Seagull Models CESSNA TURBOSKYLANE182 User manual

1

ASSEMBLY MANUAL

Code : SEA 376 PNP electric

Type---------------------- PNP electric

Wingspan--------------- 69 in------------------ (174.5 cm)

Overall Length--------- 49.1 in---------------- (124.8 cm)

Wing Arena------------- 612.3 sq.in----------- (39.5 dm²)

Flying Weight---------- 3.3 kg------------------ (7.3 lbs)

Radio-------------------- 5 channels with 6 servos

Motor-------------------- size 70E

ESC 65A/ Lipo 5s-6S 4000mAh-5000mAh

CESSNA TURBO SKYLANE 182 ELECTRIC 69” WINGSPAN PNP Instruction Manual.

2

ank you for choosing the CESSNA TURBO SKYLANE 182 ELECTRIC 69” WING-

SPAN PNP ARTF by SG MODELS. e CESSNA TURBO SKYLANE 182 ELECTRIC 69”

WINGSPAN PNP was designed with the intermediate/advanced sport yer in mind. It is a

semi scale airplane which is easy to y and quick to assemble. e airframe is convention-

ally built using balsa, plywood to make it stronger than the average ARTF, yet the design

allows the aeroplane to be kept light. You will nd that most of the work has been done

for you already. e motor mount has been tted and the hinges are pre-installed. Flying

the CESSNA TURBO SKYLANE 182 ELECTRIC 69” WINGSPAN PNP is simply a joy.

is instruction manual is designed to help you build a great ying aeroplane. Please read

this manual throughly before starting assembly of your CESSNA TURBO SKYLANE 182

ELECTRIC 69” WINGSPAN PNP Use the parts listing below to indentify all parts.

Please be aware that this aeroplane is not a toy and if assembled or used incorrectly it is ca-

pable of causing injury to people or property. WHEN YOU FLY THIS AEROPLANE YOU

ASSUME ALL RISK & REPONSIBILITY.

If you are inexperienced with basic R/C ight we strongly recommend you contact your R/C

supplier and join your local R/C model Flying Club. R/C Model Flying Clubs oer a variety

of training procedures designed to help the new pilot on his way to successful R/C ight.

ey will also be able to advise on any insurance and safety regulations that may apply.

INTRODUCTION

WARNING

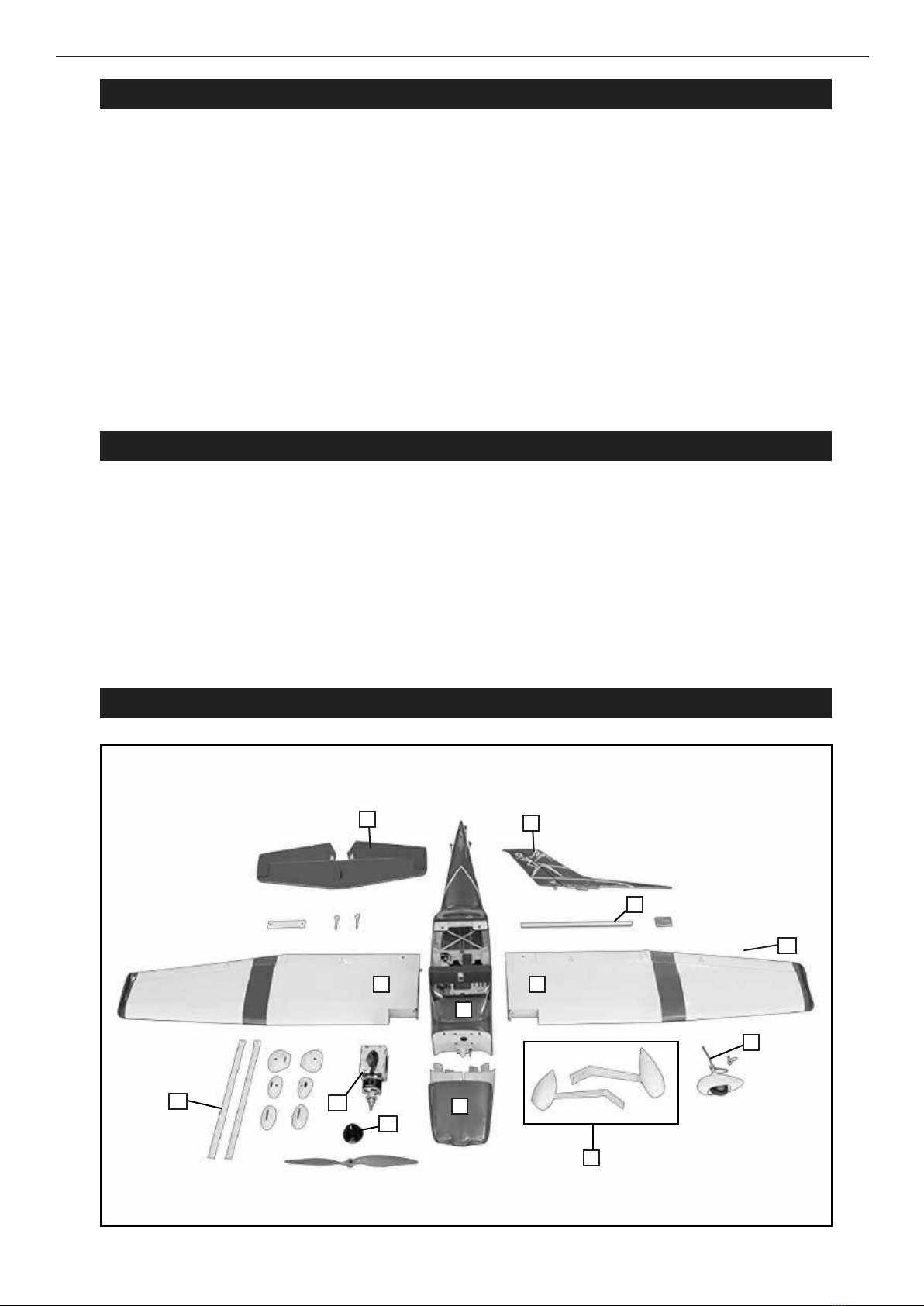

KIT CONTENTS

1

2 2

4

10

33

5

7

9

8

6

10

3

ADDITIONAL ITEMS REQUIRED

TOOLS & SUPPLIES NEEDED

in cyanoacrylate glue.

