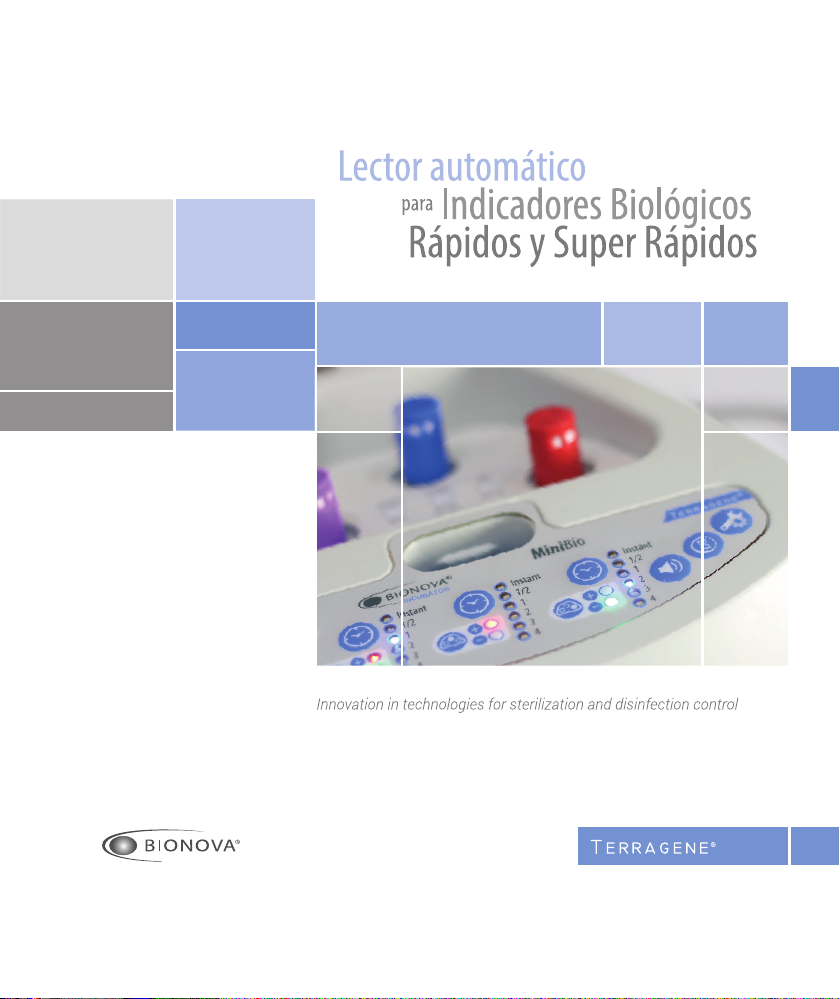

Terragene BIONOVA MiniBio User manual

Rev.0 | August 2017

MiniBio

Bionova® MiniBio Page 3

Bionova® MiniBio incubator has been designed to in-

cubate BT110 Rapid Readout Self-Contained Biological

Indicators (BIs) for Ethylene Oxide sterilization proces-

ses control, BT220 and BT221 for Steam sterilization

processes control, BT102 for Formaldehyde steriliza-

tion processes control, BT95 for Plasma or Vaporized

Hydrogen Peroxide sterilization processes control and

Super Rapid Readout Self-Contained Biological Indica-

tors BT222 and BT223 for Steam sterilization processes

control.

Microorganisms contained within the Biological Indi-

cators vary depending on the sterilization process for

which they have been designed, therefore, incubation

temperatures dier depending on the indicator. Indica-

tors for Ethylene Oxide (EO) sterilization control, should

be incubated at 37 ºC, while those involved in the mo-

nitoring of the rest of the sterilization processes should

be incubated at 60 ºC.

Simultaneous incubation of BIs for EO processes

control along with BIs monitoring the other pro-

cesses, is not possible.

Bionova® MiniBio incubator allows easy and rapid de-

Use description

Composition

tection of positive and negative Biological Indicators.

