Timan Tornado-400 User manual

OPERATING INSTRUCTIONS

Tornado-400

The instructions apply to the Tornado-400 model with the serial number: 310100-02

INTRUCTION AND SAFETY

CONTENTS

1IDENTIFICATION DATA OF THE MACHINE..............................................................1

1.1 ORDERING SPARE PARTS:............................................................................................1

2SAFETY RULES ...............................................................................................................2

3MAINTENANCE AND ADJUSTMENT SAFETY RULES ............................................4

4EXPLANATION OF THE MACHINE WARNING SIGNS ............................................6

5GUARANTEE PROVISIONS FOR TORNADO-400 ......................................................7

6MACHINE DESIGN..........................................................................................................9

6.1 COLLECTION CONTAINER ............................................................................................9

6.2 SUCTION NOZZLE ......................................................................................................10

6.3 SUCTION UNIT...........................................................................................................11

6.4 SWEEPING BRUSH......................................................................................................11

6.5 HAND SUCTION .........................................................................................................12

7INSTALLATION AND REMOVAL OF TORNADO-400.............................................13

7.1 INSTALLATION OF TORNADO-400..............................................................................13

7.2 REMOVAL OF TORNADO-400.....................................................................................14

8DRIVING THE MACHINE.............................................................................................14

8.1 ADJUSTING AND SETTING THE SIDE BRUSHES ...........................................................14

8.2 ADJUSTING THE SUCTION NOZZLE.............................................................................15

8.3 EMPTYING THE COLLECTION CONTAINER .................................................................16

8.4 FILLING THE WATER TANK........................................................................................16

8.5 FLOATING POSITION ..................................................................................................16

8.6 DRIVING TIPS ............................................................................................................16

8.7 HAND SUCTION DEVICE ............................................................................................16

8.8 STARTING ..................................................................................................................18

9SERVICE AND MAINTENANCE .................................................................................20

9.1 REPLACING TWO SIDE BRUSHES ...............................................................................20

9.2 REPLACING THE BRUSH INSIDE THE COLLECTION CONTAINER..................................20

9.3 PROTECTING THE MACHINE AGAINST FROSTS ...........................................................20

10 TROUBLESHOOTING ...................................................................................................21

10.1 WATER DISTRIBUTION SYSTEM.................................................................................21

10.2 THE MACHINE SUCTIONS INSUFFICIENTLY................................................................21

11 LUBRICATION CHART ................................................................................................22

12 TECHNICAL DATA .......................................................................................................24

13 WEAR PART LIST..........................................................................................................25

14 EC DECLARATION OF CONFORMITY FOR TORNADO-400 .................................26

ANNEX 1: INSTALLATION OF THE ELECTRIC LINE TO TORNADO-400

ANNEX 2: INSTALLATION OF THE HAND SUCTION DEVICE

ANNEX 3: SPARE PART CATALOGUE

INTRUCTION AND SAFETY

1

Congratulations on your new TIMAN Tornado-400 machine!

These operating instructions will help you to use, adjust and maintain your new machine

properly.

Before attempting to drive or work with your new machine, please carefully read these

operating instructions, especially the section on safety rules.

The right and left designations in the operating instructions and on the spare part lists are the

rear view of the machine in the direction of travel.

1IDENTIFICATION DATA OF THE MACHINE

Manufacturer:Timan A/S

Fabriksvej 13

6980 Tim

Model: Tornado 400

Identification number: Type – product – serial numbers

For example: 310100 – 02 – 1001

1.1 Ordering Spare Parts:

Your dealer will be more than happy to help you to maintain your new machine in such a way

that you can enjoy it as much as possible. Having carefully read these user instructions, you

will find out that part of the service work can be done by you yourself. But if spare parts and

larger service are required, please contact your Timan dealer from whom you purchased the

machine or your local authorized Timan service centre.

To speed up the dispatch and avoid wrong consignments, please give the following

information when you are ordering spare parts:

Machine identification number: ________________________________

Spare part number and the required number of parts

Method of delivery

The machine nameplate is located on left of the suspension hardware.

Find out the identification number and write it above and also on the front page of the

catalogue.