Medium cyanoacrylate glue.

30 minute epoxy.

5 minute epoxy.

Hand or electric drill.

Assorted drill bits.

Modelling knife.

Straight edge ruler.

2mm ball driver.

Phillips head screwdriver.

220 grit sandpaper.

90° square or builder’s triangle.

Wire cutters.

Masking tape & T-pins.

read-lock.

Paper towels.

KIT CONTENTS RECEIVER INSTALLATION

SEA376 PNP electric

CESSNA TURBO SKYLANE 182

ELECTRIC 69” WINGSPAN PNP

1. Fuselage

2. Wing set (2)

3. Tail set (2)

4. Cowling

5. Wing tube

6. Landing gear

7. Nose Landing gear

8. Ep Motor box

9. Spinner

10. Wing Strut

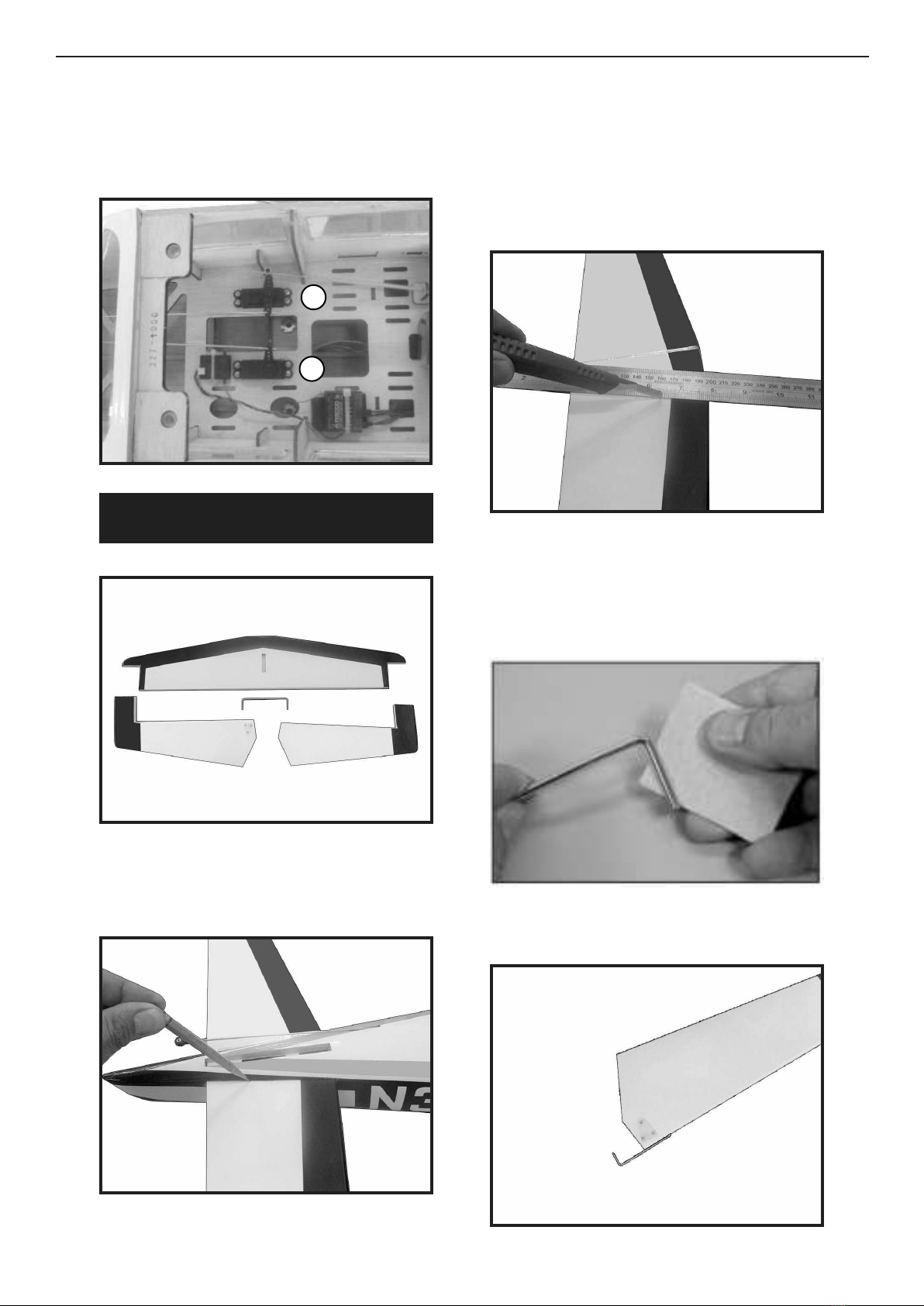

Make the connections from the rudder and

elevator servos to the receiver. Also connect

the extensions for the aps and ailerons.

All servo extensions have been provided

when using an eight channel radio. No Y-har-

nesses will be required. Mixing at the trans-

mitter will be required.

When using a six channel radio, a Y-harness

has been included for the aps. Mixing at the

transmitter will be required to operate the ai-

lerons.

Using a ve channel radio will require the

use of the included Y-harness for the aps,

and an additional Y-harness (SPMA3058) for

the ailerons.

Secure the receiver in the fuselage. Use the

instructions included with the receiver for

additional mounting details. Make sure none

of the wires from the receiver interfere with

the operation of the servos.

1.

2.

�Full-range,six-plus-channel

transmitter and receiver; 6S 4000mAh

to 5000mAh LiPo battery with TX60 or

TX60 connector; LiPo battery charger

Flying weight: 8 to 10 pounds.

�Computer radio 5 channel with 6

servos.

�Glow plug to suit engine.

�Propeller to suit engine.

