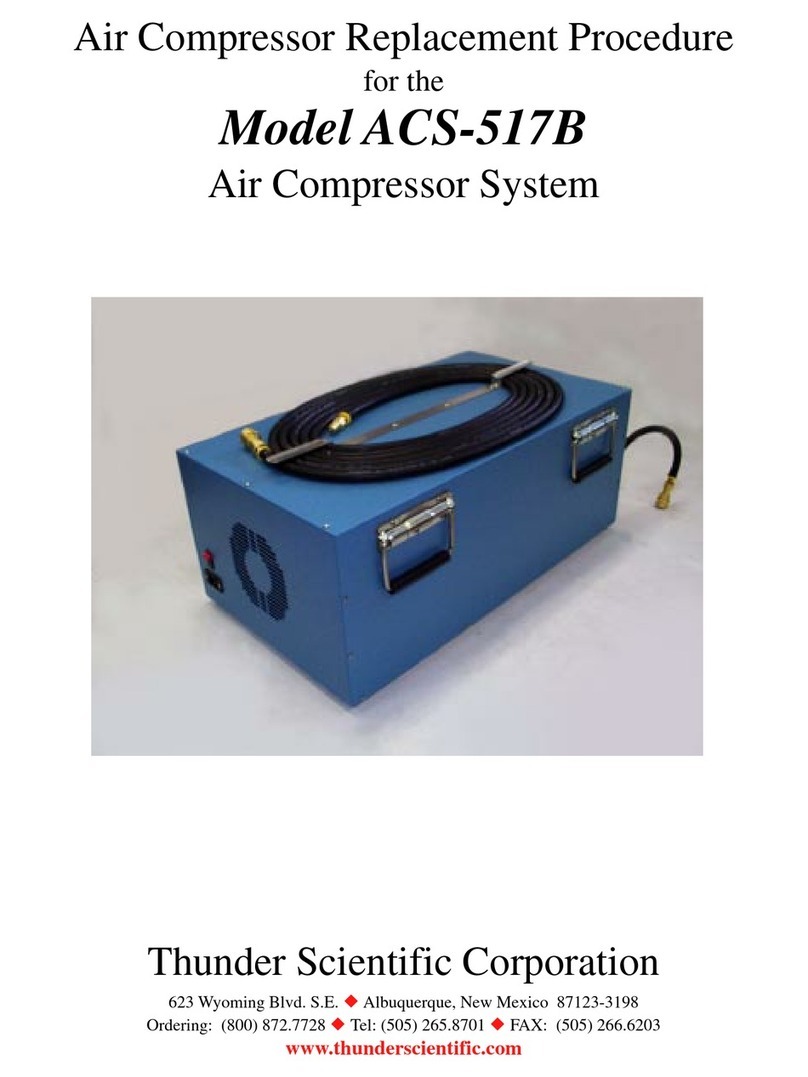

Thunder Scientific ACS-517B User manual

Operation and Maintenance Manual

for the

ACS-517B

Air Compressor System

(UPGRADE 2014)

Thunder Scientific Corporation

623 Wyoming Blvd. SE Albuquerque, New Mexico 87123-3198

Ordering: (800) 872.7728 Tel: (505) 265.8701 FAX: (505) 266.6203

www.thunderscientific.com

Copyright © 2014 by Thunder Scientific Corporation, All Rights Reserved

®

ACS Operation and Maintenance Manual

Document Edition – 06 April 9, 2014

THUNDER SCIENTIFIC® is the registered trademark of Thunder Scientific Corporation.

All the information provided in this document is correct and true at the time of publication.

Thunder Scientific Corporation reserves the right to change any technical data without notice.

WARNING

To ensure the safety of operating personnel, and to avoid damage to this equipment:

DO NOT operate this unit without a properly grounded, properly polarized power cord.

DO NOT connect this unit to a non-grounded, non-polarized outlet.

WARNING

HIGH VOLTAGE

is used in the operation of this equipment.

SEVERE INJURY OR DEATH

may result if personnel fail to observe safety precautions.

Before working inside the equipment, turn power off and disconnect power cord.

WARNING

HIGH TEMPERATURES

exist in this equipment.

FIRE and SEVERE BURNS

may result if personnel fail to observe safety precautions.

