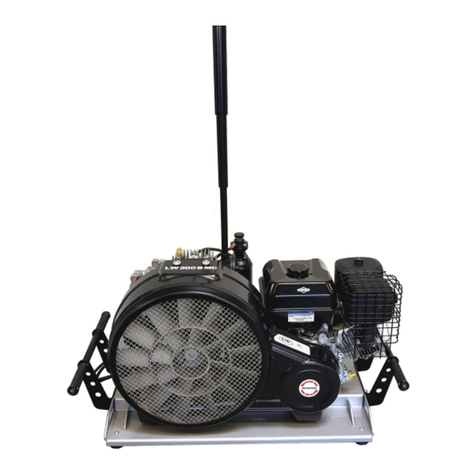

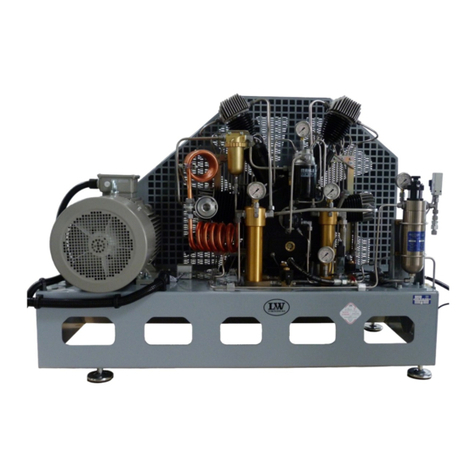

LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact

Version: 20.05.2023

Page A - 2

A

T A B L E O F C O N T E N T S

Genera Information and Technica Data

Genera Information / Description of Warning Symbo s .................................................................... 4

Scope of De ivery .............................................................................................................................. 5

Technica Data .................................................................................................................................. 6

Unit Assemb y ................................................................................................................................... 7

Switchboard ..................................................................................................................................... 8

F ow chart ......................................................................................................................................... 9

Safety Precautions

Intended Use / Operators ................................................................................................................ 11

Safety instructions on the unit ........................................................................................................ 12

Genera Safety Precautions ............................................................................................................. 13

Unit customised safety notices ....................................................................................................... 14

Maintenance instructions ............................................................................................................... 15

Transportation instructions / Safety regu ations .............................................................................. 16

Insta ation

Insta ation in c osed rooms ............................................................................................................ 18

Dimensions ...................................................................................................................................... 19

Minimum distances ........................................................................................................................ 20

Venti ation ...................................................................................................................................... 21

E ectrica Insta ation ................................................................................................................ 22 - 23

Operation

Important operation instructions .................................................................................................... 25

First commissioning ................................................................................................................. 26 - 28

Dai y commissioning ....................................................................................................................... 29

Fi ing procedure ............................................................................................................................. 30

Switch off the compressor .............................................................................................................. 31

Remedying fau ts

............................................................................................................. 32 - 36

Maintenance and Service

Service, Repair and Maintenance .................................................................................................... 38

Maintenance Lists / Maintenance Interva s ............................................................................... 39 - 42

Service Kits ..................................................................................................................................... 43

Check V-be t tension / Tension V-be t .............................................................................................. 44

Compressor ubrication ................................................................................................................... 45

Oi change ...................................................................................................................................... 46

Oi sieve change ............................................................................................................................... 47

Manua condensation dump system ............................................................................................... 48