TinLizzie18 Apprentice Plus Instruction Manual

User Guide

www.tinlizzie18.com

Apprentice Plus User Guide | 3

Table of Contents

Welcome 5

Warranty 6

Diagram showing the sides of the machine 7

Attaching the Handlebars 8

Your Rocker Arm Cover 9

Your Rear Handlebars 9

Your Thread Stand 10

Connecting Your Apprentice Plus to Your Carriage Assembly 11

General Operation of the LCD Key Pad 12

What is the Tension Release Lever? 14

Adjusting the Height of the Hopping Foot 15

Adjusting the Stroke of the Hopping Foot 15

Routine Cleaning and Oiling 16

Bobbin Winder and Bobbins 17

Threading Overview 19

Threading your Apprentice Plus 19

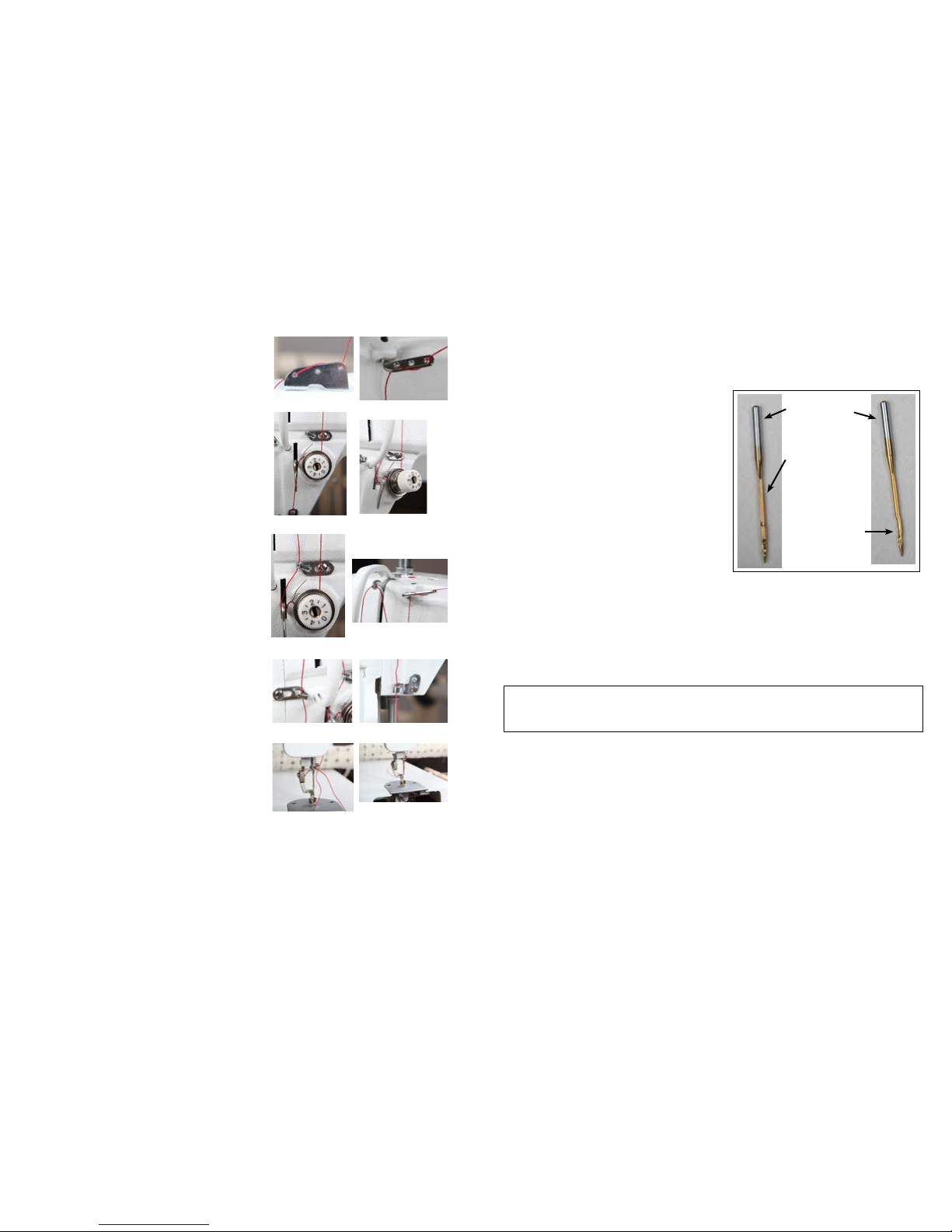

How Do I Change the Needle? 21

How Do I Make Adjustments to Make the Perfect Stitch? 22

Tension, Tension, Tension 23

Trouble Shooting Checklist

Check Spring Replacement / Tension Knob 25

Machine will not sew. I cannot turn the hand wheel 27

Timing your Machine 28

Adjusting the Bobbin Winder Lever 30

Adjusting the Tension Assemble Thread Guides for Proper Fill 30

Adjusting Bobbin Winder for Contact with the Upper Shaft 31

© 2017 Printed in the United States

First Print October 2017

4 | Apprentice Plus User Guide Apprentice Plus User Guide | 5

Dear Apprentice Plus owner,

Thank you for your purchase of the Apprentice Plus Long Arm Quilting System by

TinLizzie18… Your Aordable Long Arm Quilters. Appentice Plus by TinLizzie18 oers you

the ultimate marriage of aordability and functionality, and comes with a one-year complete

warranty. We will always stand behind our products and any warranty issues will be xed

at no charge. Warranty on parts is ve years and covers the sewing machine head, motor,

electronics and frame.

At TinLizzie18, we view our customers as family, making great strides together to build a

community of quilters. Having been in the sewing industry for over 60 years, TinLizzie’s

experience runs deep. Our customers can expect nothing less than the best. We pride

ourselves on customer service and continuing education to better your understanding of the

mechanics, and also to unleash your artistic quilting abilities.

As we continue our long arm quilting journey together, please know that we are here, ready

to assist you with any questions you may have, from quilting tips, ongoing education, and

service assistance. Do not hesitate to call (888-QUILT-18) or email us ([email protected]).

The TinLizzie18 website (www.tinlizzie18.com), contains information about long arm quilting,

our company history, a lineup of educational videos and webinars and a listing of quilt shows

coming to an area near you.

The TinLizzie18 long arm quilting system is large enough for the professional, yet aordable

