Chaparral Mooney M20E 1971 User manual

OWNERS

MANUAL

'

1

i

)

MODELS

SERIAL

NUMBERS

1971

-

M20E

31

0001

&

ON

i

-

I

MANUALS

1

204 AND

1

208

I

MAY BE SUBSTITUTED FOR

@

THIS MANUAL NO. 1202

t

i

t

1

KERRVILLE,

TEXAS

78028

MANUAL NUMBE'R

70-20E9M-8

SYSTEMS OPERATIONS

...........

SECTION

NORMAL

PROCEDURES

...........

SECTION.

ENIERGENCY PMCEDURES

........

SECTION

LDVWI"ATI0NS

.......,..........

SECTION

PERFORMANCE

...,............

SECTION

SERVICING.

...

'.

..,............

SECTION

i

,

I

This

manual

is

issued'as your operating guide for the

MooneyCHAPARRAI, It

is

importantthatyou--regardless of

your previous experience--carefully read

the

handbook

--

0

from

cover

to

cover and review it frequently.

i"

l[MPORTANT:

THIS

MAMJAL

CONTAINS

Federal

Aviation Administration

APPROVED

LIMITATIONS

AND

MUST

BE

CARRIED

IN

THE

AIRCRAFT AT

ALL

TIMES.

All information

and

illustrations in this manual

are

based

on

the

latest product information available at the time of

publication approval. Theright

is

reservedto makechanges

at

any

time without notice. Every effort

has

been made

to

present

the

material

in

a

clear

and

convenient

manner

to

enable you

to

use

the

manual

as

a

ready reference. Your

cooperation

in

reporting presentation and content recom-

mendations

is

solicited.

SECTION

I

.

GENERAL

DESCRIPTION

DESIGN FEATURE5

AIRFRAME

...........................

1.2

POWER

PLANT

........................

1.2

FLIGHT

CONTROLS

.....................

1.3

LANDING GEAR

.......................

1. 3

SPEClFlCATlOMS OUTLINE

........................

POWERPLANT 1-3

.........................

PROPELLER 1-4

LANDING

GEAR

.......................

1-4

..........................

FUEL&OIL 1-5

WEIGHT

&

WING

....................

1-5

BAGGAGE

COMPARTMENT

............+.a

1-5

rn

-

MOONEY-

OWNERS

MANUAL

DESIGN FEATURES

/

The

MOONEY

CHAPARRAL

is

a low- wing four-place air-

craftwith

a

retractable gear. Afourcylinder enginepowers

the aircraft for economical, high-performance flight. Li-

censing under Federal Aviation Administration regulations

assures that your Mooney meets the requirements of Nor-

mal

Category aircraft.

AIRFRAME

Theairframe

has

awelded, tubular- steelcabinstructure en-

closed

in

sheet-aluminum skins. Stressed skins rivet

to

main andauxiliary spars

in

the wing, stabilizer, and ver-

tical fin. Thelaminar- flow wing

has

fullwrap-around skins

with flush riveting over the forward top

two

thirds of the

wing

area.

For pitchtrim control, the empennagepivotsonthe aftfuse-

lage.

A

torque- tube-driven

jack

screw, bolted

to

the

rear

tail cone bulkhead, sets the stabilizer angle.

The forward-opening cabin door provides access to both

front and rear seats. The baggage compartment

door

is

abovethe wingtrailing edgeto enable baggageloading from

the ground.

POWER PLANT

The powerplant

is

a four-cylinder fuel-injectedengine that

develops

200

horsepower.

A

60-ampere 12-volt alternator

supplies ampleelectrical power for allstandard andoption-

al

equipment at all engine speeds from warmup to

flight

power settings.

t"

The hydraulic propeller governor, using oil pressure for

increasing blade pitch

to

control engine speed, regulates

the controllable-pitc

h

constant-speed propeller. Spring

and blade aerodynamic forces decrease blade pitch.

FLIGHT CONTROLS

Conventional dual controls link

to

the control surfaces

through push-pull tubes. The co-pilot's rudder pedalsare

removable.

The Mooney Positive Control

(P.

C.

)

system

is

standard

equipment. P

.

C

.

is

a

lateral

stability augmentation

system

that providesa high degreeof roll and yaw stability, thereby

enhancing the inherent wings-level flight characteristics

of the-aircraft. The system works full time fromtakeoff

throughlandingbut can

be

easilydeactivatedoroverpowered

for flight maneuvers.

P.C.

allows you, the pilot,

to

devote

more time

to

navigation, traffic surveillance, and com-

munications.

LANDING

GEAR

The tricycle landing gear allows maximum taxi vision

and

(

ground maneuvering. Hydraulic disc brakes and

a

steer-

able nose wheel

aid

in

positive directional control during

taxiing and crosswind landings,

The

landing

gear

is

electrically retracted.

A

gear

warning

hornalongwith amberand green position lights helpprevent

inadvertent gear-up

landings.

The retraction system in-

corporates an airspeed-actuated switch

that

prevents

gear

retraction until a

safe

airspeed

is

attained. An emergency

gear extension system

is

provided.

