Tides Marine SmartSeal User manual

Installation Manual

Temperature Sensor System

®

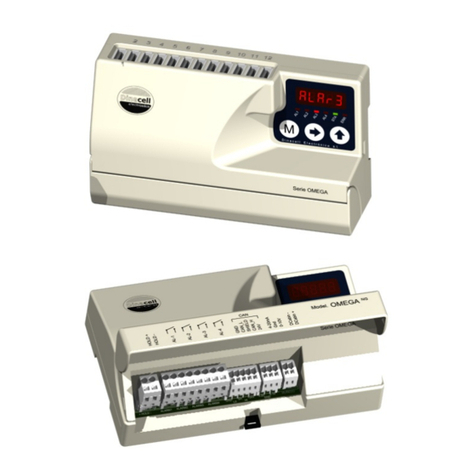

SmartSeal

Main Control Unit

12V Battery

NMEA 2000

Terminator

Male

NMEA 2000

Terminator

Female

NMEA

2000

Tee

Connector

NMEA

2000

Power

Tee

Sensor

Cable

To Water

Pick-Up

NMEA 2000

Drop Cable +-

Fuse

Ignition

or Inline

Switch

To Neutral

Safety Switch

Siren

Table Of Contents

Smart Seal System Introduction

System Overview .........................................................................

Functional Overview .....................................................................

Installation Overview ....................................................................

System Components

Main Control Unit ..........................................................................

External Siren ...............................................................................

Remote Monitoring Unit ................................................................

Sensor / Cabling ...........................................................................

Network Hardware ........................................................................

Installation

Step One: Main Control Unit..........................................................

Step Two: SmartSeal Harness-Connecting...................................

Temperature Sensor

Step Three: Connecting the Neutral Safety Switch........................

(non-NMEA Vessels)

Step Four: Installing External Siren...............................................

Step Five: Remote Monitoring Units..............................................

Step Six: Connecting To Power......................................................

Reference

Installation Templates.....................................................................

NMEA 2000 Connector Pin-Outs....................................................

NMEA 2000 Network Fundamentals..............................................

System System Diagrams:

1- Single Engine- No Remote....................................................

2- Twin Engines- No Remotes...................................................

3- Single Engine With Remote...................................................

4- Twin Engines With 2 Remotes..............................................

5- Single Engine With Remotes - NMEA 2000 Equipped..........

6- Twin Engines With Remotes - NMEA 2000 Equipped..........

Specifications.................................................................................

Certifications..................................................................................

Warranty.........................................................................................

2

2

2

3

3

4

4

5

6

7

7

8

9

11

12

13

13

15

16

17

18

19

20

21

22

22

Introduction

This manual will describe how the SmartSeal system works, what

the various system components are and how to install them.

System Overview

The SmartSeal Temperature Sensor System is designed to

compliment Tides Marine’s SureSeal Shaft Seal Systems on

vessels with single or twin engines. Its purpose is to detect and

warn of various vessel conditions which could potentially lead to

shaft seal damage or failure. It is compatible with vessels which

utilize the NMEA 2000 communication protocol for connecting

marine electronics, sensors and display units to a backbone

network for centralized monitoring of various types of vessel

information. It is also designed to operate on non-NMEA 2000

equipped vessels as well on vessels with certain other networks

via a converter (e.g. NMEA 01830).

Functional Overview

The SmartSeal System is comprised of a number of components

designed to work with a wide range of vessel types and

installation needs. At the heart of the system is a Main Control

Unit which is located in the engine compartment. Connected to

this unit are temperature sensors for each shaft seal in use.

Remote Monitoring Units can be connected and placed in other

areas of the vessel as can a remote external siren. In operation,

temperature status data is displayed on both the Main and

Remote unit’s control panels. When connected to a vessel’s

NMEA 2000 onboard network, temperature data is also sent to the

main or auxiliary computer display. In the event that the

temperature of the shaft seal(s) or the engine compartment

exceeds the normal operating range limit, visible and audible

alerts are initiated so that corrective action can be taken.

Installation Overview

This manual describes the installation procedures for the various

Smart Seal system components. There are many different types of

installations possible. Six system configurations are illustrated and

should be reviewed prior to beginning.

2

System Components / Features:

Siren

P/N SP-SS-SIREN

Main Control Unit,

Bulkhead Mount

Single Engine

P/N TPS-BH-SE

Main Control Unit,

Bulkhead Mount

Twin Engine

P/N TPS-BH-TE

Main Control Unit

External Siren

PORT Side

Harness

Connector

STBD. Side

Harness

Connector

Ambient Temp.

