Oven from the pallet for installation.

Step 2a: Install the Legs

A set of four le s is packed with units ordered with le s. (For units ordered with casters (option), o to step 2b).

A threaded le pad is fastened to the base frame at each corner. Each le has a correspondin matin thread.

The le can be adjusted to overcome a sli htly uneven floor.

1. Raise unit sufficiently to allow le pads and le s to be attached. For safety, “shore up” and support the unit

with an adequate blockin arran ement stron enou h to support the load.

2. Attach the four le pads to the bottom of the ran e usin the lock washers and machine screws. The

mountin holes are pre-drilled and threaded.

3. Screw the le s into the holes in the centers of the le pads.

4. Lower unit ently onto a level surface. Never drop or allow the unit to fall.

5. Use a level to make sure that the ran e surface is level. The le s can be screwed in or out to lower or raise

each corner of the ran e.

6. Go on to installation Step 3.

7

Installation (Continued)

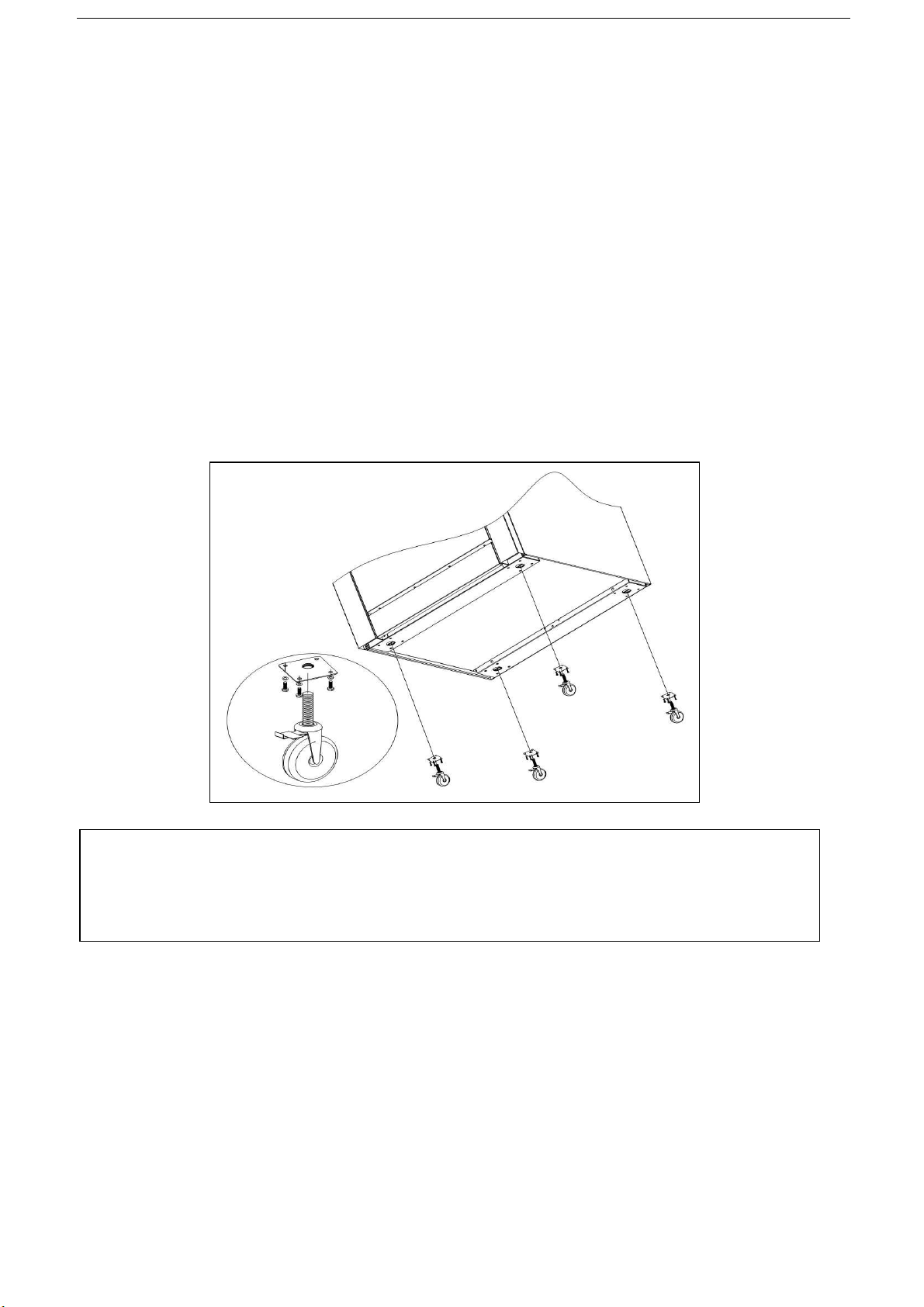

Step 2b: Install Casters (options)

A set of four casters is packed with units ordered with casters (instead of le s).

