1. Read thismanual carefully until you completely understand and follow all safety and operating instructions.

2. Keep this manual handy so that you may refer to it later whenever any questions arise. Also note, if you

have any questions which cannot be answered herein, contact the dealer from whom you purchased the

product.

3. Always be sure to include this manual when selling, lending, or otherwise transferring the ownership of this

product.

4. Never allow children or anyone unable to fully understand the directions given in the manual to use the

machine.

5. During transportation close the fuel cock and the fuel tank cap. Empty the fuel tank during transportation

on long distances or rough roads.

6. Don’t use the engine pump nearpeople or anim.a ls

7. Do not use the pump set close to cables orelectrical equipment.

8. Keep the running (or still hot)pump away from any inflammable material.

9. Be careful with the muffler or other hot engine parts. During transportation close the fuel cock and the fuel

tank cap. Emptythe fueltank during transportation on long distances or rough roads.

10. Only use the pump in well-ventilated places, do not operate the pump in explosive or flammable

atmospheres or in closed environments.

11. Check the pump each day to ensure thateach device, whether for safety or otherwise, is functional.

12. Never use a damaged, modified, or improperly repaired or assembled pump. Do not remove, damage

or deactivate any of thesafety devices.

13. Never carry out operations or repairs on your own that are other than routine maintenance. Call

specialized and authorized workshops only.

14. Keep thepump set in a dry place, raised off the ground and with the tanks empty.

15. If your pump is no longer usable, dispose of itproperly without damaging the environment by handing it

in to your local Dealer who will arrange for its correct disposal.

16. Take it to your dealer who will dispose of it properly. Always call your dealer for any clarification or priority

action.

INTEND USE

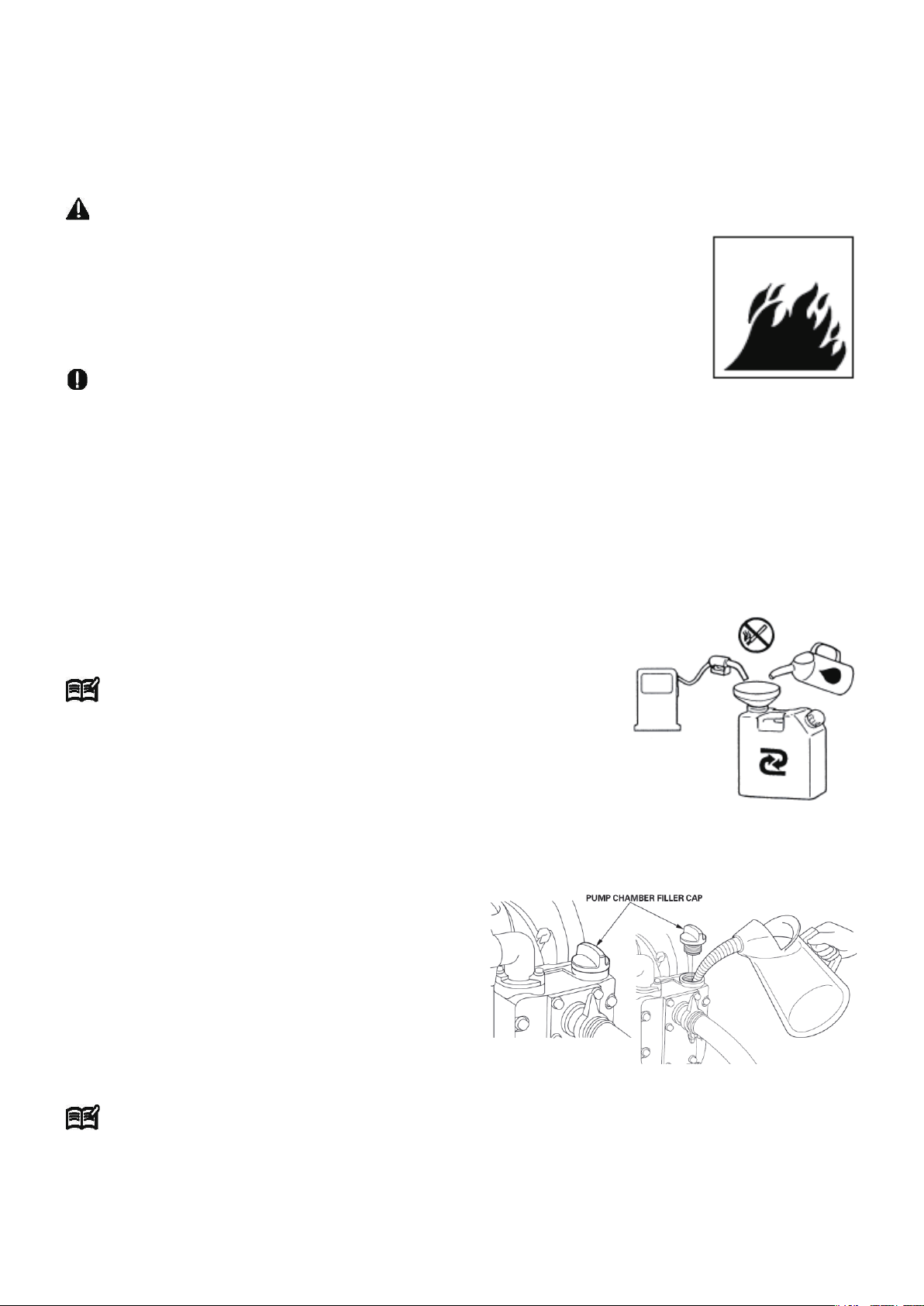

Only pump the water that is not intended for human consumption. Pumping flammable liquids, such as

gasoline or fuel oils, can result in a fire or explosion, causing serious injury. Pumping sea water, beverages,

acids, chemical solutions, or any other liquid that promotes corrosion can damage the pump.

■WORKING CIRCUMSTANCE

Please make sure youreview each precautioncarefully.

EXHAUST PRECAUTIONS

•Never inhale exhausts gasses. They contain carbon monoxide, a colorless, odorless and extremely

dangerousgas which can cause unconsciousness or death.

•Never operate theengine indoorsor in a poor venting area, such as tunnel, cave, etc.

•Exercise extreme care whenoperating the enginenear people or animals.

•Keep theexhaust pipe free offoreign objects.

4.For safe operation

GB 5