Five incubation programs are available: 4 hours at 37

ºC, 3 hours at 60 ºC, 2 hours at 60 ºC, 1 hour at 60 ºC and

30 minutes at 60 ºC. A positive result can also be evi-

denced through color change of the culture medium,

which turns to yellow after 48 hours or 7 days of incu-

bation at 60 ºC for BT220/BT221/BT222/BT223/BT102/

BT95 and after a 7-day incubation at 37 ºC for BT110

BIs. Incubation times depend on internal protocols of

the laboratory or hospital. Incubator allows incuba-

tion time programs selection independently for each

one of three positions. Bionova® MiniBio incubator not

only allows results detection but also provides a prin-

ted ticket to record them. In addition, the auto-reader

can be connected to computers by USB. This allows to

link the results with the Bionova® Automatic Readout

and Traceability System for Sterilization Biological In-

dicators program. To download the latest software

version go to http://www.terragene.com.ar/products/

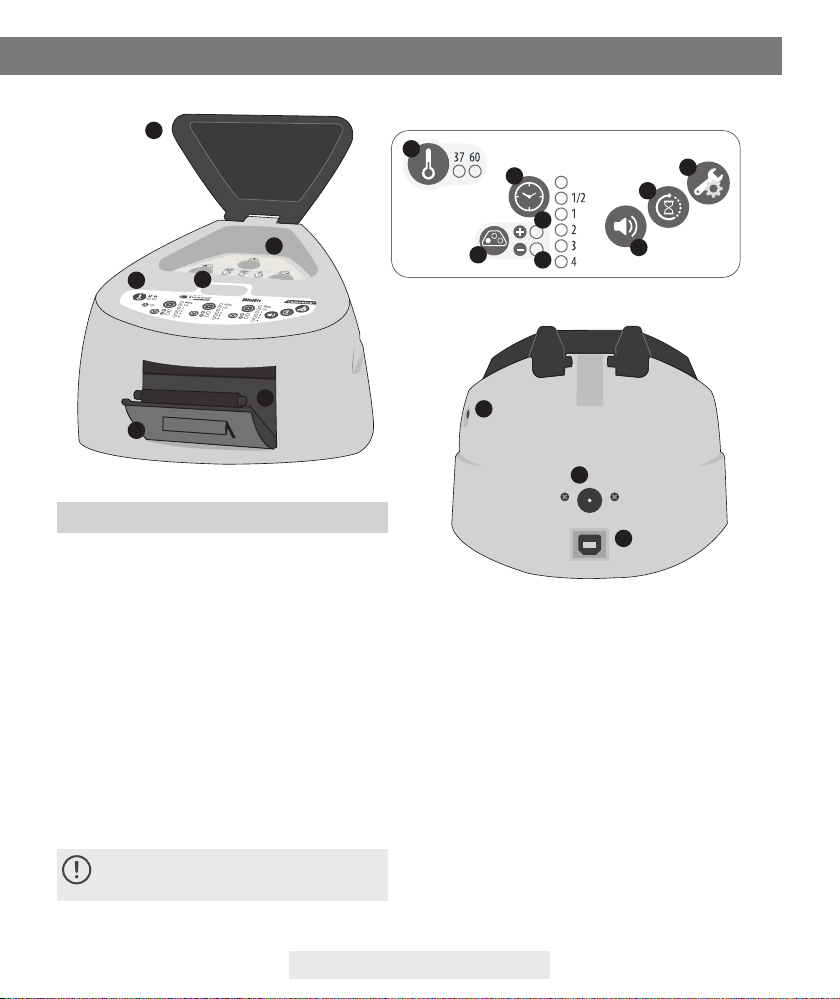

1

2

3

10

14

15

4

5

6

7

8

9

11

12

17

13

16

Instant

Bionova® MiniBio Page 4

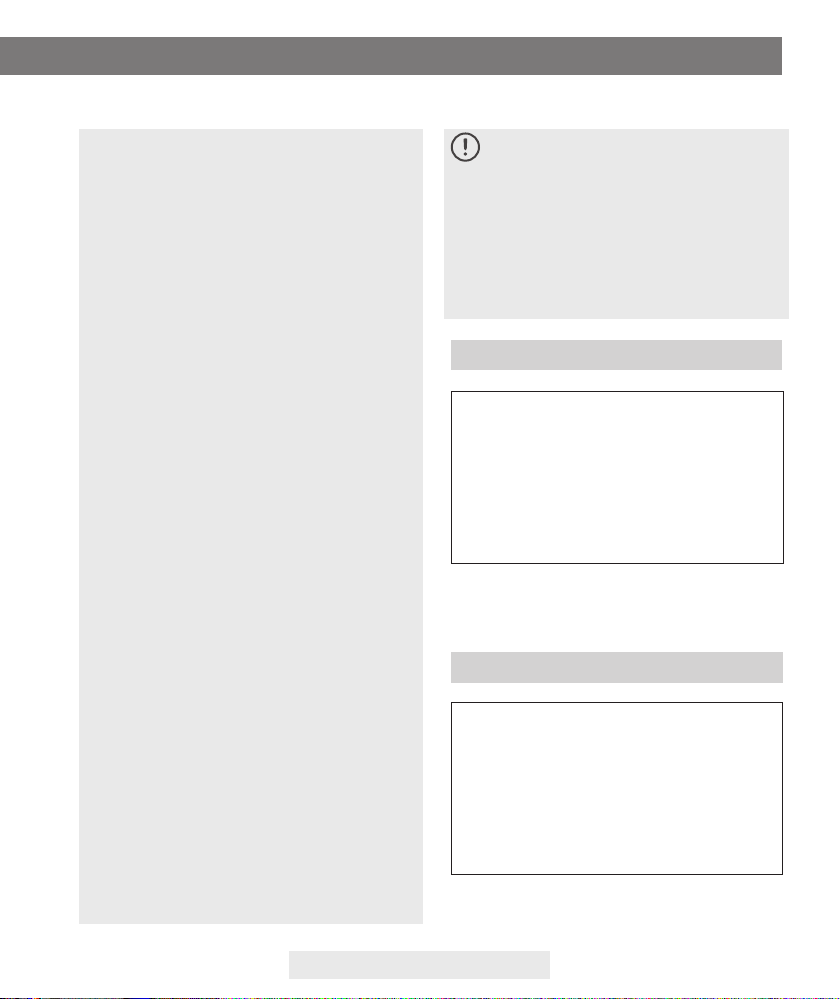

Protective Cover.

Green Light / Negative Indicator.

Red Light / Positive Indicator.

Incubation Position.

Programs Selectors for Incubation / Time Left

Control Panel.

Incubation Area.

1

2

3

4

5

6

7

8

9

10

Temperature Selector.

Sound Alarm Cancellation.

Thermal Printer.

11

12

13

14

15

16

17

Conguration / Paper Traction Button.

Cavity for paper.

USB Port.

Input for power source plug (12Volts DC).

Hole for external temperature control.

Reprint of Results.

Ampoule Crusher.

References

Safety information

Operating relative humidity.

Operating environmental temperature.

Caution, warning.

Caution: Risk of electric shock.

Caution: Hot surface.

Important, attention.

Manufacturer.

European conformity.

Serial number.

Direct current.

Product denomination.

Symbols

To avoid risks and damaging the equipment

-Do not place the incubator in an environment

exposed to direct sunlight or high intensity light

lamps.

-Do not place the incubator near devices that emit

electromagnetic elds.

-Do not use the equipment on vibrating surfaces.

-Do not pour any liquid inside.

-Do not immerse into any liquid.

-Use indoors only.

-Disconnect the power cord before cleaning.

-Do not use abrasive, corrosive cleaners or disin-

fectants.