Sensor

Temp. Status

Indicators

Alarm/Siren

Control

Onboard Alarm

Speakerl

Remote Unit

/ NMEA 2000

Connector

3

Remote Monitoring Unit,

Bulkhead Mount

Single Engine

P/N TPS-RSBH

Sensor Cable

Extension,

Length 10M

P/N TPS-SCE

Harness- (Sensor,

Siren, NSS)

Length 10M

P/N TPS-SC

Remote Unit Monitoring,

Panel Mount

Single Engine

P/N TPS-RSPN

Remote Monitoring Unit

SmartSeal Cabling

Remote Monitoring Unit,

Panel Mount

Twin Engine

P/N TPS-RDPN

Temp. Status

Indicators

Onboard Alarm

Speaker

Remote Unit,

Bulkhead Mount

Twin Engine

P/N TPS-RDBH

Main Control Unit

/ NMEA 2000

Connector

4

Network Hardware

System Components:

N2K Drop Cable,

Length 1M

P/N TPS-DC-1M

N2K Drop Cable,

Length 10M

P/N TPS-DC-10M

N2K Tee Connector

P/N TPS-T-CONN

N2K Power Tee

P/N TPS-PC

N2K Terminator, Male

P/N TPS-TERM-MALE

N2K Terminator, Female

P/N TPS-TERM-FEMALE

5

Installation

The following outlines the recommended installation procedure for

the SmartSeal system.

Step One: Installing the Main Control Unit

The Main Control Unit (MCU) is to be located in the engine

compartment mounted on a bulkhead / vertical surface where the

front panel is both visually and physically accessible.

Placement should also allow for the most direct routing of

wires/cables.

The unit has two types of connectors on the bottom of its

enclosure. The first is used to connect the SmartSeal wiring

harness for connecting the shaft seal sensor(s), neutral safety

switch (non NMEA vessels) and optional remote siren. The second

is used for connecting the Remote Monitoring Unit (RMU) and

12VDC power source or to connect to an existing NMEA 2000

network.

Using the mounting flanges on the enclosure, the unit should be

leveled and affixed with SS pan head screws. A full size template is

included for hole placement.

Mounted MCU

Cable / Harness Connectors

6

Step Two: Smart Seal Harness- Connecting the

Temperature Sensor(s)

The shaft seal temperature sensor is pre-attached to the black

SmartSeal harness cable. It needs to be connected to the water injection

fitting on the SureSeal being used. Connect the harness connector to the

MCU then route the sensor cable to the shaft seal. Twin engine systems

have two harnesses included, one for each SureSeal.

To connect the sensor to the injection fitting, remove one of the clamp

screws (philips head screw driver and 5/16 wrench required) and open

the clamp. Reassemble the sensor clamp around the shoulder of the

fitting just below the water pick-up hose attached to the fitting. Tighten

fully and check that the sensor is secure. Dress the cable(s) back to the

MCU to avoid snagging/accidental damage. Screw-mount zip ties are

recommended for wire management. If additional wire is needed, a 10M

extension cable is available. Excess wire should be bundled and

secured. Sensor cables CANNOT BE SHORTENED.

Step Three: Connecting The Neutral Safety Switch

(For Non- NMEA 2000 Vessels)

An In-Gear connection is required on vessels not equipped with a NMEA

2000 network. For a twin engine vessel, both in-gear connections must

be made, one for each transmission. Typically, the connection is made

using the Neutral Safety Switch (NSS) installed in the transmission but, if

necessary, the connection can also be made at the helm shifter control.

See following diagrams for both types of connections.

The grey harness cable is used for the NSS. Connect the white wire to

the NSS switch + and the brown wire to the NSS - terminal. Route and

dress the NSS cable to the MCU. NSS cables can be shortened as

necessary. Unused NSS cables (NMEA 2000 applications) can be cut but

should be properly capped and not left exposed.

Temperature Sensor Attaching Sensor to fitting

(water hose removed for photo)

Finished connection

7

Step Four: Connecting The External Siren

(Optional)

The Siren is a recommended accessory due to typically noisy

engine rooms. Several different types of sounds can be selected

depending on how the unit is wired. The brown harness cable is

for the external siren. Connect the white (+) wire to the siren

terminal marked 12V and the brown (-) wire to the sound terminal

of your choice. Mount the siren to a surface where it will not be

exposed to moisture as they are not waterproof. Route and dress

the siren cable to the MCU. Siren cables can be shortened as

necessary. Unused siren cables (twin engine installations use

only one siren) can be cut but should be properly capped and not

left exposed.

Transmission NSS Connection Helm Shifter NSS Connection

Battery

+

+12VDC /

24VDC

-

--

-

--

-

--

-

--

Ignition

Switch

In-Gear

Indicator

(possible)

Gear+

(To MCU)

Gear+

(To MCU)

Gear+

(To MCU)

Gear+

(To MCU)

Starter

Solenoid

Vessel Ground Vessel Ground

Neutral

Safety

Switch

(Closed = Neutral)

Neutral

Safety

Switch

(Closed = Neutral)

8

Step Five: Connecting Remote Monitoring Unit(s)

The Remote Monitoring Units (RMU) are display extensions of the Main

Control Unit. On larger vessels, one or more RMUs are typically installed

in locations where they can be easily monitored.

Two mounting configurations are offered: Surface / Bulkhead mount

(identical to the Main Control Unit), and a panel mount design for

installing into Consoles or Helm Stations. A full size template is included

for panel mounting. Panel mount units have an integral gasket on the

underside of the flange to seal against moisture ingress in wet locations.