INTRUCTION AND SAFETY

2

2SAFETY RULES

IF THIS SYMBOL IS IN THE MANUAL, YOUR SAFETY IS CONCERNED

The user is responsible for the installation of the protective cover and the overall use of the

safety equipment and for compliance with all safety rules.

Careful driving is the best guarantee for preventing accidents. Before using this machine,

please read carefully this chapter. All drivers, regardless of their level of experience, are

obligated to read this manual and other related operating instructions before they start using

the machine. Training for all drivers in safe driving is the responsibility of the owner.

Safety rules are intended for your safety – therefore, BE SURE TO:

1. Inform all persons who will work with or in the vicinity of the machine and who are not

yet familiarized with them about the safety rules.

2. Never start the machine before you are clear about your plan and intention.

3. Never start the machine before all protective covers are installed and closed. Replace or

repair immediately any missing or damaged protections.

4. Ensure that persons who are in the vicinity of the machine keep a minimum distance of

5 m from the machine in case that the machine is started and working. This requirement

does not apply when the hand suction device is used if the operator uses hearing

protection.

5. Stop the implement carrier engine and wait until the engine and the implement stop

completely. Before cleaning, lubricating, adjusting or repairing the machine, remove

the key from the ignition (starter switch) and turn the main switch to the OFF position.

6. The implement carrier quick change mechanism (quick hitch) must always be engaged

when the machine is connected.

7. No other passengers must ever be present on the machine.

8. If the machine is lifted from the ground during a service inspection or maintenance, the

implement carrier quick change system (quick hitch) must be tilted completely back

and locked using the safety hook to ensure safety.

9. If the machine is lifted from the ground during a service inspection or maintenance, it is

always necessary to use the safety support on the implement carrier multifunctional

arm.

10. No objects must be placed in the machine which would block its functions.

INTRUCTION AND SAFETY

3

11. When working with the machine, never wear loose clothing and keep a safe distance

from rotating parts.

12. Do not touch your hands to working parts of the machine.

13. Open the tank lid only when the machine is stopped.

14. Look round well where you are driving.

15. Before driving, let always the implement carrier multifunctional arm fall down as much

as possible.

INTRUCTION AND SAFETY

4

3MAINTENANCE AND ADJUSTMENT SAFETY RULES

1. Before any maintenance or adjustment of the machine, it is necessary to switch off the

implement carrier engine. Always remove the key from the ignition and turn the main

switch to the OFF position (to prevent the engine from starting unexpectedly).

2. Before carrying out any maintenance or adjustment, make sure that the machine is

switched off completely.

3. Hydraulic equipment:

a. The hydraulic equipment of the machine can only be used for the intended purpose

and maintenance and repairs may only be carried out by persons having

knowledge of the hydraulic equipment (including the hazards when exposed to

hydraulic fluid, especially when under pressure).

b. It is prohibited to carry out the adjustment of the pressure relief valves set at the

factory without the prior agreement with the dealer, importer, or Timan A/S

service department.

c. Liability for damage will not apply to damage caused by improper use or improper

maintenance/repair.

d. The hydraulic components used must comply with the rules and standards adopted

by the technician.

e. Before every use, check the hoses for damage (cracks, holes, improper

entanglement, and the like). Replace them immediately if they are damaged.

Protect the quick coupling from the penetration of water and dirt when it is not

connected.

Note: Never attempt to detect any leak in the hydraulic system by hand – hydraulic

fluid under high pressure which escapes from small leaks may not be visible and

even a little drop of oil can cause hand injuries. Use a piece of wood, cardboard,

and the like.

4. Always reinstall the protective covers if they have been removed for adjustment or

maintenance. After adjustment, always ensure that all nuts and bolts are properly

tightened. Ensure that any tools used are removed from the machine before reinstalling

the protective covers and starting the machine.

5. Before starting the machine, ensure that all persons are out of its reach and at a distance

visible to the machine operator.