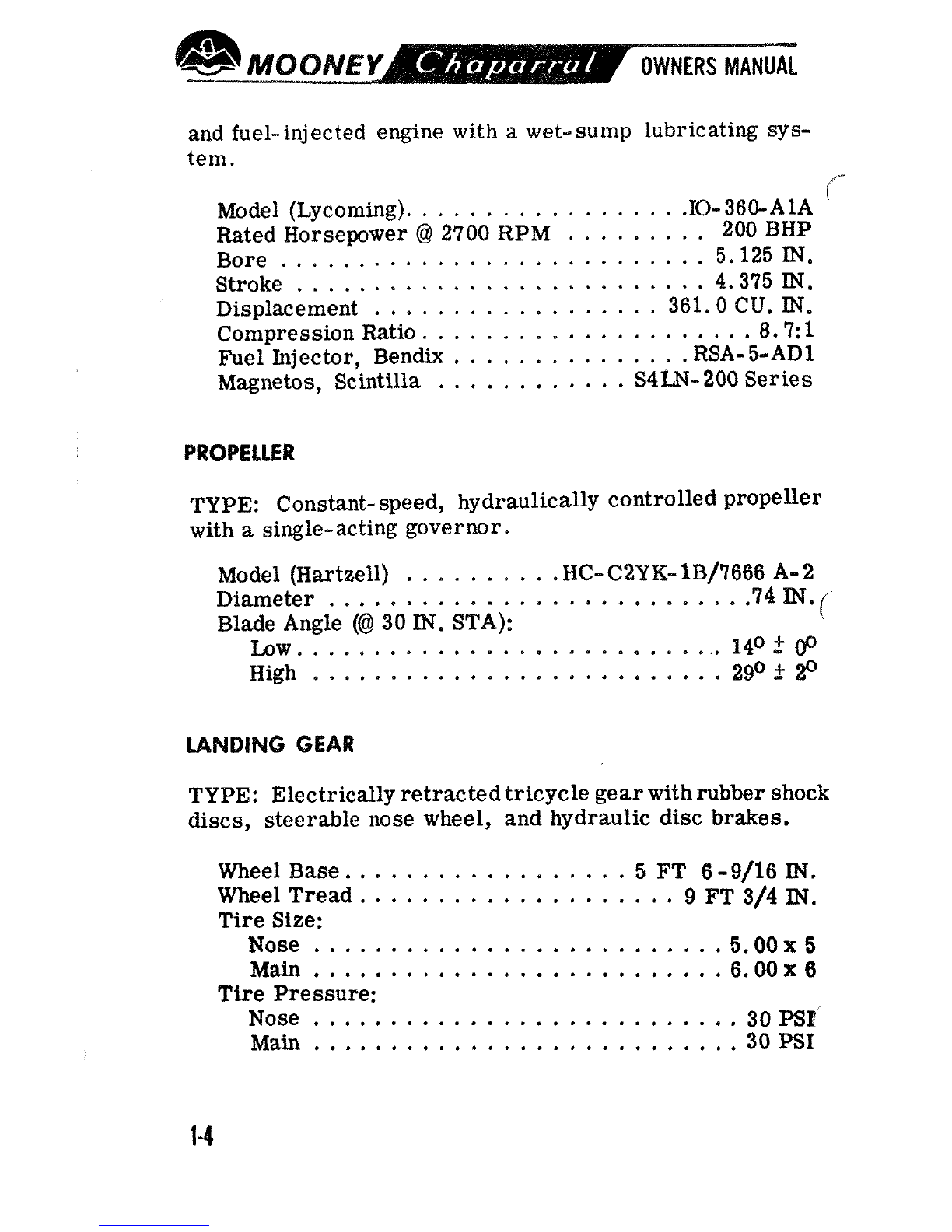

SPECIFICATIONS OUTLINE

C'

POWER

PLANT

TYPE:

Four-cylinder, air cooled,

horizontally

opposed,

and fuel- injected engine with a wet- sump lubricating sys-

tem.

Model (Lycoming).

.IO-

36GAlA

<-

................

Rated Horsepower

@

2700

RPM

.........

200

BHP

...........................

Bore 5.125

IN.

..........................

Stroke

4.375

IN.

..................

Displacement 361.0 CU,

IN.

.....................

Compression Ratio

8.7:

1

...............

Fuel Injector, Bendix RSA- 5-AD1

............

Magnetos, Scintilla

S4W-

200 Series

PROPELLER

TYPE: Constant- speed, hydraulically controlled propeller

with

a

single-acting governor.

..........

Model (Hartzell)

HC-

C2Y

K-

'lB/7666

A-

2

..........................

Diameter

.74

IN.

j

Blade Angle

(@I

30

IN.

STA):

...........................

Low.

14O

2

00

High

..........................

2g0

f

20

LANDING GEAR

TYPE: Electricallyretractedtricycle gearwithrubber shock

discs, steerable nose wheel, and hydraulic disc brakes.

Wheel Base.

.................

5

FT

6

-

9/16

IN.

Wheel Tread

....................

9 FT

3/4

IN.

Tire Size:

Nose

.........................

.5.00

x

5

Main

.........................

.6.00

x

6

Tire Pressure:

Nose

...........................

30

PSE

Main

...........................

30

PSI

FUEL

&

811

.-.-

Usable Fuel Capacity

.................

52

GAL

Minimum Fuel Octane Rating (aviation grade)

.

100/13

0

Oil Capacity

(6

QTS

MIN

for flight)

.........

8

QTS

WEIGHT

&

LOADING

Gross Weight

.....................

2575 LBS

Approximate Empty Weight (with standard

equipment)

......................

.I600

LBS

.

Useful Load

......................

975 LBS

Wing Loading

@

Gross Weight

..........

15.1

PSF

Power Loading

@

Gross Weight

.........

14.3

PHP

BAGGAGE

COMPARTMENT

Maximum Loading (unless limited

by

loading envelope):

Baggage Area

...................

