TI STURMEY ARCHER S3B Instruction Manual

3-speed wide-ratio

Hub combined with

internal expanding brake

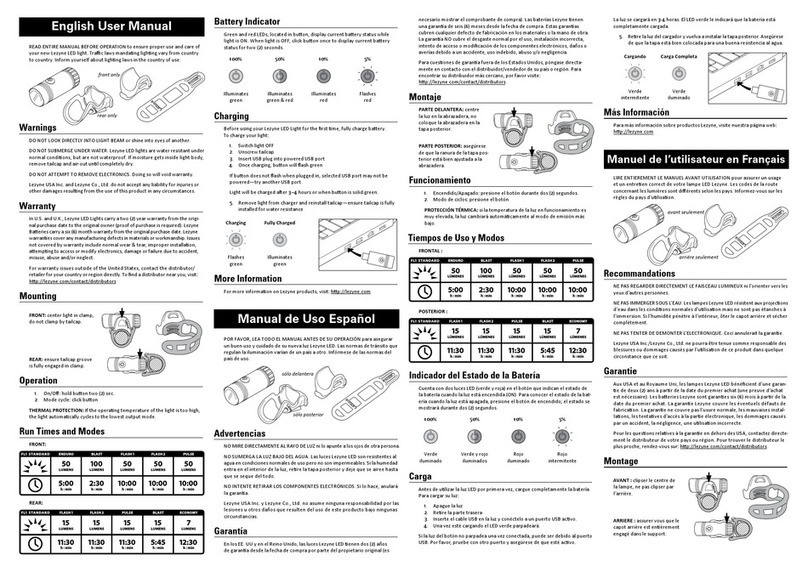

PHOTO No. SALES No. DESCRIPTION

1HSL 710 Brake Arm Clip complete

2HMN 118 Left-hand Axle Nut

3RMW 137 Axle Washer

4HMN 132 Locknut

5HMN 323 Nut for Brake Arm adjustment

6HSB 237 Brake Return Spring

7HSB 239 Rear Brake

8HMN 314 Left-hand Cone Locknut

9HSA 276 Left-hand Cone and Dust Cap

10 HSA 277 28H Shell

10A NSA 282 Water Shield—plastic

11 HSA 112 Pawl Pin

12 HSA 120 Pawl Spring

13 HSA II I Planet Cage Pawl

14 HSA 153 Planet Cage

15 HSA 116 Clutch Sleeve

16 NSA 117 Sliding Clutch

17 NSA 124 Axle Key

18 HSA 283 Thrust Ring

PHOTO No. SALES No. DESCRIPTION

19 HSA 119 Gear Ring Pawl

20 NSA 118 Gear Ring

21 HSA 280 Ball Ring

22 NSA 281 Driver Assembly

23 NSA 101 Right-hand Cone and Dust Cap

24 HSL 713 Sprocket 13T

25 BMW 127 Sprocket Spacing Washer

26 HSL 721 Sprocket Circlip

27 HM W 147 Cone Lockwasher

28 HMW 146 Spacing Washer IV Thick

29 HMN 129 Right-hand Axle Nut

30 HSA 262 Axle 51'

31 HSA 115 Planet Pinion

32 HSA 114 Pinion Pin

33 HSA 125 Indicator complete (51 Axle)

34 HSA 128 Clutch Spring

35 HSA 129 Clutch Spring Cap

36 HMN 134 Indicator Locknut

by )STURNEY

ARCHER(

SPARE PARTS LIST

AND SERVICE

INSTRUCTIONS

TO DISMANTLE THE S3B HUB

1. Remove left-hand locknut and brake adjuster nut. Lift out brake assembly.

2. Remove cone locknut and cone.

3. Unscrew right-hand ball ring from hub shell, using hammer and punch and

withdraw internals as a complete unit. One notch of the right-hand ball ring

should be marked and a piece of string or adhesive tape attached to spoke

adjacent to the marked notch.

The reason for this is that the right-hand ball ring has a two-start thread and

must be replaced in the same position to avoid having to retrue wheel after

re-assembly.

4. Remove the low gear pawls, pins and springs. The pawl pins are easily pushed

out of the planet cage to release the pawls and springs.