Both configurations are IP 66 Rated.

Surface mount remote units have their connector on the bottom like the

MCU and Panel mount versions have their connector on the back.

NOTE*

This part of the installation involves connecting to an existing NMEA

2000 network or (in the absence of a NMEA 2000 network), creating a

private SmartSeal system network. If not familiar with these types of

networks please read the Fundamental Network Tips pp.xx before

beginning.

For NMEA 2000 Installations:

Locate the point of the NMEA 2000 network where tie in will be easiest.

Ideally this will be centrally located and relatively close to the 12V power

source connection. If there are unused/ terminated tee connectors

available, run drop cables from them to the MCU and RMU units. If there

are no unused connections available, you must add them by inserting

tees to the existing network as follows:

Connect two N2K tee connectors together using the mating side legs.

Insert this tee assembly into the backbone run such that both remaining

side connectors are connected to their mating counterparts of the

existing network. Use the two new tee connections to connect the MCU

and RMU(s).

9

NMEA 2000

Terminator

Male

NMEA

2000

Tee

Connector

NMEA

2000

Tee

Connector

NMEA

2000

Power

Tee

Drop Cable

To RMU

Drop Cable

To MCU To 12V

Battery

NMEA 2000

Terminator

Female

Existing

NMEA 2000

Network

Additional SmartSeal

NMEA 2000

Network Components

12V Battery

+-

NMEA 2000

Terminator

NMEA 2000

Tee

Connector

NMEA 2000

Drop Cable

To RMU

NMEA 2000

Drop Cable

To MCU

Drop Cables

To Electronics

NMEA 2000

Tee

Connector

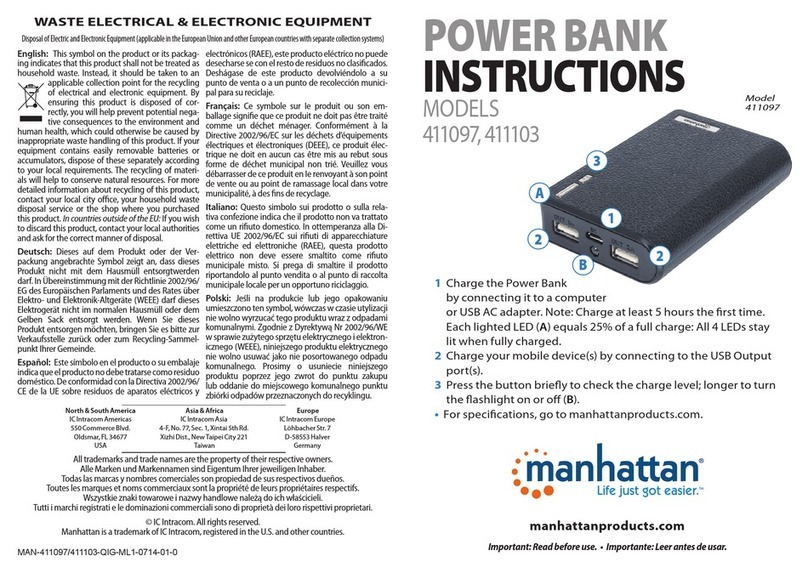

For Non-NMEA Installations:

Plan the mounting location for the RMU so that it can be connected

to the MCU directly using network drop cable(s). Tides offers several

cable length options. (10M, 4M, 2M, 1M plus bulk wire)

Connect a N2K tee connector to each side of a Power Tee. Add both

Male and Female terminators to the remaining two side legs.

Connect the drop cable from the RMU to one of the N2K connectors.

Connect the Drop Cable from the MCU to the other N2K connector.

The Power Tee cable is used to connect to the 12VDC power supply.