This Page Intentionally

Left Blank

TABLE OF CONTENTS

1 INTRODUCTION ............................................................................................. 2

2 SPECIFICATIONS and ENVIRONMENTAL CONDITIONS............................ 2

2.1 Specifications......................................................................................... 2

2.2 Environmental Conditions ...................................................................... 2

2.3 Warranty ................................................................................................ 2

3 SAFETY GUIDELINES .................................................................................... 3

4 INSTALLATION ............................................................................................... 3

4.1 Unpacking .............................................................................................. 3

4.2 Location ................................................................................................. 3

4.3 Hose Installation .................................................................................... 4

4.4 Power..................................................................................................... 4

4.4.1 Extension Cord ...................................................................................... 4

5 COMPONENTS and CONTROLS................................................................... 4

5.1 Power Receptacle.................................................................................. 4

5.2 Hour Meter ............................................................................................. 4

5.3 Outlet Pressure Regulator ..................................................................... 4

5.4 Outlet Pressure Gauge .......................................................................... 4

5.5 Air Compressor ...................................................................................... 5

5.6 Membrane Air Dryer............................................................................... 5

5.7 Safety Valve ........................................................................................... 5

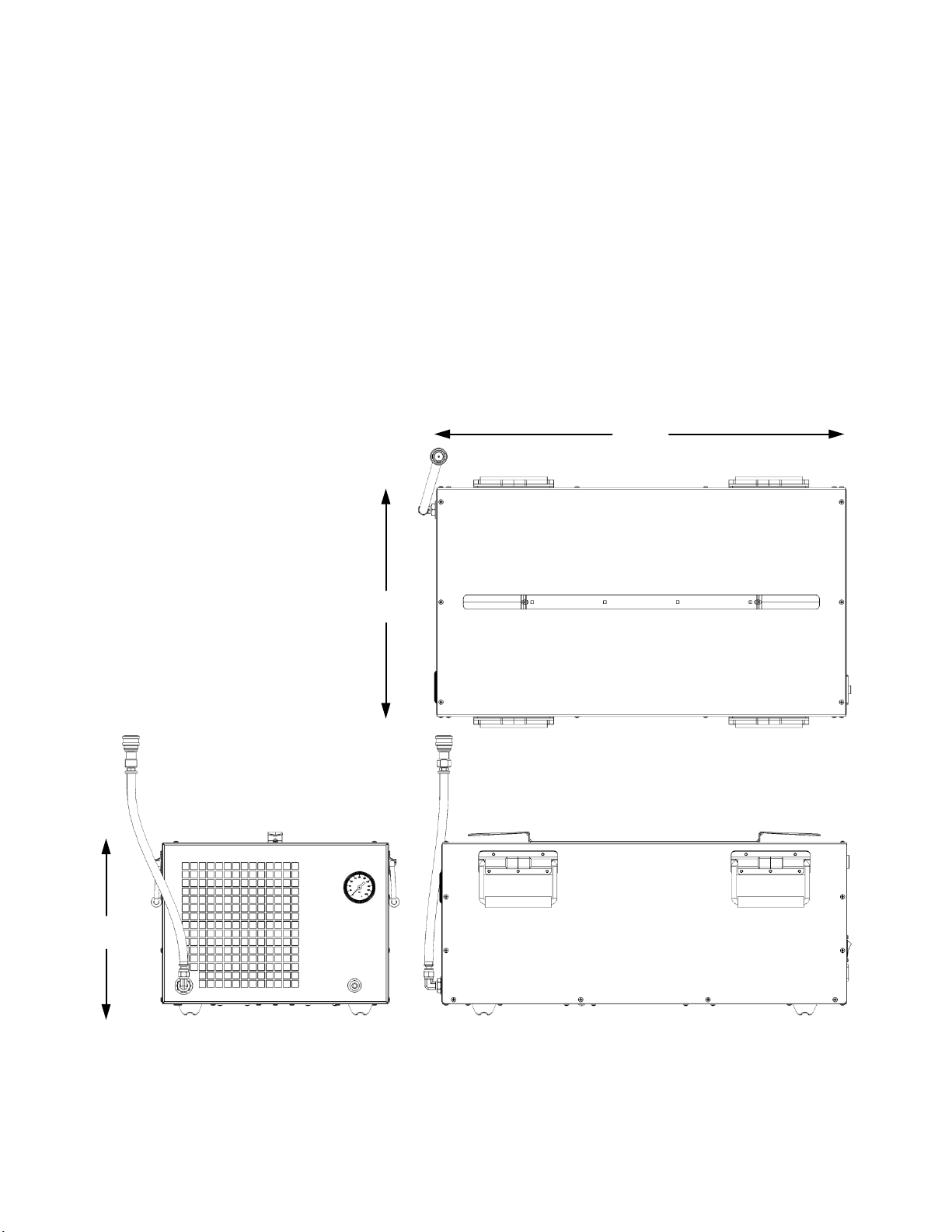

5.8 Dimensional Drawing ............................................................................. 5

5.9 Component Locations ............................................................................ 6

6 GENERAL OPERATION ................................................................................. 7

6.1 Set-up .................................................................................................... 7

6.2 Pressure Adjustment ............................................................................. 7

6.3 Shut-down.............................................................................................. 7

7 INSPECTION and MAINTENANCE ................................................................ 8

7.1 Recommended Maintenance Schedule................................................. 8

7.2 Filter Inspection and Replacement ........................................................ 8

7.3 Storage Procedures ............................................................................... 9

7.4 Service Kit .............................................................................................. 9

8 SCHEMATICS ............................................................................................... 10

8.1 Pneumatic Schematic .......................................................................... 10

8.2 Electrical Schematic............................................................................. 10

9 TROUBLESHOOTING GUIDE ...................................................................... 11

10 PARTS LIST .................................................................................................. 11

Thunder Scientific Corporation ACS-517B Air Compressor System 1-1

Document Number: ACS-517B.doc - Edition 06 - April 2014

1 INTRODUCTION

The ACS-517B Oil-Less Compressed Air System is designed to be used as the air supply

for a Thunder Scientific Model 2500 humidity generator. The ACS-517B consists of a

vibration isolated oil-less piston compressor, membrane style air dryer, and output

regulator, all incorporated into a sound muffling cabinet. The ACS-517B is ideal for