-In case of technical fault, contact the manufactu-

rer for support. Please, do not try to open or repair

the incubator on your own, since this will imply the

loss of product warranty and could lead to a major

80 %

30 %

10 ºC

30 ºC

REF

infection-control/control-of-sterilization-processes/

incubators/minibio/, you can also download its opera-

tor’s manual from there.

Bionova® MiniBio Page 5

Power supply specications

Environment operating conditions

Input parameters

Voltage range

Frequency

Current

Output parameters

Voltage

Current

Operating

conditions

(100-240)

50/60

0,5

Values

12

2

Units

Volts

Hertz

Ampers

Units

DC Volts

Ampers

Terragene® recommends using a UPS instead of stabili-

zers, since the former has two functions: it stabilizes and

provides a continual power source during energy cuto.

Environmental conds.

Altitude

Operation temperature

Relative Humidity

Installation/overvoltage

Degree of contamination

Storage temperature

Voltage

Functional

conds.

3500 (máx.)

10-30

30-80

category II

2

0-50

12

Units

Meters

ºC

%

ºC

DC Volts

Safety information

and irreversible damage.

-Make sure that the incubator is connected to a

properly rate power cord.

To reduce the risk of using incompletely steri-

lized loads:

-Make sure to use each BI with its incubation and

reading program:

BT110 (green top) with 4 hs. 37 ºC program

BT220 (brown top) with 3hs. at 60 ºC program

BT221 (blue top) with 1 h. at 60 ºC program

BT222 (violet top) with 1 h. at 60 ºC program

BT223 (light blue top) with 30 min. at 60 ºC program

BT102 (red top) with 2 hs. at 60 °C program

BT95 (white top) with 2 hs. at 60 °C program

-Check that culture medium completely wets the

spore carrier.

-Do not remove the BI until the equipment reports

the nal readout result, check the impression of

the ticket.

To avoid the risk of injury, because of glass

fragments generated after the glass ampoule

inside the BI tube is crushed:

-Cool the BI during the indicated time before crus-

hing the ampoule.

-Do not handle the BI excessively since this might

cause the glass ampoule to burst.

-Wear safety glasses and gloves when removing

the BI from the sterilizer.

-Wear safety protective glasses and gloves to crush

the ampoule and to press the cap of BI.

To avoid a potentially hazardous situation:

avoid contact with the hot surface of the metal

incubator block.

To avoid BIs from absorbing uorescent resi-

dues: avoid BIs direct contact with chemical indi-

cators or tapes.

Do not use this product in a manner not specied

by Terragene® S.A., otherwise the protection provi-

ded by the product might be aected.

Do not replace the power supply cord for other not

provided within the product.

Only personnel authorized by Terragene® S.A can

access the inside of the incubator and its compo-

nents. Parts or components inside the machine

should not be manipulated by the user.

Serial/Batch Number

For easy identication, each Bionova® MiniBio incubator has

a unique serial number and a batch number printed on a

label found at the bottom of the incubator and on its packa-

ging. Please, register your serial number and batch number in

this manual for future reference:

Serial number:

Batch number:

Bionova® MiniBio Page 6

Instructions for use

Record Table

Use the following table to record rmware updates.

NOTE: manufacture rmware is printed on a label found

on the bottom of the incubator and on its packaging.

Please, register your manufactory rmware in this manual

for future reference:

Manufacture Firmware:

Fecha Versión Operador

Start-up

All devices are manufactured with the following

settings:

- Time zone: UTC +0:00

- Printing language: English

If you want to change the time zone, refer to Modication

of time zone section. If you want to change the print lan-

guage, refer to Modication of print language section.

1-Place the auto-reader on a rm surface, free from vibra-

tions, away from sunlight, currents of hot or cold air, che-

mical and corrosive or ammable substances. Do not pla-

ce the equipment in a way that disconnection of the plug

from the power supply could be dicult. Leave a gap of

at least 10 cm from the wall. Do not move the auto-reader

periodically or during its use. Connect the auto-reader to

a secure and stable electrical power source.

Do not wet or heat the auto-reader. If liquid is spi-

lled on the incubator, disconnect it and dry it im-

mediately. Before turning on, verify that all reading

positions of the MiniBio incubator are empty.

2-Turn on the incubator by connecting the end of the AC

of the power supply to the power source and then con-

nect the other end of the source (plug) on the rear of the

Bionova® MiniBio unit. The equipment will start by run-

ning the last time and temperature set-up.

3-Synchronize the Bionova® MiniBio incubator with lo-

cal time, using Bionova® software available in: http://

www.terragene.com.ar/products/infection-control/

control-of-sterilization-processes/incubators/minibio/.

Connect incubator USB port to the computer and start

the program. Bionova® MiniBio incubator unit will be

synchronized with computer time. This synchronization

can only be used when the reading positions are empty.

4- Check that required incubation temperature is correct.

To change it, press button 3 seconds. Lights corres-

ponding to 37 ºC and 60 ºC will start blinking, indicating

that the temperature program must be selected. Press

the button to select the incubation temperature pro-

gram, 37 ºC or 60 ºC. After 3 seconds, temperature modi-

cation will be accepted.

For 37 ºC, Bionova® MiniBio auto-reader will automatically

select 4 hs. nal readout for all positions.

For 60 ºC the incubator allows choosing between 30 mi-

nutes, 1 hour, 2 hours or 3 hours nal readout. It is possi-

Bionova® MiniBio Page 7

ble to select an incubation program for each of the po-

sitions depending on the nal reading characteristics of

the indicators to be used.

Check that the time setting is appropriate for the BIs to be

incubated in each position

To change the time program, press the button of the

correspondent position as many times as necessary to

choose the right setting.

5- Wait for the temperature of the machine to be stable.

Once is stable, the indicator of the desired temperature

will remain steady.

Do not place any Biological Indicator in read posi-

tions until the incubator does not conrm tempe-

rature stability.

