THRUSH S2R-T34 Technical specifications

Thrush Aircraft Inc Model S2R-T34 MANUAL

Albany, GA AIRPLANE FLIGHT MANUAL ORGANIZATION

FAA APPROVED: Oct. 24, 2006 Revision 2, page i

SECTION I-----------------------------------------------------LIMITATIONS

SECTION II-------------------------------------- NORMAL PROCEDURES

SECTION III--------------------------------EMERGENCY PROCEDURES

SECTION IV-------------------------------------------------PERFORMANCE

Thrush Aircraft Inc Model S2R-T34 SECTION I

Albany, GA AIRPLANE FLIGHT MANUAL LIMITATIONS

FAA APPROVED: Oct. 24, 2006 Revision 2, SECTION I-1

SECTION I

LIMITATIONS

TABLE OF CONTENTS

Subject page | Subject page

POWER PLANT................................................... I-1 | WEIGHT AND CENTER OF GRAVITY ...........I-5

INSTRUMENT MARKINGS ............................... I-3 | MANEUVERS .....................................................I-6

AIRSPEED LIMITATIONS ................................. I-4 | TYPES OF OPERATION....................................I-6

ALTITUDE LIMITATIONS................................. I-4 | GROUND OPERATION .....................................I-6

FLIGHT LOAD FACTORS.................................. I-4 | PLACARDS.........................................................I-6

NOISE ABATEMENT.......................................... I-4

POWERPLANT:

ENGINE:

STANDARD: Pratt & Whitney Canada PT6A-34AG

OPTIONAL: Pratt & Whitney Canada PT6A-34

Pratt & Whitney Canada PT6A-36 (Dry Configuration Only)

Pratt & Whitney Canada PT6A-41, -41AG

Pratt & Whitney Canada PT6A-42

FUEL:

JET A, JET B, JP-4, JP-5. (If jet fuel is not available, aviation gasoline, MIL-G-5572, all grades,

may be used for a maximum of 150 hours between overhauls).