A threaded le pad is fastened to the base frame at each corner. Each caster as a correspondin matin

thread. The caster can be adjusted to overcome a sli htly uneven floor. Casters are provided with a Zerk fittin

for proper lubrication when required.

1. Raise unit sufficiently to allow le pads and casters to be attached. For safety, “shore up” and support the

unit with an adequate blockin arran ement stron enou h to support the load.

2. Attach the four le pads to the bottom of the ran e usin the lock washers and machine screws. The

mountin holes are pre-drilled and threaded.

3. Screw the caster into the holes in the centers of the le pads. Install the casters that have a lockin brake

under the front of the unit.

4. Lower unit ently onto a level surface. Never drop or allow the unit to fall.

5. Use a level to make sure that the ran e surface is level. The casters can be screwed in or out to lower or

raise each corner of the ran e. After the unit has been leveled, ti hten the lock nuts.

6. Secure the restrainin -device bracket to a wall stud located as close as possible to the appliance connector

inlet and outlet connections. Use four screws.

NOTICE

Adequate means must be provided to limit the movement of the appliance without dependin on the

connector and the quick-disconnect device or its associated pipin to limit the appliance movement.

The restrainin means should be attached to a frame member on the back of the unit.

8

Installation (Continued)

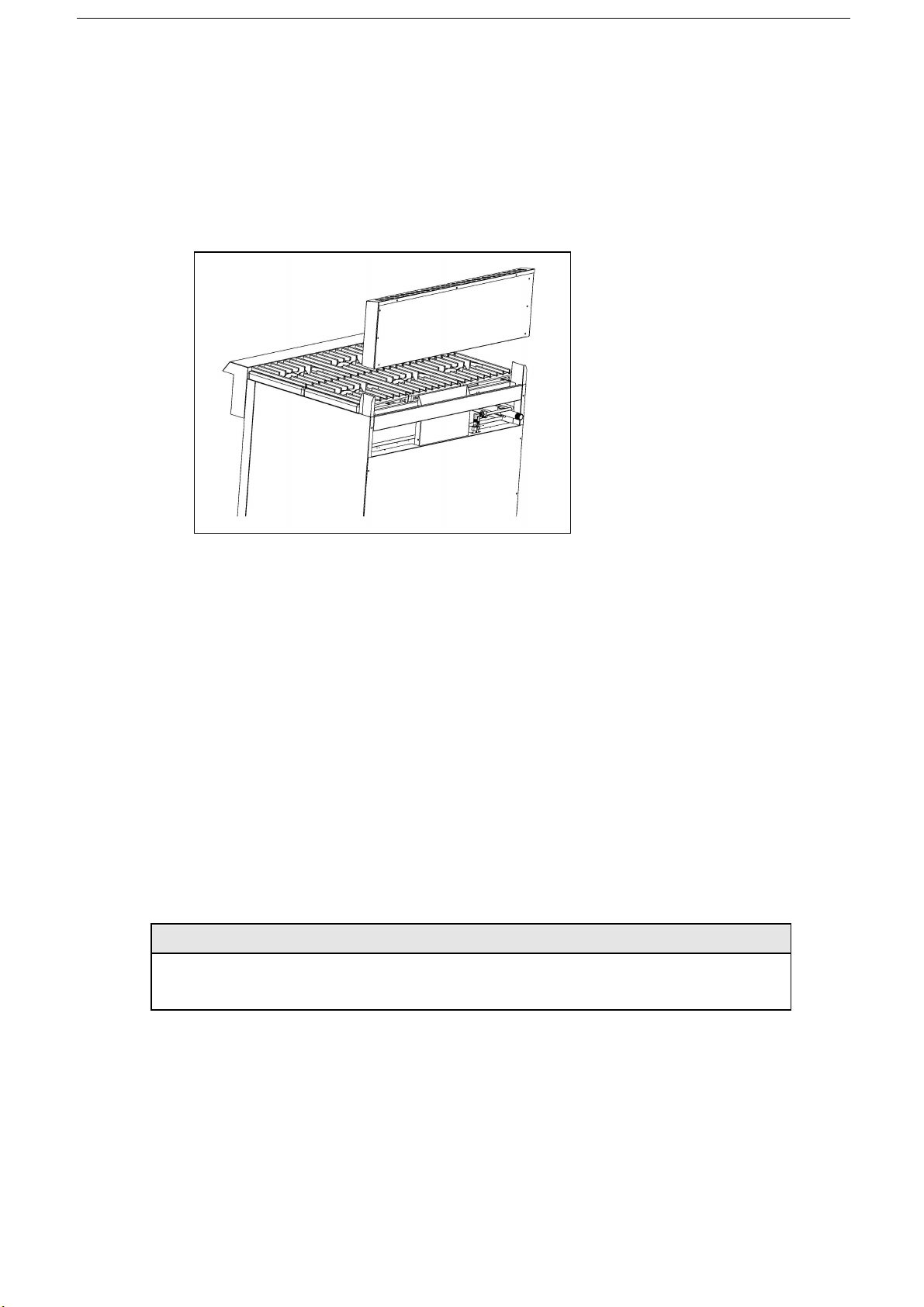

Step 3: Attach Flue Riser

1. Place the flue riser assembly on the ran e as shown on the appropriate dia ram below.

2. Slide the flue riser assembly over the bayonets until it bottom out, as shown below.

3. Secure ends of flue riser assembly with two M6 hex head bolts, flat washers and lock-washers

Sin le-Oven Models

Location

1. Installation must allow for a sufficient flow of fresh air for the combustion air supply.

2. Installation must include adequate ventilation means, to prevent dan erous build-up of combustion

products.

3. Any as burnin appliance requires adequate clearance and ventilation for optimum and trouble-free

operation. The minimum installation clearances shown below are to be adhered to.

4. Position the appliance in its approximate workin position.

5. All air for burner combustion is supplied from underneath the unit. The le s must always be fitted

and no obstructions placed on the underside or around the base of the unit, as obstructions will

cause incorrect operation and / or failure of the appliance.

6. Components havin adjustments protected by manufacturer are only allowed to be adjusted by an

authorized service a ent. They are not to be adjusted by the installation person.

Clearances

NOTE: Only non-combustible materials can be used in close proximity to this appliance.

Combustible

Surface

Non Combustible

Surface

Left / Ri ht Hand Side

Rear

355mm

250mm

0mm

0mm

Assembly

NOTE:

•

This appliance is assembled before delivery except feet.