�Protective foam rubber for radio

system.

CESSNA TURBO SKYLANE 182 ELECTRIC 69” WINGSPAN PNP Instruction Manual.

4

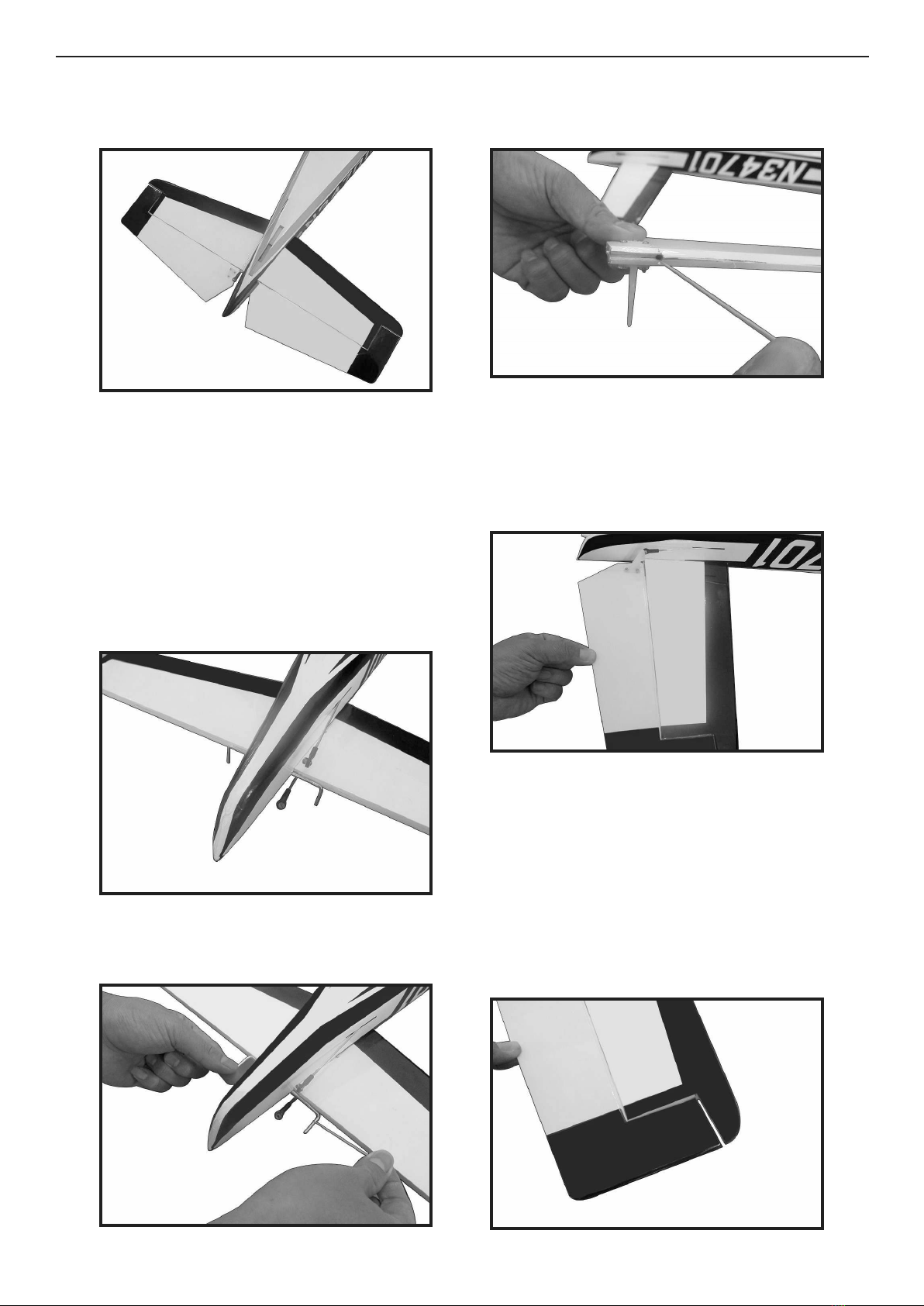

Check that the servo arms for the eleva-

tor (1) and rudder (2) are at 90-degrees to the

pushrods. Adjust the sub-trim of the radio or

reposition the servo arms as necessary.