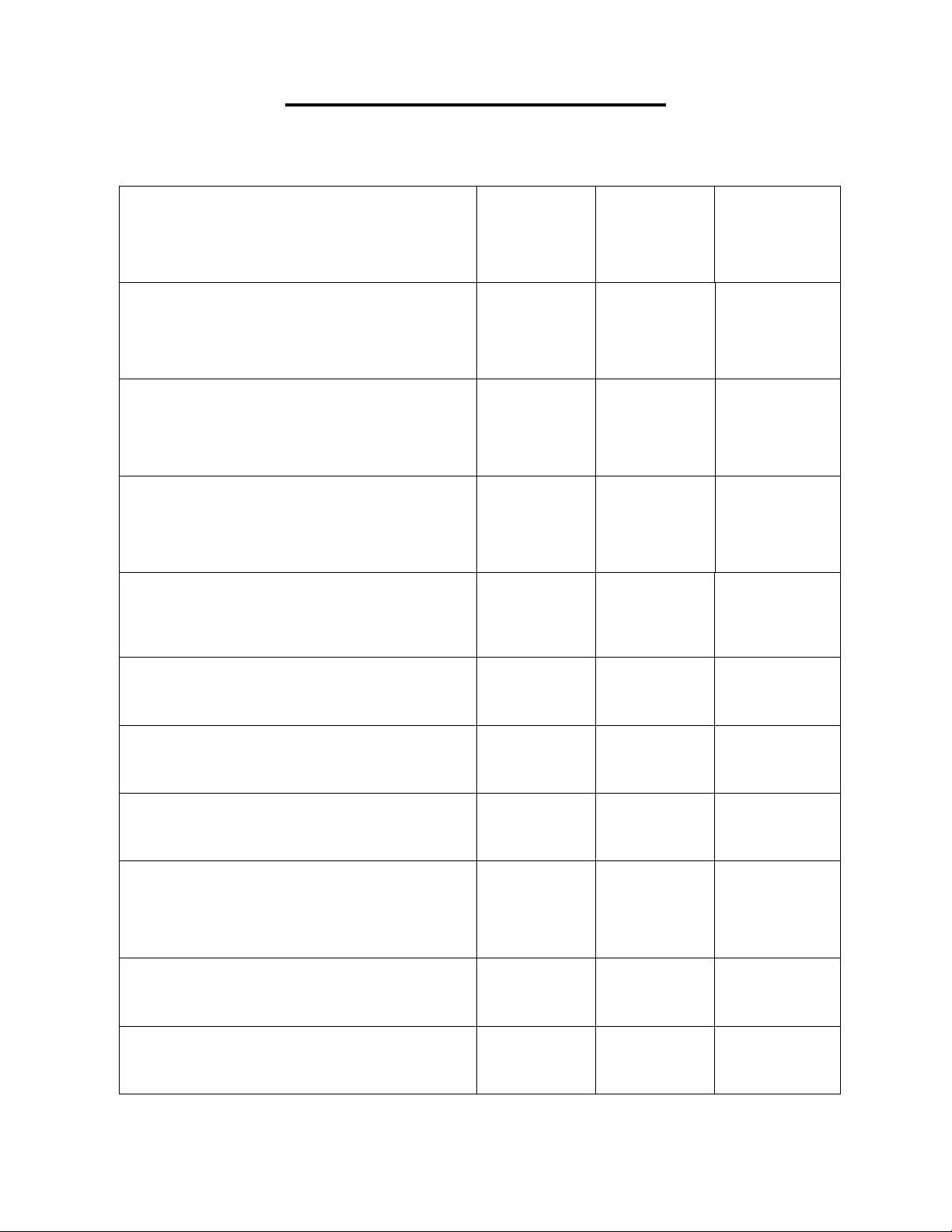

ENGINE LIMITS: PT6A-34AG, -34, -36 (PT6A-34AG shown)

POWER

SETTING SHP TORQUE

(PSI) ITT

(ºC) NG

(%) NP

(RPM)

OIL

PRESS.

(PSIG)

OIL

TEMP.

(ºC)

Takeoff & Max

continuous 750 64.5***

58.7**** 790 101.6 2200 85 to 105 10 to 99

Max Climb 700 60.2***

54.7**** 765 101.6 2200 85 to 105 0 to 99

Max Cruise 700 60.2***

54.7**** 740 2200 85 to 105 0 to 99

Idle 685 50 40 Min. -40 to 99

Starting 1090* -40 Min.

Acceleration 68.4** 850* 102.6* 2420 0 to 99

Max. Reverse 750 64.5***

GENERAL NOTE: The operating parameters in this Table are individual limits for each engine

parameter and do not necessarily apply simultaneously.

61.4**** 790 101.6 2100 85 to 105 0 to 99

*These values are time limited to two (2) seconds.