The incubator will keep running the incubation program

during all reading process. The system does not allow the

incubation program to be modied once the reading is

started, except it has been completed.

6- Reading can be initiated when the temperature blue

light remains stable indicating that incubation tempera-

ture was met. Then an automatic testing of the status of

the incubation positions of the biological indicators will

be performed. The indicating lights of each position will

be turned on to show the result: green light will show a

satisfactory result while red light will indicate error.

When the device detects an error in any position, it will

print a ticketindicating date, time and positions with

error. To guarantee the reliability of the results, these

positions will be deactivated avoiding their use. To make

this clear, red light in that position will remain blinking in-

denitely to indicate that the position has been disabled.

For the correct performance of the automatic

check, it should be done with the protective cover

closed.

Read BI´s instructions for use. Before placing the

vials in the incubator, press the top to seal the

tube. Crush the internal ampoule (using the am-

poule crusher within the box of BIs or the one lo-

cated within the incubation area of the incubator)

and make sure that the liquid has completely wet

the spore carrier placed at the bottom of the biolo-

gical indicator plastic tube.

Do not remove or change placement of BI once the

reading process has begun. If this occurs, results

may be invalidated.

7-Place the rapid BI in a reading position, close the pro-

tective cover and wait for the result. Reading will start au-

tomatically. Immediately after placing the BI in a position,

Bionova® MiniBio auto-reader will emit a sound alarm

indicating that reading has successfully began and status

position light will turn on and will blink until the result is

informed.

NOTE: If the incubator does not run automatically, it mi-

ght indicate that the incubator temperature is not steady

yet (check the temperature indicating light to remain ste-

ady) or that the incubation position is disabled due to an

error in the initial autotest.

8- When a positive result is detected, the red light and the

audible alarm will turn on. This will indicate that the steri-

lization process to which the BI was subject, has failed. 30

seconds after removing the IB from the incubation posi-

tion, the alarm and the red light will turn o automatically

and the position will be available to start a new reading.

The negative BIs will be informed with a green light in the

corresponding position, this will indicate that the sterili-

zation process to which it was subject has been success-

ful. The green light will remain on for up to 30 seconds

after the BI is withdrawn from the reading position.

The incubator will inform results within 30 min. (60 ºC),1

h. (60 ºC), 2 hs. (60 °C), 3 hs. (60 ºC) or 4 hs. (37 ºC), accor-

ding to the program selected. These periods of incuba-

tion are the time-limits used by the equipment to inform

the uorescence nal readout.

9- Every time a positive result is detected, it will be infor-

med through the printing of the corresponding ticket

and with an audible alarm. The alarm can be cancelled by

pressing the button .

10- To register the tickets, take the paper and press up for

the paper to be cut with the serrated edge of the printer.

NOTE: If the printer runs out of paper, printer’s blue light

will start blinking (see Replacement of the paper roll in the

printer).The incubator will save the last 3 results, for re-prin-

ting, follow the Reprinting of the last results instructions.

Instructions for use

Use a non-sterilized biological indicator as a posi-

tive control every time a processed indicator is in-

cubated. For more information refer to the Positive

Control section of this user guide.

Bionova® MiniBio Page 8

POSITIVE CANCELEDNEGATIVE

Replacement of the paper roll

Thermal paper specications

Recommended paper: JUJO AF50KSE3 or similar (order

code ICTP).

Paper width : 58 mm

Maximum paper thickness: 60 g/m2

Maximum diameter size: 23 mm

The printer uses thermal paper rolls.

1. To replace the paper

roll, pull the handle of the

printer’s door. Open the

printer’s cover and remo-

ve the spent roll.

2. Place the new paper roll

with the outer side up.

3. Close the printer cover

by pressing on the sides

of the lid.

The incubator allows reprinting of the last 3 results by

uorescence readout. For printing the results, press the

button for 3 seconds.

Reprinting of results

The Bionova® MiniBio allows verifying the remaining in-

cubation time in every reading position by ticket printing.

Whenever a reading process is in course, press and hold

the button for 3 seconds, a ticket will then be printed

informing reading position, incubation program and re-

maining incubation time.

To verify remaining incubation time of 2 or more readings

in course press both 2 buttons ; the device renders a

ticket informing remaining incubation time of all positions.

Remaining incubation time

Instructions for use

The positive control should belong to the same

batch of the processed BI.

Use a non-sterilized biological indicator as a po-

sitive control every time a processed indicator is

incubated.

Positive Control

Bionova® MiniBio Page 9

Rapid Readout

The indicator used as positive control should show a po-

sitive result (red light). The processed BI results are not

valid until the biological indicator used as positive control

shows a positive result (red light). A processed BI with a

positive result (red), indicates a failure in the sterilization

process. A negative result, (green light) after 30 min. (60

ºC), 1 h. (60 ºC), 2 hs. (60 °C), 3 hs. (60 ºC) 4 hs. (37 ºC) accor-

ding to the used program, indicates that the sterilization

process was eective.

Take action on any positive result immediately. A positive

result indicates a sterilization process failure may have

occurred. Always retest the sterilizer and do not use the

sterilizer for processing loads until 3 consecutive BI results

are negative.

Visual Readout

The Rapid readout system allows the conrmation of re-

sults by color change after 48 hours or 7 days incubation

Dispose Bls after use, according to your healthcare and

safety regulations. Positives BIs can be sterilized (see BIs

instructions for use).

Disposal

Interpretation of results

analysis (if 7-day readout is made, an humidied incuba-

tor will be required to avoid media dry out). If the sterili-

zation process was not successful, the growth media con-

tained in the indicator will turn to yellow, as it is shown

in Instruction of Use of BIs. If the sterilization process

was successful, the media will remain unchanged. Color

change to yellow of the growth media shows a failure in

the sterilization process. If after the incubation time (see

biological indicators directions for use), no color change

is noticed in the processed indicators, then the result is

negative (the sterilization process was successful).