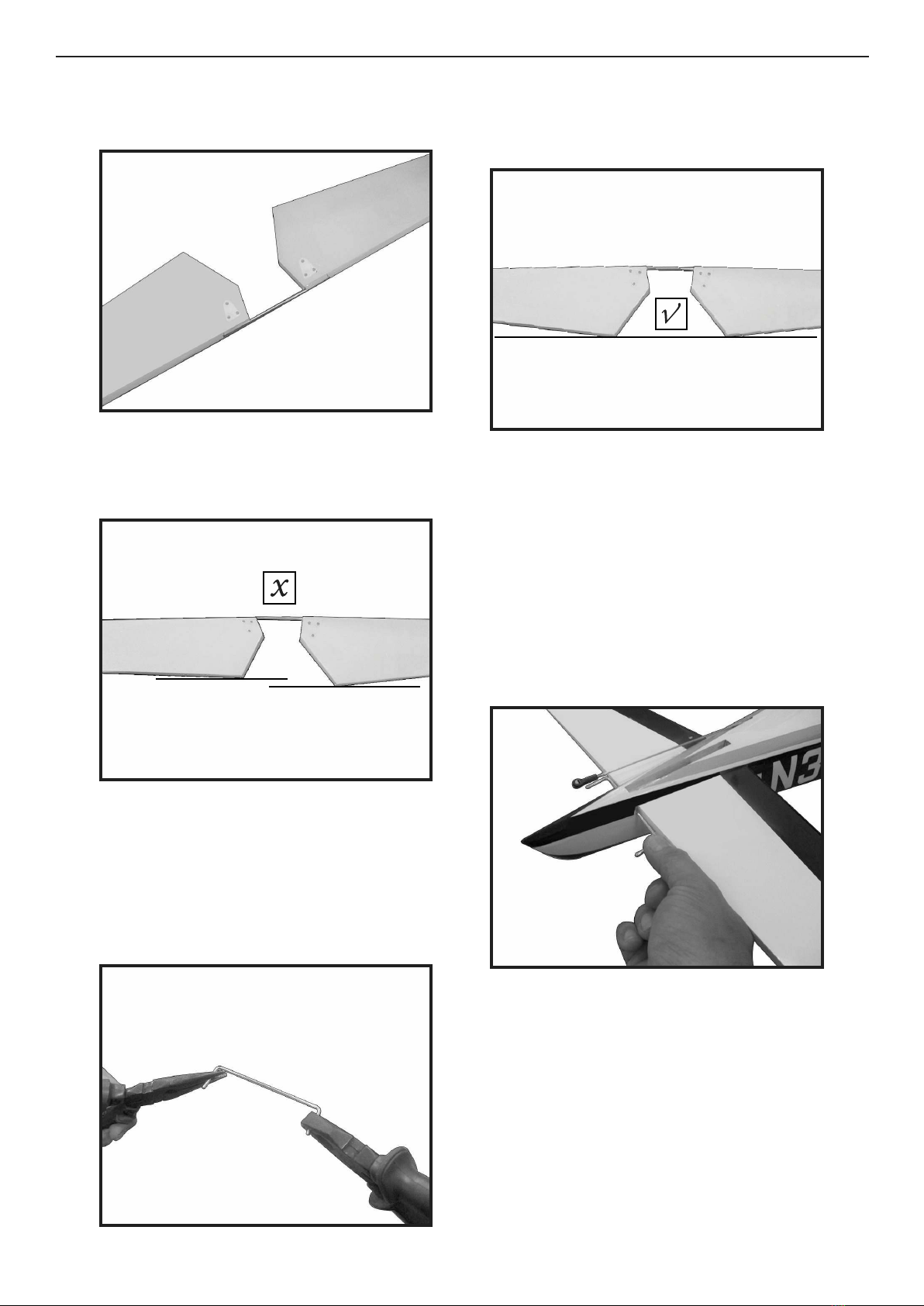

Use a ruler and carefully cut the covering

1/8 inch (3mm) inside the line drawn on the

stabilizer to remove the covering from the

center of the stabilizer. Remove the top and

bottom covering. Use care not to cut into the

underlying wood, weakening the stabilizer.

Lightly sand the elevator joiner wire where

it contacts the elevators. Use a paper towel

and isopropyl alcohol to remove any oil or

debris from the joiner.

Fit the joiner wire into the elevator halves.

Check all alignments. Mark the outline of

the fuselage on the top and bottom of the sta-

bilizer.

3.

2

1

INSTALLING THE HORIZONTAL

STABILIZER

1.

4.

2.

5.

3.

5

e elevator joiner wire must be ush with

the leading edge of the elevator as shown.

Continue the assembly of your model once

joiner wire has been correctly checked and

adjusted.

Remove the elevators from the joiner wire.

Fit the joiner wire into the fuselage, noting

the position from the previous step. is will

guarantee the joiner is placed correctly so the

elevators will be oriented as prepared inthe

previous step.

e slot for the elevator horn will be located

on the bottom right of the fuselage when the

elevators are installed.

Slide the stabilizer partially into the fuse-

lage so the wood at the center is exposed. Mix

1/2 ounce (15ml) of 30-minute epoxy. Use an

epoxy brush to apply the epoxy to the ex-

posed wood on the top of the stabilizer.

Check to make sure the elevator halves are

in alignment with each other.

If the elevators are not in alignment, use pli-

ers to bend the joiner wire slightly to bring

the halves into alignment.

Poorly aligned elevators will cause problems

with trimming your model in ight

6.

7.

10.

8.

9.

CESSNA TURBO SKYLANE 182 ELECTRIC 69” WINGSPAN PNP Instruction Manual.

6

11.

12.

14.

15.

16.

13.