10

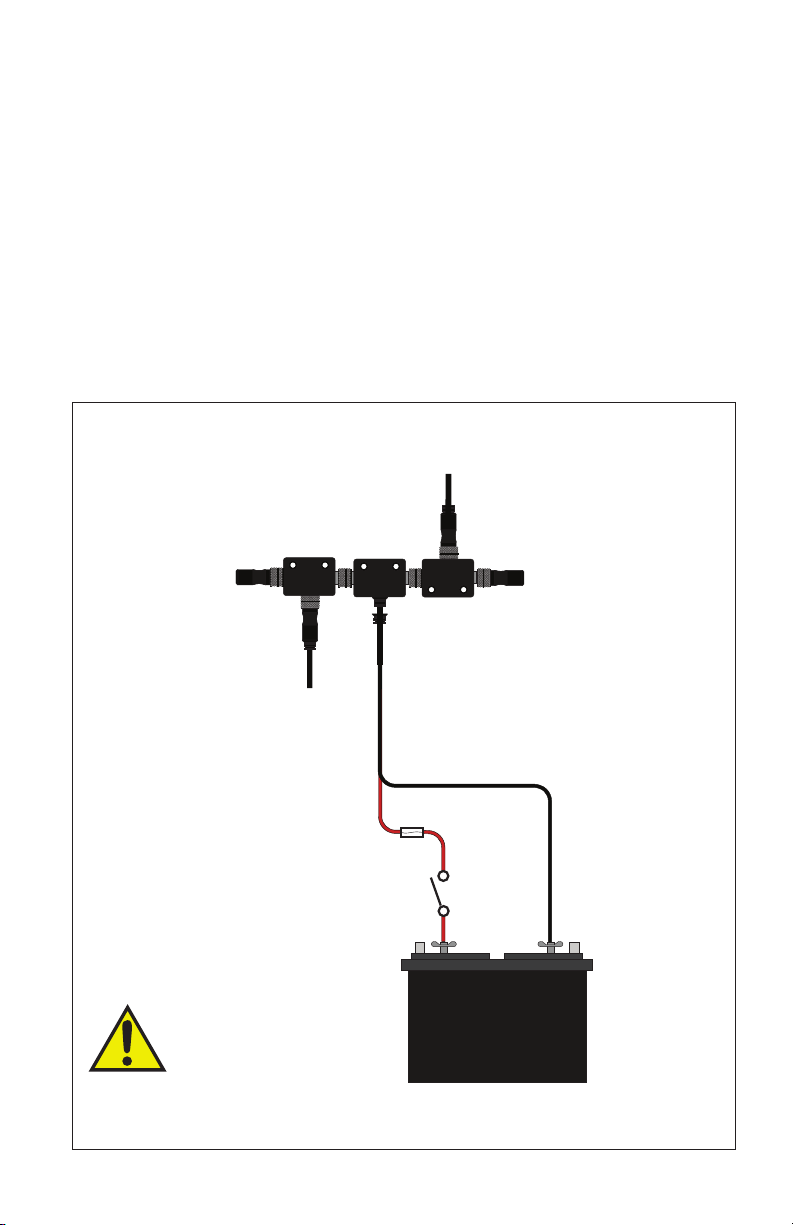

Step Six: Connecting To Power

(For Non-NMEA 2000 Vessels)

SmartSeal Systems which are connected to NMEA 2000 networks,

do not need to be separately connected to the power source as

the network is already connected and provides the necessary

operating power

Connect the Power Tee cable to a 12VDC Battery as shown below.

Make sure the + wire is fused.