laboratory use because of the its high pressure capability, 100% duty cycle capability, low

sound level of less than 70 decibels, and long service life.

2 SPECIFICATIONS and ENVIRONMENTAL CONDITIONS

2.1 Specifications

Voltage/Frequency 60Hz: ............................................................................... 115/230/60/1

Voltage/Frequency 50Hz: ..........................................................................110/220/240/50/1

Pressure Rating (MAWP): .................................................................................... 165 psiG

Pressure Dew Point............................................................. approximately 0 °C at 165 psiG

Duty Cycle: ................................................................................................................. 100%

Physical Dimensions: ... 28.875 w" x 16.125 d" x 12.89 h" (73.5 cm x 40.9 cm x 32.7 cm)

Dry Weight: ............................................................................................................. 100 lbs.

2.2 Environmental Conditions

Operating Temperature: .................................................................................... 15 to 30 °C

Storage Temperature: ...................................................................................... > 0 to 50 °C

Humidity: .................................................................................... 5 to 90% Non-condensing

2.3 Warranty

Thunder Scientific Corporation (TSC) warrants this product to be free of defects in

material and workmanship under normal use and service when operated within the

specified design limitations for a period of 90 days from date of shipment or 2000

operating hours, whichever comes first. TSC's obligation under this warranty shall be

limited to the following: the Product is returned to TSC with transportation charges prepaid

and that TSC's examination reveals the Product to be defective, TSC, at its option, shall

repair or replace at TSC's plant, any part or parts of the Product which is or are defective.

This warranty shall not apply to any Product that has become damaged or inoperative

because of ordinary wear, misuse, cold, heat, rain, excessive humidity, freeze damage,

use of improper chemicals, negligence, accident, failure to operate the product in

accordance with the instructions provided in the Owners Manual(s) supplied with the

product, improper maintenance, the use of accessories or attachments not recommended

by TSC or unauthorized repair or alterations.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ANY WARRANTY OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR ANY OTHER

WARRANTY, WHETHER EXPRESS OR IMPLIED, AND ALL OTHER LIABILITIES AND

OBLIGATIONS ON THE PART OF TSC; TSC SHALL NOT BE LIABLE FOR ANY

INCIDENTAL, INDIRECT OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT

MAY RESULT FROM ANY DEFECT, FAILURE OR MALFUNCTION OF THE PRODUCT.

All warranties; express or implied, with respect to any device or component not

manufactured by TSC but incorporated into its Product are the responsibility of the

original manufacturer and shall not affect or apply to TSC.

Thunder Scientific Corporation ACS-517B Air Compressor System 1-2

Document Number: ACS-517B.doc - Edition 06 - April 2014

3 SAFETY GUIDELINES

All compressed gases, including air, can be dangerous. Know and follow all safety rules

when using compressed air and especially when disconnecting and venting compressed

air lines.

Always operate the ACS-517B system in a clean, dry, well ventilated area, free of

combustible materials, or solvent vapors. Operate the ACS-517B in an open area at least

12 inches away from any wall or obstruction that would restrict the flow of fresh air to the

ventilation openings. Restricting any of the ACS-517B housing openings will cause

serious overheating leading to probable failure or possible fire.

Your ACS-517B system is powered by electricity. Like any other electrically powered

device, if not used properly it may cause electric shock. Never operate in wet conditions

and never operate with cover removed. Failure to provide adequate grounding could

result in serious injury or death from electrocution. Make certain that the electrical circuit

to which the ACS-517B is connected provides proper electrical grounding, correct voltage

and adequate fuse protection.