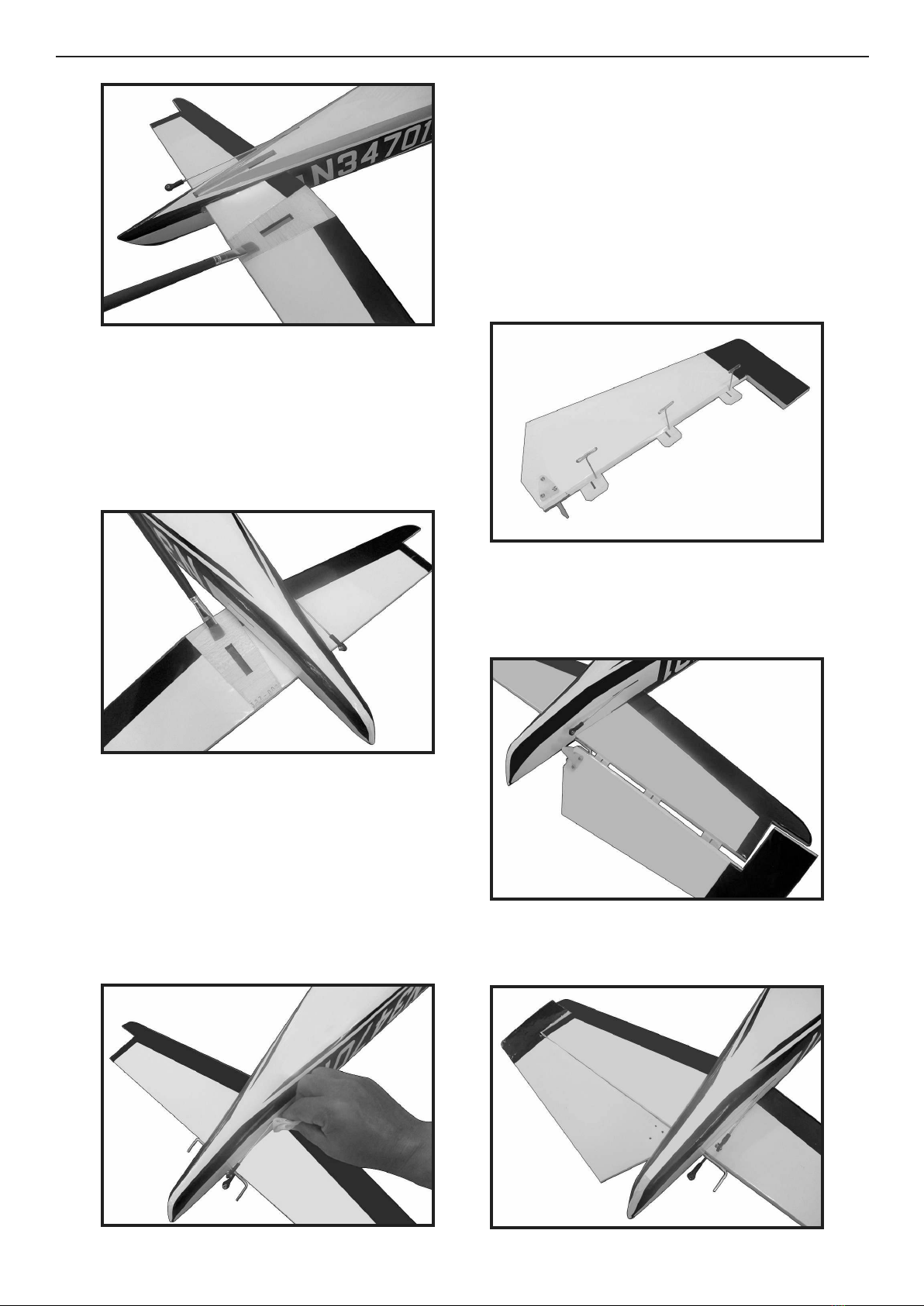

Carefully turn the model over and apply

epoxy to the exposed wood on the bottom

of the stabilizer. Slide the stabilizer back into

position.

Use a pin vise and 1/16-inch (1.5mm) drill

bit to drill a hole in the center of each hinge

slot to allow the CA to wick into the hinge.

Drill holes in both the elevators and stabiliz-

er surfaces at this time. Place a T-pin in the

center of each hinge along side the slot in the

hinge. is will help center the hinge when

it is placed in the elevators. Slide the hinges

into position with the T-pin resting against

the edge of the control surface.

Fit the elevator into position on the stabi-

lizer. Guide the joiner wire and hinges into

position.

Fit the elevator so the leading edge ts tight-

ly against the trailing edge of the stabilizer.

Once the alignment of the stabilizer has

been veried, use a paper towel and isopro-

pyl alcohol to remove any excess epoxy from

the fuselage and stabilizer. Allow the epoxy to

fully cure before proceeding.

If you nd epoxy on the joiner wire, use the

paper towel and isopropyl alcohol to clean

the joiner.

Use care not to get epoxy on the elevator

joiner wire.

7

17.20.

21.

22.

18.

19.

Check the t of both elevators at this time.

Once checked, remove the elevators.

Use a toothpick to apply epoxy to the stabi-

lizer where it contacts the joiner wire.

Fit the elevators back into position. Remove

the T-pins and slide the elevators tightly

against the stabilizer. Use a paper towel and

isopropyl alcohol to remove any excess epoxy

before it begins to cure.

Check the alignment of the elevators in re-

lationship to the stabilizer at the tips. ere

should be enough gap between the balance

tab and stabilizer to they can move freely.

Do not use CA accelerator when gluing

hinges. e CA must be allowed to soak into

each hinge to provide the greatest bond be-

tween the hinges and surrounding wood.

Use a small strip of the clear packaging ma-

terial and slide it between the joiner wire and

stabilizer. Make sure the packing material

is cut so it does not obstruct the hinge slot.

Use a small piece of low-tack tape to hold the

packing material in position.

e clear packing material is used to prevent

accidentally gluing the elevators or joiner

wire to the stabilizer.

Mix a small amount of 15-minute epoxy. Use

a toothpick to apply epoxy to the joiner wire.

CESSNA TURBO SKYLANE 182 ELECTRIC 69” WINGSPAN PNP Instruction Manual.

8

HINGING THE RUDDER

Glue the top two rudder hinges in place

using the same techniques used to hinge

the ailerons.

e lower hinge will be glued when the

/rudder assembly is attached to the fu-

selage.

1.

2.

Pen

23.

26.

24.

25.

Flex the elevator slightly, making sure to

keep the gap between the elevator and stabi-

lizer as narrow as possible. Saturate each of

the hinges using thin CA. Apply CA to the

bottom of the hinges. Allow the CA to cure

before proceeding.

Gently pull on the xed and moving surface

to make sure the hinges are glued securely. If

not, reapply thin CA to any hinges that are

found loose.

Flex the elevator slightly, making sure to

keep the gap between the elevator and stabi-

lizer as narrow as possible. Saturate each of

the hinges using thin CA. Apply CA to the

top of the hinges.

Flex the control surface through its range

of motion a few times to break-in the hinges.

is will reduce the initial load on the servo

when the surface is rst actuated.

9

5.

6.

3.

4.

C/A glue

7.

8.

9.

10.

Epoxy.

CESSNA TURBO SKYLANE 182 ELECTRIC 69” WINGSPAN PNP Instruction Manual.

10

ELEVATOR AND RUDDER

LINKAGE CONNECTIONS

Remove the 2mm nut from the elevator

ball link. read then screw Use a 1.5mm

hex wrench to thread the screw through

the center hold of the elevator control

horn.

With the radio on and the elevator stick

and trim centered, use a ruler to check

that the elevator is aligned with the sta-

bilizer.

1.

11.If the elevator and stabilizer are not

aligned, thread the ball on the elevator

in or out to correct the alignment. Make

sure to thread the ball end at the control

horn and servo arm equally as not to

damage the ball ends.

Repeat the steps for the elevator to at-

tach the rudder pushrod and ball end to

the rudder control horn.

