PTR302 Rotary Proof Tester

Table of Contents

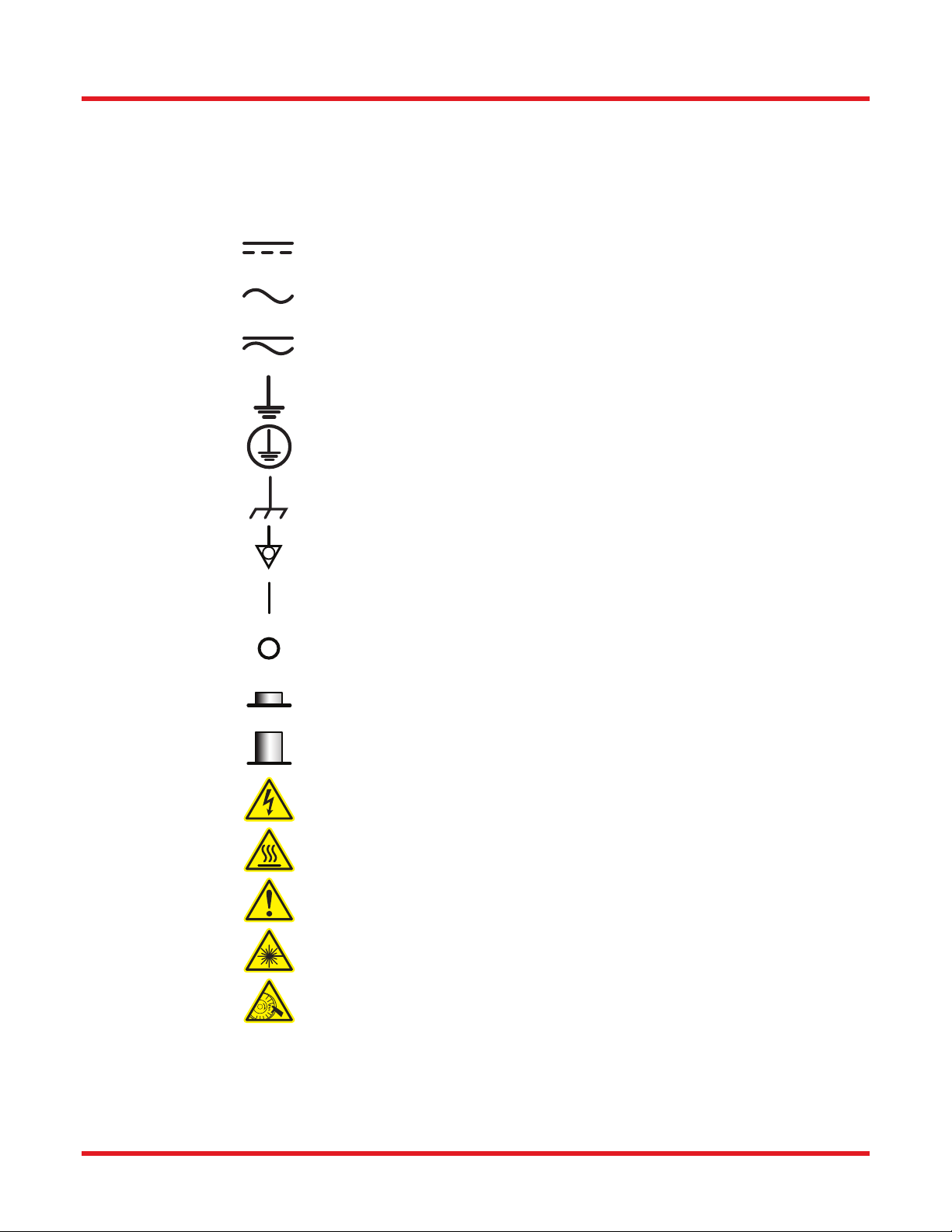

Chapter 1Warning Symbol Definitions..............................................................................................1

Chapter 2Safety....................................................................................................................................2

Chapter 3Description...........................................................................................................................3