•

This appliance is fitted with adjustable feet to enable the appliance to be positioned securely and

level. This should be carried out on completion of the as connection. Refer to the ‘Gas

Connection’ section.

•

IM will be stated that the appliance shall be installed in such a way that side body surfaces are not

accessible in the installed position.

9

Installation (Continued)

Gas Connection

NOTE: ALL GAS FITTING MUST ONLY BE CARRIED OUT BY A QUALIFIED PERSON.

1. The Gas Ovens do not require an electrical connection, as they function totally on the as

supply only.

2. It is essential that the as supply is correct for the appliance to be installed and that

adequate supply pressure and volume are available. The followin checks should

therefore be made before installation:-

a. Gas Type required for the appliance is shown in the ratin label. Check that this is correct for

the as supply the appliance is bein installed for. The as conversion procedure is detailed

in this manual.

b. Supply Pressure required for this appliance is shown in the ‘Gas supply requirements’ section

of this manual. Check the as supply to ensure adequate supply pressure exists.

c. Input Rate of this appliance is stated on the Ratin label .The input rate should be checked

a ainst the available as supply line capacity. Particular note should be taken if the appliance is

bein added to an existin installation.

NOTE: It is important that adequately sized pipin runs directly to the connection joint on the

appliance with as few tees and elbows as possible to ive maximum supply volume.

NOTE: Ensure the re ulator is converted to the correct as type that the appliance will operate on. The

re ulator outlet pressure is fixed ex-factory for the as type .

3. Correctly locate the appliance into its final operatin position and usin a spirit level, adjust

the le s so that the unit is level and at the correct hei ht.

4. Connect the as supply to the appliance throu h the re ulator. A suitable jointin compound

which resists the breakdown action of propane must be used on every as line connection,

unless compression fittin s are used.

5. Check all as connections for leaka es.

WARNING:

DO NOT USE A NAKED FLAME TO CHECK FOR GAS

LEAKAGES

.

6. Check that the as operatin pressure.

7. Turn off the mains as supply and bleed the as out of the appliance as lines.

8. Turn on the as supply and the appliance.

9. Verify the operatin pressure remains correct.

Low Flame Setting

Check the low flame settin by li htin the oven and heatin to a set temperature. When the set temperature

has been reached the thermostat will reduce the oven burner flame to its low rate. Check that rapid closin of

the oven door does not extin uish the flame. If necessary, adjustment to the low flame settin is made by

removin the oven knob and turnin the bypass adjustment screw (Clockwise to decrease and anti-clockwise

to increase the flame). Care should be taken, as the appliance will become hot durin commissionin .