DO NOT USE A VOLTAGE SOURCE

THAT IS NOT 12VDC +/- 3VDC AS IT

WILL DAMAGE THE SMARTSEAL SYSTEM

12V Battery

+-

Fuse

Ignition

or Inline

Switch

NMEA 2000

Terminator

Male

NMEA

2000

Tee

Connector

NMEA

2000

Tee

Connector

NMEA

2000

Power

Tee

Drop Cable

To RMU

Drop Cable

To MCU

NMEA 2000

Terminator

Female

11

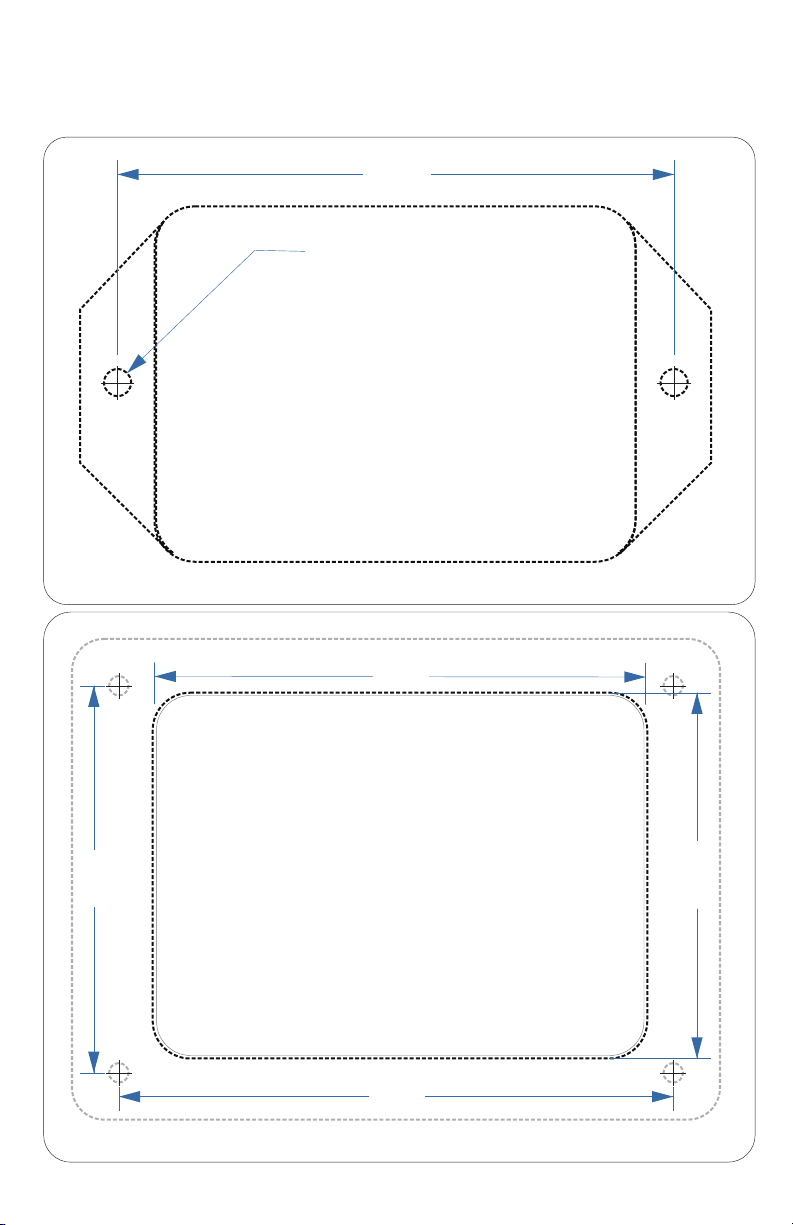

MCU / RMU Surface Mount Template

Panel Mount- RMU Template

Cut On Dotted Line

Cut On Dotted Line

Cut On Dotted Line

Cut On Dotted Line

3.87"

.188 DIA. TYP. 2 PL

FOR #8 SCREW

Mounting / Cutout Templates

3.41"

2.54"

3.85"

2.69"

12

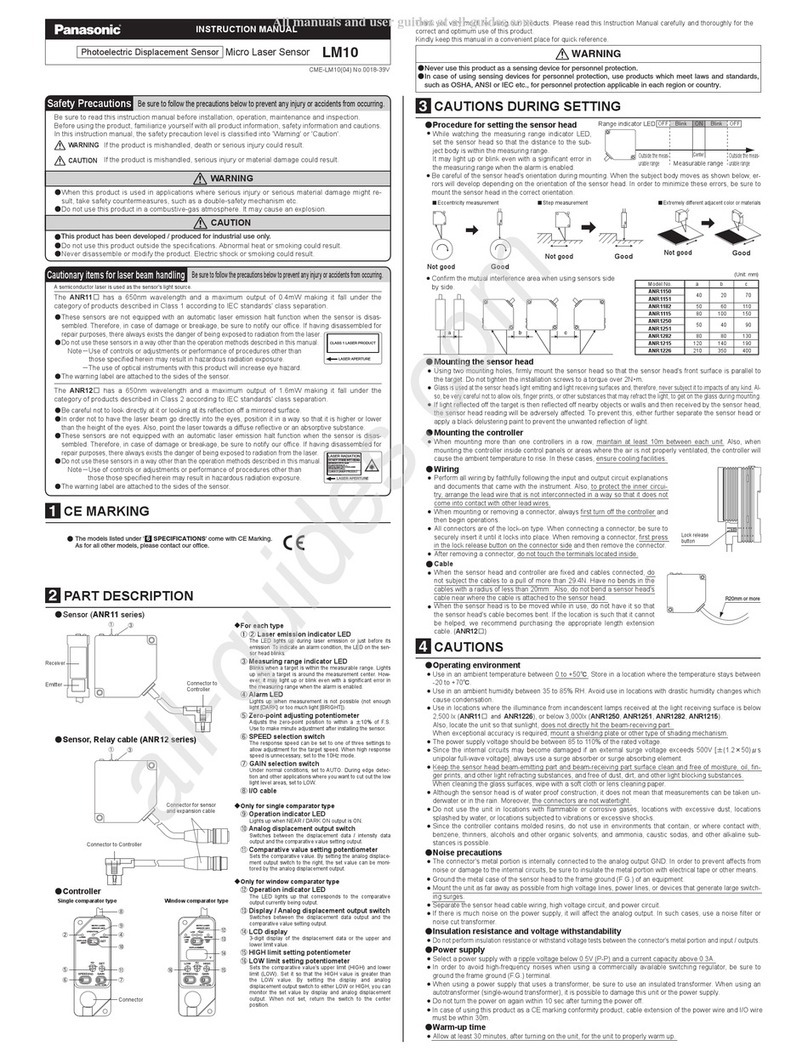

NMEA Network Fundamentals / Tips

NMEA 2000

11

55 22

33

44

MaleFemale

Pin 1: Shield

Pin 2: NET-S. (Power Supply +)

Pin 3: NET-C. (Power Supply -)

Pin 4: NET-H. (CAN-H)

Pin 5: NET-L. (CAN-L)

Connector Pin-Outs

NMEA 2000 plug-and-play components make it easier than ever to

integrate marine electronics, allowing you to view, control and share

functions and information across a network of displays. Yet there are

some do’s and don’ts that ensure that your NMEA 2000 cable and

connections function properly. Here are six Network Fundamentals tips:

(courtesy of Garmin)

13

1 Power Up the Network

Remember that an NMEA 2000 network requires 12-volt DC power.

Special connectors with positive and ground wires (with inline fuses for

the positive wire) let you supply onboard power to the so-called

backbone – the main communication channel for the system. These

power cables should be connected near the center of the backbone in

order for the system to function properly.

2 Use 12 Volts DC Only

Make sure any power source you choose is 12 volts DC; do not

connect your NMEA 2000 network to any other power source such as

24 volts DC.