enough for the everyday quilter. No other machine oers you more for less. Happy quilting!

Sincerely,

The TinLizzie18 Team

Small enough to know you personally, yet

large enough to service all of your long arm quilting needs.

6 | Apprentice Plus User Guide Apprentice Plus User Guide | 7

Warranty

We believe that we have designed and are manufacturing the best long arm quilting machine available.

As you unpack your machine, be sure to keep the box and packing materials designed to

protect the machine during shipping. Should it become necessary for you to return the

machine for warranty work, please call us for specic instructions for packing and shipping

your machine.

• Your Apprentice Plus has a full labor warranty for one year from the day you receive your machine.

We guarantee the machine parts for ve years.

• The machine must be cleaned and oiled regularly according to the instructions in this manual. Failure

to properly maintain the machine will void this warranty.

• Your Apprentice Plus must be plugged into a surge protected electrical outlet. We highly recommend

using an Uninterrupted Power Supply (UPS) also known as a Battery Backup. This helps to ensure

that you are getting a regulated 110 volts into your machine. See photo below of UPS Battery

Backup.

• Should we mutually decide that your machine cannot be repaired using normal communications we

will arrange for machine to be returned to the factory.

Be sure to register your warranty on the TinLizzie18 website.

Should You Have a Problem

Please contact your selling dealership as they are also your servicing dealership. If your dealership is

unable to fulll your needs, please visit www.Tinlizzie18.com and choose Service and Support.

Diagram Showing the Sides of the Machine

Front

Back

1. Handlebars

2. Control Screen

3. Thread Stand (left side of machine)

4. Bobbin Winder

5. Motor Cover

6. Hand Wheel

7. On/off Switch (power plug in)

8. Needle

1

2

3

4

5

6

7

8

8 | Apprentice Plus User Guide Apprentice Plus User Guide | 9

Attaching the Handlebar and Control Box to the Front

Your Apprentice Plus comes with two handlebars (a right and left) along with the main control box which

attach to the front of the Apprentice Plus. There are four screws and four clamps to hold these in place.

Step 1: Locate your set of handlebars and the

control box.

Step 2: Remove the four screws and clamps located

on the front of the machine above the needle. Figure

1 shows the front of the machine without the screws

and clamps.

Note: The front and rear handlebars are set up for left

and right. The right handlebar has red and white buttons

while the left handlebar has blue and yellow buttons.

