TileWare Victoria Series Reference guide

Fastener

Thumb screw

Stud

Stabilizer

MORTAR BASED INSTALLATION SYSTEM –NO MASTIC

Victoria™ Series ADA 18” Grab Bars

Installation Procedures For The Following Models:

Model T200-001

ADA 18” Straight Grab (Contemporary)

Note: System will not work on tile thicknesses less than

5/32” or greater than 1/2”

Revised: 1/29/16

Model T200-002

ADA 18” Straight Grab (Traditional)

T200-001-PC T200-001-BN T200-001-ORB

T200-002-PC T200-002-BN T200-002-ORB

STEP 1 Understand “Z” Fastener

•Each PermaTile™ Fastener is equipped with a stabilizing bracket. The bracket

ensures that grab bar mounts properly. Remove stabilizer after thin-set has

met minimum cure times specified by manufacturer.

Warning: Each threaded stud is covered with a plastic thumb screw to prevent

thin-set mortar from corrupting threads. Do not remove until after grouting.

Technical Fact:

Each PermaTile™ “Z” Fastener is constructed from high quality stainless

steel materials. The welded fastener is equipped with (2) 10-24 internal

threaded studs (only one pictured)

STEP 2 Determine Location & Install Fastener

Technical Fact:

Each PermaTile™ “Z” Fastener will work with all 1/2” thick cement, fiber

and foam-core tile board materials. (Only use materials that meet ANSI

specification for tile construction.)

Determine where the PermTile™ “Z” Fastener will be located.

•First apply a 1/4” bead of urethane caulk to underside of “Z” Fastener to

waterproof.

•Attach “Z” Fastener to wood studs with #8 x 2” wood screws (2-

provided). Fastener MUST be mounted to 2 stud placements 16” on

center.

•After attaching fastener, apply a second bead of urethane caulk on top

of tile board edge, covering entire edge including fastener.

•Place tile construction board on top of fastener system and attach

securely.

Warning: When installing “Z” Fastener for

ADA, first consult local municipalities.

•Apply thin-set mortar with no less than a 1/4” x 3/8” notch trowel, key

thin-set into perforations in “Z” Fastener.

•Measure location of threaded stud by marking tile or using a tape

measure.

•Transfer marks using a square.

•Use only 10mm diamond drill bit (core), pre-drill all holes before applying

thin-set mortar. Back-butter tile making sure sufficient mortar is around

drilled hole.

Warning: Use only latex modified mortars that meet ANSI A118.4 or A118.11

performance standard. Notches or drilled holes should not exceed 3/8” in

diameter to ensure trim has sufficient surface area during grab bar mounting.

Inadequate mortar coverage around drilled or notched holes will result in tile

damages when tightening bushing and mounting grab bar.

STEP 3 Install Tile over “Z” Fastener

Technical Fact:

When drilling glass tile always drill from both sides. Failure to do so will create

blow-outs and weaken tile structure. Do not mount grab bar to glass tile

where drilling has occurred on one side only.

Note: Mortar required around hole

Thin-Set

Use wood

screw provided

Attach #8 x 2” wood screw

using small perforations

Use level to ensure all

tiles in fastener are FLAT

& on identical plane

Grab Bar Screw

Configuration

Guidelines 5/32” 3/16” 1/4”5/16” 3/8” 7/16” 1/2”

Thin-Set

& Screed

Build-up

Thicknesses

1/16”

3/16”

3/8” N/A

©2012-2016 TileWare Products. All rights reserved. PermaTile™ Fastener Patented. US Patent No. 8,161,700, Australian Patent No. 2011205360

MORTAR BASED INSTALLATION SYSTEM –NO MASTIC

Victoria™ Series ADA 18” Grab Bars

Installation Procedures For T200-001 & T200-002

Thank you for using our

products!

TileWare Products

PO Box 793, Hickory, NC 28603

Technical Support: 828-322-9273

Email: info@tilewareproducts.com

www.tilewareproducts.com

STEP 4 Remount Stabilizer

Warning: Do not proceed with accessory installation until thin-set mortar has

met minimum curing requirements specified by manufacturer.

