-2-

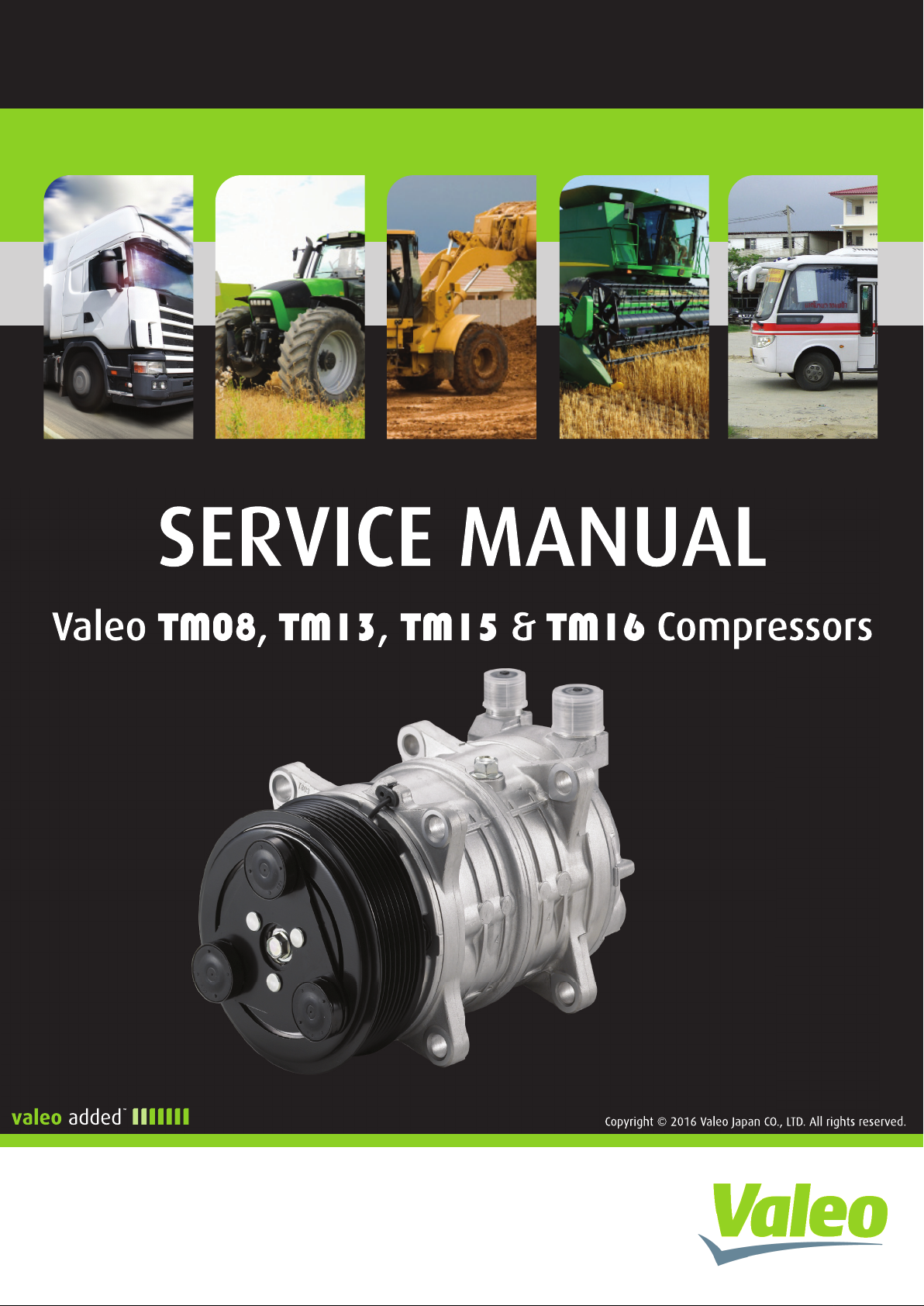

Contents

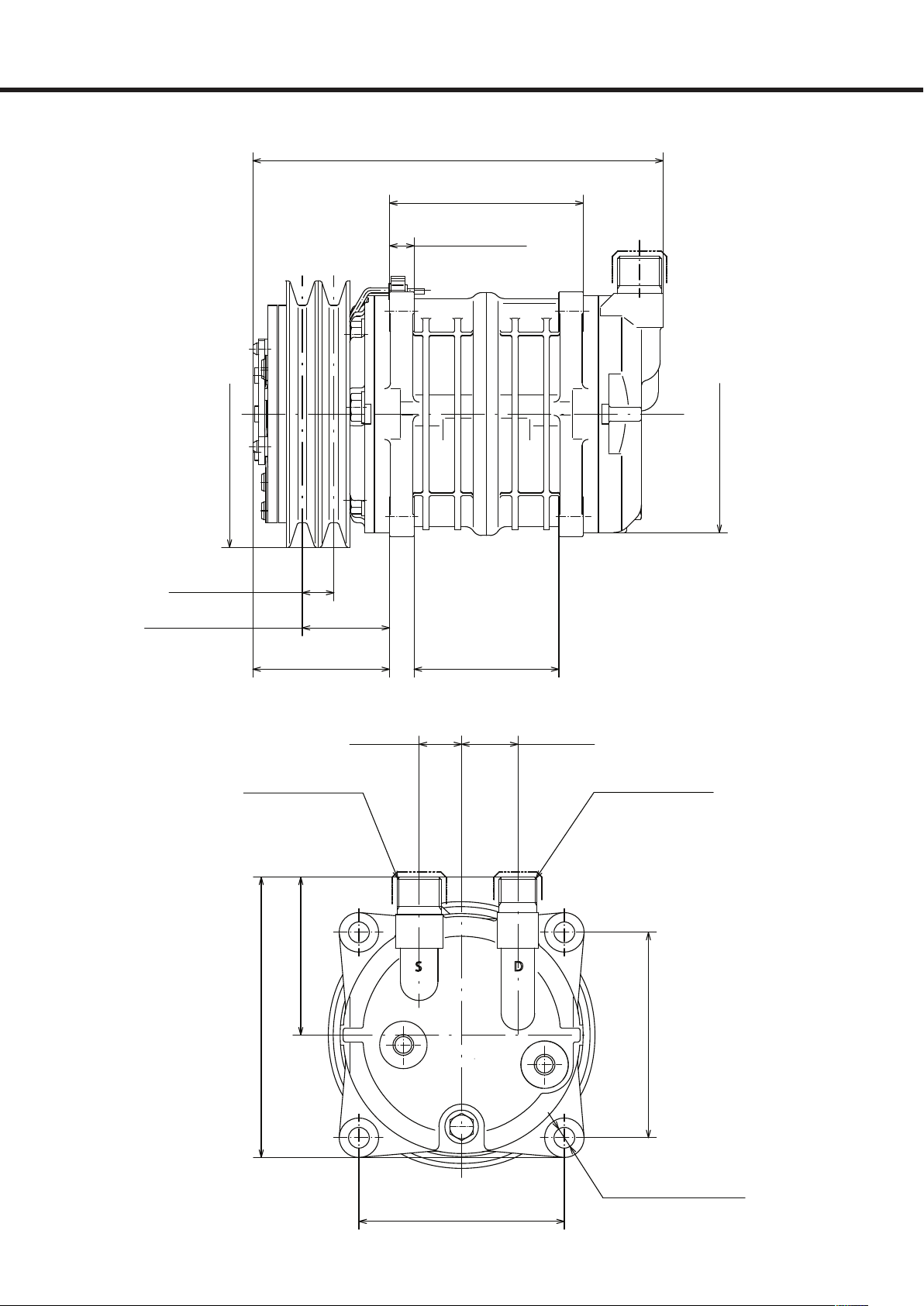

1-Product description................................................................................... 3

2-Operation precautions.............................................................................. 18

3-Handling instructions................................................................................ 19

Maintenance precautions............................................................................. 19

Work area............................................................................................... 19

Refrigerant handling.................................................................................. 19

Compressor handling.................................................................................. 20

Compressor removal................................................................................... 20

Oil return operation.................................................................................... 21

Oil handling............................................................................................... 21

Oil contamination....................................................................................... 22

Oil check.................................................................................................... 22

Replacement of components......................................................................... 23

Running-in operation................................................................................... 24

Compressor runnning-in............................................................................... 24

Magnetic clutch running-in........................................................................... 24

Leak test.................................................................................................... 25

Storing a repaired compressor ....................................................................... 25

Refrigerant charging................................................................................... 26

Installation position..................................................................................... 27

Installation precautions................................................................................ 27

Piping precautions....................................................................................... 28

4-Troubleshooting ........................................................................................ 29

Compressor troubleshooting ........................................................................ 29

Compressor troubleshooting tree .................................................................. 29

A/C cycle diagnosis by gauge pressure........................................................... 33

5-Tightening torques.................................................................................... 35

6-Service procedures - Magnetic clutch..................................................... 36

7-Services procedures - Shaft seal assembly.............................................. 40

8-Services procedures - Cylinder heads...................................................... 43

9-Service tools.............................................................................................. 47

Magnetic clutch service tools........................................................................ 47

Compressor tools....................................................................................... 48

Test and inspection tools ............................................................................. 48