.I20

LBS

Hat

Rack

.......................

10

LBS

@MOOMY-

000

OWNERS

MANUAL

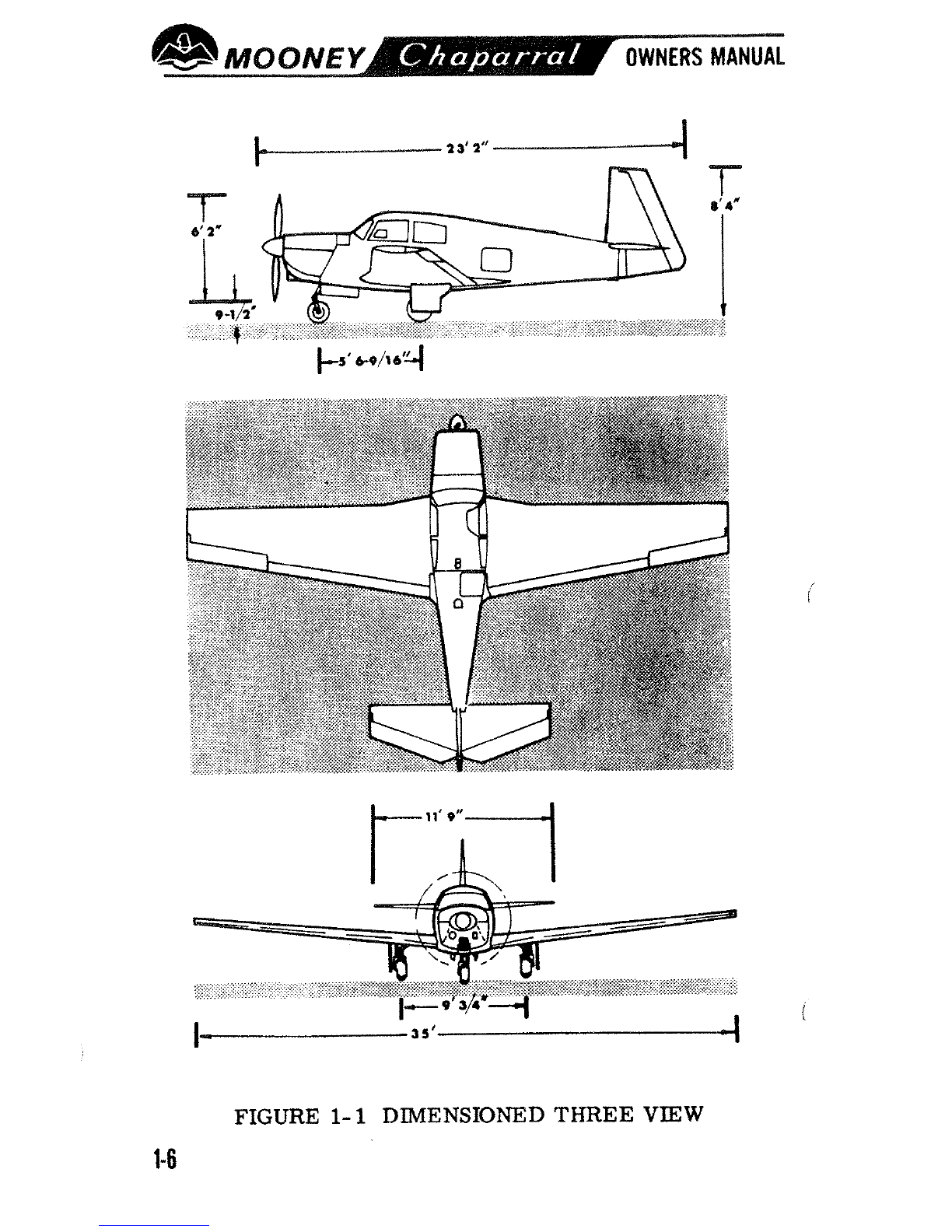

FIGURE

1-

1

DIMENSIONED

THREE

VIEW

1-6

SECTION

POWER PLANT

a

ENGINE CONTROLS

....................

2-4

IGNITION SYSTEM

.....................

2-5

.......................

FUEL SYSTEM

2-6

OIL SYSTEM

.........................

2-6

ENGINE COOLING

.....................

2-7

.....................

VACUUM SYSTEM

2-7

INSTRUMENTS

FLIGHT INSTRUMENTS

.................

2-7

FLIGHT

CONTROLS

............

PRIMARY FLIGHT CONTROLS

2-8

BOSITrVE CONTROL

...................

2-9

.....................

TRIM CONTROLS

2-10

.................

WING FLAP CONTROLS

2-10

UNDING

GEAR

ELECTRIC GEAR RETRACTION SYSTEM

.....

2-11

EMERGENCY GEAR EXTENSION SYSTEM

.....

2-12

BRAKE

&

STEERING SYSTEMS

............

2-12

ELECTRICAL POWER

ALTERNATOR

&

BATTERY

...............

2-12

CIRCUIT

BREAKERS

...................

2-13

ANNUNCIATOR LIGHTS

.................

2-15

INSTRUMENT

&

PLACARD LIGHTS

.........

2-16

CABIN LIGHTING

.....................

2-16

CABIN ENVIRONMENT

HEATDAG

&

VENTILATING SYSTEM3

........

2-16

WINDSHIE

W

DEFROSTING SYSTEM

........

2-17

CABIN

SEATS

&

SAFETY BELTS

................

2-18

BAGGAGE

&

CARGO AREAS

..............