5. Place the left-hand end of the axle in a vice and remove the right-hand locknut,

washers if any, cone lock washer and cone, making a note of their arrangement

so that they can be replaced in their original positions.

6. Lift off, in the following order, the clutch spring and its cap, the driver, the

right-hand ball ring and the gear ring.

7. Remove the gear ring pawls, pins and springs. The pawl pins are easily pushed

out of the gear ring to release the pawls and springs.

8. Remove thrust ring and unscrew the indicator rod.

9, Push out the axle key and remove the sliding clutch and sleeve.

101 Lift off the planet cage complete.

111 Take Out the pron pins and remove the pinions from the planet cage.

POINTS TO CHOI

1. Slide the clutch up and down the driver prongs and check that the movement

is free.

2. See that there are exactly 24 balls (3/16" diameter) in the right-hand ball ring.

3. Examine the gear ring for cracks, chipping, or signs of wear on the internal

splines and teeth. Check also gear ring pawls for wear.

4. Check the truth of the axle between centres.

5. Examine all ball races for pitting or signs of wear.

6. Examine the sliding clutch for signs of wear (rounding off at the points of

engagement).

7. Examine all pinion teeth for signs of wear or chipping.

8. Examine the pinion pin ends for wear.

9. Examine the brake linings for signs of wear or oil.

10. Check that brake drum is free from oil.

TO RE-ASSEMBLE THE S38 HUB

1. Prepare the following preliminary sub-assemblies:

a. Fit the ball cage into the driver, with the ring of the ball-retainer facing

outwards and the recess in the dust cap also facing outwards. If a new

ball-retainer is being fitted, the dust cap also should be new. Replace the

sprocket and spacing washers in the arrangement noted when dismantling,

and add the circlip.

b. Fit the balls (only 24) and the inner dust cap to the right-hand ball ring,

making sure that the balls can revolve freely with the dust cap in place.

c. Fit the pawls, pins and springs into the gear ring. Place the gear ring, with

the teeth downwards, on a flat surface. Place a pawl spring along the side

of a pawl so that the loop is over the pin hole and the foot is under the

long nose of the pawl. While holding a pawl pin ready in the left-hand,

grip the nose of the pawl and the foot of the spring between the thumb and

forefinger of the right-hand and slide the pawl, tail first, between the flanges

of the gear ring. When the hole in the pawl and the loop in the spring

coincide with the holes in the flanges, push the pawl pin into position.

d. Smear grease in the channels of the dust caps of the driver and in the recess

of the right-hand ball ring. Do not use grease anywhere else.

2. Hold the left-hand end of the axle in a vice, so that the slot for the axle key

is above the sun pinion, and fit the planet cage.

3. Add the planet pinions and pins. (Small ends of the pins protrude).

4. Fit the sleeve (flange first), the sliding clutch (with the recess over the flange of

the sleeve), and the axle key (with the flat of the key facing upwards), and

screw in the indicator rod to hold them in that position.

5. Fit the thrust ring making sure that the flatted ends of the key engage

properly in the slots of the thrust ring.

6. Fit the previously prepared gear-ring sub-assembly.

7. Fit the previously prepared right-hand ball-ring sub-assembly.

8. Fit the previously prepared driver sub-assembly.

9. Drop the clutch spring over the axle.

10. Screw up the right-hand cone finger-tight. Then slacken it back half a turn

and lock it in that position with the special washer and locknut. On no account

must the cone be unscrewed more than half a turn, as that would throw the

gear mechanism out of adjustment.

11. Invert the assembly in the vice and fit the planet-cage pawls. Place a pawl

between the flanges, with the flat top surface pointing towards the right, and

insert a pawl pin through the outside flange and half-way through the pawl.

With tweezers grip the bent leg of the pawl spring in the right-hand and pass

the spring along the side of the pawl until the loop of the spring is in line with

the hole through the pawl and both legs of the spring are between the pawl

and the planet cage. The pawl pin can now be pushed right in.

12. Remove the assembled mechanism from the vice and, while holding it with

the planet cage uppermost„ pour about two teaspoonsfuls of Sturmey-Archer

oil into the cage. 1

13. Hold the cycle wheel in the left-hand, with the open (right-hand) end of the

hub shell facing downwards, and insert the assembled mechanism from below,

screwing up the right-hand ball ring finger-tight only.