The color of the growth media in the BI used as

positive control must turn to yellow during the

process of incubation for the results to be valid.

Record the positive ones and discard them im-

mediately as shown in the biological indicators

instructions for use.

Instructions for use

An audible alarm will sound every time a positive result

is detected in the Bionova® MiniBio incubator. The alarm

allows the user to immediately detect a positive result

without the need to visually control the equipment. The

alarm can be cancelled by pressing the button .

When a BI is removed from its position during incubation

process, an audible alarm will sound to indicate that the

tube should be returned to the corresponding position.

If the indicator is not re-introduced into the reading posi-

tion after 10 seconds of being withdrawn, the reading will

be cancelled and the cancelation will be informed throu-

gh the printing of a ticket.

Cancellation of a reading

Audible alarm

Incubate the processed biological indicator and the

indicator used as positive control as long as speci-

ed in the instructions.

Press the cap to seal the tube and crush the ampoule, make

sure the media completely wets the carrier. Write a C (for

control) and the date on the label. The positive control can

be placed in any position of the Bionova® MiniBio incuba-

tor. The positive control should belong to the same batch

of the processed BI.

It is a good practice to use a positive control, this helps

ensuring:

-Correct temperature is reached.

-Viability of spores has not been altered due to improper

storage temperature, humidity, or proximity to chemicals.

-Capability of the media to promote rapid growth and uo-

rescence generation.

-Proper functioning of Bionova® MiniBio incubator.

The Bionova® MiniBio incubator contains an internal tem-

perature control. If the temperature falls outside of the spe-

cied range (37±2) ºC or (60±2) ºC, the blue temperature

led light will start to twinkle.

Temperature can be externally monitored by using a Bio-

nova® TB- IC1020 thermometer or other similar. The Au-

to-Reader MiniBio has a special hole for placing the ther-

mometer which is located at the right side of the device.

Temperature monitoring

Bionova® MiniBio Page 10

Instructions for use

Clean the outer surface of the Bionova® MiniBio incubator

with a damp cloth moistened with a small amount of de-

tergent. Do not clean interior components. If additional

cleaning of the internal components of the equipment is

required, contact your distributor or manufacturer.

Always unplug the MiniBio incubator and allow it

to cool before cleaning. Do not immerse the unit

in liquid.

NOTA: Bionova® MiniBio incubator does not need routine

maintenance.

Firmware update

Care and cleaning

The MiniBio auto-reader allows updating the rmware

periodically (program that controls the device and de-

nes its dierent features) through the use of the Bioupda-

te Software. This software veries, by using the internet,

the latest rmware version available for MiniBio auto-rea-

der; downloads it and installs it in a few seconds without

the loss of any device data.

The Bioupdate Software must be downloaded, only

once, from the following web site: http://www.terragene.

com.ar/products/infection-control/control-of-steriliza-

tion-processes/incubators/minibio/.

Download le:

UPDATE PROCEDURE:

Before starting the process, make sure that the Bionova® sof-

tware is closed.Turn o the incubator for ve seconds, then turn

it on and follow these steps:

1-Connect the incubator to a PC using a USB cable and make

sure to have an internet connection.

2-Open Bioupdate program.

3-Select the device and press Start button to update.

4- Wait until the software indicates that the upgrade pro-

cess is complete. The incubator will print a ticket indica-

ting the new rmware version.

NOTE: This process must be repeated every time that a

new rmware version is available, this will be informed in

the website.

Incubator’s calibration procedure is described in the sof-

tware manual attached (“Automatic reading and traceabi-

lity system for biological indicators for sterilization”). It can

also be downloaded from http://www.terragene.com.ar/

products/infection-control/control-of-sterilization-pro-

cesses/incubators/minibio/.

Calibration

Setup Mode

Bionova® MiniBio has a setup mode from which, the equi-

pment time zone and the print language can be set up.To

enter Setup mode, turn on the incubator while holding

down the button . The red and green LEDs in the

three positions will remain on, indicating that the device

is in this mode. The printer will render a ticket indicating

that it is in Setup Mode.

To change the time zone and the print language, follow

the instructions below.When nished, restart the compu-

ter to exit Setup mode.

Modication of time zone

The time zone modication function allows changing

the time zone of the device to suit the time zone of your

country.

To make this change, the incubator must be started in

Setup mode (see Setup Mode), then press the button .

The current time will be printed to set a reference.

To subtract hours, press the button as many times as

necessary. To add hours, press the button as many ti-

mes as necessary. After 2 seconds, a ticket will be printed

informing the selected time.

To conrm the change hold down the button for 3

seconds. To discard the changes, unplug the incubator

from the power source.

Modication of printing language

This functionality allows changing the language in which

Bionova® MiniBio Page 11

the incubator printer renders the tickets.

To make this change, the device must be started in Setup

mode (see Setup Mode), then press the button .

The current language and list of available languages will

be printed to establish a reference. Press the button to

scroll down and to scroll up. After 2 seconds, a ticket

will be printed informing the selected language.

To conrm the change, press and hold the button for

3 seconds. To discard the change, unplug the incubator

from the power source.

Instructions for use

Bionova® MiniBio Page 12

Troubleshooting chart

The incubator does not start.

The incubator gives an error in

one position during “Autotest”.

The incubator gives an error in

the “Autotest”.

The incubator does not run a BI

reading.

The red light of that position is

blinking.

The incubator does not run a BI

readout in any position.

The incubator does not allow chan-

ging the incubation program.

The printer does not print.

The printer releases unprinted

paper.

The Bionova® traceability softwa-

re does not detect the incubator.

The update of the incubator fails.

Power source is not connected.

A BI is placed in the position at the

moment of starting the incubator.

Soil particles might be obstruc-

ting the light path between the

sensors.

The “Autotest” gives an error in

that position, which becomes

disabled.

The incubation temperature is not

stable.

Ongoing reading.

The printer cover is not tightly locked.