2-18

dB

-

MOONEY-

#

00

OWNERS

MANUAL

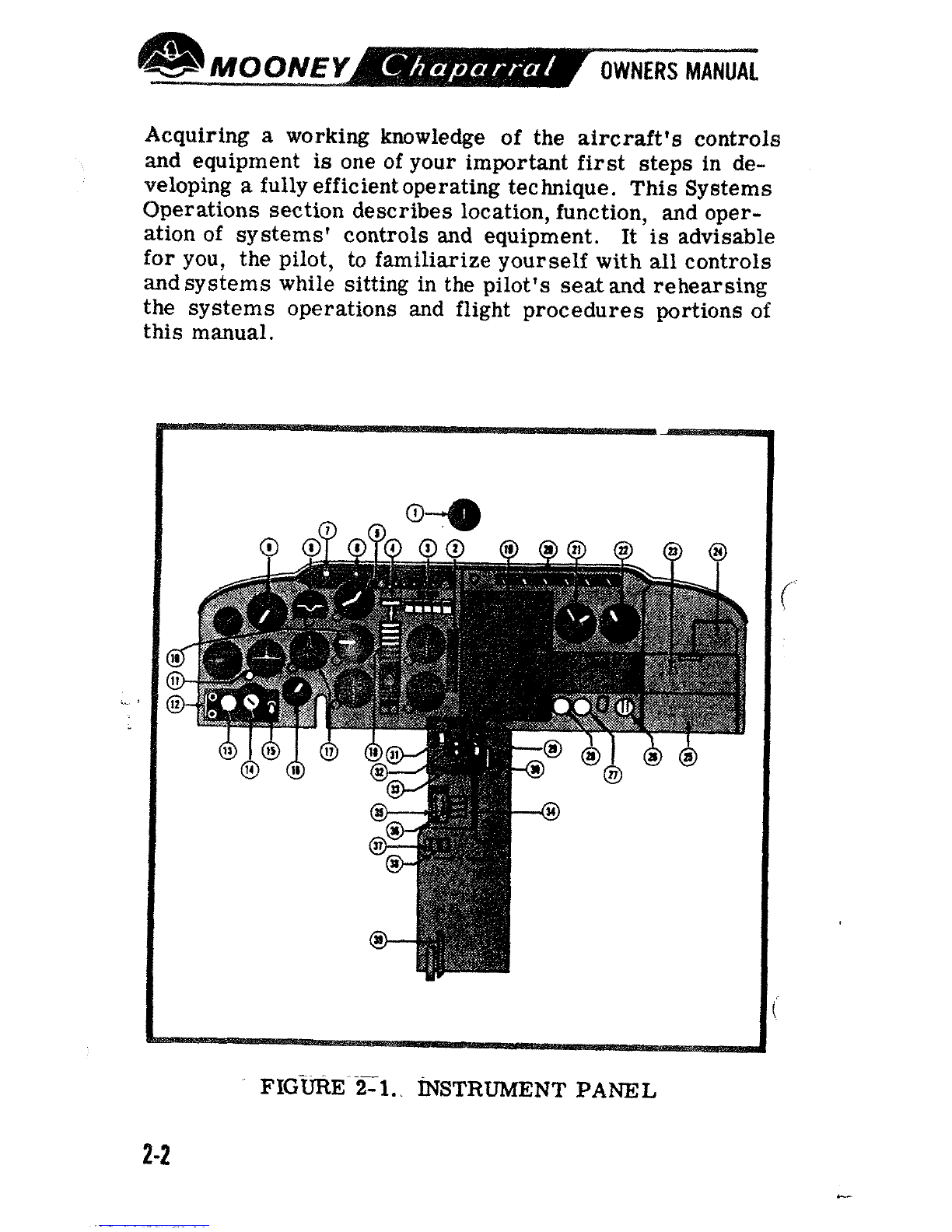

Acquiring a working knowledge of the aircraft's controls

and equipment is one of your important first steps

in

de-

veloping a fullyefficientoperating technique. This Systems

Operations section describes location, function, and oper-

ation of systems' controls

and

equipment. It

is

advisable

foryou, the pilot, to familiarize yourself with

all

controls

and

systems while sitting in the pilot's seat

and

rehearsing

the systems operations

and

flight procedures portions of

this manual.