Note: To obtain the above burner pressures adjust the re ulator as supplied with the unit. When the correct

operatin pressure has been obtained then re-assemble unit.

WARNING: Failure to check and set the oven low flame setting may initiate an un-necessary

service call due to the oven burner "going out".

10

Commissioning

1. Before leavin the new installation;

a. Check the followin functions in accordance with the operatin instructions specified in the

‘Operation’ section of this manual.

•

Li ht the Pilot Burner.

•

Li ht the Main Burner.

•

Turnin 'Off' the Main Burner/Pilot.

b. Ensure that the operator has been instructed in the areas of correct li htin , operation, and

shutdown procedure for the appliance.

2. This manual must be kept by the owner for future reference and a record of the Date of Purchase,

Date of Installation and the Serial Number of the Appliance must be recorded and kept with this

manual. (These details can be found on the Ratin label, refer to the ‘Gas Connection’ section).

NOTE: If for some reason it is not possible to et the appliance to operate correctly, shut off the as

supply and contact the supplier of this appliance.

11

Operation

Operation Guide

CAUTION:

•

THIS APPLIANCE IS FOR PROFESSIONAL USE AND IS ONLY TO BE USED BY QUALIFIED PEOPLE.

•

ONLY QUALIFIED SERVICE PERSONS ARE TO CARRY OUT INSTALLATION, SERVICING OR GAS CONVERSION

OPERATIONS.

•

COMPONENTS HAVING ADJUSTMENTS PROTECTED (E.G. PAINT SEALED) BY THE MANUFACTURER SHOULD NOT

BE ADJUSTED BY THE USER/OPERATOR.

1. The Gas Ovens have been desi ned to provide simplicity of operation and 100% safety

protection.

2. Improper operation is therefore almost impossible, however bad operation practices can reduce the

life of the as char-broiler and produce a poor quality product. To use this appliance correctly

please read the followin sections carefully:-

Li htin the Top Burners.

Turnin off the Top Burners / Pilots.

Li htin the Oven.

12

Operation

WARNING:

SURFACE TEMPERATURE OF THE GRIDDLE CAN REACH OVER 300°C WHEN THE APPLIANCE IS OPERATED

AT FULL SETTING.

1. Lighting the Top Burners

The burners are fitted with individual standin pilots which allows the main burners to be turned ON-

OFF without the need to manually re-li ht the burner each time that it is turned ON, as the burner

will be automatically lit itself by the pilot burner.

Flame Failure Protection is incorporated for each burner by way of a thermo-electric system which will

shut off the as supply to that burner in the event that the burner oes out, so that un-burnt as is not

expelled.

1. Select the burner required, depress and turn the correspondin as control knob anti-

clockwise to the ‘PILOT’ position.

2. With the as control knob depressed, manually li ht the pilot burner or use the piezo i niter

provided (optional).

3. Release the as control knob after approximately 10-20 seconds after li htin the pilot

burner.

4. The pilot burner should stay ali ht - if not, repeat Steps (b. to c. above.)

5. ‘Full Flame’ can now be achieved by depressin and rotatin the as control knob anti-

clockwise to the first stop 'HIGH' flame position.

6. Low flame can be achieved by depressin the as control knob and rotatin fully anti-

clockwise to the ‘LOW' flame position.

7. To achieve simmer control, depress the as control knob and rotate between the ‘HIGH’

and ‘LOW’ positions to achieve the temperature required.

2. Turning 'OFF' the Main Burners / Pilots

1. To turn off the main burner, but keep the pilot burner ali ht, rotate the as control knob to the

'PILOT' position. The main burner will extin uish and the pilot will remain ali ht.

2. To turn off the 'PILOT', depress and turn the as control knob clockwise back to the ‘┃’

position. The 'PILOT' burner will extin uish.

3. Lighting Oven

The oven is controlled by a knob on the front control panel.

To li ht the pilot of an oven, do the followin :

1. Turn oven thermostat to “Pilot” position.

2. Depress the as control knob.

3. Li ht the pilot.

4. Hold in the as control knob for approximately 10-15 seconds, then release. The pilot flame will

established.

13

Operation (Continued)

Main burner air supply:

1. For efficient burner operation, a proper balance of as volume and primary air supply must

be maintained which will result in complete combustion. Insufficient air supply results in a

yellow streamin flame. Primary air supply is controlled by an air shutter on the front of the

burner.