Printer without paper.

Paper roll is placed in the wrong

direction.

The incubator is turned o or the

USB cable is disconnected.

The incubator is connected to the

Bionova® traceability software.

Check that the power source is connec-

ted to the power supply according to its

characteristics and that the plug is con-

nected to the incubator.

Check that every position is empty at

the moment of starting the incubator.

Ensure cleanliness of the incubation

position. Use of air is recommended.

Do not use solid objects that could da-

mage internal components. Restart the

incubator.

Make sure that the position is empty

when starting the incubator. Restart the

incubator.

Wait for temperature to be stable.

Wait for the reading of corresponding

position to nish.

Printer without paper.

Place a new paper roll in the right direction.

Check the paper roll direction.

Check that the incubator is turned on,

the USB cable is connected and the

COM port is correctly installed and ac-

cepted by the operative system.

Close the program, restart the incubator

and try again.

Fault Possible cause Action

Bionova® MiniBio Page 13

Terragene® S.A. guarantees both the quality of the pro-

duct material components and the quality of its manu-

facturing process. Should any material or manufacturing

faults be detected within the warranty period (1 year from

the time of purchase), the only obligation of Terragene®

S.A. will be product repairing or substitution.

Limitation of liability

Intellectual property

Technical assistance

Terragene® S.A. shall not be held liable for any loss or da-

mage that may result from the unsuitable use of the equi-

pment, negligence or user’s full responsibility.

Bionova® MiniBio auto-reader incubator may aect the

intellectual property of other manufactures in some

countries, invading certain aspects of patents related to

this product. Terragene® S.A. shall not be liable for any

damages or injuries that may result from the marketing

of this product in those countries where Terragene® S.A.

does not market it directly.

Terragene S.A.

Güemes 2879 (S2002JBM)

Rosario. Santa Fe. Argentina.

Warranty

Rev.0 | Agosto 2017

MiniBio

Bionova® MiniBio Page 16

La incubadora Bionova® MiniBio ha sido diseñada para

incubar los Indicadores Biológicos (IBs) Autoconteni-

dos de lectura Rápida BT110 para el control de esterili-

zación por Óxido de Etileno, BT220 y BT221 para el con-

trol de esterilización porVapor, BT102 para el control de

esterilización por Formaldehído, BT95 para el control

de esterilización por Vapor o Plasma de Peróxido de

Hidrógeno, y los IBs Autocontenidos de lectura Súper

Rápida BT222 y BT223 para el control de esterilización

por Vapor.

Los microorganismos contenidos dentro de los indi-

cadores biológicos varían de acuerdo al proceso de

esterilización para el cual han sido diseñados, por ello,

las temperaturas de incubación son diferentes según

el indicador. Los indicadores para el control de esterili-

zación por óxido de etileno (OE), deben ser incubados

a 37 °C, mientras que aquellos para el control de los

restantes procesos de esterilización deben incubarse

a 60 °C.

No es posible la incubación simultánea de IBs para

el control de procesos por OE junto con IBs para el

control de los demás procesos.

Descripción de uso

Composición

La incubadora Bionova® MiniBio permite la detección

rápida y fácil de indicadores biológicos positivos y ne-

gativos. Dispone de 5 programas de incubación: 4 hs. a

37 °C, 3hs. a 60 °C, 2 hs. a 60°C, 1 h. a 60 °C y 30 min. a 60

°C. Un resultado positivo también puede evidenciarse a

través del cambio de color del medio de cultivo al color

amarillo luego de 48 horas o 7 días de incubación a 60

°C para los IBs BT220/BT221/BT222/BT223/BT102/BT95

y luego de 7 días de incubación a 37 °C en el caso de

los IBs BT110. Los tiempos de incubación dependen de

los protocolos internos de cada laboratorio u hospital.

La incubadora permite la selección de programas de

tiempo de incubación de manera independiente para

cada una de las 3 posiciones. La incubadora Bionova®

MiniBio no sólo permite la detección de los resulta-

dos, también proporciona un ticket impreso para su

registro. Además, puede conectarse a una PC por un

puerto USB. Este permite vincular los resultados con

el programa Bionova®, Sistema Automático de Lectura

1

2

3

10

14

15

4

5

6

7

8

9

11

12

17

13

16

Instant

Bionova® MiniBio Page 17

Cubierta protectora.

Luz verde / Indicador negativo.

Luz roja / Indicador positivo.

Posición de incubación.

Selectores de programas de incubación /

tiempo restante.

Panel de mandos.

Área de incubación.

1

2

3

4

5

6

7

8

9

10

Selector de temperatura.

Cancelación alarma sonora.

Impresora térmica.

11

12

13

14

15

16

17

Botón de conguración / tracción de papel.

Cavidad para papel.

Puerto USB.

Entrada para clavija de fuente de alimentación

(12Voltios CC)

Oricio para control externo de temperatura.

Reimpresión de resultados.

Rompe ampollas para IBs (crusher).

Referencias

y Trazabilidad para Indicadores Biológicos de Esterili-

zación. Para descargar la última versión del software

ingrese en: http://www.terragene.com.ar/productos/

control-de-infecciones/control-de-procesos-de-esteri-

lizacion/incubadoras/minibio/, desde allí también po-

drá descargar el manual de uso del mismo.

Información de seguridad

Humedad relativa de funcionamiento.

Temperatura ambiente de funcionamiento.

Precaución, advertencia.

Precaución: riesgo de descarga eléctrica.

Precaución: supercie caliente.

Importante, atención.

Fabricante.

Conformidad europea.

Número de serie.

Corriente directa.

Denominación de producto.

Símbolos

Para evitar riesgos y daños en el equipo

-No coloque el equipo en un ambiente expuesto a

la luz solar directa o a lámparas de alta intensidad

lumínica.

-No coloque el equipo cerca de dispositivos que

emiten campos electromagnéticos

-No utilice el equipo sobre supercies con vibra-

ciones.