See gure 2

Step 3: Place two clamps around the right handlebar

as seen in gure 3

Step 4: Place the main control box with bracket

behind the handlebar. See gure 4

Step 5: Using one of the four screws, attach the

bottom screw in the right handlebar and secure to

machine front nger tight, making sure that the main

control box bracket is lined up with the four screw

holes. See gures 5 and 6

Step 6: Place the brackets around the left handlebar

and attach the lower screw to the main control box

bracket to the machine. Finger tight for now. See

gure 7

Step 7: Attach remaining two screws to secure

the handlebars and main control box to the font of

the machine. See gure 8. Figure 9 shows the

handlebars and main control box in place.

Step: 8 Check that all your screws holding the

handlebars and main control box in place are tight.

Step 9: Use the remaining unconnected cable

coming from the side of the machine to connect the

main control box to the machine electronics. See

gure 10

Figure 1 Figure 2

Figure 3

Your Rocker Arm Cover

The Apprentice Plus machine ships without the

rocker arm cover attached to the machine.

Step 1: Remove the four screws from the casting

so that you can install the rocker arm cover.

Step 2: Dress the cords so that they are in a group

ready to be placed in the rocker arm cover. See

gure 11

Step 3: Line up the cords in the base of the rocker

arm cover thru the provided opening in the front of

the cover. See gure 12

Step 4: Secure the rocker arm cover to the

machine using the four screws you removed from

the machine. See gure 13

Figure 11

Figure 12

Figure 13

Figure 4

Figure 5 Figure 6

Figure 7 Figure 8

Figure 9 Figure 10

Your Rear Handlebars

Step 1: Using the same style clamps but from

the back of your machine you will attach your rear

handlebars.

Step 2: Take the left handlebar (blue and yellow

buttons) and attach to the left side of the machine

when standing in the back.

Step 3: Take the right handlebar (red and white

buttons) and attach to the right side of the machine

when standing in the back.

Step 4: Set handles for your comfort and tighten in

place.

10 | Apprentice Plus User Guide Apprentice Plus User Guide | 11

Your Thread Stand

Your Apprentice Plus comes with a four spool thread stand. This thread stand is connected to the side

of your machine and can hold bobbin thread you are using to wind onto your bobbins and the top thread

you are using to quilt. You can also have a second spool of thread on the stand if you are using two

dierent threads on your quilt. This 4 spool thread stand has a telescoping thread holder which needs to

be all the way up when you are quilting to help the thread come o the spool evenly and smoothly.

Step 1: If the telescoping thread tree is not on the thread

stand then you will need to attach it.

Step 2: Slide the telescoping thread tree into the hole

provided between the tread holders.

Step 3: Using the supplied screw with washer insert from

the bottom side to secure the telescoping thread tree in

place.

Step 4: On the left side of your machine ( the left side of

the machine is the side with the motor) you will see two

screws not holding anything on yet. See gure 15

Step 5: Loosen these two screws. You don’t need to take

them out but they do need to be loose so that you can

slide the thread stand over them.

Step 6: On the thread stand you will see two holes on the

underside which can be placed over the two screws and

then drop into place. See gure 16

Step 7: Once you have the thread stand in place over the

two screws tighten the screws to hold the thread stand in

place. See gure 16

Remember to pull the telescoping thread tree to the full up

position to use. See gure 17

Figure 14

Figure 15

Figure 16

Figure 17

Connecting your Apprentice Plus to your Carriage Assembly

Your Carriage Assembly will need the encoder assemblies attached to the carriage before placing your

machine on the carriage. Using the Apprentice Plus encoder assembly instructions attach your encoder

assembly to the carriage.

Step 1: Locate the encoders and cables on the carriage. Check them for damage prior to

placing the machine onto the carriage. See gure 18

Note: If your encoder assemblies are not installed on your carriage, use the Apprentice Plus install

instructions and install the encoder assembly before loading your machine on the carriage.

Step 2: Place the machine on the upper carriage. Center the machine as much as possible to

get the full range of the quilting area.

Step 3: Locate the upper carriage encoder cable and connect it to the second connection

point on the side of the power box.

Step 4: Locate the lower carriage encoder cable and connect it to the third connection point

on the side of the power box.

Figure 18

Upper Encoder

Lower Encoder

Left Rear Handle Bar

Right Rear Handle Bar

Laser Light port

12 | Apprentice Plus User Guide Apprentice Plus User Guide | 13

General Operation of the LCD Key Pad

When you turn on your Apprentice Plus, during start up you will see

some screens ash by if you watch the display, which show you the

version among other things. Once you see the screen in Figure 19,

you are ready to use the machine.

The control keys are as follows:

Auto Stitch (Stitch Regulation)

At this point, if you want to change the stitches per inch (SPI), you can

press and release the (-) key to decrease the number of stitches, or you

can press and release the (+) key to increase the number of stitches.