6. It is allowed to use original Timan A/S spare parts only.

7. Service and maintenance with the multifunctional arm lifted.

INTRUCTION AND SAFETY

5

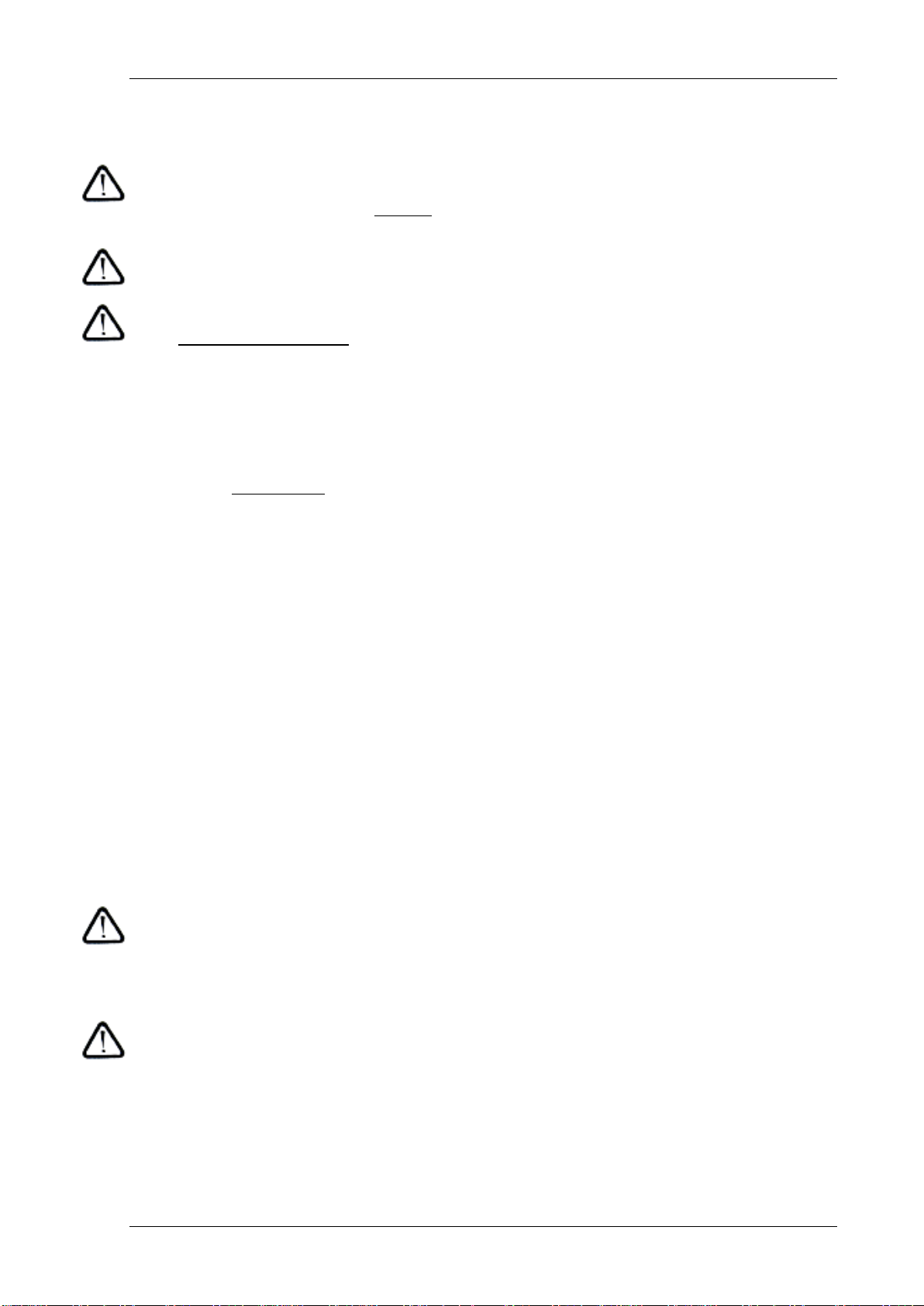

In case that the Tornado-400 machine is lifted from the ground during a service

inspection or maintenance, the implement carrier quick change system (quick hitch)

must be tilted completely back and secured using the safety hook.

In case that the Tornado-400 machine is lifted from the ground during a service

inspection or maintenance, it is always necessary to use the implement carrier

multifunctional arm safety support.