Remount stabilizing bracket as shown and tighten thumb screws securely. Use

stabilizer to check if “Z” Fastener was installed level.

•Immediately proceed to accessory mounting after grouting is completed.

•Simply slip Bushing over hex studs. Position 6-32 threads down by placing

index finger over threaded hole while slipping onto hex stud.

•Attach to hex studs using 10-24 stainless steel screws (see table to right).

Hand tighten with #2 Phillips head screw driver.

Technical Fact:

Mortar coverage behind drilled hole will ensure bushing can be firmly

mounted with 10-24 stainless steel screw. Screw is patched to prevent threads

from reversing or loosing.

STEP 5 Remove Stabilizer & Install Bushings

•Each Grab Bar is drilled with 2 countersink holes that will match mounted

bushing locations. Simply slip grab bar over bushings (Note: tolerances are

precise so grab bar will feel snug when installing).

•Simply insert 6-32 stainless steel screws through countersink holes in grab

bar and attach to threaded bushings.

•Using a #2 Phillips-head screw driver, attach screws firmly to grab bar.

Loosely mount all screws first before firmly tightening.

Warning: Make sure screw and stud are parallel to avoid cross-threading. Turn

carefully, cross-threading will require fastener removal.

STEP 6 Mount Grab Bar

Grab Bar

quantity 1 per kit

PermaTile™ “Z” Fastener

quantity 1 per kit

Wood Screw

quantity 2 per kit

Bushing

quantity 2 per kit

Optional

Cover Washer

quantity 2 per kit

10-24

3/4” -1 1/4” Screw

quantity 2 each per

kit

6-32

Screw

quantity 2

per kit

A220-181

A220-182

PT100-514 C200-026 C220-021 C220-023

SOLD

SEPERATELY

C200-015

&

C200-027

C200-011

OR

C200-012

Grab Bar Parts List

Not using stabilizer will result in grab bar mounting failure

Use 6-32

Screws provided

Use 10-24

screws provided

Optional

Cover Washer

to correct

drilling/notch

errors

Stabilizer used as leveling

tool & drilling template

Screws For Specific

Tile Thicknesses:

10-24 x 3/4” Screw

For Standard Build-up

10-24 x 1 1/4” Screw

For Thicker Screeds

Countersink

hole

Bushings

This manual suits for next models

8

Popular Home Safety Product manuals by other brands

Summer

Summer 07030A instruction manual

schmersal

schmersal SLC 415 Mounting and wiring instructions

Intelligent Motion Systems

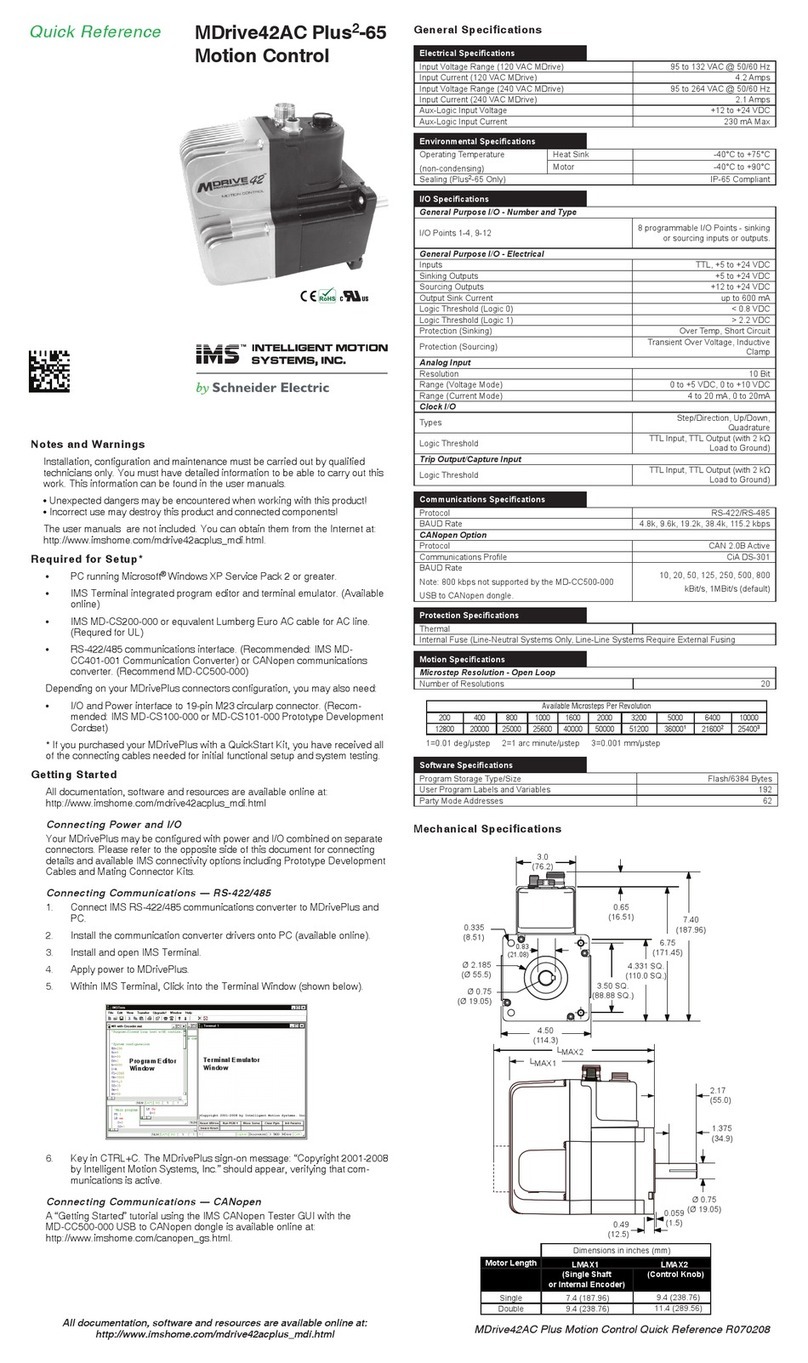