Note: If you press and hold the (-) or (+) keys, you will see the numbers

decrease or increase more quickly than if you just press and release the (-) or

(+) keys.

Once you are happy with the SPI, you can press and release the Start/

Stop key and the LCD will change. You can see on the LCD that next

to the stitch, you see the word ON. This means the quilter is ready to

quilt and as you move the quilter it will stitch.

Figure 19

Auto Stitch

Pressing this button activates the stitch regulation

with stop feature

Manual Stitch

Pressing this button activates the manual stitch

Decrease Button

Lowers stitches per inch, speed or change menu

options

Menu Button

Opens the menu

Increase Button

Increases stitches per inch, speed or change

menu options

Manual Stitch

If you choose Manual, you will be in the manual stitch mode of the

machine. Figure 20 shows the LCD screen for Manual. You will

notice you have the OFF just like in Auto, but you have numbers

with percentages at the bottom rather than just numbers. As with

Auto, the (start/stop) key will turn the machine on and you will be

ready to stitch. Unlike Auto, once you hit the (start/stop) key, the

machine will be sewing.

As with Auto, you can use the (-) or (+) keys to decrease or

increase the speed of the machine. Manual does not have a

default to turn o once it has been turned on. If you stop moving,

thread will build up until it runs out of thread or your thread

breaks. It will keep running until you press the (start/stop) key.

Figure 20

White Lights

By pressing the + key you can increase the intensity of the light

from 0% to 100%.

By pressing the - key you can decrease the intensity of the light

from 100% to 0%.

The lights change by 20% with each push of the + or - keys.

Black Lights

The black lights are either on or o. Pressing the + key turns

them on and pressing the - key turns them o.

Laser Port

The laser port is also either on or o. Pressing the + key turns the

port on and pressing the - key turns the port o.

Figure 21

14 | Apprentice Plus User Guide Apprentice Plus User Guide | 15

What is the Tension Release Lever?

The tension release lever raises the hopping foot

and releases the tension on the thread. See gure

24

You can watch the tension disc plates open as you

lift the lever.

NEVER start sewing with the lever up. There will be

no tension on the thread which will result in stitches

on the bottom being bad with huge loops and other

wrong looking stitches. Tension Release Lever

Figure 24

Encoders

Encoders show two sets of numbers. When you are on this

display, you will see the numbers change as you move the

machine and the encoders send a signal to the machine.

Encoder 1 is for the top encoder port.

Encoder 2 is for the bottom encoder port.

Motor/Index

Here you will see two sets of numbers as well.

Motor—if the motor is turning the numbers will change.

Index—shows the needle up sensor reading. The needle position

sensor numbers will change. Figure 23

Figure 22

Adjusting the Height of the Hopping Foot

There are many reason to adjust the height of the hopping foot. You could be using a thicker batting,

quilting a quilt with thicker seams, or just need a little more clearance. You don’t want the foot to be too

high as that can cause strain on the thread, create agging of the fabric while stitching, or may be too

high if you put a ruler next to it for measuring.

To adjust the height of the hopping foot, use these steps.

Step 1: Lower the needle into the fabric to get the hopping

foot to its lowest position (close to a seam is a good place since

you can then tell how high you need to be to clear the seam).

Step 2: Loosen screw (A) on the side of the hopping foot (B).

See gure 25

Step 3: Move the foot up or down to adjust for your project.

Step 4: While holding the hopping foot where you want it

tighten the screw back down.

Factory setting for this is, with needle down a dime should be

able to pass below the foot and touch the foot as it passes

under. See gure 26

Adjusting the Stroke of the Hopping Foot

Factory setting is in the down position. The reason for

less stroke is for better ability when working with rulers.

Adjustment of stroke is for going over thicker seams.

Step 1: Remove the four (4) screws (A) holding the

cover (B) in place on the front left side of machine.

See gure 27

Step 2: Using a wrench, loosen the bolt (C) on the link

adjusting crank (D) and slide up to increase the stroke

or down to decrease the stroke. See gure 28

Step 3: Use your wrench to tighten the bolt (C)

Step 4: For your safety, replace the cover (B) prior to

use, using the four (4) screws (A)

Figure 28

Figure 27

Figure 26

Figure 25

16 | Apprentice Plus User Guide Apprentice Plus User Guide | 17

Routine Cleaning and Oiling

Routine cleaning and oiling is very important to the longevity of your quilting machine. Brush out the

fuzz from around the hook and foot. Change your needle regularly to avoid thread breakage, tension

problems and needle breakage. A worn needle can mean skipped stitches, shredded thread and a

weakening of the needle itself. These things can lead to stitch quality issues.