Safety support Safety hook

INTRUCTION AND SAFETY

6

4EXPLANATION OF THE MACHINE WARNING SIGNS

When developing the machine, every effort was made to ensure operator protection against

safety hazards. However, in special situations the machine can still represent a hazard.

Warning signs are therefore placed on the machine to reduce the risk of damage. It is

therefore important to pay attention to the hazards indicated on the following labels. Read

carefully the explanation of individual warning symbols and learn their meanings.

Keep the warning signs clean and if damaged, replace them or add the missing signs

immediately.

a. b. c. d. f. g.

a. WARNING: Rotating parts. Keep the safe distance.

b. CAUTION – Before maintaining and repairing the machine, stop the implement

carrier and set the main switch to the OFF position. Use the operating

instructions.

c. WARNING. Risk of crushing your body. It is prohibited to stay or move under

the lifted machine.

d. Do not stay or move under the machine without using the safety support and the

safety hook.

f. WARNING. It is prohibited to lift the collection container lid unless the machine

is stopped and the key is pulled out of the implement carrier.

g. CAUTION – Read the instructions before handling.

INTRUCTION AND SAFETY

7

5GUARANTEE PROVISIONS FOR TORNADO-400

Liability for defects on delivery:

1. For all the parts where it is proved that they are not usable or that their usability is

significantly reduced for reasons caused before the takeover, especially manufacturing

defects, bad material, or faulty design, their repair or replacement will be carried out

free of charge at the discretion of the supplier or after appropriate examination. The

supplier must be informed of defects determined in this way immediately in writing.

The replaced parts are the property of the supplier.

The guarantee period is 1,000 hours of operation or 12 months whatever comes sooner.

Liability expires not later than 12 months after the goods leave the factory or are taken

over by the end customer.

For important parts of a different brand, the supplier’s liability is limited to the

guarantee given by the supplier of the other brand.

2. Liability does not arise for damage caused by the following reasons:

Improper or unauthorized use, incorrect installation or starting by the customer or

a third party, natural wear, incorrect or careless handling, improper operation

equipment, replaceable parts, lack of installation, or chemical or electrical influences if

they cannot be transferred back to the supplier.

3. The customer is obligated to give the supplier by agreement the time and possibilities

necessary for carrying out any improvements and supplies of spare parts as reasonably

assessed by the supplier. Otherwise, the supplier is released of its liability. However, if

work safety is still endangered and to avoid excessive damage, the customer - after

concluding the relevant agreement with the supplier - is entitled to remedy the defect by

itself or through a third party and to obtain pre-agreed compensation.

4. If (in accordance with par. 2) a defect is shown, the supplier shall bear the costs of spare

parts, including the transport costs and the appropriate installation costs at the

supplier’s rates known. It also bears the costs if in individual cases it is possible to

require extra assistance and help of technicians who may be provided by the supplier.

The payment of the other costs is the customer’s responsibility.

Wrongly filled in complaint records will not be taken into consideration.

A repair will be carried out without undue delay, not later than 14 days from the date

when the damaged was incurred.

Complaint records received by the importer after the lapse of 8 days from the date of

repair will not be recognized.

The parts under claim which are required by Timan A/S to be returned must be

delivered not later than within 8 working days after the takeover of the spare parts. The

returned parts will be accepted only if they bear the label and the complaint record

number.

INTRUCTION AND SAFETY

8

Any decision concerning a complaint can be appealed against not later than within

3 weeks after the takeover of the complaint.

5. The guarantee period for spare parts and repairs is three months. However, this

guarantee period applies only until the end of the original guarantee period for the

relevant delivery.

6. If unauthorized modifications or repairs are carried out by the customer or a third party

without prior agreement with the supplier, the liability for any damage caused by such

modifications or repairs ceases to exist.

7. Other claims of the customer, especially the claim for compensation of damage not

caused on the machine, are excluded.

MACHINE DESIGN

9

6MACHINE DESIGN

The machine is mounted on the implement carrier tilting frame with a hydraulic quick change

device (quick hitch).

The machine collection container is an integral part of the machine frame, which ensures the

compact design and a good driver’s view of the sweeping brushes.