Attempting to operate the ACS-517B with damaged or missing parts or attempting to

repair the ACS-517B with protective cover removed can expose you to moving parts and

can result in serious injury. Any repair required should be performed by authorized

personnel. Repairs attempted by unqualified personnel can result in serious injury or

death by electrocution.

The compressed air directly from the ACS-517B is not safe for breathing, and should

never be used to supply air for human consumption. The dried air from a membrane

dryer will contain less oxygen than normal air and under some conditions the dried air will

not meet breathing air standards for oxygen content. The air stream may also contain

carbon monoxide, toxic vapors, or solid particles. Breathing these contaminants can

cause serious injury or death.

This ACS-517B can fall from a table or workbench causing damage to the compressor

and could result in serious injury. Always operate the ACS-517B in a stable secure

position to prevent accidental movement of the unit.

Refer to attached TA-5172 Piston Pump Operating and Maintenance Manual for

additional specifications, service instructions, safety guidelines, hazard and warning

information.

4 INSTALLATION

4.1 Unpacking

Unpack the ACS-517B carefully and inspect it for any damage that may have occurred

during shipment. If there is shipping damage, notify the carrier immediately. Verify that

the power cord, air hose, and manual are present. If possible, save shipping container

for future use.

4.2 Location

Locate the ACS-517B in a clean, dry and well ventilated area. The system should be

located at least 12 inches away from the wall or other obstructions that will restrict the flow

of air to the ventilation openings. The compressor enclosure is designed to allow for

proper cooling; therefore ventilation openings must remain unrestricted to maintain proper

operating temperature.

Thunder Scientific Corporation ACS-517B Air Compressor System 1-3

Document Number: ACS-517B.doc - Edition 06 - April 2014

4.3 Hose Installation

Connect the air hose via the quick connect fitting to the air tank assembly. The other end

of hose is connected to the air outlet of the ACS-517B compressor system. Open the ball

valve on the air tank before starting the system.

4.4 Power

The ACS-517B is equipped with a power receptacle and cord having a grounding wire

with an appropriate grounding plug. The plug must be used with an outlet that has the

same configuration as the grounded plug and has been installed and grounded in

accordance with all local codes and ordinances.

Power of the appropriate voltage, frequency, and current capacity, is applied via power

cord to the ACS-517B power receptacle.

4.4.1 Extension Cord

If an extension cord must be used, be sure it is a 3-wire extension cord that has a 3-blade

grounding plug, and a 3-slot receptacle that will accept the plug on the ACS-517B and is

14 gauge or larger and no longer than 50 feet.

5 COMPONENTS and CONTROLS

5.1 Power Switch

The Power Switch (CBS1) allows power to be turned on or off at this location independent

from the 2500 generator. The Power Switch also has a built-in circuit breaker.

5.2 Hour Meter

The Hour Meter (HM1) tracks total run time of the ACS-517B air compressing system.

5.3 Outlet Pressure Regulator

The Output Pressure Regulator (REG) controls the pressure available at the ACS-517B

outlet which is indicated on the pressure gauge located on the 2500’s cart. Turn the 9/32”

(7mm) adjustment shaft clockwise to increase pressure and counterclockwise to

decrease pressure.

Note: Pressures higher than 165 psi should be avoided. Higher pressures will be

indicated by the "popping off" of the compressor safety valve.

Note: Adjustment may be necessary after one hour of run time to keep the indicated

pressure at 165 psi.

5.4 Outlet Pressure Gauge

Note: If you have the Outlet Pressure Gauge (G1) it indicates the regulated pressure

available at the outlet of the ACS-517B air compressing system. This pressure is

controlled by the outlet pressure regulator.

Thunder Scientific Corporation ACS-517B Air Compressor System 1-4

Document Number: ACS-517B.doc - Edition 06 - April 2014

5.5 Air Compressor

The Oil-less Air Compressor (COMP1) provides a maximum pressure of 165 psiG at a

flow rate of 30 liters per minute or less.

5.6 Membrane Compressed Air Dryer

The Membrane Compressed Air Dryer (AD1) is located after the air compressor and is

specifically designed to remove water vapor from the compressed air stream. Typical

pressure dew points of 0 °C or less are maintained.

5.7 Safety Valve

The Safety Valve (mounted on compressor) protects the system against over pressure.

Over pressure is indicated by the "popping off" sound of the safety valve.