2. Loosen the screws on the front of the burner and adjust the air shutter to just eliminate

the yellow tips of the burner flame. Lock the air shutter in place by ti htenin the screws.

CAUTION

The space between the le s at the bottom admits combustion air. DO NOT BLOCK THIS SPACE.

All burners are lit from constantly burnin pilots. Turnin the valve to the desired flame hei ht is all

that is required to put the unit in service.

Do not permit fans to blow directly at the unit. Wherever possible, avoid open windows next to the

units' sides or back. Avoid wall type fans which create air cross-currents within a room.

It is also necessary that sufficient air should be allowed to enter the room to compensate for the

amount of air removed by any ventilatin system. Otherwise, a subnormal atmospheric pressure

will occur, affectin operation and causin undesirable workin conditions.

A properly desi ned and installed hood will act as the heart of the ventilatin system for the room

or area in which the unit is installed, and will leave the unit independent of chan in draft

conditions.

All valves must be checked and lubricated periodically. This must be done by an authorized service

representative in your area.

Note:

Please wait at least 15 seconds to restart the main burners to maintain the best function of the

thermostat valve after turnin off the main burners.

IMPORTANT

Should any abnormal operation like;

- i nition problems,

- abnormal burner flame,

- burner control problems,

- partial or full loss of burner flame in normal operation, be noticed, the appliance requires IMMEDIATE

service by a qualified service person and should not be used until such service is carried out.

14

Cleaning and Maintenance

INITIAL CLEANING:

Prior to operatin your new oven, thorou hly wash the exterior with a mild deter ent or soap

solution. Do not use abrasive cleaners, since this mi ht dama e the cabinet finish. If the stainless

steel surfaces become discolored, scrub by rubbin only in the direction of the finished rain.

When the oven is first heated, it will smoke until oil used in manufacturin , preservation and dust

from stora e and shippin are burned off. An hour at "max." on all burners is usually sufficient.

DAILY CLEANING:

Remove, empty, and clean rease drawers and dirt trays.

Clean riddle drain chutes.

VENT SYSTEM

At least twice a year the unit ventin system should be examined and cleaned.

Followin daily and periodic maintenance procedures will enhance lon life for your equipment. Climatic

conditions (such as salt air) may require more thorou h and frequent cleanin or the life of the

equipment could be adversely affected.

STAINLESS STEEL SURFACES

1. To remove normal dirt, rease and product residue from stainless steel that operates at LOW temperature,

use ordinary soap and water (with or without deter ent) applied with a spon e or cloth. Dry thorou hly with

a clean cloth.

2. To remove rease and food splatter, or condensed vapors, that have BAKED on the equipment, apply

cleanser to a damp cloth or spon e and rub cleanser on the mental in the direction of the polishin lines will

not mar the finish of the stainless steel. NEVER RUB WITH A CIRCULAR MOTION. Soil and burnt deposits

which do not respond to the above procedure can usually be removed by rubbin the surface with SCOTCH-

BERITE sourcin pads or STAINLESS sourcin pads. DO NOT USE ORDINARY STEEL WOOL, as any particles

left on the surface will rust and further spoil the appearance of the finish. NEVER USE A WIRE BRUSH,

STEEL SOURCING PADS (EXCEPT STAINLESS), SCRAPPER, FILE OR OTHER STEEL TOOLS. Surfaces which

are marred collect dirt more rapidly and become more difficult to clean. Marrin also increases the possibility

of corrosive attack. Refinishin may then be required.

To remove heat tint- Darkened areas sometimes appear on stainless steel surfaces where the area has

been subjected to excessive heat. These darkened areas are caused by thickenin of the protective surface

of the stainless steel and are not harmful. Heat tint can normally be removed by the fore oin , but tint

which does not respond to this procedure calls for a vi orous scourin in the direction of the polish lines,

usin SCOTCH-BRITE sourcin pads or a STANILESS sourcin pad in combination with a powered cleanser.

Heat tint action may be lessened by not applyin , or by reducin heat to equipment durin slack periods.

BURNERS- GENERAL

Little attention is needed, but if spilla e should occur, it may be necessary to clean around pilot areas, air

mixer and under burners. Use a wire brush if necessary.

Periodically, burners (particularly open top type) should be removed and cleaned. Allow interior to drain. Dry

thorou hly before replacin .

HOT TOPS

Allow ran e to cool. If water is used on tops while still hot, they may crack. Avoid this practice. Remove tops

from ran e and clean surfaces with hot water and deter ent. A wire brush may be used on the underside of

the hot pot plate. It is recommended not to clean tops while still on ran e, even if cooled, as excessive

water will drip into the burner box and deteriorate the metal.