When the collection container is full, the machine can be lifted above the container using the

implement carrier multifunctional arm and then the bottom of the collection container is

hydraulically opened and the collection container is emptied.

To reduce dust, the machine is equipped with a water tank, a water pump (12 V), a filter, and

a water nozzle.

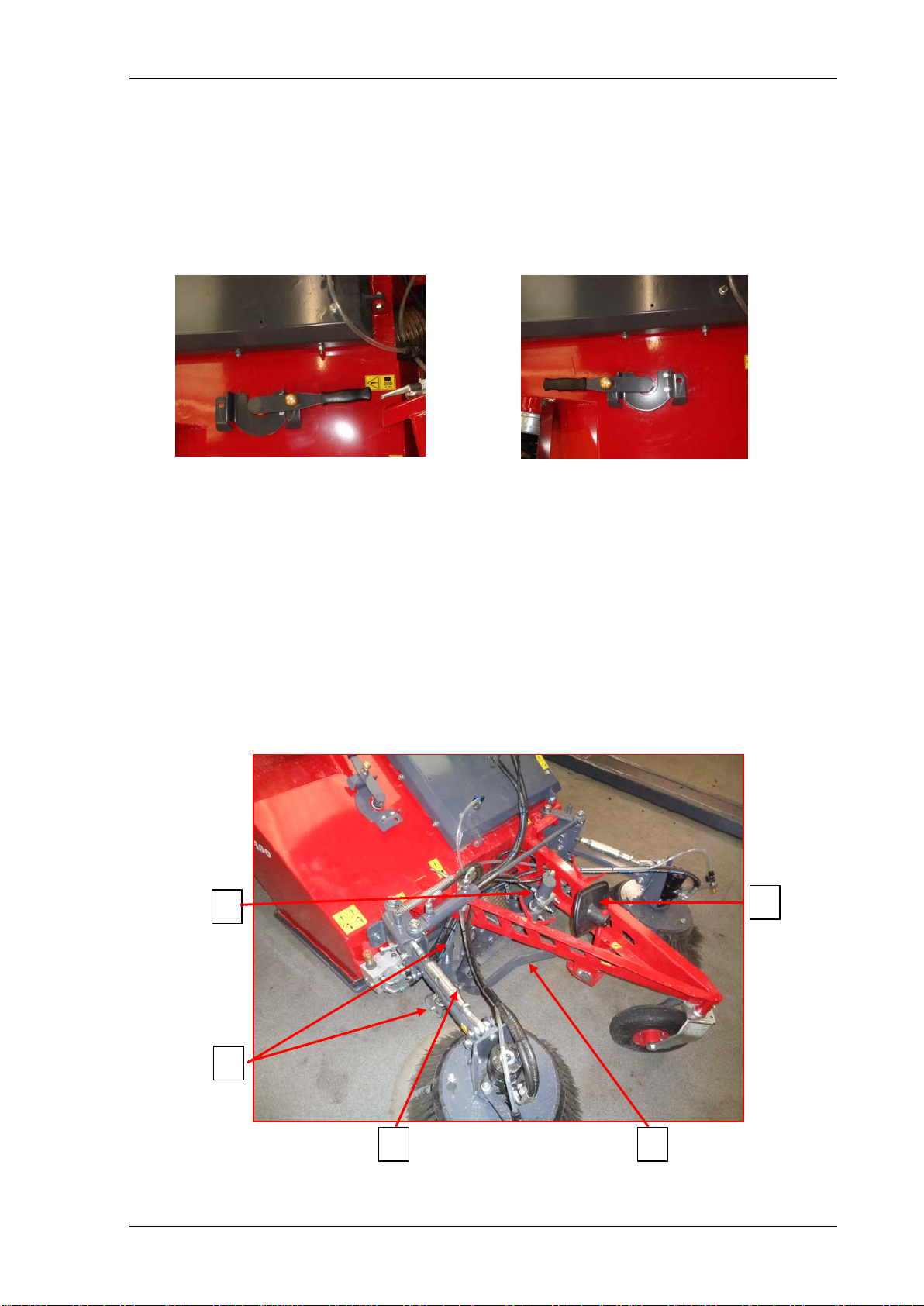

2) 4) 3) 1)

The machine has the following main parts:

1) Collection container

2) Suction nozzle

3) Suction unit

4) Sweeping brush

5) Hand suction device - additional equipment

6.1 Collection Container

The machine includes a collection container with a volume of 400 l. The implement carrier is

connected to it using its hydraulic quick hitch.