-No vierta ningún líquido en su interior.

-No sumerja la incubadora en ningún líquido.

-Utilice sólo en interiores.

-Desconecte el cable de alimentación antes de

proceder a su limpieza.

-No utilice limpiadores o desinfectantes abrasivos

o corrosivos.

-En caso de algún desperfecto técnico, contáctese

con el fabricante para su asesoramiento. Por favor,

80 %

30 %

10 ºC

30 ºC

REF

Bionova® MiniBio Page 18

evite abrir y/o intentar arreglar la incubadora; esto

provoca la pérdida de la garantía y puede ocasio-

nar un desperfecto mayor e irreversible.

-Asegúrese que la incubadora esté conectada a la

fuente de alimentación adecuada.

Para reducir el riesgo de utilización de cargas

no estériles:

-Asegúrese de utilizar cada IB con su programa de

lectura e incubación adecuado:

BT110 (tapa verde) con el programa de 4 hs. a 37 ºC

BT220 (tapa marrón) con el programa de 3 hs. a 60 ºC

BT221 (tapa azul) con el programa de 1 h. a 60 ºC

BT222 (tapa violeta) con el programa de 1 h. a 60 ºC

BT223 (tapa celeste) con el programa de 30 min. a 60 ºC

BT102 (tapa roja) con el programa de 2 hs. a 60 °C

BT95 (tapa blanca) con el programa de 2 hs. a 60 °C

-Verique que el medio de cultivo humecte el por-

tador con esporas.

-No retire el IB hasta que el equipo informe el re-

sultado nal de la lectura, compruebe la impresión

del ticket de resultado.

Para evitar riesgos de lesiones por los frag-

mentos de vidrio que se generan al romper la

ampolla de vidrio contenida dentro del tubo

plástico del IB:

-Deje enfriar el IB durante el tiempo indicado antes

de romper la ampolla.

-Evite la manipulación excesiva del IB antes de que

el mismo se enfríe, ya que esto puede provocar

que la ampolla estalle.

-Utilice gafas y guantes de seguridad al retirar el IB

del esterilizador.

-Utilice gafas y guantes de seguridad al romper y

presionar la tapa del IB.

Para evitar potenciales situaciones de peligro:

evite contacto con la supercie caliente del bloque

metálico del incubador.

Para evitar que los IBs absorban residuos uo-

rescentes: evite que los IBs entren en contacto di-

recto con indicadores químicos o cintas.

No utilice este producto de manera no especica-

da por Terragene® S.A., de lo contrario, la protec-

Especicaciones de la fuente de alimentación

Condiciones ambientales de operación

Parámetros de entrada

Rango de voltaje

Frecuencia

Corriente

Parámetros de salida

Voltaje

Corriente

Valores

(100-240)

50/60

0,5

Valores

12

2

Unidades

Voltios

Hertz

Amperios

Unidades

Voltios DC

Amperios

Terragene® recomienda el uso de UPS en lugar de estabi-

lizadores, ya que el mismo cumple dos funciones: estabi-

liza y mantiene la energía durante cortes de suministro.

Cond. ambientales

Altitud

Temp. de operación

Humedad relativa

Instalación/sobre voltaje

Grado de contaminación

Temperatura de

almacenamiento

Voltaje

Cond. de func.

3500 (máx.)

10-30

30-80

categoría II

2

0-50

12

Unidades

Metros

ºC

%

ºC

Voltios DC

Información de seguridad

ción proporcionada por el producto podría verse

afectada.

No sustituya el cable de alimentación de la fuente

por otros no provistos con el producto.

Solo personal autorizado por Terragene® S.A.

puede acceder al interior de la incubadora y sus

componentes. Ninguna parte o componente del

interior del equipo debe ser manipulada por el

usuario.

Bionova® MiniBio Page 19

Número de Serie/Lote

Instrucciones de uso

Para una fácil identicación, cada incubadora Bionova® Mi-

niBio posee un único número de serie y un número de lote

impresos en una etiqueta que se encuentra en la base de la

incubadora y en el packaging de la misma. Por favor registre

su número de serie y su número de lote en este manual para

una referencia futura:

Número de serie:

Número de lote:

Tabla de registro

Utilice la siguiente tabla para registrar las actualizaciones

del rmware.

NOTA: el rmware de fábrica está registrado en una eti-

queta que se encuentra en la base del equipo y en el pac-

kaging de la misma.

Fecha Versión Operador

Por favor registre su versión de rmware de fábrica en este

manual para una referencia futura:

Firmware de fábrica:

Puesta en marcha

Todos los dispositivos son fabricados con las si-

guientes conguraciones:

- Huso horario: UTC +0:00

- Idioma de impresión: Inglés

Si desea modicar el huso horario consulte la sección

Cambio de huso horario. Si desea modicar el idioma de

impresión, consulte la sección Modicación de idioma de

impresión.

1-Coloque la incubadora en una supercie rme, sin vi-

braciones, lejos de la luz solar, corrientes de aire caliente

o frío, productos químicos y sustancias corrosivas o ina-

mables. Posicione el equipo de modo que la desconexión

de la clavija de la fuente de alimentación no sea dicul-

tosa. Deje un espacio de al menos 10 cm desde la pared.

No mueva la incubadora de forma periódica o durante su

uso. Conecte la incubadora a una fuente de energía eléc-

trica segura y estable.

No moje, ni caliente la incubadora. Si algún líqui-

do se derrama sobre la incubadora, desconéctela

y seque de inmediato. Previo a su encendido, debe

vericarse que el equipo MiniBio tenga todas las

cavidades vacías.

2-Encienda la máquina conectando el extremo de AC de

la fuente de alimentación a la red de suministro eléctrico

y luego conecte el otro extremo de la fuente (clavija) en la

parte posterior de la unidad Bionova® MiniBio. El equipo

iniciará tomando la última conguración de programa de

tiempo y temperatura utilizada.