**These values are time limited to twenty (20) seconds.

***Torque limit for Max NP= 2000 RPM

****Torque limit for NP= 2200 RPM

Thrush Aircraft Inc Model S2R-T34 SECTION I

Albany, GA AIRPLANE FLIGHT MANUAL LIMITATIONS

FAA APPROVED: Jan. 27, 2009 Revision 4, SECTION I-2

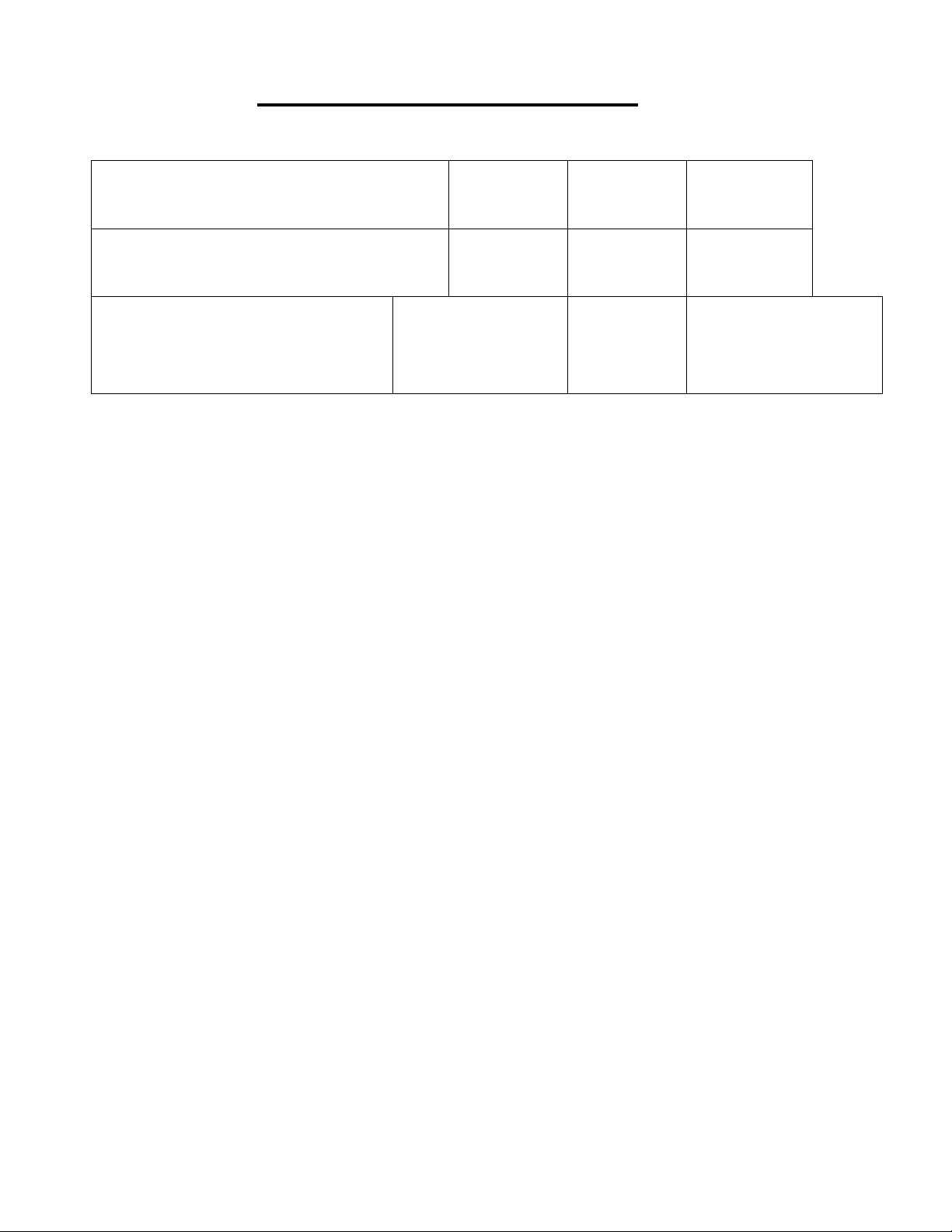

ENGINE LIMITS: PT6A-41AG, -41, -42 (PT6A-41AG shown)

***

TORQUE

POWER

SETTING SHP

GENERAL NOTE: The operating parameters in this Table are individual limits for each engine

parameters and do not necessarily apply simultaneously.

(PSI)

ITT

(ºC) NG

(%) NP

(RPM)

OIL

PRESS.

(PSIG)

OIL

TEMP.

(ºC)

Takeoff & Max

continuous 750 64.5 750†101.5 2000 105 to

135††† 0 to 99

Max Climb 700 60.2 725†† 101.5 2000 105 to

135††† 0 to 99

Max Cruise 700 60.2 725†2000 105 to

135††† 0 to 99

Idle 50 60 Min. -40 to 99

Starting 1000* -40 Min.

Acceleration 68.4* 850 102.6 2205 99 to 104**

Max. Reverse 750 64.5 750 101.5 2000 105 to

135††† 0 to 99

*These values are time limited to five (5) seconds.

**Time limited to ten (10) minutes at any operating condition.

***Torque limit shown for NP= 1600-2000 RPM.

†For PT6A-42 790ºC.

††For PT6A-42 765ºC.

†††For PT6A-42 100 to 135

STARTER: Maximum starter engagement duration is 30 Seconds followed by a 60 Seconds

cool down period. Total of 3 cycles to be followed by 30 minutes starter cool

down.

AIR STARTS: Normal air starts are approved from sea level to 12,000 feet altitude and from 80

MPH to 126 MPH air speed. See the Emergency Procedures in Section III.

PROPELLER: Hartzell Hub Model HC-B3TN-3C (or HC-B3TN-3D) with Blade Model T-10282,

Diameter 102.5 inches maximum, 92.5 inches minimum or optional Blade Model

T-10282 (N) +4, Diameter 106.5 inches maximum, 98.0 inches minimum.

REVERSE POWER: Do not use in flight

P-3 HEATER: Regardless of fuel type used, the P-3 heater switch must be turned on (if installed)

for flight and ground operations when the free air temperature is below 40 Degrees

F.

Thrush Aircraft Inc Model S2R-T34 SECTION I

Albany, GA AIRPLANE FLIGHT MANUAL LIMITATIONS

FAA APPROVED: OCT 24, 2006 Revision 2, SECTION I-3

INSTRUMENT MARKINGS:

Limits Features Meaning

OIL TEMP ( °C)