3 Avoid Long Strings of T-Connectors

As you add NMEA 2000-compatible electronics and sensors to the

backbone, there’s a tendency to string a number of T-connectors while

tying into the system. This is a mistake, as a long series of T-

connectors is prone to damage and broken connections. Replace these

long strings with T-junctions – two to four unified T-connectors. These

are more robust and compact; a four-way T-junction is 25 percent

shorter than a string of four connectors.

4 Keep Drop Cables Short

Avoid using long drop cables (the cables that connect your electronics

to the backbone). NMEA 2000 signals can be hampered by resistance,

which causes a reduction in voltage. The maximum length for a single

drop cable is 20 feet. If you require a longer cable run to connect an

item such as a transducer or sea-surface temperature sensor, use a T-

junction to either at the end or the middle of the run to tie in 12-volt

power. Augmenting the power in this manner helps prevent an

excessive drop in voltage.

5 Use the Sides of T-Connectors to Build a Backbone

By using only the sides of the T-connectors to assemble an NMEA

2000 backbone, you create a linear format. Also, use only the top of the

T-connector to attach devices and sensors.

6 Don’t Forget the Terminators

An NMEA 2000 backbone requires terminators at each end. You need

to use one female terminator and one male terminator at opposite ends

of your NMEA 2000 linear backbone.

14

Main Control Unit

12V Battery

NMEA 2000

Terminator

Male

NMEA 2000

Terminator

Female

NMEA

2000

Tee

Connector

NMEA

2000

Power

Tee

Sensor

Cable

To Water

Pick-Up

NMEA 2000

Drop Cable +-

Fuse

Ignition

or Inline

Switch

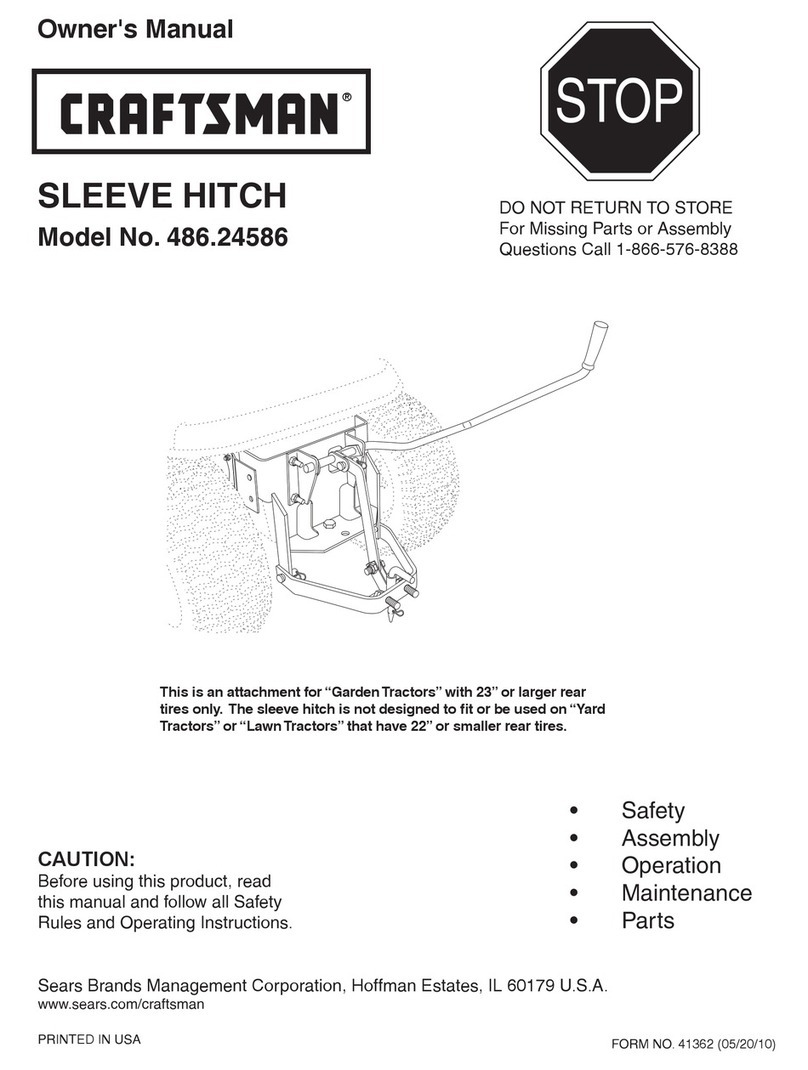

NOTE*

Tee connectors may be

connected directly to each

other or with Drop Cables

depending on installation.

To Neutral

Safety Switch

Siren

Single Engine Vessel, Without Remote

Normal Critical

Warning

Temperature Sensor

®

SmartSeal

TIDESMARINE

Schematic System Diagram 1

15

Main Control Unit

12V Battery

NMEA 2000

Terminator

Male NMEA 2000

Terminator

Female

NMEA 2000

Tee Connector

NMEA 2000

Power Tee

NMEA 2000

Drop Cable

Port

Sensor

Cable

Stbd.

Sensor

Cable

To Port

Neutral Safety Switch

To Stbd.