14. Make sure that the ball ring comes into the same position as noted before

dismantling and then screw up tightly.

15. Fit the left-hand cone and locking-nut.

16. Replace the brake plate complete with shoes.

17. Fit the brake adjusting nut and the locknut.

18. Replace the wheel in the cycle frame and adjust the gear.

•

MAINTENANCE & GENERAL NOTES.

1. The hub provides three gears. The direct drive is in normal gear, top gear

provides a rise of 33.3% and low gear a drop of 25% from normal.

2. Sprockets.—A range of sprockets from 13T to 20T., also 22T., is available for

this hub.

3. It is important that the axle should be prevented from rotating in the chainstay

slots and the flats on the axle are provided for this purpose. If the fork ends

are too wide for the axle, special lock washers are supplied.

GEAR CHANGING

The gear change is quick and easy and should be made smartly. Continue

pedalling, but ease pressure on pedals whilst changing gear.

LUBRICATION

OIL Hub sparingly through the lubricator on hub shell. A few drops every

fortnight—Keep oil from brake arm and linings.

USE ONLY STURMEY-ARCHER OIL—DO NOT use thick oil or grease.

AUTO TWIST GRIP-SERVICE NOTES

IMPORTANT.—This unit is factory assembled for fitting directly on to the

bicycle handlebars.

The Grip must NOT be twisted until fitted to the bicycle and the gear cable

connected to the gear indicator rod at the hub as described below.

TO FIT TWIST GRIP CONTROL TO BICYCLE

I. Slide control on to handlebar as far as possible, adjust grip to required pos

Now tighten fixing screws.

2. Fit Fulcrum Clip to cycle frame top tube (or chain stay as required).

3. Pass cable inner wire through Fulcrum Clip and fit wire into clip slot.

4. Push Outer Cable up to Fulcrum Slot.

.5. If pulley used, fit inner wire under arm and on to pulley wheel.

TO SET GEARS

Turn Grip to No. 3 (High Gear) position:

1. Connect control cable to gear indicator chain at hub.

2. Slide Fulcrum Clip to take up any slackness in Cable. Now tighten Clip Screw.

3. Twist the grip until bottom gear (No. I) is indicated, i.e., the blue coloured

section can be seen through top casing aperture. Continue to turn grip until

no further movement can be obtained.—

All three gears are now automatically in adjustment.

4. Remember to screw gear indicator locknut up to cable adjuster and lock

tightly.

NOTE—If for any reason the twist grip is turned too far, i.e., no colour can

be seen through the aperture of the locating spring — all the cable adjustment

will have been taken up. The twist grip must be dismantled and the gear

indicator spring refitted: See Assembly Notes.

FIT NEW CABLE

RESET GEAR LOCATING SPRING

ASSEMBLY OF TWIST GRIP MECHANISM

1. First fit detent spring (7) and the 3/16" dia. ball (6) into recess in operating

sleeve (5) — (use grease to hold spring and ball into position).

2. Fit cable nipple into slotted recess of operating sleeve.

3. Fit cable inner wire into slot of gear locating spring (3) and position this

spring over operating sleeve. Check that 3/16" dia. ball is positioned in elon-

gated hole of gear locating spring.

4. Keeping thumb of right hand over ball and spring, feed inner wire into cable

slot of bottom half of casing (2). Now press locating spring into casing —

until spring clicks right down into its groove.

5. Fit top of casing (4) over operating sleeve, and holding two halves of casing

together, fit clamping screws (8).

6. Refit Twist Grip on to Handlebar, and take up any slackness in Control

Cable. Set gears as described.

HUB CONE ADJUSTMENT

The right-hand cone is fixed during factory assembly and should not be

touched.

Adjust hub bearings from the left side, Remove brake locknut and brake

adjusting nut. Lift off brake arm complete with shoes and linings (handle

carefully); do not allow grease to contact brake linings. Using special spanner

(HTR 127) hold cone whilst loosening cone locknut. Rotate cone as required

—afterwards remember to tighten cone locknut.

Acorrectly set wheel should run freely with a trace of side play at the rim.

NOTE.—If, for any reason, the rear wheel is removed from the bicycle,

remember to fit a bush in the brake arm clip bolt hole and then tighten the

brake arm clip when wheel is re-fitted.