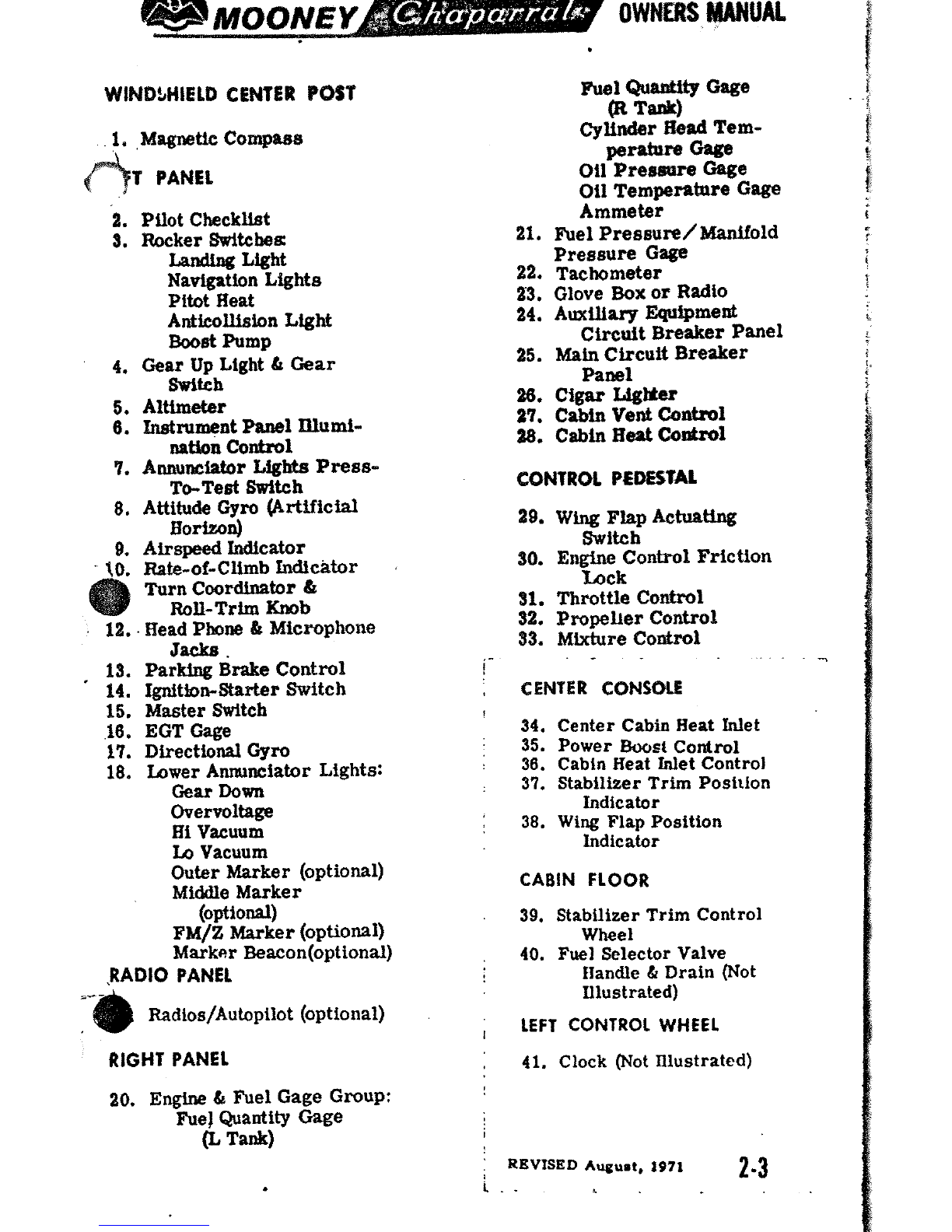

2.

PUot Checklbt

3.

Rocker

Switcbea

Landtng Light

Navigation Lights

Pitot Heat

Anticollision

Light

Wst

Pump

4.

Gear

Up

Light

t

Gear

Mteh

5.

Altimeter

6.

Inetntment

Panel

Illumi-

nation

Control

7.

Annunciator

Lights

Press-

To-Test

Switch

8.

Attitude

Gyro

(Artificial

Borfion]

9.

Airspeed

Indicator

10. W-of-Climb Indicator

Turn Coordinator

&

a

Roll-Trim

Knob

12.

Head Phone

&

Microphone

Jacks.

13.

Parking

Brake

Control

'

14.

Ignition-Starter Sroitch

15.

Master Switch

16.

EGT

Gage

17.

Directional

Gyro

18.

Lower

Annunciator

Lights:

Gear

Down

Overvoltage

Hi

Vacuum

I.&

Vacuum

Outer Marker (optional)

Middle Marker

(optional)

FM/Z

Marker (optional)

Marker

Beacon(optional)

.RADIO PANEL

-6

mdios/iiutopilot (optional)

RIGHT

PANEL

20.

Engine

6.

fie1Gage Group:

Fuel

Quantity Gage

(L

T&)

Aael

Quaatttp

Gage

(R

Task)

Cylinder

&sad

Tem-

pe-n,

Onee

Oil

Pmssrt~e

Gage

011Ternperatare

Gage

Ammeter

21.

Fuel Pressure/Bdantfold

Pressure

Gage

22.

Tachometer

23.

Glove

Box

or Radio

24.

Auxiliary

Eqrripmed

circuit Breaker Panel

25.

Main

Circuit Breaker

Palael

20.

Cigar

Lightsr

27.

Cabin

Vent

Control

28. Cabin

Reat

Coadrol

CONTROL

P€DES"IAL

2s.

Wing

Flap Actuating

Switch

30.

Engine

Control Friction

Lock

31.

Throttle Control

32.

Propeller Control

33.

Mixture

Control

CENTER

CONSOLE

34.

Center Cabin

Heat

Inlet

35.

Power

&lost

Control

36.

Cabin

Heat

Inlet Control

37. Stabilizer

Trim

Position

Indicator

38.

Wing

Flap Position

Indicator

CABIN

FLOOR

39. Stabilizer

Trim

Control

Wheel

40.

Fuel

Selector Valve

Handle

&

Drain (Not

Illustrated)

LEFT CONTROL WHEEL

41.

Clock (Not Illustrated)

REVISED

August,

1971

2.3

L.

POWER

PUNT

('1

C,

ENGINE

CONTROLS

The engine control levers are centrally located, between

the pilot and co-pilot, on the engine control pedestal. The

throttle lever, withitsround

knob,

regulates manifoldpres-

sure. Pushing the lever forward increases

the

setting;

pulling the lever aft decreases the setting.

The propeller control lever, with its crowned

knob,

con-

trols engine

RPM

through the propeller governor. Push-

ing

the lever forward increases engine

RPM;

pulling

the

lever

aft

decreases

RPM.