On the front of the collection container there is a rubber wheel, thanks to which the machine

always floats on the surface.

5)

MACHINE DESIGN

10

The machine also includes a water tank with a capacity of 50 litres and a water jet designed to

moisten the environment to eliminate dust generated during work. A jet is placed at each side

brush and on the brush before the suction device leading to the tank.

On the top of the collection container there is a turning handle, using which it is possible to

adjust suction to the suction nozzle (Fig. 1) or to the hand suction device (Fig. 2).

6.2 Suction Nozzle

The suction head is firmly attached to the machine using two free arms (a), on which the eye

rod (b) is welded. Two wheels (c) are mounted on each side of the nozzle.

The suction hose floats on the terrain and keeps a constant distance from the surface.

On the front of the nozzle there is a rubber cover, which is firmly attached to the hydraulic

cylinder (d). In the case of large objects, the suction nozzle opening can be enlarged by

activating the cylinder.

A mirror (e) is located on the front of the machine; the operator can see if the suction nozzle is

clogged or the flap should be raised for large objects.

Fig. 1: Suction from the hand suction

Fig, 2: Suction from the suction nozzle

a

b

c

d

e

MACHINE DESIGN

11

6.3 Suction Unit

The suction unit is mounted on the hinged lid (a), which facilitates the servicing and cleaning

of the unit. The suction device is driven hydraulically by a hydraulic motor.

Important: Never open the lid if the machine is in operation.

To reduce the dust concentration from the machine exhaust air, the suction unit is equipped

with the rotating brush (b). Due to the brush large particles cannot enter the suction wheel.

The brush sorts fine dust particles and takes them into the collection container.

If the weather is dry, the brush can be kept wet using the water jet (c), which increases the

size of the particles and thus increases the efficiency of the brush.