BRAKE ADJUSTMENT

NOTE—During the first few miles of running, brake linings will "bed down"

ion, and the brake will need re-adjustment.

Slacken off locknut (A) and tighten Adjuster

(B) so that the brake linings are just in contact

with the drum, then slacken adjuster until the

wheel spins freely. Tighten locknut.

N.B. Cable Pinch Bolt must be tight.

Fit Bush HSB242 here

Note-The major cause of trouble is faulty gear adjustment. Check to see that

the Outer shoulder of the indicator is level with the end of axle when gear control

lever is in No. 2 gear position. If the complaint is sluggish gear change or stiffness

Symptom Fault Remedy

No low gear (1st). I. Low gear pawls upside down or pointing in wrong

direction.

I. Re-assemble pawls correctly.

2. Sliding clutch thrust collar not seating over axle key. 2. Fit thrust collar correctly.

3. Incorrect axle spring. 3. Fit correct axle spring.

Slipping in low gear (1st). I. Sliding clutch 'nosed' off, due to bad adjustment. I. Fit new sliding clutch and adjust correctly.

2. Indicator not screwed home fully. 2. Screw indicator home.

.Right-hand cone wrongly adjusted. 3. Re-adjust right-hand cone.

4. Bad cable ends or kinks in wire. 4. Fit new control cable.

5. Twisted gear indicator chain through over-tightening. 5. Replace or refit as required.

Fluctuating between low gear (1st)

normal gear (2nd).

I. Faulty or worn gear ring pawls. I.

,

Change both gear ring pawls.

Slipping in normal gear (2nd). I. Gear ring dogs and/or sliding clutch 'nosed' off due

to bad adjustment.

I. Fit new gear ring and/or sliding clutch.

2. Indicator not screwed home fully. 2. Screw Indicator home.

Slipping in top gear (3rd). I. Pinion pins or sliding clutch badly worn due to bad

adjustment.

I.

,

Fit necessary new parts, and check adjustment.

.

2. Very weak or distorted axle spring. 2. Fit new spring.

3. Incorrect right-hand cone adjustment. 3. Re-adjust.

4. Grit between clutch sleeve and axle. 4. Clean away grit.

Hub runs stiffly. Drag on pedals I. Too many balls in ball ring. I. 24 balls.only should be fitted.

when free-wheeling. 2. Cones excessively tight. i. Re-adjust cones.

3. Chainstay ends not parallel. 3. Correct chainstay ends. Ills essential that the ends are

parallel, otherwise the axle will be strained when the

nuts are tightened and the internals may be seriously

affected.

4. Corrosion due to inferior oil or lack of lubrication. 4. Clean hub thoroughly and use only Sturrney-Archer oil.

5. Distorted dust caps. 5. Check dust caps and replace those showing distortion,

or signs of binding.

Sluggish gear change. I. Distorted axle spring. I. Replace spring.

2. Bent axle. 2. Replace axle.

3. Worn gear indicator chain link. 3. Replace indicator and chain,

4. Lack of lubrication of control cable, or frayed control

wire.

4. Lubricate control wire or replace.

Poor Braking. I. Oil on brake linings. I. Replace brake assembly.

Brake feels spongy, 1. Incorrect brake adjustment. I. Re-adjust Brake-see notes.

2. Loose cable pinch-bolt. 2. Fully tighten pinch-bolt (use spanner).

Stiff hand brake lever action. I. Cable inner wire not free. I. Lubricate full length of inner wire.

Brake is stiff or sticks in the "on" position. I. Incorrect brake arm adjustment. I. Ensure that the brake-arm has free movement - check

brake arm adjustment - ensure that brake arm adjus-

tMg nut is loosend at least half a turn - then tighten

Iocknut.

Also fit metal bush (HSB 242) through clip bolt hole in

brake arm.

Tighten clip bolt securely.

PRINTED IN ENGLAND

12/60/S.31188

GEAR AND BRAKE CORRECTION GUIDE

this may point to lack of oil. Hub should be oiled and re-tested before going,

further. If the fault persists, the following chart should locate the trouble.

APRODUCT OF RALEIGH INDUSTRIES LTD., NOTTINGHAM