The mixture control lever, with its red hexagon

knob,

es-

tablishes the fuel-air ratio (mfxture). Pushing the lever

full

forward sets themixture

to

full-rich, pulling the lever

aft leans

the

mixture,

and

pulling the lever

to

its

maximum

aft

travel position closes the idle cutoff valve, shutting

down

the engine. Precise mixture settings

are

established

by

observing the

EGT

gage

on the pilot's instrument panel

while aqjusting the mixture

control lever.

A

large friction-lock knob

on the right side of the en-

gine

control pedestal holds

the controls in the desired

setting

and

preventscontrol

creeping during flight.

The

powerboost

air

control

lever, mounted in

the

cen-

ter consoleto the left of the

..

,

engine control pedestal

allows the selection of

fil-

FIGURE

2-2.

ENGINE

tered induction

air

or un-

mUCTION

SYSTEM

filtered directram

air.

An

annunciator light on

the

instrument panel illuminates when

the power boostair control lever

is

set for ram air and

the

0

landing

gear

is

down. When operating

at

full throttle, us-

ing ramair will increase the manifold pressure

by

allowing

engine induction

air

to

bypass the induction air

filter.

The

use of ram air must

be

limited to clean, dust-free

air

at

altitude. The engine

will

operate on direct unfiltered air

when the power boost

air

control lever

is

down. The an-

nunciator light reminds the pilot to push the engine induc-

tion

air

control leverupward forfiltered

air

before landing.

Should

the

induction

air

filter

clog,

a

spring-loaded door

in the induction system

will

open

by

induction vacuum to

allow alternate

air

to

enter

the

engine.

A11

engine

instruments

except

the

EGT

gage

are

grouped

in

the rightinstrumentpanel. Colorarcson instrument faces

markoperating ranges. Properinterpretation of engine in-

strument readings

is

essential for selecting optimum con-

trolsettings

and

for maintaining maximum cruise fuel

eco-

nomy. Engine limitations

are

given

in

Section

V.

IGNITION SYSTEM

The

left

magneto has a setof fixed

retard

breaker points

thataid

in

smoother, easier starting.

A

battery-powered

starting vibrator supplies a long-duration, boosted spark.

The starter-ignition switch, mounted on the left of the in-

strument panel, combines both ignition and starting func-

tions. Turning the ignition key clockwise through

R,

L,

and BOTH to the START

MAG

position and then pushing

forwardonthe key and receptacleengages the

starter.

Re-

leasing the key when the engine starts allows the switch

to

return by spring action

to

the

BOTH

position. For safety,

the starter-ignition switch must

be

left at OFF when the

engine

is

not running.

FUEL

SYSTEM

Two integral sealed sections

carry

the fuel in the forward

C'

inboardarea of the wings. Full fuelcapacity

is

52

gallons.

There are sump drains at the lowest point in each

tank

for

takingfuelsamples

to

check forsedimentcontamination and

condensed water accumulation. Section

VII

discusses the

fuel sampling procedure.

An illuminated three-position

fuel

selector handle on the

cabinfloor setsthe selector valve below the floorboard for

LEFT

tank,

RIGHT

tank,

or the

OFF

position. The fuel

selector valve assembly contains

a

valve for draining con-

densedwater andsediment fromthe lowest

point

in

the fuel

linesbeforethe first flightof the

day

and

after

each refuel-

ing. Section

VII

discussesthe selector valve flushing pro-

cedure.

Fuel feedsfrom onetank ata time

to

the selector valve and

through the electricfuelpump enroute

to

the engine-driven

pump

and

the fuel injector unit. Electric fuel-level trans-

@

mitters inthetanks operatefuel gages inthe enginecluster.

The master switchactsatesthe fuelquantity indicator sys-

tem

to

maintain anindication of fuelremaining

in

each

tank.

The fuel pressure

gage

registers fuel pressure

in

the line

to

the injector. Vents in each fuel

tank

allow for overflow

and ventilation.

OIL

SYSTEM

The engine

has

a full-pressure wet-sump oil system with

an

8

quart capacity. The automatic bypass control valve

routes oil flow around the oil cooler when operating

tem-

peratures

are

below norm& or when the cooling radiator

is

blocked.

The enkine oil should be kept at

6

to

8

quarts. Lycorning

a

ServiceInstruction

1014

(latest revision)givesrecommended

oil specifications and oil change intervals.

0

The

down-draft

engine cooling system provides ground and

inflight power plantcooling.

Engine

bafflingdirects

air

over

and around the cylinders and out the cowl flap openings.

Cowl flap

doors

allow

proper

air

flow on the ground

and

during

low-speed high-power climb. Pulling the cowl

flap

control below the instrument panel,

to

the

left

of the engine

control pedestal, opens

the

cowl flaps.

VACUUM

SYSTGM

Anengine- drivenvacuum pump

supplies

suction

br

t&

vac-

uum-operated gyroscopic

flight

instrumente

and

the

Mboney

Positive

Control

sy@em.

Air

entering

the

vamum-powered

instruments

is

filtered; hence,

sluggish

or

erratic

opera-

tion

of

vacuum- driven

Instruments

may

indieate

that

a

clog-

ged vacuum filter element

is

preventing

ackquate

airin-

a

take.

The

HI

or

LO

vacuum annunciator

light

will

ilhuni-

nate

if

vacuum

is

above or

below

limits.