3-Sincronice la incubadora MiniBio Bionova® con la

hora local, usando el software Bionova® disponible en:

http://www.terragene.com.ar/productos/control-de-in-

fecciones/control-de-procesos-de-esterilizacion/incu-

badoras/minibio/. Para esto, conecte el puerto USB de

la incubadora a la PC e inicie el programa. La incubadora

Bionova® MiniBio será sincronizada con la hora de la PC.

Sólo funciona y se puede utilizar cuando no hay IBs de

lectura rápida iniciados.

4-Corrobore que la temperatura de incubación sea la

requerida. Para cambiarla, presione el botón por 3

segundos. Las luces correspondientes a 37 °C y 60 °C se

volverán intermitentes indicando que se debe seleccio-

nar un programa de temperatura. Para la selección de la

temperatura de incubación, presione el botón para

seleccionar 37 °C o 60 °C. Luego de 3 segundos se acepta-

Bionova® MiniBio Page 20

rá la modicación de temperatura realizada.

Para 37 °C el autolector Bionova® MiniBio seleccionará

automáticamente 4 hs. de lectura nal en todas las po-

siciones de lectura.

Para la selección de 60 °C puede seleccionar 30 min., 1,

2 o 3 hs. de lectura nal. Es posible seleccionar un pro-

grama de incubación para cada una de las posiciones

dependiendo de las características de lectura nal de los

indicadores a utilizar.

Corrobore que el programa de tiempo sea el indicado

para los IBs a incubar en cada una de las zonas.

Para cambiar el programa de tiempo, presione el botón

de la posición correspondiente tantas veces como sea

necesario hasta elegir la opción deseada.

5- Aguarde que la temperatura del equipo se estabilice.

Cuando esto suceda, el indicador de la temperatura de-

seada permanecerá jo.

No coloque ningún indicador biológico en las po-

siciones de lectura hasta que el equipo no indique

que la temperatura se encuentra estable.

La incubadora mantendrá el programa de incubación se-

leccionado durante todo el proceso de lectura. El sistema

no permite que el programa de incubación sea modica-

do una vez iniciada la lectura, a menos que haya naliza-

do la misma.

6-Se podrán iniciar las lecturas cuando la luz azul de tem-

peratura permanezca estable, indicando que se alcanzó la

temperatura de incubación. Al encender el equipo y esta-

bilizarse la temperatura, se realizará una comprobación au-

tomática del estado de las posiciones de incubación de los

Indicadores Biológicos. Las luces indicadoras de cada posi-

ción se encenderán para indicar el resultado de la compro-

bación: la luz verde indicará que la misma fue satisfactoria

y la roja que se ha producido algún error.

Cuando el equipo detecte un error en alguna posición, im-

primirá un comprobante indicando la fecha, la hora y las

posiciones con error. Para garantizar la conabilidad de los

resultados, estas posiciones se desactivarán evitando así su

utilización. Para evidenciar esto, la luz roja de dicha posi-

ción permanecerá parpadeando indenidamente, para

señalar que esa posición ha sido deshabilitada.

Para el correcto funcionamiento de la comprobación

automática, la misma debe ser realizada con la tapa

de la incubadora cerrada.

Lea las instrucciones de los IBs. Antes de colocar

los mismos en la incubadora, asegúrese de se-

llarlos presionando la tapa hacia abajo. Rompa la

ampolla contenida en su interior (utilice el rompe

ampollas incluido en la caja de los IBs o el crusher

que posee la incubadora) y asegúrese de que el

medio de cultivo moje completamente el portador

de esporas colocado en la parte inferior del tubo.

Utilice un IB que no ha sido expuesto al proceso de

esterilización como control positivo, cada vez que

un indicador procesado sea incubado.

Para más información remítase a la sección Control

positivo de este manual de usuario.

No retire o cambie el IB de lugar una vez que haya

sido iniciado el proceso de incubación y lectura.

Si esto se produce, se pueden invalidar los resul-

tados.

7-Coloque el IB rápido en una posición, cierre la cubierta

protectora y aguarde el resultado. La lectura se iniciará

de forma automática. Inmediatamente después de haber

ingresado el IB rápido a una cavidad, el autolector Biono-

va® MiniBio emitirá una alarma sonora para indicar que se

inició la lectura y los leds de posición se encenderán de

forma intermitente hasta que el resultado sea informado.

NOTA: Si la incubación no comienza automáticamente,

puede deberse a que la incubadora aún no ha estabiliza-

do la temperatura (para ello corroborar que la luz de la

temperatura se encuentre ja) o a que la posición utiliza-

da se encuentre deshabilitada debido a un error en el test

automático inicial.

8-Si la incubadora detecta un resultado positivo, se en-

cenderán una luz roja y una alarma sonora. Esto indicará

que el proceso de esterilización al que fue expuesto dicho

IB ha fallado. Transcurridos 30 segundos después de reti-

rar el IB de la cavidad, la alarma y la luz roja se apagarán

automáticamente indicando que la posición está disponi-

ble para iniciar una nueva lectura.

Los IBs negativos serán informados con una luz verde en

la posición correspondiente. Esto indicará que el proce-

so de esterilización al que fue expuesto dicho IB ha sido

exitoso. La luz verde permanecerá encendida hasta 30

segundos posteriores a que el IB rápido sea retirado de

la cavidad de lectura.

El lector informará resultados dentro de 30 min. (60 ºC),1

hora (60 ºC), 2 horas (60 °C), 3 horas (60 ºC) ó 4 horas (37

ºC) respectivamente, según el programa de incubación

elegido. Estos períodos de incubación son el límite de

tiempo utilizado por la máquina para informar la lectura

nal de uorescencia a las respectivas temperaturas.

Instrucciones de uso

Other manuals for BIONOVA MiniBio

3

Table of contents

Languages:

Other Terragene Accessories manuals