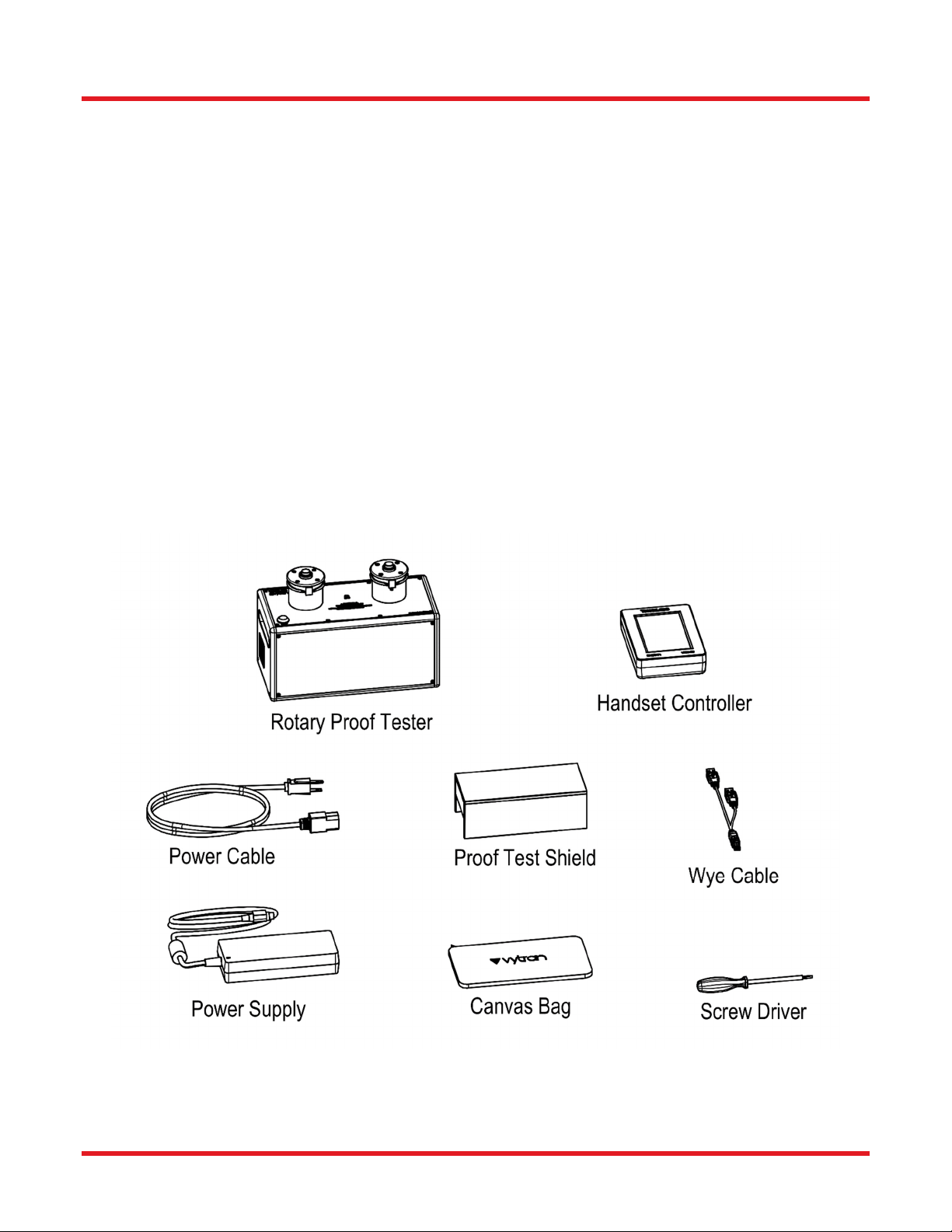

3.1.Introduction .....................................................................................................................3

3.2.Parts Checklist ................................................................................................................3

Chapter 4Initialization and Control....................................................................................................4

4.1.Controlling the PTR302...................................................................................................4

4.2.Controlling the PTR302...................................................................................................5

4.2.1.Unit Control Button ................................................................................................................ 5

4.3.VYT300C Handset Controller .........................................................................................6

4.3.1.Power Up ............................................................................................................................... 6