FLIGHT

INSTRUMENTS

The basic flight instruments

are

grouped on the shock-

mounted

flight

panel directly in front of the pilot's

seat.

Instrument arrangement

is

in the standard T-grouping

with

the attitude

gyro

at

top

center

and

the directional

gyro

im-

mediately below. The airspeed indicator and the altimeter

cross

the

"T".

The

vertical speed indicator

and

the

turn

coordinator atleft

of

the directionalgyrocomplete thestand-

ard flight instrumentation.

A

standard eight-day clock

is

mounted

in

the pilot's control

wheel. Themagnetic compass

is

mountedonthe windshield

post above the instrument panel. The outside air temper-

ature gage

is

installed in the windshield.

~MOONEV-

0#0

OWNERS

MANUAL

There

is

spaceand ltghtingfor fouropttonal radio tndtcrttore

on the flight panel.

A

back-lighted flight checklist

is

on the

C)

extreme right of the flight panel.

Space

for

an

optional re-

mote indicating compass

is

at the top left of the panel. The

optional marker beacon indicator lights mount between the

radio indicators at right center

below

the annunciator ltght

group.

A pitot

tube,

mounted on the lower surface of the left

wing,

picks up airspeed indicator ram air.

A

heated pitot pre-

vents pitot

tube

icing when flying

in

moisture-laden

air.

A drain valve

is

located on the forward bottom skin of

the left

wing

just outboard of the

wing

fillet. Static portson

each side of the

tail

cone supply static air pressure for

the

altimeter, the

air

speed indicator,

and

the vertical speed

indicator.

A

drain valve

is

located on

the

fuselage bottom

skin below the tail cone access door. An optional alternate

staticpressure source valve may be installed behind the

vertical speed indicator.

0

A

stall warning horn, mounted in the cabin head

liner

and

triggered

by

a

sensing vane on the left wing leading edge,

will sound when airspeed drops to near

stall

speed.

The

sound becomes steady astheaircraftapproaches

a

complete

stall.

A

landing gear position light in theannunciator panel shows

amberwhen the gear

is

retracted.

A

green annunciatorlight

illuminates when the gear

is

down-and-locked. Retarding

the throttle settingbelow

12

inches manifold pressure when

the gear

is

not in the down-and-locked position causes the

gear warning horn in the cabin headliner

to

sound with

a

regular, intermittent tone.

FLIGHT

CONTROLS

PRIMARY FLIGHT CONTROLS

7

,

Push-pull tubes withself-aligning rodend bearings actuate

the primaryflight controlsurfaces. Beveled aileron

trail-

ing edgeshelp reduce pilot controlforces requiredforflight

maneuvering. A spring-

loaded interconnect device

Cb

indirectly joins the aileron

and rudder control systems

to assist

in

lateral stability

during flight maneuvers.

Control surface gap

seals

minimize airflow through

the hinge slots and reduce

drag.

POSITIVE

CONTROL

CUTOFF

VALVE

WON

,

ROU-TRIM

KNOB

FIGURE

2-3.

P.C.

1

SYSTEM CONTROLS

1

i

The Mooney Positive Control (P.C.) systeib provides

a

high degreeof roll and yaw stability, thereby enhancing the

inherent wings-level flight characteristics of

the

aircraft.

Positive Control willblda reasonable heading over

a

long

periodof timewhen the aircraft

is

trimmed properly. How-

ever, without the installation of a magnetic heading lock,

P

.

C

.

will not maintain an absolute preselected heading.

The system

is

a

pneumatically operated, two-axis auto-

matic control superimposed on the primary flight control

systems, An electro-vacuum poweredturncoordinator sup-

plieapneurnatic inputs to servo unitsthat link

to

the aileron

and rudder control systems. Since the engine-driven vac-

uum pump

is

the power source,

P.

C.

is

operative when-

ever the propeller

is

windmilling at more than

1000

RPM.