5.8 Dimensional Drawing

28.875

Top View 16.125

12.89

Left View Front View

Thunder Scientific Corporation ACS-517B Air Compressor System 1-5

Document Number: ACS-517B.doc - Edition 06 - April 2014

5.9 Component Locations

ITEM DESCRIPTION ITEM DESCRIPTION

1. On / Off Switch (CBS1) 7. Particulate Filter (LF2)

2. Power Receptacle (RCP1) 8. Circulation Fan (CF1)

3. Hour Meter (HM1) 9. Air Compressor (COMP1)

4. Pressure Gauge (G1) 10. Air Intake Filter (LF1)

5. Regulator (REG) 11. Air Dryer (AD1)

6. Air Outlet

Right View

10

3

5

9

1

2

Thunder Scientific Corporation ACS-517B Air Compressor System 1-6

Document Number: ACS-517B.doc - Edition 06 - April 2014

Left View

6 GENERAL OPERATION

6.1 Start-up

Be sure the "Hose Installation" of paragraph 4.3 has been completed before proceeding

and that the 2500 utility cart inlet valve has been opened.

Insert the power cord into the ACS-517B power receptacle. With the ACS-517B power

switch in the off position, plug the power cord into an AC mains outlet of the appropriate

voltage, frequency, and current capacity.

Apply power to the ACS-517B using the On/Off power switch. The compressor will start

and the pressure gauge will indicate approximately 165 psiG.

6.2 Pressure Adjustment

If pressure adjustment is required adjust the output pressure to 165 psiG, during no-flow

conditions, by turning the 9/32” (7mm) adjustment shaft on the regulator clockwise to

increase pressure and counterclockwise to decrease pressure.

6.3 Shut-down

Disconnect power to the ACS-517B using the On/Off power switch. Slowly open the air

tank drain valve and vent the tank pressure as indicated by the outlet pressure gauge.

6

11

7

8

Regulator

Adjustment

Access

5

4

Thunder Scientific Corporation ACS-517B Air Compressor System 1-7

Document Number: ACS-517B.doc - Edition 06 - April 2014

Important: All pressure MUST be vented before disconnecting the air supply

hose or personal injury may result.

7 INSPECTION and MAINTENANCE

7.1 Recommended Maintenance Schedule

Periodic Hours

Maintenance 100% Duty Cycle

Initial Inlet/Outlet Filter Inspection 1st 500

To establish service period

Minor Service Kit 1,500

Major Pump Rebuild or

Replacement 3,000

7.2 Filter Inspection

The Intake Filter, Outlet Filter, and Regulator Muffler require periodic inspection. Initial

inspection is suggested at 500 hours; then user should determine the frequency

thereafter. Most problems can be prevented by keeping the intake filter and particulate

filter clean. A dirty intake filter will decrease pump performance and can decrease pump

life.

Warning: Disconnect power and be sure all pressure has

been vented before service!

1. Intake a. Remove the snap-fit cover.

Filter (LF1) b. Clean felt filter using air or vacuum.

c. Replace snap-fit cover.

2. Particulate a. Remove the hose by turning the flare nut counterclockwise.

Filter (LF2) b. Unscrew the adapter (1) by turning counterclockwise.

c. Remove filter (3) and clean with water and blow dry or replace.

d. Inspect bowl (4 & 5) and seal (2). If dirty, clean by wiping

the bowl with a soft dry cloth.

e. Insure seal is clean and in place then re-install filter and

rotate the adapter clockwise until snug.

f. Re-install hose flare nut using a backup wrench turning

clockwise.

Particulate Filter (LF2)

Thunder Scientific Corporation ACS-517B Air Compressor System 1-8

Document Number: ACS-517B.doc - Edition 06 - April 2014

7.3 Storage Procedures

Proper shutdown procedures must be followed to prevent pump damage. Failure to do so

may result in premature pump failure. The non-lubricated compressor is constructed of

ferrous metals and/or aluminum which are treated for corrosion protection but are still

subject to possible rust and corrosion when pumping condensable vapors such as water.

Follow the steps below to assure correct shutdown and storage between use:

1. NEVER oil this non-lubricated compressor as damage will result.

2. For long term storage of the ACS-517B, disconnect the air hose at outlet and

apply power allowing the compressor to run "open" for at least five minutes.

After five minutes remove power and plug/cap outlet to prevent contaminants

from entering. The ACS-517B is now ready for storage.

Warning: All pressure MUST be vented before

disconnecting air supply hose!

7.4 Service Kit

Refer to Thomas TA series operating and maintenance manual for parts and procedures.