-40

-40 to10

10 to 99

99

Red Radial

Yellow Arc

Green Arc

Red Radial

MINIMUM

CAUTION

NORMAL

MAXIMUM

OIL PRESSURE (PSI) PT6A-34AG, -34, -36

40

40 to 85

85 to 105

105

Red Radial

Yellow Arc

Green Arc

Red Radial

MINIMUM

CAUTION

NORMAL

MAXIMUM

OIL PRESSURE (PSI) PT6A-41AG,-41

60

60 to 105**

105 to 135

135

Red Radial

Yellow Arc

Green Arc

Red Radial

MINIMUM

CAUTION

NORMAL

MAXIMUM

OIL PRESSURE (PSI) PT6A-42

60

60 to 100***

100 to 135

135

Red Radial

Yellow Arc

Green Arc

Red Radial

MINIMUM

CAUTION

NORMAL

MAXIMUM

FUEL PRESSURE (PSI) 5

5 to 50

50

Red Radial

Green Arc

Red Radial

MINIMUM

NORMAL

MAXIMUM

ITT (°C) PT6A-34AG, -34, -36 400 to 790

790 Green Arc

Red Radial NORMAL

MAXIMUM

ITT (°C) PT6A-41AG, -41 400 to 750

750 Green Arc

Red Radial NORMAL

MAXIMUM

ITT (°C) PT6A-42 400 to 800

800 Green Arc

Red Radial NORMAL

MAXIMUM

TORQUE (PSI) PT6A-34AG, -34, -36

0 to 58.7

58.7*

64.5

Green Arc

Red Radial

Red Diamond

NORMAL

MAXIMUM

Max @

2000RPM

TORQUE (PSI)

PT6A-41AG, -41, -42 0 to 64.5

64.5 Green Arc

Red Radial NORMAL

MAXIMUM

PROPELLER RPM (NP)

PT6A-34AG, -34, -36 0 to 2200

2200 Green Arc

Red Radial NORMAL

MAXIMUM

Thrush Aircraft Inc Model S2R-T34 SECTION I

Albany, GA AIRPLANE FLIGHT MANUAL LIMITATIONS

FAA APPROVED: OCT 24, 2006 Revision 2, SECTION I-4

INSTRUMENT MARKINGS (Continued)

Limits Features Meaning

PROPELLER RPM (NP)

PT6A-41AG, -41, -42 0 to 2000

2000 Green Arc

Red Radial NORMAL

MAXIMUM

GAS GENERATOR SPEED (% NG) 50 to 101.6

101.6 Green Arc

Red Radial NORMAL

MAXIMUM

AIRSPEED

66 to 123 MPH CAS

70 to 126 MPH CAS

126 to 159 MPH CAS

159 MPH CAS

White Arc

Green Arc

Yellow Arc

Red Radial

Flaps Operating Range

Normal Operating Range

Caution Range

Never Exceed

* In addition to a red radial limit marker at 58.7 PSI, the torque meter is marked with a red diamond at 64.5

PSI. (58.7 PSI is the torque limit for 2200 RPM, the normal takeoff RPM. 64.5 PSI is the torque limit for

2000 RPM, an optional RPM setting for in-flight use.)

** The 60-105 oil pressure caution range is for idling and for emergency completion of a flight using 36 PSI

torque or below.

*** The 60-100 oil pressure caution range is for idling and for emergency completion of a flight using 36 PSI

torque or below.

AIRSPEED LIMITATIONS:

Never Exceed Speed VNE – 159 MPH

Maximum Structural Cruising - VNO – 126 MPH

Maneuvering Speed – VA– 126 MPH

Flap Extended Speed – VFE – 123 MPH

Maximum Dump Speed – 120 MPH

Maximum Crosswind Velocity – 15 MPH

All airspeeds are given in Calibrated Air Speeds.

ALTITUDE LIMITATIONS:

Maximum approved altitude is 12,000 feet.

FLIGHT LOAD FACTORS:

Design Load Factors - Flap Up; 3.8 Positive, 1.9 Negative

Design Load Factors - Flap Down; 2.4 Positive, 0.0 Negative

NOISE ABATEMENT:

This airplane has not been shown to comply with the noise limits in FAR 36 and must be

operated in accordance with the noise operating limitation prescribed under FAR §91.815.

Thrush Aircraft Inc Model S2R-T34 SECTION I

Albany, GA AIRPLANE FLIGHT MANUAL LIMITATIONS

FAA APPROVED: Jan. 27, 2009 Revision 4, SECTION I-5

WEIGHT AND CENTER OF GRAVITY:

NOTE

Datum is the leading edge of the wing.

Maximum Weight – 6000 pounds

C.G. Range for SINGLE & DUAL COCKPIT

* Forward Limit at 6000 pounds is 26.5 inches AFT of Datum.

* Forward Limit at 4000 pounds is 24.0 inches AFT of Datum.

* AFT Limit is 29.0 inches AFT of Datum (Normal Category).

Straight Line variation in the Forward Limit between 4000 pounds and 6000 pounds.