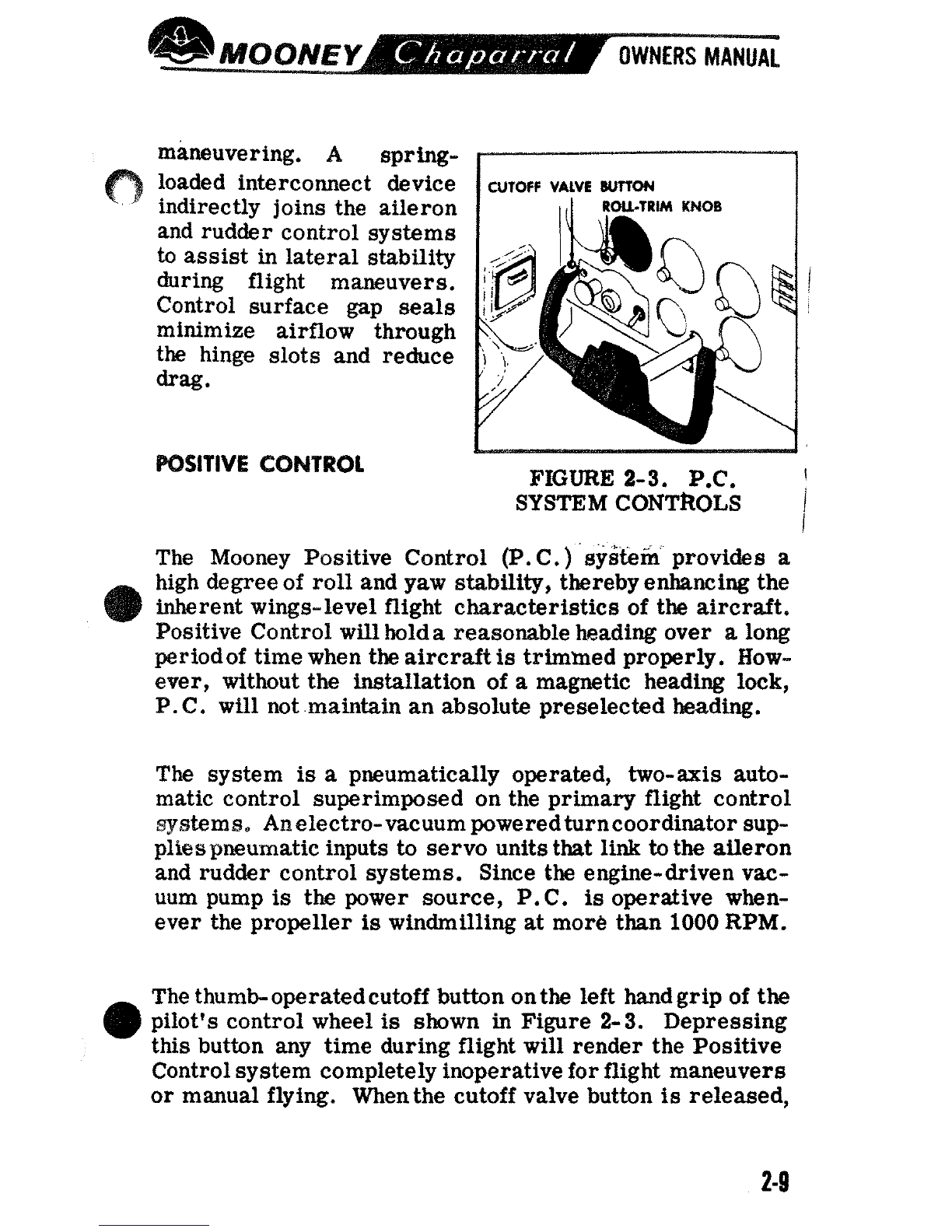

Thethumb-operatedcutoff button on

the

left handgrip of

the

pilot's control wheel

is

shown

in

Figure

2-3.

Depressing

this button any time during flight will render the Positive

Control system completely inoperativeforflight maneuvers

or manual flying. Whenthe cutoff valve button

is

released,

the aircraft will return unassisted

to

was-level flight.

P.C. can be manually overriden with little effortif the sys-

tem should malfunction. Manually over-powering the sys-

<'

tem will not damage the aircraft or the P.C. components.

The roll-trim knob on the turn coordinator, as shown in

Figure

2-

3,

provides an aileron trim function throughthe

P.C. system. Rotating the knob trims the aircraft about

its

roll axis to compensatefor asymmetrical fueland

pas-

senger loadings.

The P.

C.

system

is

installed

to

help alleviate pilot fatigue.

But like any other system in the aircraft, P.C. must

be

monitored for proper functioning.

TRIM CONfROLS

For pitch trim control, the entire empennage pivots on the

tail

cone attachmentpoints to increaseordecrease the hori-

c:

zontal stabilizer angle. This design allows flight trim

es-

tablishment with minimum control surface deflection. A

pointer in

a

slot located on the center console indicates

stabilizertrim position. Forward rotationof the trimwheel

lowersthe nose; rearward rotationraises the nose in flight.

WING

FLAP

CONTROLS

The flap switch on the right of the engine control pedestal

operates the electrically-actuated wide- span wing flaps.

Holdingthespring-loaded switch in the down positionlowers

the flaps to the desired angleof deflection. A pointer in the

center console indicates flap position. The intermediate

mark in the pointer range

is

the flap TAKEOFF setting.

(

Holding the switch in the

UP

position, retracts

the

flaps.

-

Simply releasing the spring-loaded switch to return to the

OFF

positionstops the flaps at

an

intermediatepositiondur-

ing either extension or retraction.

LANDING

CEAR

ELECTRIC

GEAR

RETRACTION

SYSTEM

The two-position electric

par

control switch, identified by

its wheel-shaped

knob,

is

located

to

the right of the altim-

eter between the annunciator light panels.

There are three ways to see that the electrically-actuated

gear

is

down-

and- locked:

(1)

The

green gear-down annunciator light illvminates

.

(2) The indicator marks

align

as

seen

on

that.

floorboard

visual gear-position indicator.

(3)

The gear warning

horn

does

mt

sound

at

approach

power setting

of

below

12

inches manifold pressure.

f

Position annunciatorlights and a warning horn provide

vis-

ual and audible gear position signals. An amber

signal

light

(marked

GEAR

UP)

will

show continuously when the

gear

is

fully retracted. A green signal light (marked

CEAR

DN)

shows continuously when

the

gear

is

fully extended. Both

lights are out

as

the

gear changes position.

Theilluminatedgear- down position indicator

in

the

floor-

board aftof the centerconsole

has

two

marksthat alignwhen

the gear

is

down.

Retarding

the

throttle below 12 inches

manifold pressure causes the gear warning horn to emit

a

regular, intermittent tone unless the gear

is

down-and-

locked.

An

airspeed-actuated safety switch in the pitot system or

a

mechanically actuated "Sq~quat-Switch"in

the

retraction

C

system prevents landing gear retraction until attaining

a

safe takeoff airspeed. The safety switch

is

not designed

to

substitute for the gear switch in keeping

the

gear

extend-

'

ed while taxiing,

taking

off, or landing.

i

-