Once the elevator and stabilizer are

aligned, use a 1.5mm hexn wrench to

tighten the screw while holding the 2mm

locknut with hemostats or needle nose

pliers.

3.

4.

2.

11

LANDING GEAR INSTALLATION

5.

1.

2.

3.

4.

5.

6.

Slide an M4 washer on the M4 x 20

socket head cap screw. Place a drop of

threadlock on the screw. Prepare all three

screws.

It is not essential to use threadlock if the

model will be disassembled for transport.

CESSNA TURBO SKYLANE 182 ELECTRIC 69” WINGSPAN PNP Instruction Manual.

12

Use the screws to attach the landing gear

to the bottom of the fuselage. Use a 3mm

hex wrench to tighten the screws. Do not

over-tighten the screws and damage the

fuselage.

7.

ead locker glue

8.

4x15mm

9.

10.

11.

C/A glue

1.

Locate the items necessary to attach the

nose landing gear that are included with

your model.

INSTALL NOSE GEAR

13

3.

2.

1.

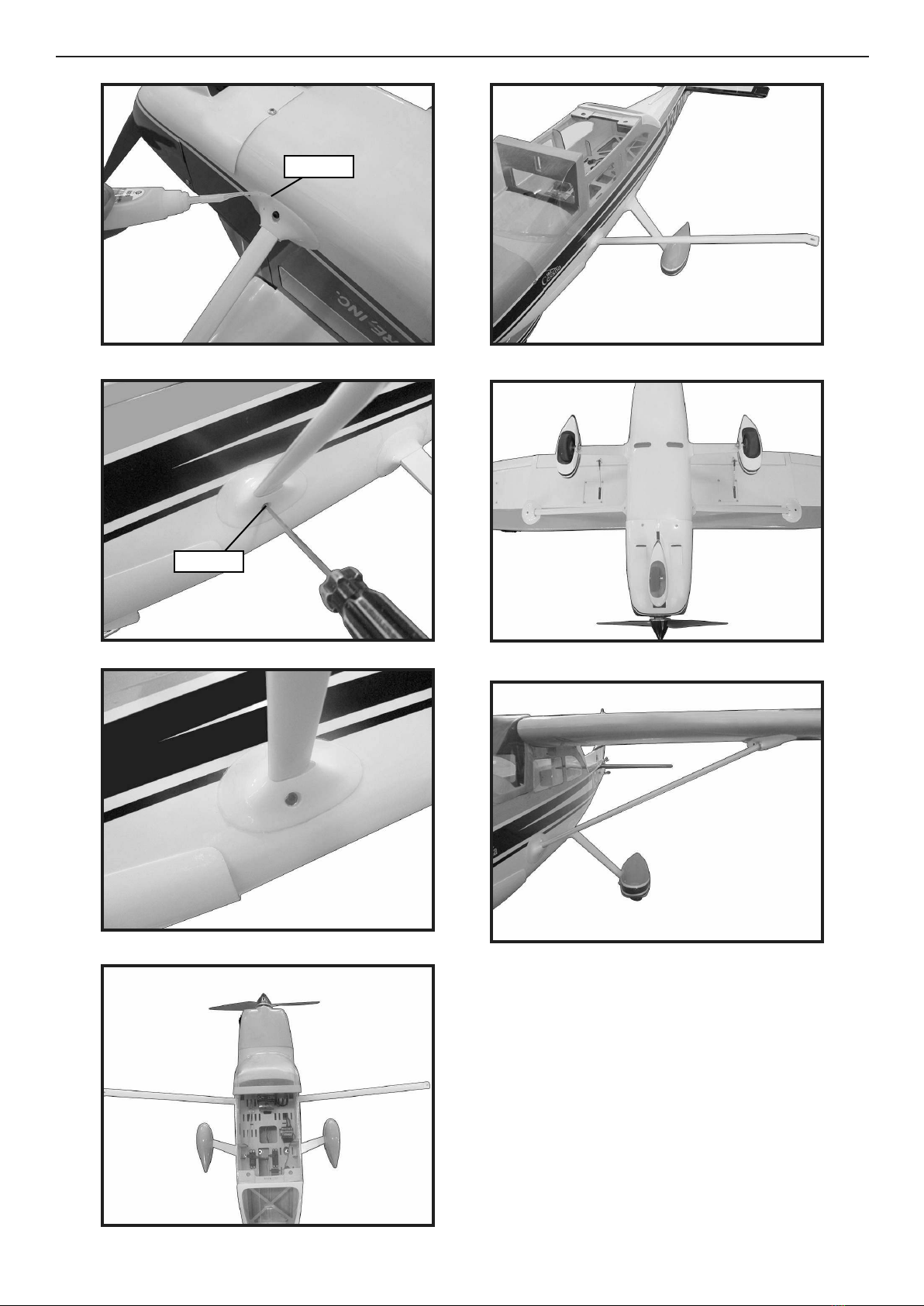

ELECTRIC POWER CONVERSION

- Please see below pictures.

3.

4.

2.

e photo shows the order of the items

as installed on the motor.

Use caution around the motor once the

propeller has been installed. e propel-

ler can cause injury if the motor starts

when the battery is connected.

MOTOR BATTERY AND

PROPELLER INSTALLATION

1.

Slide the propeller adapter, propeller

drive washer and spinner backplate on

the motor sha.

CESSNA TURBO SKYLANE 182 ELECTRIC 69” WINGSPAN PNP Instruction Manual.

14

Fit the propeller on the adapter. read

the propeller nut on the adapter and

tighten the nut using a 7/8-inch socket or

box end wrench.

Do not use pliers to tighten the nut, as

they will damage the aluminum nut over

time.

2.

3.

Fit the spinner cone in position. Position

the spinner cone so it does not contact the

propeller, Secure the spinner cone using

the provided screw and 1.5mm hex

wrench.

Secure the motor battery in the fuselage

using the hook and loop straps.

SUse hook and loop tape (not included)

between the battery and battery tray to

secure the battery during more aggressive

ying.

4.

5.

6.

7.