Neutral Safety Switch

To Water

Pick-Up

Port Engine

To Water

Pick-Up

Port Engine

Crossover Water Line Between Seals

NMEA 2000

Drop Cable

+-

Fuse

Ignition

or Inline

Switch

NOTE*

Tee connectors may be

connected directly to each

other or with Drop Cables

depending on installation.

Twin Engine Vessel, Without Remote

Siren

Normal Critical

Warning

Temperature Sensor

®

SmartSeal

TIDESMARINE

Port

Starboard

Schematic System Diagram 2

16

Main Control Unit

Sensor

Cable

To Water

Pick-Up

NMEA 2000

Drop Cable

To Neutral

Safety Switch

Siren

Normal Critical

Warning

Temperature Sensor

®

SmartSeal

TIDESMARINE

Remote Monitor Unit

(panel mount shown)

NMEA 2000

Terminator

Male

NMEA

2000

Tee

Connector

NMEA

2000

Tee

Connector

NMEA

2000

Power

Tee

NMEA 2000

Drop Cable

NOTE*

Additional

Remote Units

may be added to

the system

through the use

of additional Tees

12V Battery

NMEA 2000

Terminator

Female

+-

Fuse

Ignition

or Inline

Switch

Normal Critical

Warning

Temperature Sensor

®

SmartSeal

TIDESMARINE

Single Engine Vessel, With Remote

Schematic System Diagram 3

17

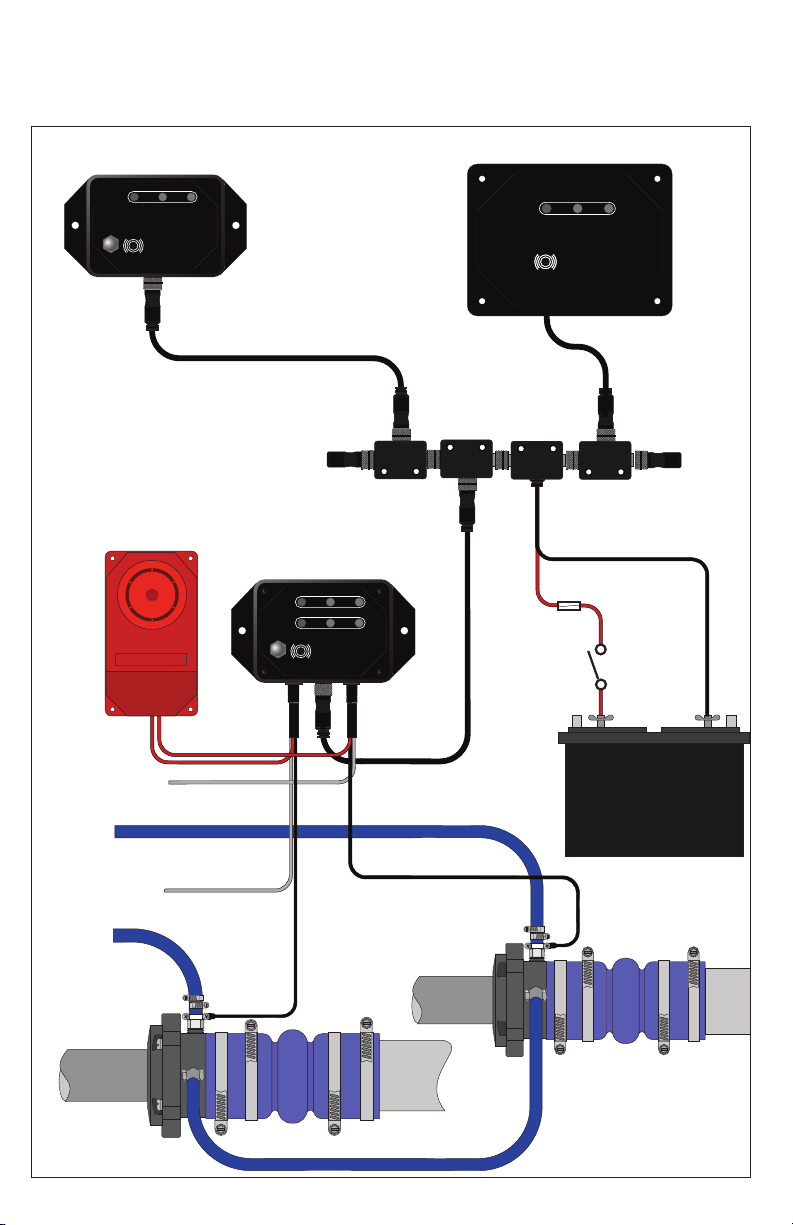

Main Control Unit

Port

Sensor

Cable

Stbd.

Sensor

Cable

To Port

Neutral Safety Switch

To Stbd.