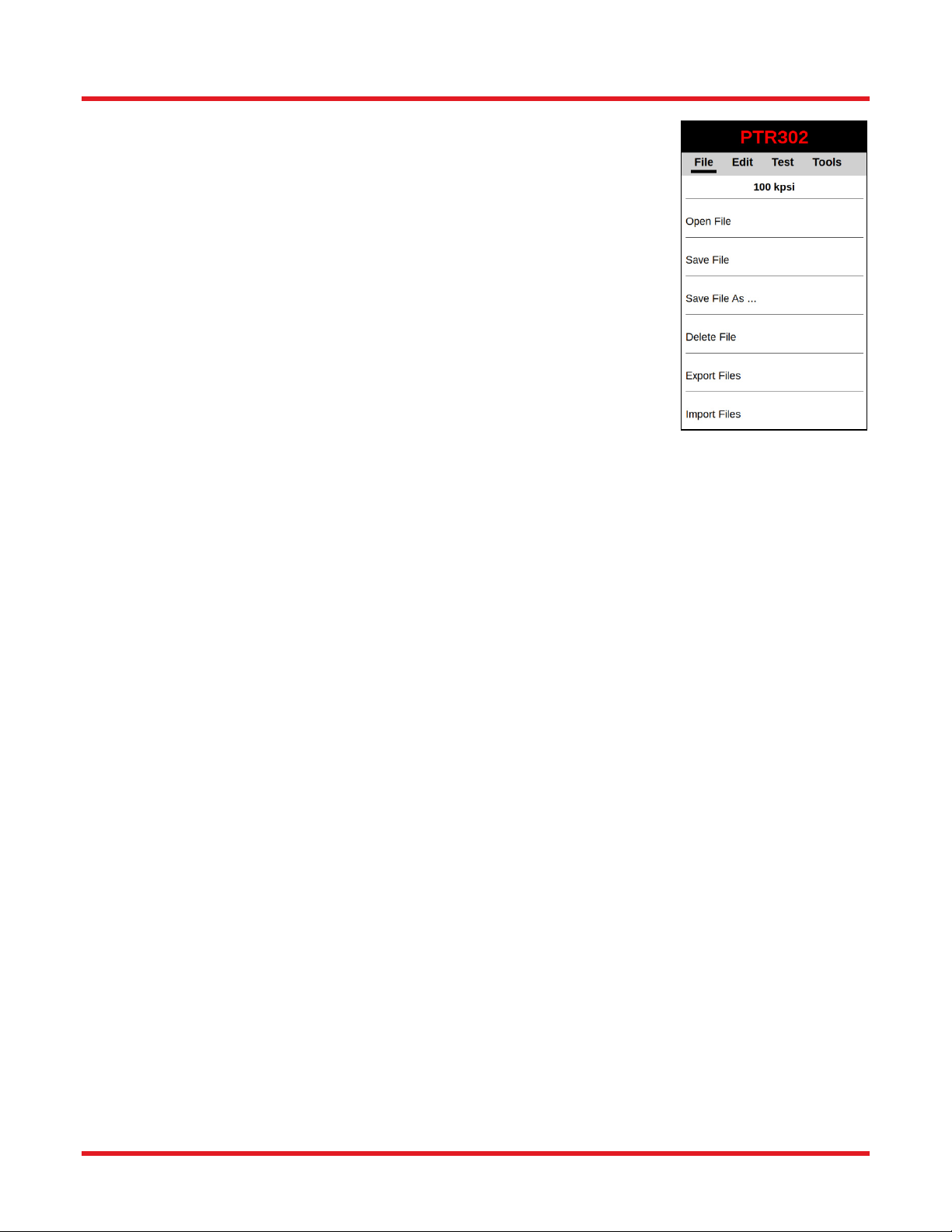

4.3.2.File Menu ............................................................................................................................... 7

4.3.3.Edit Menu .............................................................................................................................. 8

4.3.4.Test ....................................................................................................................................... 8

4.3.5.Tools Menu............................................................................................................................ 9

Chapter 5Proof Test Process.............................................................................................................11

5.1.Position the Fiber for Proof Test .................................................................................11

5.2.Proof Testing .................................................................................................................11

5.3.Adjusting Ramp Rate ....................................................................................................12

Chapter 6Maintenance........................................................................................................................13

6.1.Planned Maintenance....................................................................................................13

6.2.Replace Proof Test Grips .............................................................................................13

6.3.Check Proof Test Calibration / Re-Calibration ...........................................................13

Chapter 7Trouble Shooting................................................................................................................14

7.1.Proof Test Diagnostics .................................................................................................14

Chapter 8Specifications.....................................................................................................................15

Chapter 9Regulatory...........................................................................................................................16

9.1.Waste Treatment is Your Own Responsibility............................................................16

9.2.Ecological Background ................................................................................................16

Chapter 10Thorlabs Worldwide Contacts..........................................................................................17