15

Connect the leads from the ap and

aileron extensions to the leads from the

wing. Mark each lead so they can be re-

connected in the same positions.

With the radio on and the aileron stick

and trim centered, check that the aileron

is aligned with the wing tip. Adjust the

linkage as necessary to correct the align-

ment.

1.

2.

8.

WING INSTALLATION

Slide the wing tube into the wing tube

socket.

e wing tube may be a tight t in the

socket. Polishing the wing tube with ne

sandpaper or steel wool will help ease the

installation of the wing tube. Do not force

the wing tube in the sockets as it can dam-

age the structure inside the wing.

Slide the wing panels together. ey will

t tightly together when in the correct

position.

With the radio on and the ap switch

centered, check that the ap is aligned

with the aileron. Adjust the linkage as

necessary to correct the alignment.

3.

4.

5.

CESSNA TURBO SKYLANE 182 ELECTRIC 69” WINGSPAN PNP Instruction Manual.

16

4.

8.

5.

6.

7.

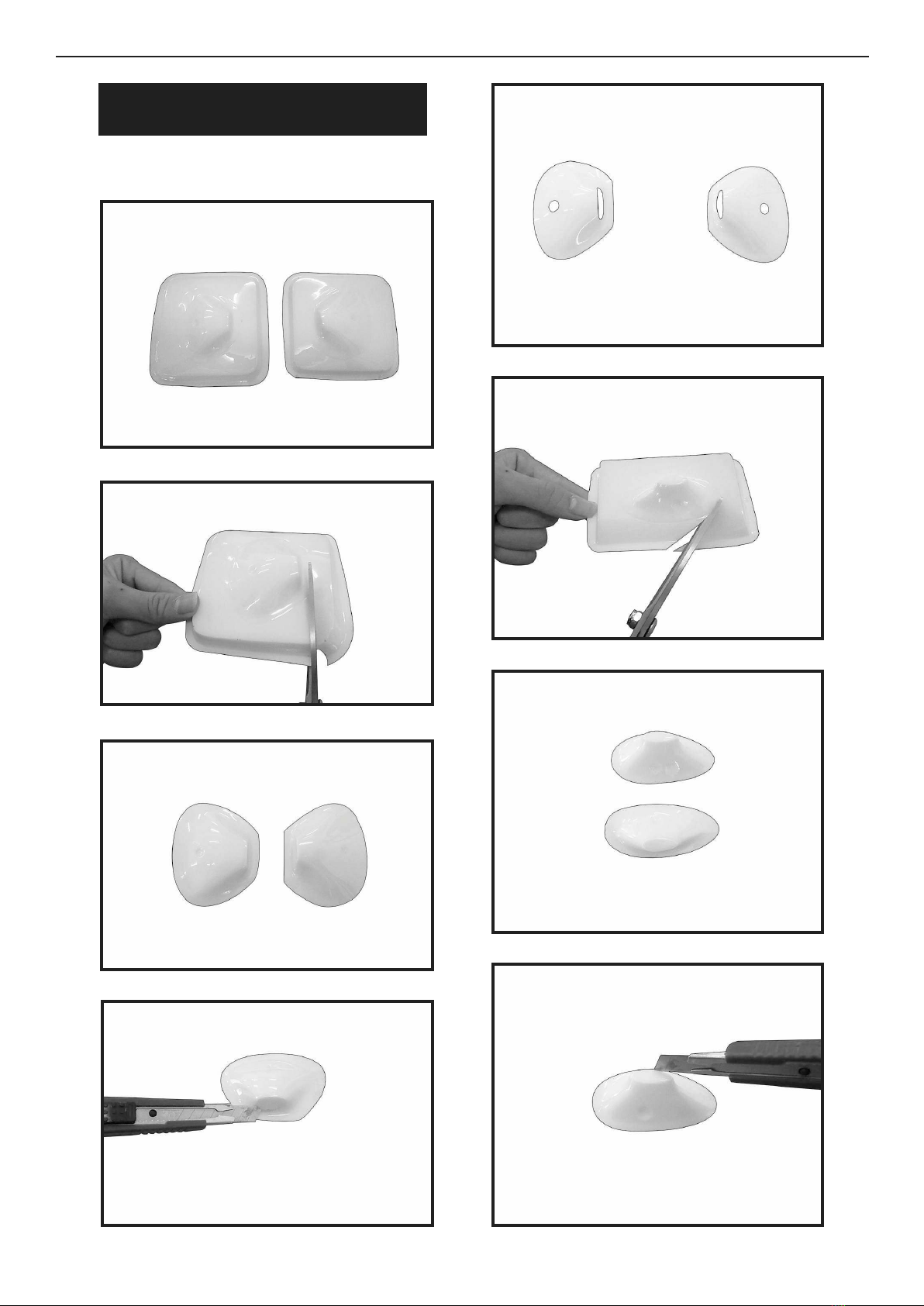

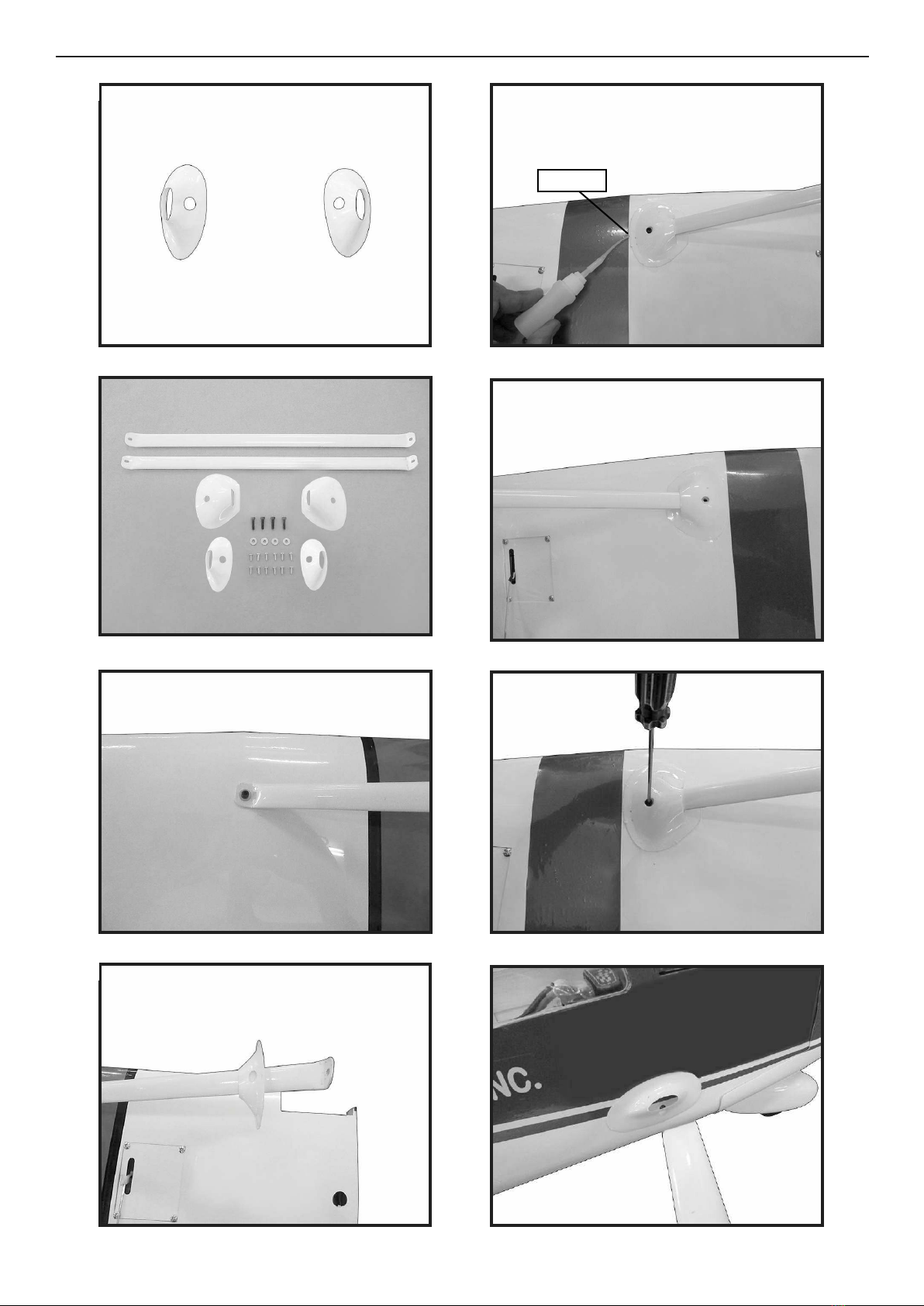

- Parts requirement.See pictures below.

INSTALLATION WING- FUSELAGE

STRUTS

1.

2.

3.

17

9.

12.

10.

11.

13.

14.

15.

C/A glue

16.

CESSNA TURBO SKYLANE 182 ELECTRIC 69” WINGSPAN PNP Instruction Manual.

18

18.

17.

19.

20.

3x12mm

Connect the leads for the aps and ai-

lerons.

Make sure the extensions will not inter-

fere with the operation of the rudder and

elevator servos.

23.

22.

21.

C/A glue

19

Place the wing bolt plate on the wing,

then thread the 1/4-20x 13/4-inch nylon

wing bolts into the blind nuts in the fuse-

lage to secure the wing.

Finger-tighten the wing bolts. Over-

tightening the wing bolts can damage the

wing structure or wing bolt plate.

24.

25.

- If all the decals are not precut, please

use scissors or a sharp hobby knife to cut

the decals from the sheet. Please be cer-

tain the model is clean and free from oily

ngerprints and dust. Position decal on

the model where desired, using the pho-

tos on the box and aid in their location.

APPLY THE DECALS

- If all the decals are precut and ready to