7,000

6,500

6,000

5,500

5,000

4,500

4,000

3,500

3,000

23.0 23.5 24.0 24.5 25.0 25.5 26.0 26.5 27.0 27.5 28.0 28.5 29.0 29.5 30.0

4,000 lbs

@ 24.0 in

6,000 lbs

@ 26.5 in

4,000 lbs

6,000 lbs

@ 29.0 in

Center of Gravity - in. aft of datum

Airplane Weight - lbs

Thrush S2R-T34 Single & Dual Cockpit

Weight & Center-of-Gravity Envelope

Normal Catagory

Thrush Aircraft Inc Model S2R-T34 SECTION I

Albany, GA AIRPLANE FLIGHT MANUAL LIMITATIONS

FAA APPROVED: OCT 24, 2006 Revision 2, SECTION I-6

NOTE

It is the responsibility of the airplane owner and the

pilot to insure that the airplane is properly loaded. See

the aircraft’s Weight and Balance Sheet for loading

information.

MANEUVERS:

NORMAL CATEGORY

Flight maneuvers include steep turns, chandelles, and lazy-eights in which bank angles do

not exceed 60 degrees and pitch angles do not exceeds 30 degrees. Gradual entry rate

stalls are also approved. Acrobatic maneuvers and intentional spins are PROHIBITED.

TYPES OF OPERATION:

The Model S2R-T34 aircraft is approved for day and night VFR flight conditions. Flight

into known icing conditions is PROHIBITED.

GROUND OPERATION:

Ground operation is approved at ground idle power with the propeller feathered and with

no time limits. The pilot should monitor the engine instruments for operation within

limits during all ground operations.

PLACARDS:

A. Located on Right Hand lower instrument panel:

“THIS AIRPLANE MUST BE OPERATED AS A NORMAL CATEGORY AIRPLANE IN

ACCORDANCE WITH THE OPERATING LIMITATIONS STATED IN THE FORM OF

PLACARDS AND THE AIRPLANE FLIGHT MANUAL. NO ACROBATIC MANEUVERS,

INCLUDING SPINS APPROVED. DESIGN MANEUVERING SPEED-126 MPH. MAX.

FLAP-DOWN SPEED-123 MPH. MAX. CROSSWIND VELOCITY,

LANDING-15 MPH. USABLE TANK CAPACITY 114 GALLONS EACH SIDE.”

“THE OPERATION OF THIS AIRPLANE IS LIMITED TO DAY AND NIGHT VFR

CONDITIONS. FLIGHT INTO KNOWN ICING CONDITIONS IS PROHIBITED.”

“NO SMOKING”

“SULFUR DUSTING IS PROHIBITED UNLESS SPECIAL FIRE PREVENTION MEASURES

HAVE BEEN INCORPORATED IN AIRCRAFT.”

“PUSH STICK FORWARD TO UNLOCK TAILWHEEL.”

“TAKING OFF IN VISIBLE MOISTURE BELOW 40°F IS PROHIBITED.”

Thrush Aircraft Inc Model S2R-T34 SECTION I

Albany, GA AIRPLANE FLIGHT MANUAL LIMITATIONS

FAA APPROVED: OCT 24, 2006 Revision 2, SECTION I-7

B. Located near Park Brake Valves:

“PARK BRAKE – ON, DEPRESS PEDALS AND PULL LEVER. OFF, DEPRESS PEDALS”

C. Located on Forward Lower Corner of Each Door Side Window:

“DO NOT OPEN DOOR IN FLIGHT”

“DO NOT OPEN DOOR ON THE GROUND WITH ENGINE RUNNING UNLESS HEADED

OUT OF THE WIND WITH THE PROPELLER FEATHERED”

D. Located adjacent to the torque meter:

“MAXIMUM TORQUE IS 58.7 PSI AT 2200 RPM OR 64.5 PSI AT 2000 RPM WITH

STRAIGHT LINE VARIATION BETWEEN THESE POINTS”

E. At both fuel filler caps:

“FUEL – 115 GAL. CAP. JET A, JET B, JP-4 & JP-5”

F. Located on upper instrument panel:

“DO NOT USE REVERSE POWER IN FLIGHT. AT HIGH TAXI

SPEEDS USE REVERSE POWER ONLY IF THE TAIL WHEEL IS

LOCKED AND FIRMLY ON THE GROUND.”

WARNING

G. Located on cockpit wall (If P-3 Heater is installed):

WARNING

“REGARDLESS OF FUEL TYPE USED, THE P-3 HEATER SWITCH

MUST BE TURNED ON FOR FLIGHT AND GROUND OPERATIONS

WHEN THE FREE AIR TEMPERATURE IS BELOW 40 DEGREES F.”

H. Located on top of hopper

“HOPPER CAPACITY 3336 LBS.”

I. Located on Left Hand Lower instrument panel:

“FILTER CONDITION – FLIGHT IN RED IS PROHIBITED.”

J. Located on the fuel gauge:

“USABLE FUEL 114 U.S. GAL. FUEL ABOVE 82 GAL. IS UNGAGEABLE”.