Thunder Scientific Corporation ACS-517B Air Compressor System 1-9

Document Number: ACS-517B.doc - Edition 06 - April 2014

8SCHEMATICS

8.1 Pneumatic Schematic

Figure 1-1

8.2 Electrical Schematic

Figure 1-2

Thunder Scientific Corporation ACS-517B Air Compressor System 1-10

Document Number: ACS-517B.doc - Edition 06 - April 2014

9 TROUBLESHOOTING GUIDE

Possible Reason No / Low High Excessive Over Won't

Pressure Pressure Noise Heating Start

Dirty Intake Filter X

Hose Leak X

Regulator Adjustment X X X

Worn or Damaged Compressor X X X

Worn or Damaged Fan X X

Safety Valve Leak X

Safety Valve "Popping Off" X X

Plugged Pressure Line X X

Low Voltage X X

Blocked Ventilation Opening X X X

High Outlet Pressure X

Overheating X X

10 PARTS LIST

Find # Qty Description Part Number

CBS1 1 Circuit Breaker Switch BTPWRSW-R

* PWRSW-2P

HM1 1 Hour Meter HRMETERACS

COMP1 1 Compressor, 115/230/60/1 TA5172/60

COMP1 1 Compressor, 110/220/240/50/1 * TA5172/50

G1 1 Gauge, Pressure G1X510

REG 1 Regulator, Back Pressure JBPREG

AD1 1 Air Dryer, Membrane MD1015

CF1 1 Fan, Circulation MR2B3

* MR77B3

LF1 1 Filter Element C87713

LF2 1 Filter Element G6B225

* Asterisk Indicates High Voltage Parts

Thunder Scientific Corporation ACS-517B Air Compressor System 1-11

Document Number: ACS-517B.doc - Edition 06 - April 2014

This Page Intentionally

Left Blank

Thunder Scientific Corporation ACS-517B Air Compressor System 1-12

Document Number: ACS-517B.doc - Edition 06 - April 2014

TASKAIR™ (TA) SERIES

1/2 HP

FEATURES

•Oil-less design

•Permanently lubricated and sealed bearings

•Cast iron cylinders

•PTFE piston rings and skirts

•Long, service free life

•Field service capability

•Totally enclosed motor

•Low vibration

•Quiet Operation

•Low profile

•Fifty-micron inlet filter(s)

TA-5172

MODELS

(270078)

(270073)

TA-5172

TA-5172

Thomas Division is an ISO 9001 registered company

14.30 4.26

TYP BOTH

SIDES RELIEF VALVE

1/4" NPT

EXHAUST

11.20

3.50

6.95

WIRING DIAGRAM

(SUPPLIED BY MOTOR VENDOR)

(APPLIED BY THOMAS)

WARNING LABEL (RED)

(SUPPLIED BY MOTOR VENDOR)

(APPLIED BY THOMAS) MOTOR NAMEPLATE

(SUPPLIED BY MOTOR VENDOR)

1/3, 1/2, 3/4 TA Performance Data

TA SERIES | Pressure | 2

Standard Standard Standard

MODEL NUMBER

MANUFACTURING CODE

HEAD CONFIGURATION

NUMBER OF CYLINDERS

PRESSURE

cfm @ psi l/min @ bar

psi bar

0 0

10 1.0

20 2.0

25 3.0

30 5.0

35 7.0

40 8.0

50 9.0

60 10.0

70 11.0

80 12.0

90

100

110

120

130

140

150

160

175

MAX. PRESSURE

MAX. AMBIENT AIR TEMP.

MIN. AMBIENT START TEMP.

MAX. RESTART PRESSURE

MOTOR VOLTAGE/FREQUENCY

HORSEPOWER

MOTOR TYPE

CURRENT AT RATED LOAD (AMPS)

POWER AT RATED LOAD (WATTS)

STARTING CURRENT

(LOCKED ROTOR, AMPS)

MIN. FULL LOAD SPEED (RPM)

THERMAL PROTECTOR

CAPACITOR VALUE

NET WEIGHT

SHIP WEIGHT

TA-4172

270072

Pressure

2

Flow @ 115/60

cfm l/min

1.40 39.6

1.38 38.5

1.35 37.4

1.33 36.5

1.32 34.4

1.31 32.5

1.30 31.9

1.27 31.1

1.25 30.0

1.22

1.20

1.18

1.15

1.14

1.12

1.10

1.08

175 psi 12 bar

(40ºC) 104ºF

(0ºC) 32ºF

175 psi 12 bar

115/230/60/1

1/3

Capacitor Start

8.0 / 4.0 A

450 W

34.8 / 18.0 A

1725 rpm

Yes

243 mfd

45 lb. 20.4 (kg)

47 lb. 21.3 (kg)

TA-5172

270073

Pressure

2

Flow @ 115/60

cfm l/min

1.80 50.9

1.79 50.4

1.78 50.1

1.77 49.5

1.77 48.0

1.76 46.5

1.75 45.2

1.75 44.4

1.72 43.3

1.70

1.69

1.67

1.65

1.62

1.61

1.60

1.58

175 psi 12 bar

(40ºC) 104ºF

(0ºC) 32ºF

175 psi 12 bar

115/230/60/1

1/2

Capacitor Start

7.3 / 3.6 A

760 W

34.8 / 18.0 A

1725 rpm

Yes

324 mfd

51 lb. 23.1 (kg)