stick. Please be certain the model is clean

and free from oily ngerprints and dust.

Position decal on the model where de-

sired, using the photos on the box and aid

in their location.

BALANCING

An important part of preparing the air-

cra for ight is properly balancing the

model.

1) Attach the wing panels to the fuselage.

Make sure to connect the leads from the

aileron to the appropriate leads from the

receiver. Make sure the leads are not ex-

posed outside the fuselage before tight-

ening the wing bolts. Your model should

be ight-ready before balancing.

With the wing attached to the fuselage,

all parts of the model installed ( ready to

y), and empty fuel tanks, hold the mod-

el at the marked balance point with the

stabilizer level.

Li the model. If the tail drops when

you li, the model is “tail heavy” and you

must add weight* to the nose. If the nose

drops, it is “nose heavy” and you must

add weight* to the tail to balance.

*If possible, rst attempt to balance the

model by changing the position of the

receiver battery and receiver. If you are

unable to obtain good balance by doing

so, then it will be necessary to add weight

to the nose or tail to achieve the

proper balance point.

2) e recommended Center of Gravity

(CG) location for your model is (80mm)

back from the leading edge at the center

of the wing.

3) When balancing your model, make

sure it is assembled and ready for ight.

Support the plane upright at the marks

made on the wing with your gers or a

commercially available balancing stand.

is is the correct balance point for your

model.

CESSNA TURBO SKYLANE 182 ELECTRIC 69” WINGSPAN PNP Instruction Manual.

20

Ailerons:

High Rate :

Up : 20 mm

Down : 20 mm

Low Rate :

Up : 15 mm

Down : 15 mm

Elevator:

High Rate :

Up : 20 mm

Down : 20 mm

Low Rate :

Up : 15 mm

Down : 15 mm

Rudder:

High Rate :

Right : 30 mm

Le : 30 mm

Low Rate :

Right : 25 mm

Le : 25 mm

Flap:

Mid : 30mm

CONTROL THROWS

1.

80mm

15-20mm

15-20mm

25-30mm

25-30mm

Wing

Fuselage

15-20mm

15-20mm

30mm

This manual suits for next models

1

Table of contents

Other Seagull Models Aircraft manuals