Thrush Aircraft Inc Model S2R-T34 SECTION I

Albany, GA AIRPLANE FLIGHT MANUAL LIMITATIONS

FAA APPROVED: Jan. 27, 2009 Revision 4, SECTION I-8

K. Located on inside of baggage door: (Single Cockpit Only)

“60 LBS. MAXIMUM BAGGAGE”

L. Located on right hand side panel, rear cockpit: (Dual Cockpit Only)

“PASSENGER OR CARGO 200 LBS MAXIMUM”

M. Located at each door latch:

OPEN or OPEN

N. Located on the Outside of the rear cockpit door: (Dual Cockpit Only)

OPEN

O. Located at each door knockout panel:

“PUSH OUT AND LIFT HINGE PIN FOR EMERGENCY EXIT”

P. Located (inverted) at each door hinge pin:

“PULL HINGE PIN ÆFOR EMERGENCY EXIT”

Q. Located on face of Fuel Shut-off Valve handle bracket:

S/N 273 through 277 and 279:

“FUEL, 228 GAL USEABLE

ON OFF”

S/N 278, 280 and up:

“FUEL, 228 GAL USEABLE

ON OFF

PUSH BUTTON TO TURN”

R. Located on upper instrument panel (Dual Cockpit Only):

100# REMOVABLE BALLAST @ FS – 85.0

MUST BE INSTALLED IF PASSENGER OR

MORE THAN 50# OF CARGO IS ON BOARD

Thrush Aircraft Inc Model S2R-T34 SECTION II

Albany, GA NORMAL PROCEDURES

AIRPLANE FLIGHT MANUAL

SECTION II

NORMAL PROCEDURES

TABLE OF CONTENTS

Subject page | Subject page

DEFINITIONS................................................II-1 | CLIMB ..........................................................II-8

VISUAL INSPECTION..................................II-2 | GLIDE AND APPROACH ...........................II-8

BEFORE STARTING ....................................II-5 | GO AROUND ...............................................II-8

STARTING ENGINE.....................................II-5 | LANDING.....................................................II-8

DRY MOTORING RUN................................II-6 | AFTER CLEARING THE RUNWAY..........II-9

TAXI...............................................................II-7| ENGINE SHUTDOWN ................................II-9

BEFORE TAKE-OFF.....................................II-7 | SECURING THE AIRCRAFT......................II-9

TAKE-OFF.....................................................II-7

DEFINITIONS:

Personal injury or loss of life could result if the operating procedures

and techniques are not followed carefully.

Damage to equipment could result if the operating procedures and

techniques are not followed carefully.

NOTE This is used when it is essential to emphasize an operating procedure or

technique.

Airspeeds All airspeeds in this Section are Indicated Airspeeds (IAS) in

Miles per Hour (MPH), unless otherwise noted.

WARNING

CAUTION

VISUAL INSPECTION:

NOTE

Visually check the aircraft for general condition during the walk around

inspection. Verify that all skin panel Camlocs are fastened. In cold weather

remove all accumulations of frost, ice, or snow from wing, tail and control

surfaces. Check that control surfaces contain no internal accumulations of ice. If

a night flight is planned, check operation of all lights and assure a flashlight is

available.

FAA APPROVED: Apr. 10, 2007 Revision 3, SECTION II-1

Thrush Aircraft Inc Model S2R-T34 SECTION II

Albany, GA NORMAL PROCEDURES

AIRPLANE FLIGHT MANUAL

EXTERIOR INSPECTION ROUTE

Exterior Inspection Route - Figure 2-1

(POSITION)

c1. Control Lock – REMOVE

2. Ignition Switch - OFF

3. Power Lever – FORWARD IDLE

4. Fuel Lever – CUTOFF

5. Fuel Valve – ON

6. Parking Brake – TEST and SET

7. Battery Switch – ON

8. Fuel Quantity – CHECK Each Tank Indication

9. Battery Switch – OFF

10. Elevator Trim Tab – SET, for takeoff (T.O. Arc)

11. Oil Quantity – CHECK dipstick and SECURE cap

NOTE

Operate between 1 and 3 quarts below the

maximum oil level mark on the oil dipstick.

FAA APPROVED: Apr. 10, 2007 Revision 3, SECTION II-2

Thrush Aircraft Inc Model S2R-T34 SECTION II

Albany, GA NORMAL PROCEDURES

AIRPLANE FLIGHT MANUAL

d12. Wing Flap – CHECK, for security

13. Spray Boom (if installed) – CHECK, for leaks and security

14. Aileron – CHECK, for free and correct movement

15. Aileron hinges – CHECK, for looseness. Use a brisk UP and DOWN motion

but use caution so as not to damage control or stops.

e16. Wing Tip – CHECK, for damage

17. Wing Leading Edge – CHECK, for damage

NOTE

Keep the wing leading edge clean. An excessive

build-up of dirt, bugs, and chemicals can have

the same negative effect on lift as an

accumulation of ice or frost.