51 lb. 23.1 (kg)

TA-5172

270076

Pressure

2

Flow @ 230/60

cfm l/min

1.80 50.9

1.79 50.4

1.78 50.1

1.77 49.5

1.77 48.0

1.76 46.5

1.75 45.2

1.75 44.4

1.72 43.3

1.70

1.69

1.67

1.65

1.62

1.61

1.60

1.58

175 psi 12 bar

(40ºC) 104ºF

(0ºC) 32ºF

175 psi 12 bar

190/380/50/3

208-230/460/60/3

1/2

Polyphase

2.0 / 1.9 / .95 A

628 W

12.5 / 12.0 / 6.0 A

1725 / 1425 rpm

No

51 lb. 23.1 (kg)

51 lb. 23.1 (kg)

TA-5172

270078

Pressure

2

Flow @ 220/50

cfm l/min

1.43 40.4

1.42 39.9

1.41 39.6

1.40 39.2

1.40 38.4

1.39 37.3

1.39 36.7

1.38 35.9

1.37 34.8

1.36

1.35

1.34

1.32

1.31

1.30

1.28

1.26

175 psi 12 bar

(40ºC) 104ºF

(0ºC) 32ºF

175 psi 12 bar

110/220-240/50/1

1/2

Capacitor Start

8.2 / 4.1 / 4.3 A

670 W

39.0 / 19.5

A

1425 rpm

Yes

324 mfd

51 lb. 23.1 (kg)

51 lb. 23.1 (kg)

TA-6172

270080

Pressure

2

Flow @ 115/60

cfm l/min

2.40 67.9

2.39 67.1

2.37 66.8

2.36 66.1

2.36 64.9

2.35 63.5

2.34 62.2

2.33 61.4

2.31 60.3

2.30

2.28

2.26

2.25

2.22

2.21

2.20

2.18

175 psi 12 bar

(40ºC) 104ºF

(0ºC) 32ºF

175 psi 12 bar

115/230/60/1

3/4

Capacitor Start

10.6 / 5.3 A

825 W

60.0 / 30.0 A

1725 rpm

Yes

378 mfd

56 lb. 25.4 (kg)

60 lb. 27.2 (kg)

TA-6172

270082

Pressure

2

Flow @ 230/60

cfm l/min

2.40 67.9

2.39 67.1

2.37 66.8

2.36 66.1

2.36 64.9

2.35 63.5

2.34 62.2

2.33 61.4

2.31 60.3

2.30

2.28

2.26

2.25

2.22

2.21

2.20

2.18

175 psi 12 bar

(40ºC) 104ºF

(0ºC) 32ºF

175 psi 12 bar

190/380/50/3

208-230/460/60/3

3/4

Polyphase

2.8 / 2.8 / 1.4 A

800 W

17.0 / 17.0 / 8.5 A

1725 / 1425 rpm

No

56 lb. 25.4 (kg)

60 lb. 27.2 (kg)