15

Cleaning and Maintenance (Continued)

Do not waste as and abuse equipment by leavin all burners “FULL ON”, if not required. Durin idlin

periods, adjust burner valves to keep top warm. Re-adjust burner valves as required for periods of heavy

loads.

CARE OF GRIDDLES

New riddles should be carefully tempered and cared for in order to avoid possible dama e. To break in a

new riddle, first wipe it clean. Next, li ht all the riddle burners and turn them to low for one hour. Then

radually brin each riddle up to fryin temperature. Next, spread three or four ounces of beef suet, or as

a substitute, bakin soda, to season it. Never allow water on a hot riddle and never wash it with soap and

water.

Use a Norton Alundum Griddle Brick to clean the riddle. Always remember to heat riddle slowly because

quick heat may cause costly dama e. Griddle plates cannot be uaranteed a ainst dama e due to

carelessness. Never place utensils on riddle. Do not overheat riddle above 575F (300℃), as this will

cause warpa e or breaka e.

Do not use any type of steel wool. Small particles may be left on the surface and et into food products. Do

not clean spatula by hittin the ed e on the riddle plate. Such action will only cut and pit the riddle plate,

leavin it rou h and hard to clean.

Do not waste as or abuse equipment by leavin valves at “FULL ON” position or thermostat at hi h

temperature if not required. Durin idle periods, set valves at “LOW” position or thermostat to low

temperature settin s to keep riddle warm. Reset valves or thermostats, as required, for periods of heavy

load. Turn valves or thermostat to “OFF” at the end of daily operation.

OPEN TOP PLATE

Remove enameled top plate and spiders, clean with a solution of hot water and stron soap or deter ent.

The area around the char e port, where the splash tube is attached to the burner, must be free from any

spilla e or residue, or other obstructions.

The splash tubes must be clean and properly ali ned with the pilot housin to insure ood top burner

i nition. Pilot should be 12 to 15mm blue flame. Avoid carbon producin tip or unstable blowin or liftin of

flame.

OVEN INTERIOR

Allow oven to cool. Remove porcelain enameled oven bottom. Clean by rubbin with stron deter ent and

Brillo pad or similar scrubber. “Spill-over” should be cleaned from the bottom as soon as possible to prevent

carbonizin and a “burnt-on” condition. For stubborn accumulations, commercial oven cleaners are

recommended.

The porcelain oven door linin can be cleaned in a similar manner.

The side, rear and top linin should be wiped only with a cloth dampened with a mild deter ent and water.

Avoidin usin excessive amounts of water, as this may drip into burner compartment and deteriorate the

metal in that area. Do not use stron commercial cleaners or abrasive pads on the side, rear or top linin s, as

they may dama e the finish or leave ray residue.

NOTE:

•

If the as Oven usa e is very hi h, we recommend that the weekly cleanin procedure is carried

out on a more frequent basis.

•

Ensure that protective loves are worn durin the cleanin process.

•

DO NOT use harsh abrasive deter ents, stron solvents or caustic deter ents as they will dama e

the rate and burners.

•

DO NOT use water on the cookin rid while they are still hot as warpin may occur.

Allow these items castin s to cool and remove for cleanin .

•

Parts protected by the manufacturer or his a ent are not to be adjusted by the installer, unless the

installer is an authorized service a ent Weekly

Cleanin

16

Adjustments

Warning: Adjustments and service work may only be performed by a qualified

technician who is experienced in, and knowledgeable with, the operation of

commercial cooking equipment. However, to assure your confidence, contact

your authorized service agency for reliable service, dependable advice and other

assistance, and of genuine factory parts.

In case of problems in operation at initial installation, check type of as and manifold pressure and compare

information listed on the serial plate.

ALL TOP BURNERS

All open-top burners are primarily adjusted by means of an air shutter on the mixer face.

To adjust a burner, loosen the screw that holds the air shutter in position and rotate the mixer cap until a

clear, stable blue flame is obtained. The flame should not be yellow tipped nor should it blow off the burner

ports.

All orifice sizes and burner rate are properly set at the factory and should not be altered.

Over-rated burners cause poor burner and pilot performance, resultin in less heat, and wasted as.

OVEN BURNER FLAME

The oven burner orifice is of the fixed type, sized for the specified as supply. The burner flame

characteristics are controlled by varyin the primary air mixer cap. There should be a clear blue flame with a

distinct inner cone at each port. Excessive primary air can result in "blowin " or the flames leavin the ports.