18. Wing Tie Down – REMOVE, condition and freedom of movement.

18a. Stall Vane – CHECK, condition and freedom of movement.

f19. Fuel Quantity – CHECK, visually and secure cap.

20. Oil Cooler – CHECK, for leaks and stoppage.

21. Accessory Section – CHECK, for debris, oil leaks, or any other

irregularities.

22. Air Filter – CHECK, for cleanliness and condition.

23. Main Wheel Tire – CHECK, for inflation, damage, and wear.

24. Left Wing Sump – DRAIN.

24a. Header Tank Sump – DRAIN.

24b. Left fuel Vent Sump – DRAIN.

25. Firewall Fuel Filter – DRAIN.

25a. Firewall Fuel Filter By-pass Indicator – CHECK.

26. Fuel Vent – CHECK, for obstruction.

26a. Residual Fuel Reservoir (EPA Tank) – DRAIN.

g27. Engine – CHECK, for oil leaks, loose fittings, cracked exhaust stacks, and

excessive dirt or corrosion.

28. Propeller – CHECK, for spinner damage or oil leaks.

29. Propeller – CHECK, the propeller blades for nicks, cracks, or excessive

erosion of the leading edge.

FAA APPROVED: Apr. 10, 2007 Revision 3, SECTION II-3

Thrush Aircraft Inc Model S2R-T34 SECTION II

Albany, GA NORMAL PROCEDURES

AIRPLANE FLIGHT MANUAL

h30. Dispersal Equipment (if installed) – CHECK, the windmill, the pump, the

hose, the spreader, the mounting, and so forth.

31. Wheel Chocks – REMOVE

32. Fuel Quantity – CHECK, visually and secure the cap.

33. Main Wheel Tire – CHECK, for inflation, damage, and wear.

34. Right Wing Sump – DRAIN.

34a. Right Fuel Vent Sump – DRAIN.

i35. Wing Leading Edge – CHECK, for damage.

NOTE

Keep the wing leading edge clean. An excessive

build-up of dirt, bugs, and chemicals can have

the same negative effect on lift as an

accumulation of ice or frost.

36. Pitot Mast – CHECK, for blockage of opening.

37. Wing Tie Down –REMOVE.

38. Wing Tip – CHECK, for damage.

j39. Aileron – CHECK, for free and correct movement.

40. Aileron Hinges – CHECK, for looseness. Use a brisk UP and DOWN

motion but use caution so as not to damage control or stops.

41. Spray Boom (if installed) – CHECK, for leaks and security.

42. Wing Flap – CHECK, for security.

42a. Fuel Quantity – CHECK, visually and secure cap.

43. Battery Vent – CHECK for obstruction.

43a. Static Port Opening – CHECK for blockage.

44. Rudder Gust Lock (if installed) – REMOVE.

k45. Empennage – CHECK, for condition

46. Struts – CHECK, for condition and security.

47. Tail Wheel Tire – CHECK, for inflation, damage, and wear.

48. Tail Wheel Spring – CHECK, for condition.

48a. Tail Wheel Assembly – CHECK, for condition.

49. Rudder and Elevator – CHECK, for freedom of movement and security.

50. Elevator Trim Tabs – CHECK, for near neutral position (take-off) and

excessive play

FAA APPROVED: Apr. 10, 2007 Revision 3, SECTION II-4

Thrush Aircraft Inc Model S2R-T34 SECTION II

Albany, GA NORMAL PROCEDURES

AIRPLANE FLIGHT MANUAL

51. Tail Tie-Down – REMOVE.

52. Static Port Opening – CHECK, for blockage

10 53. Rear Cockpit – CHECK, cargo secure (Dual Cockpit Only)

54. Rear Cockpit Door – CHECK, closed and secure (Dual Cockpit Only)

BEFORE STARTING ENGINE:

1. Visual Inspection – COMPLETE

2. Seat – ADJUST

3. Rudder Pedals – ADJUST and LOCK

4. Seat Belt and Shoulder harness – ADJUST and LOCK

5. Altimeter – SET

6. Door Latches – CHECK

7. Parking Brake – SET

8. Propeller – CLEAR Area

9. Rear Cockpit Occupant – STRAPPED IN (Dual Cockpit Only)

STARTING ENGINE:

1. Battery Switch – ON

2. Power Lever – FORWARD IDLE STOP / BETA STOP

3. Propeller Lever – Anywhere in operating range, but normally feather.

4. Fuel Lever – CUT OFF

5. Fuel Valve – ON

6. Fuel Aux. Pump Switch – ON

7. Fuel Inlet pressure Indicator – CHECK, 5 PSIG Minimum

8. Engine Starter Switch – ON. The minimum speed to obtain a satisfactory light is Ng

12%.