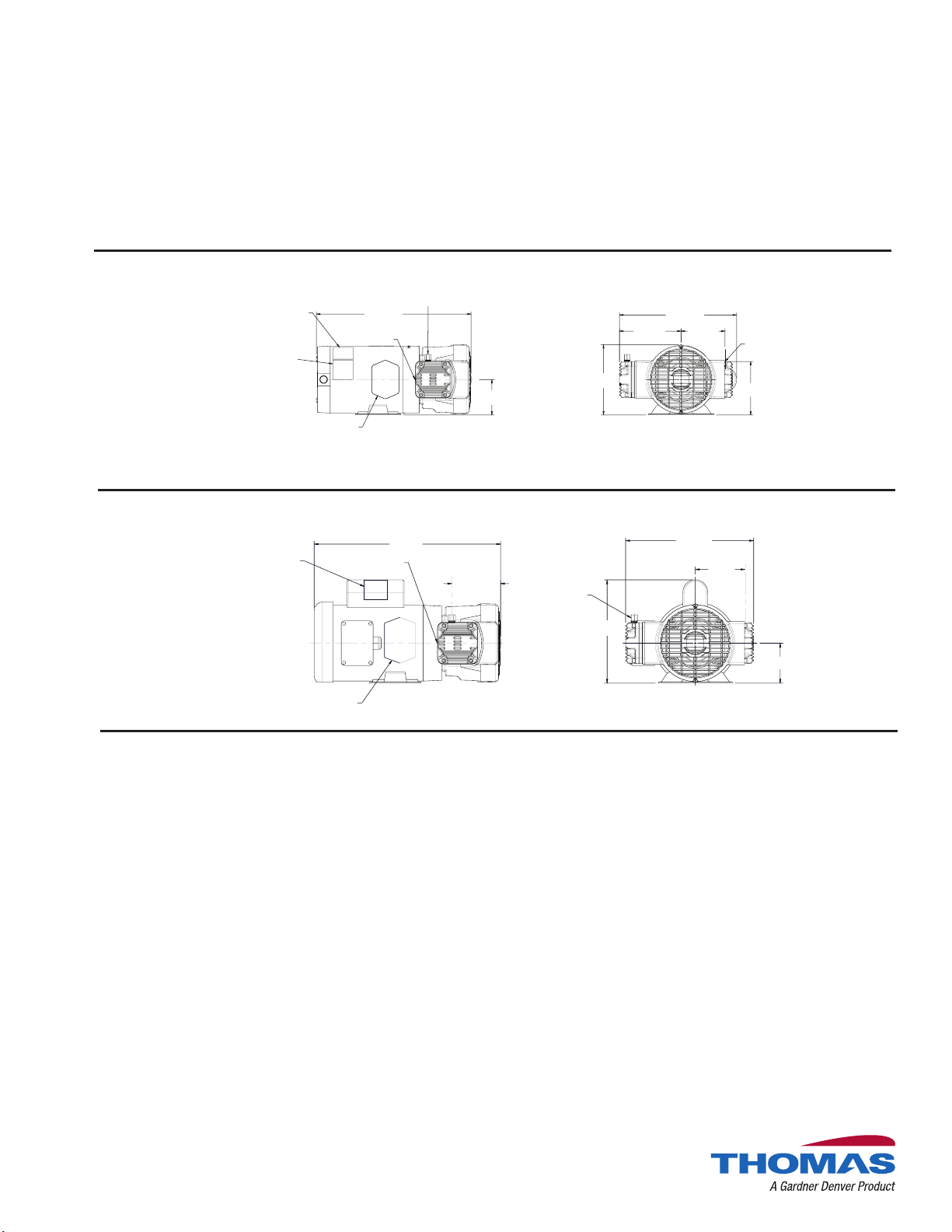

TA-4172

270072

14.30

1/4" NPT

EXHAUST

RELIEF

VALVE

1/4" NPT

INLET

5.29

11.59

3.50 6.95

6.10 4.35

WIRING DIAGRAM

(SUPPLIED BY MOTOR VENDOR)

(APPLIED BY THOMAS)

WARNING LABEL (RED)

(SUPPLIED BY MOTOR VENDOR)

(APPLIED BY THOMAS)

MOTOR NAMEPLATE

(SUPPLIED BY MOTOR VENDOR)

TYP BOTH

SIDES

OF PORTS

C

L

OF PORT

C

L

16.30

4.26

1/4" NPT

EXHAUST

RELIEF

VALVE

4.35

11.20

3.50

9.04

WIRING DIAGRAM (WHITE)

(SUPPLIED BY MOTOR VENDOR)

(APPLIED BY THOMAS)

MOTOR NAMEPLATE

(SUPPLIED BY MOTOR VENDOR)

Dimensions

TA SERIES | Pressure | 3

270078

TA-5172

270073

TA-5172

The information presented in this material is based on technical data and test results of nom-

inal units. It is believed to be accurate and reliable and is offered as an aid to help in the selec-

tion of Thomas products. It is the responsibility of the user to determine the suitability of the

product for the intended use and the user assumes all risk and liability in connection there

with. Thomas does not warrant, guarantee or assume any obligation or liability in connection

with this information.

Models presented in this catalog are representative of the product family. Photos of prod-

ucts pictured in this catalog do not necessarily represent a specic model number. To

obtain further information for custom options, contact your local Thomas ofce.

Printed in USA

Form No. 850-4006 10/13

©2011 Gardner Denver Thomas, Inc. All rights reserved.

Thomas Division

1419 Illinois Avenue

Sheboygan, WI 53081 USA

Phone: +1 920 457 4891

Fax: +1 920 451 4237

www.gd-thomas.com

gd-thomas.com

PUMP AND COMPRESSOR SOLUTIONS FOR OEMSWORLDWIDE

Worldwide

Manufacturing and Distribution

SALES OFFICES

Australia

Austria

Brazil

China

Czech Republic

Denmark

France

Germany

Hong Kong

Italy

Japan

Korea

Netherlands

New Zealand

Sweden

Switzerland

United Kingdom

United States

MFG. LOCATIONS

Memmingen, Germany

Monroe, LA, USA

Wuxi, China

Representatives in other

countries see

www.gd-thomas.com

Other manuals for ACS-517B

1

Table of contents

Other Thunder Scientific Air Compressor manuals