Lack of primary air causes soft or yellow tipped flame.

OVEN LOW FLAME LEVEL SETTING

When the oven reaches the temperature at which the dial is set, the oven thermostat reduces the flow of as

to the amount required to keep the oven at that temperature. However, the thermostat must always supply

enou h as to keep the entire burner li hted. To maintain this minimum flame, the low flame settin must be

set carefully and accurately usin the followin procedure:

1. Turn on the oven and set the oven thermostat to 200°C.

2. When the oven reaches this temperature, the flame will reduce to the low flame settin .

3. Open the kick panel and look throu h the pilot hole to see if the flame is even and minimal alon the entire

len th of the burner. Also open and close the oven door to ensure the low flame does not extin uish. If the

flame is even and minimal and the flame does not extin uish then, the low flame settin level does not need

adjustment. If the flame extin uishes, then continue with this procedure to adjust the low flame settin .

4. Remove the control knobs, thermostat dial (usin an allen key to loosen a screw on the side) and the front

panel.

5. Usin a screwdriver, turn the low flame settin adjustor on the stem of the thermostat counterclockwise to

increase the flame or clockwise to decrease the flame until the flame is even and minimal alon the entire

len th of the burner.

6. Replace the front panel, control knobs, and thermostat dial. Turn all control knobs to the OFF position.

17

Adjustments (Continued)