9. After approximately 5 seconds of motoring at a stabilized gas generator speed above

12%:

a) MOVE Ignition Switch to On Position and,

b) MOVE the Fuel Condition Lever to the Low Idle / Ground Idle position.

10. Observe that the engine accelerates normally to idle RPM and that the maximum

allowable interturbine temperature starting limit is not exceeded.

FAA APPROVED: Apr. 10, 2007 Revision 3, SECTION II-5

Thrush Aircraft Inc Model S2R-T34 SECTION II

Albany, GA NORMAL PROCEDURES

AIRPLANE FLIGHT MANUAL

CAUTION

Whenever the gas generator fails to light up within 10 Seconds

after moving the fuel lever to the LOW IDLE / GROUND IDLE

position, cut off fuel, starter, and ignition. Allow a 30 second fuel

draining period followed by a 15 second dry motoring run before

attempting another start. If for any reason a starting attempt is

discontinued, allow the engine to come to a complete stop and

then accomplish a dry motoring run. (See the following Section.)

11. Engine Starter Switch and Ignition Switches – OFF.

12. Oil Pressure – CHECK, 85 PSIG Minimum.

13. Fuel Aux. Pump – OFF.

14. Fuel Pressure from Engine Driven Pump – CHECK 5 PSI Minimum

15. Generator – ON and CHECK charging normally.

16. P-3 Heater Switch – ON (if installed) (When the free air temperature is below 40°F.)

17. Warning Lights – CHECK and consider.

DRY MOTORING RUN:

The following procedure is used to clear an engine at any time when it is deemed

necessary to remove internally trapped fuel and vapor or if there is evidence of a fire

within the engine. Air passing through the engine serves to purge fuel, vapor, or fire

from the combustion sections, gas generator turbine, power turbine, and exhaust system.

1. Fuel Condition Lever – CUT OFF

2. Ignition Switch – OFF

3. Master Switch – ON

4. Fuel Valve – ON

5. Fuel Auxiliary Pump Switch – ON, to provide lubrication for the engine driven fuel

pumping elements.

6. Engine Starter Switch – ON

WARNING

If the fire should persist as indicated by

sustained interturbine temperature, close the

fuel system shutoff valve immediately and

continue motoring.

7. Maintain the starter operation for the desired duration. (Maximum starter duration is 3

minutes.)

8. Engine Starter Switch – OF

FAA APPROVED: Apr. 10, 2007 Revision 3, SECTION II-6

Thrush Aircraft Inc Model S2R-T34 SECTION II

Albany, GA NORMAL PROCEDURES

AIRPLANE FLIGHT MANUAL

9. Fuel Auxiliary Pump Switch – OFF

10. Fuel Valve – OFF

11. Battery Switch – OFF

12. Allow a 5-minute cooling period for the starter before going any further with the starting

operation.

TAXI

The Beta Region of the throttle quadrant may be utilized for taxing. Push the stick full

forward to unlock the tailwheel.

BEFORE TAKE-OFF:

Before proceeding with a ground run-up, be sure that the propeller system is purged, by

feathering the propeller once or twice with the Power Lever in the Idle Position.

The following procedures should be used to check the Propeller Overspeed Governor:

1. Place the propeller lever in full increase RPM (forward) position.

2. Increase RPM with the power lever to at least 2100 RPM.

3. Momentarily exercise the prop test switch and note a small decrease in the RPM

(2025 ± 20). This checks the prop overspeed governor.

CAUTION

HOLD the Elevator Control firmly FULL UP

during all high power ground operation to keep

the airplane from nosing over.

4. Flight Controls – CHECK free and full travel.

5. Elevator Tab – SET for take-off

6. Flaps – As required

7. Fuel Lever – HIGH IDLE / FLIGHT IDLE (check, 68% Ng).

8. Fuel Aux. Pump – ON

9. Ignition Switch – ON

10. Rear Seat Occupant – CONFIRM ready (Dual Cockpit Only)

11. Prior to flights apply take off power and read the filter condition indicator. If the

needle enters the red arc, do not fly until the filter element has been cleaned.

TAKE-OFF:

1. Brakes – RELEASE

2. Power Lever – ADVANCE. Do not exceed engine operational limitations. (See the

Limitations Section)

FAA APPROVED: Apr. 10, 2007 Revision 3, SECTION II-7

Table of contents

Other THRUSH Aircraft manuals