Intelligent Motion Systems MDI AC42Plus MDrive42AC Quick reference guide

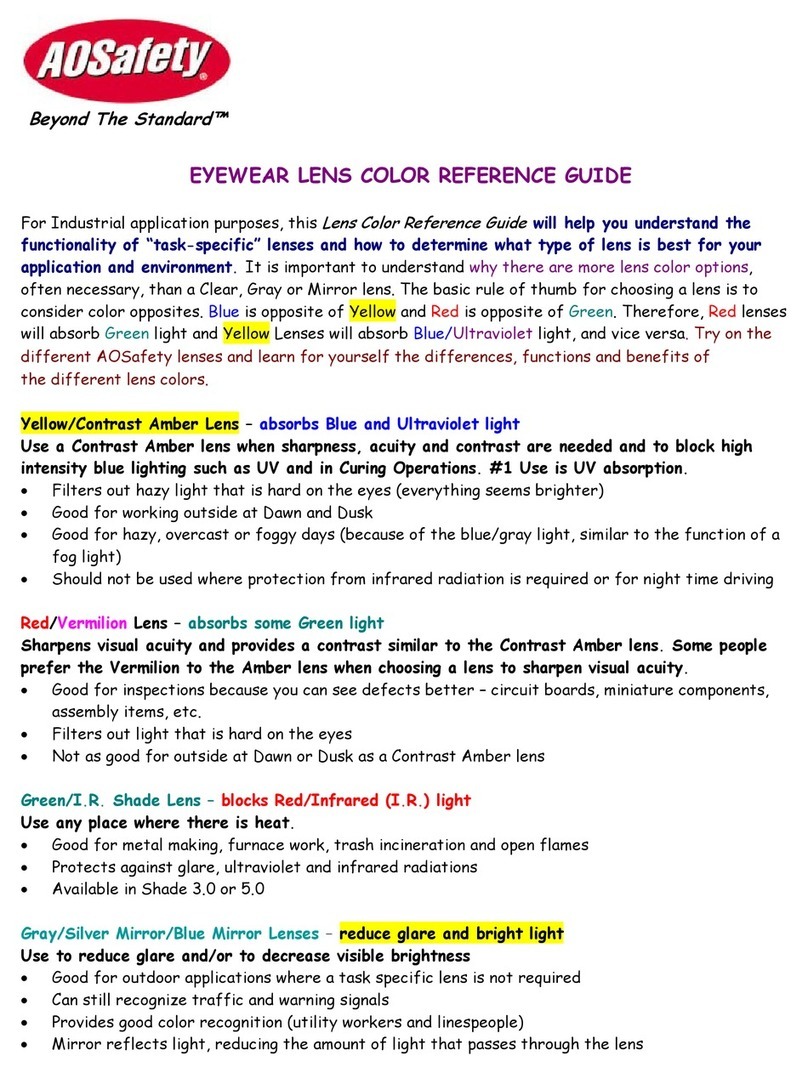

AOSafety

AOSafety Beyond The Standard Eyewear Lens reference guide

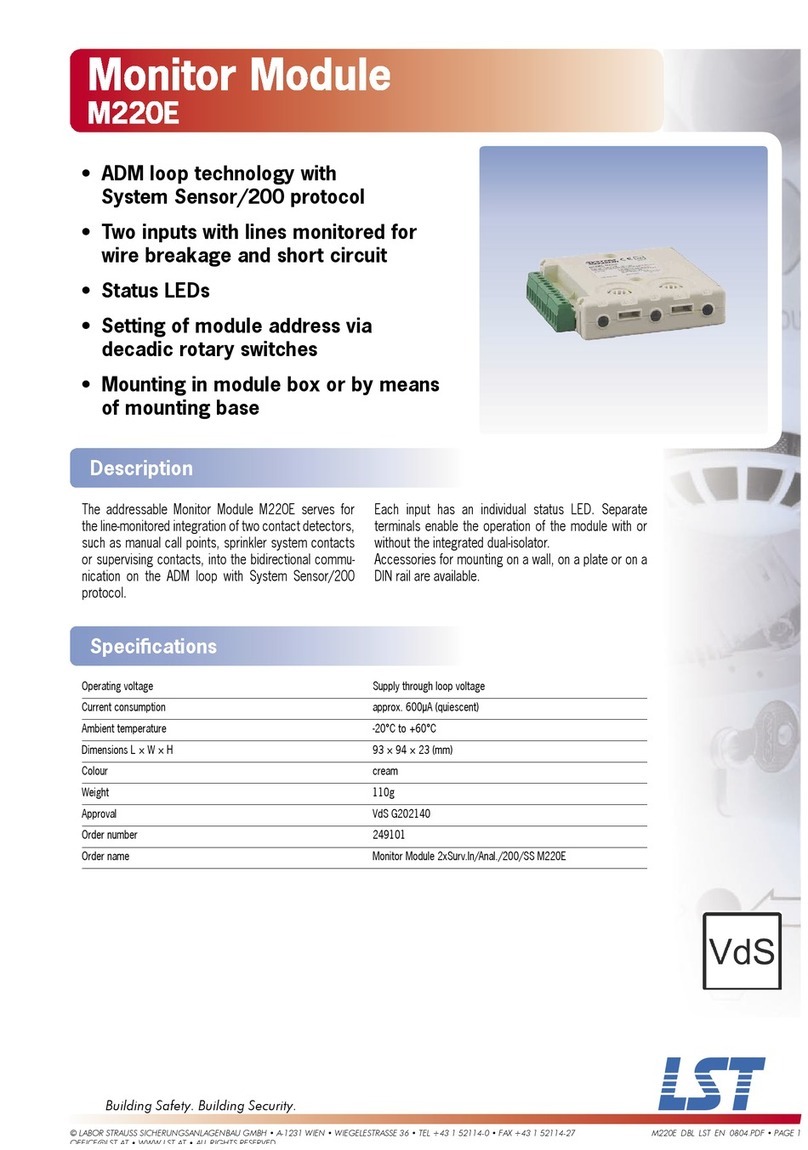

LST

LST M220E Specification sheet

Heath Zenith

Heath Zenith Professional Motion Sensor Quartz Security Light... owner's manual