Neutral Safety Switch

To Water

Pick-Up

Port Engine

To Water

Pick-Up

Port Engine

Crossover Water Line Between Seals

NMEA 2000

Drop Cable

Siren

Normal Critical

Warning

Temperature Sensor

®

SmartSeal

TIDESMARINE

Port

Starboard

Remote Monitor Unit

(panel mount )

Remote Monitor Unit

(surface mount )

NMEA 2000

Terminator

Male

NMEA

2000

Tee

Connector

NMEA

2000

Tee

Connector

NMEA

2000

Power

Tee

NMEA 2000

Drop Cable

NMEA 2000

Terminator

Female

12V Battery

+-

Fuse

Ignition

or Inline

Switch

Normal Critical

Warning

Temperature Sensor

®

SmartSeal

TIDESMARINE

Normal Critical

Warning

Temperature Sensor

®

SmartSeal

TIDESMARINE

Twin Engine Vessel, With 2 Remotes

18

Schematic System Diagram 4

NMEA 2000

Terminator

NMEA 2000

Tee Connector

NMEA 2000

Drop Cable

NMEA 2000

Drop Cable

(connection to

NMEA network)

Sensor

Cable

To Water

Pick-Up

NMEA 2000

Drop Cable

NMEA 2000

Tee Connector

Existing NMEA 2000 Network

Main Control Unit

12V Battery

+-

Siren

Normal Critical

Warning

Temperature Sensor

®

SmartSeal

TIDESMARINE

Normal Critical

Warning

Temperature Sensor

®

SmartSeal

TIDESMARINE

Remote Monitor Unit

(surface mount shown)

NMEA 2000 Network Equipped, Single Engine Vessel, With Remote

Schematic System Diagram 5

19

Table of contents

Popular Accessories manuals by other brands

Foerster

Foerster CIRCOGRAPH DS operating instructions

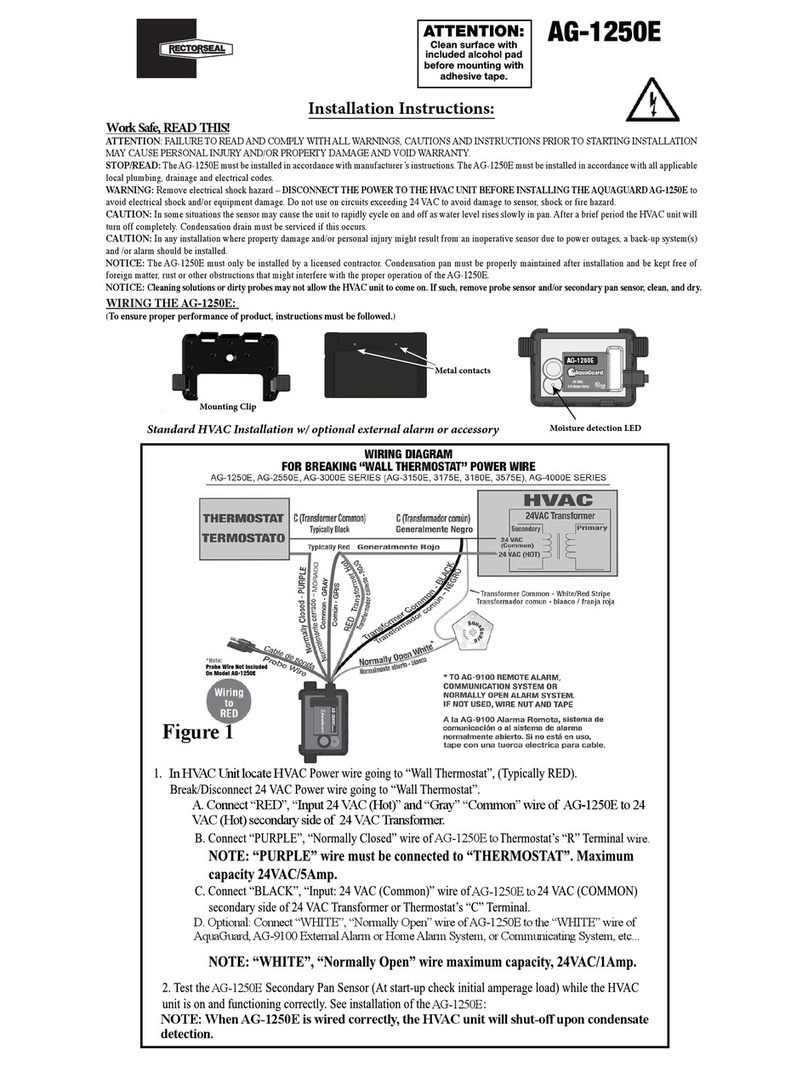

RectorSeal

RectorSeal AG-1250E installation instructions

novotechnik

novotechnik RFC-4800 user manual

Grundfos

Grundfos Pt100 instructions

Genius

Genius EasyPen M610X user manual

Honeywell

Honeywell Ex-Or MSB1001T Installation and commissioning instructions

Qdos

Qdos StayPut Easy installation guide

PCB Piezotronics

PCB Piezotronics IMI SENSORS 642A00 Installation and operating manual

ekwb

ekwb EK-FC970 GTX WF3 Backplate Installation and mounting manuals

Rockler

Rockler Titanium Gold Pioneer instructions

WMF

WMF Ambient Herbs home Single operating manual

IFM

IFM SI 5000 manual