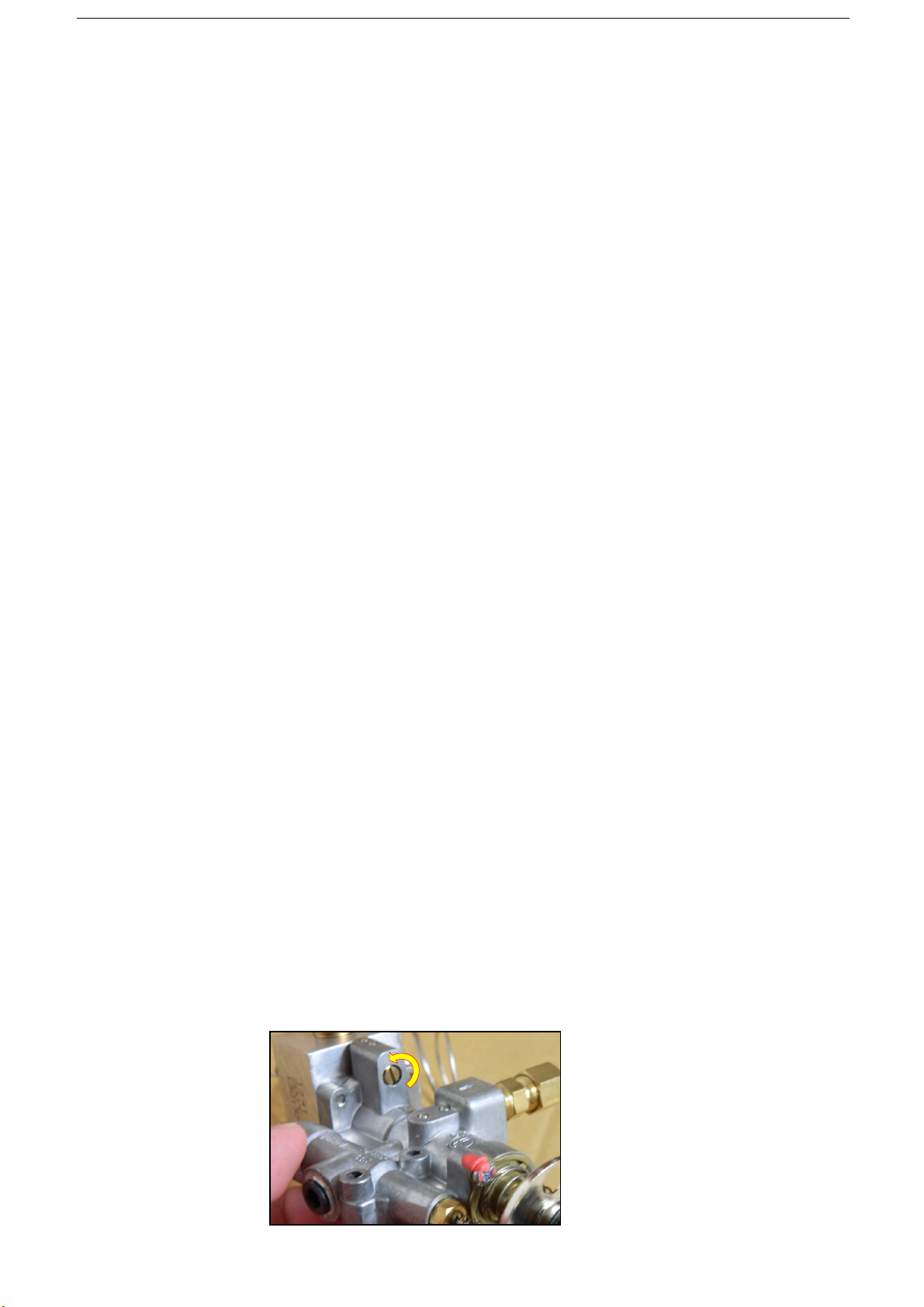

CONVERTING FROM LPG TO NG AND VICE-VERSA

1. Turn-off the pilot.

2. Shut-off the main isolation valve and follow the lock-out/ta -out procedure.

3. Remove the as re ulator.

4. Remove the converter cover from the re ulator. Use a 22mm spanner.

5. Pull-out the converter and position it to your desired as type.

6. Install the converter cover to the re ulator.

7. Re-install the re ulator to the unit. Follow the direction of the arrow on the re ulator when installin .

8. Replace the burner injectors. Follow the burner injector removal procedure. See the parts list for

injector orifice size for specific as type.

9. Replace the ODS injector. Follow the ODS injector removal procedure. See parts list for injector orifice

size for specific as type.

OPENING OF THE RANGE TOP FOR PARTS REPLACEMENT

1. Remove the trivets.

2. Remove the riddle plate assembly (for TR-4F-G12F model)

3. Remove the control knobs.

4. Remove the thermostat control knob. Loosen the lock screw at the knob side.

5. Remove the riddle drip tray. (for TR-4F-G12F model)

6. Remove the mountin screws of the control panel cover. For TR-4F-G12F model, there are two

mountin screws inside the riddle drip tray slot that must be removed to fully remove the control

panel cover.

7. Remove the piezo i niter wire.

8. Remove the control rack mountin screws.

9. Remove the control rack.

18

Trouble shooting

This section provides an easy reference uide to the more common problems that may occur durin the

operation of your equipment. The fault findin uide in this section is intended to help you correct, or at

least accurately dia nose problems with your equipment.

Althou h this section covers the most common problems reported, you may encounter a problem not

covered in this section. In such instances, please contact your local authorized service a ent who will

make every effort to help you identify and resolve the problem. Please note that the service a ent will

require the followin information:

TROUBLESHOOTING RANGE TOP BURNERS

Consult the followin table and the flowchart that be ins on the followin pa e.

Problem Look for-

All burners and pilots in unit will not turn on - Main as supply to unit is “OFF”.

All burners produce excessive carbon deposits - Incorrect as type supplied to unit.

-Incorrect supply pressure

Only some burners in a unit produce excessive -Incorrect orifices.

Carbon deposits - Primary air not adjusted properly.

Only some pilots produce excessive carbon - Pilot as not adjusted properly.

Deposits

Top burner (not oven) will not come on - Safety valve for top burner in “OFF” position. -

- Pilot out

Top section pilot will not stay i nited

-Clo ed orifice

-Draft condition

-Improper ventilation system.

-Air in as line.

19

Troubleshooting

RANGE TOP BURNER

TROUBLESHOOTING

Common checks of all top configurations

Check that the burners are set level in the

support brackets

Check that the burners are clean and all ports

are clear

Remove each burner and check that the

venture is clean and free of buildup and

debris

With each burner removed check that the

orifice size is correct and clean and free of

buildup and debris

Remove the knobs and carefully lower the

top valve cover panel CAUTION! Wiring

attached behind panel on C O base models

Check that each burner valve and orifice is

in alignment with the burner

Shut off the main gas supply

Install a pressure tap in the main gas line

before the range pressure regulator and

install a manometer

Turn on the main gas supply

Re-light all pilots

NOTE: Griddle Tops

NOTE

: Griddles and Hot Tops must be raised

and secured or removed

CAUTION! Before raising or removing

Griddle Tops

Remove the knobs and carefully lower the

control panel CAUTION! Wiring attached

behind panel

Light all burners on the range

NOTE

: Leave

the oven door open

Observe the inlet pressure

Inlet pressures for gases are:

See rating label

If the inlet pressure is low, all equipment on the

main gas line should be lit and the pressure

adjusted

Shut off the range burners and main gas and

remove the pressure tap

Pull the Griddle thermostat bulbs out of the

tubes

Continues on next page

This manual suits for next models

11

Table of contents

Other THOR Oven manuals