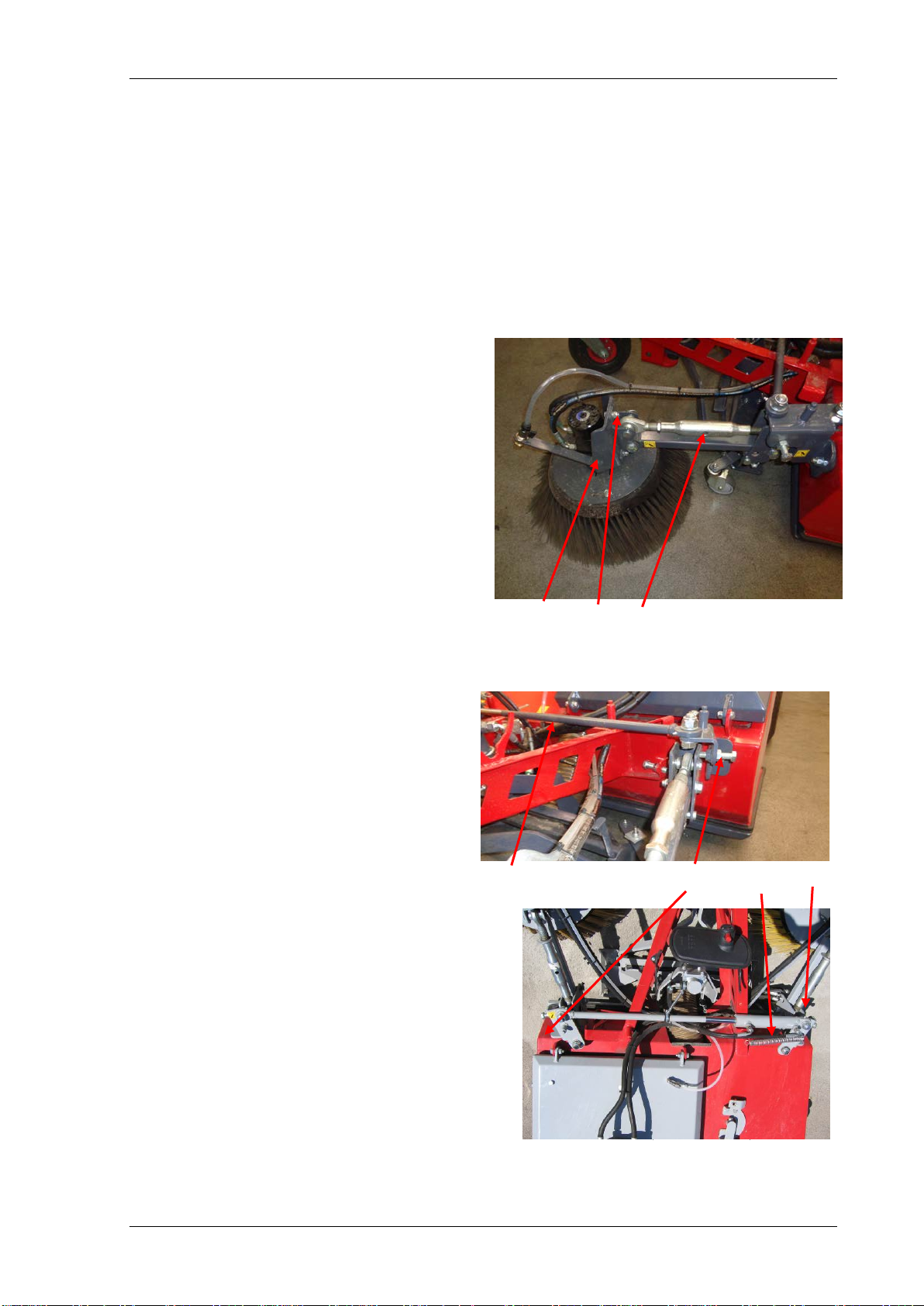

6.4 Sweeping Brush

The machine is equipped with 2 hydraulically driven sweeping brushes (a), which are

suspended from the parallel arms. This ensures that they will always float on the surface and

that the angle which is included by the brushes and the surface when they are worn does not

change.

The hand control button on the flow control valve (b) on the right side of the machine can

continuously adjust the speed of rotation of the sweeping brushes.

The hydraulic cylinder (c) enables to adjust stepless the width of sweeping from 1,360 mm to

1,800 mm for new brushes.

a c b

a

c

b

MACHINE DESIGN

12

6.5 Hand Suction

Also a hand suction device for cleaning the areas where it is not possible to drive the machine

can be part of the machine as additional equipment.

The hand suction device is placed in the holder (a) on the implement carrier multifunctional

arm. To be of lightweight construction, the hand suction device is made of aluminium.

The eight meters long flexible hose is empty during transport and is stored as an integral part

of the hand suction device.

When disconnected from the machine, the hand suction device is placed on the front of the

machine.

Important: When using the hand suction device, always use hearing protection.

a)

DRIVING THE MACHINE

13

7INSTALLATION AND REMOVAL OF TORNADO-400

7.1 Installation of Tornado-400

1. Connect the machine using the implement carrier quick change system (quick hitch).

Activate the hitch to secure the machine firmly to the implement carrier.

2. Lift the machine 100 mm above the ground and tilt it forward in such a way that the

wheel in the front of the machine touches the ground. This will give you more space

for connecting the hydraulic hoses.

3. Stop the implement carrier; the pressure on 3 hydraulic ports on the multifunctional

arm will be released.

4. Disconnect the hydraulic hoses for the quick hitch and place them into the holder on

the bottom of the multifunctional arm (1).

5. Connect four ¼'' hydraulic quick couplings. Please note that the hoses are arranged as

2 and 2. The longest hose must be placed on the highest level on the multifunctional

arm.

6. Connect the drain hose.

7. Connect the light plug (3).

8. Connect 2 pieces of 3/4'' hydraulic quick couplings (4). The longest of them is placed

on the highest level.

9. Additional equipment: Pull the hand suction device out of the holder on the machine

(5) and place it on the multifunctional arm, where it will be placed into the appropriate

holder (6). Then secure the adjusting screw (7).

DRIVING THE MACHINE

14

7.2 Removal of Tornado-400

When removing the sweeping/suction machine, proceed in reverse order.

Make sure that before driving the implement carrier from the machine all hydraulic hoses,

lines, and hand suction device are disconnected from the machine.

8DRIVING THE MACHINE

8.1 Adjusting and Setting the Side Brushes

Use the top bar (c) to set the brush angle in

such a way that only the front half of the brush

touches the surface. The brushes must touch

the surface just enough to be able to sweep

throughout their working widths. Use the

attached spanner to loosen the lock nut.

For optimal sweeping, it is necessary to rotate

the brush bracket (d). Rotate the right brush

a few degrees clockwise and rotate the left

brush counter clockwise. Thus, the brush will

operate on the external side.

Adjust by loosening 3 bolts (e) on the turning

bracket.

d) e) c)

The hydraulic cylinder (f) enables to set the working width of the sweeping brushes between

1,360 mm and 1,800 mm (new brush).

When the brushes are gradually worn, material residues will remain near the suction nozzle

when driving with the full working width.

To avoid this, set the machine to the

maximum sweeping width. Do this by

loosening the lock nut (g) using the attached

spanner and then tighten the bolt until the

brush reaches the same level as the inner

edge of the suction nozzle. Make sure to

retighten the lock nut after adjustment.

After starting the machine, the brushes will

automatically move against the limit switches (h)

on which the cylinder (f) is mounted.

The spring (i) determines whether the right or left

brush will move the first on expanding the

cylinder, depending on whether the spring is

located on the right or left side of the machine.

If the spring is placed on the right side as shown

in the figure, the left brush is lifted first.

f)

i)

f)

g)

h)

i)

DRIVING THE MACHINE

15

The speed of rotation of the brushes can be

adjusted using the adjustment screw (k).

The speed of rotation of the brushes depends

partly on the speed of travel of the machine and

partly on the surface material.

The brushes can be manually stopped using the

ball valve (l). Turn the handle approx. ¼ of a

turn.

8.2 Adjusting the Suction Nozzle

To achieve the optimal suction power, it is important to set and adjust the wheels properly.

1. Find a smooth and level ground to place the sweeper on. Place the sweeper on the

ground.

2. Stop the implement carrier.

3. Place the small disc under the front of the suction mouth, and the square plate under

the rear of the suction mouth. The disc is 2,5 mm thick, and the plate is 5 mm thick.

4. Adjust the screws until the suction mouth is just above the disc and plate. Lock the

screws.

Wrong adjustment reduces the life of the wheels and reduces the suction power of the

machine. Check adjustment every 50 hours.

k)

l)

DRIVING THE MACHINE

16

8.3 Emptying the Collection Container

Empty the collection container directly onto

the ground or into a container.

To open the bottom of the collection

container, the suction device and the brushes

must be off.

When emptying the collection container,

remain seating on the driver’s seat and keep

the door closed.

Warning! It is forbidden to stay near the

machine during emptying the collection

container.

8.4 Filling the Water Tank

1. Fill the water tank with water.

2. The sweeper includes a water jet designed to moisten the environment to eliminate dust

generated during work. A jet is placed at each sweeping brush and another one is placed on

the middle brush inside the container. If all the three jets are used, water consumption is

approx. 1.2 litres per minute.

The water content in the container can be found on the transparent plastic hose on the right

side of the water tank.

8.5 Floating Position

When driving the machine, the implement carrier

multifunctional arm falls completely down and

the hydraulic quick change system (quick hitch) is

tilted completely to the rear.

The quick change system (quick hitch) is tilted

forward until the chain is loose (b).

The rubber wheel in the front of the machine can

now float because if there is any unevenness on

the surface, the machine will pivot around the

point (c).

8.6 Driving Tips

After sweeping, material often remains captured between the brush and the suction nozzle and

can be removed by putting the brushes to each other and reversing one meter back (with the

brushes rotating) and then you can drive forward again.

8.7 Hand Suction Device

The procedure for preparing hand suction:

1) Start the machine and set the number of revolutions on the implement carrier to the

required level.

2) In dusty conditions, when the sprayer is used, close the water jets on the side brushes

using the ball valve (a) not to waste water unnecessarily.

Table of contents