Lint has a tendency to build up in the bobbin case. A tiny amount of lint can cause poor stitches. Check

the bobbin case each time you change the bobbin to keep it clean. We suggest using a soft bristle brush

to wipe out the bobbin case and the bobbin area. Canned air only blows the lint around. By using a soft

bristle brush, you collect the dust on the brush. Occasionally, place a drop of machine oil on a cotton

swab to wipe out the bobbin case.

Keep your table clean of dust and oil. Clean the bars and carriage deck regularly for smooth movement.

Oiling is extremely important to the longevity of your quilting machine. Failure to oil your machine

regularly can void your warranty.

The one oiling spot (marked with red arrow below) is marked with red paint on your machine. An oil

bottle is included with your machine. The one oiling spot (marked with a blue arrow below) contains a dip

stick. Remove the dip stick by lifting it up with a ngernail or screw driver. Place drops of oil in this same

hole if you nd no oil on the dip stick.

Recommended oiling:

After every nished quilt, place three to four drops of oil at the location with a red spot toward the front

(needle side) of the machine. This is located on the top of the machine. See gure 29 The other

location is the oil dip stick found just behind the needle. At this time make sure oil is present on the

dip stick. If not, add three to four drops of oil where you pulled the dip stick out. Run the machine to

lubricate. Use a clear, high grade sewing machine oil.

Note: The machine pictured here is before complete assembly from factory; your machine has more components

attached.

Oil spot on top

Oil reservoir location

Oil dip stick lifted

Oil dip stick out Figure 32

Figure 31

Figure 30

Figure 29

Bobbin Winder and Bobbins

A bobbin winder is included with your machine. The thread on a properly wound bobbin should be snug

and have even layers of thread. A sloppy or mushy wound bobbin will result in poor stitch quality.

How do I wind a Bobbin?

Step 1: Insert an empty bobbin on the bobbin winder

spindle. See gure 33

Step 2: Place a cone of thread on the holder.

Step 3: Bring the thread up through the guide over the

cone of thread. See gure 34

Step 4: Insert the thread through the top guide hole, then

around the tension disk and through the bottom thread

guide. See gure 35

Step 5: Wrap the thread around the bobbin clockwise

three or four times.

Step 6: Push trip mechanism forward until it snaps into

position. See gure 36

Use step 7 if you plan to quilt while your bobbin is winding.

Use step 8 if you are winding bobbins without quilting.

Step 7: Bobbin winder will start winding the bobbin once

you press the start/stop key. You can quilt while your

bobbin is winding. Once it is full, it will stop.

Step 8: If you wind your bobbin when not quilting, ensure

that you do not have thread in the needle to prevent jams.

Also remove the bobbin and bobbin case to prevent

damage. Select the constant stitch mode, then press

and release the start/stop button. Once the bobbin is full,

press and release the start/stop button again to stop the

machine.

Note: The needle will continue to move up and down

while you are lling the bobbin.

The bobbin will ll until the trip mechanism is pushed out by

the thread. It will then disengage the wheel. The bobbin

should ll to just below the rim. Having the bobbin too full

will cause tension problems.

Figure 35

Figure 34

Figure 33

Figure 36

18 | Apprentice Plus User Guide Apprentice Plus User Guide | 19

Check the tension of the bobbin by holding the loaded

bobbin case in one hand. With one hand under the

bobbin case, hold the tail of thread and watch as the

thread ows out of the bobbin case. A slight bounce

should cause the bobbin case to slide down the thread.

If the thread slides out of the case as you pick it up, it

needs more tension. If it barely moves down the thread or

doesn’t move at all, it needs less tension. See gure 37

To adjust the tension: See gure 38

Use a small screwdriver to turn the largest set screw

on the bobbin case to adjust tension. Make very small

adjustments. Be very careful not to remove the screw as

it is very small and dicult to nd if lost. Remember, righty

(clockwise) tighty, lefty (counter clockwise) loosey.

To place the bobbin into the machine:

Step 1: Insert the bobbin into the bobbin case. It does

not matter which way you put the bobbin in, but once you

have it one way just keep doing it that way.

Step 2: Holding the bobbin case, pull the thread through

the slot.

Step 3: Draw the thread down and under the spring,

making sure the thread is in the highest position of the

bobbin case.

Step 4: Place the bobbin case in the machine. Always

listen for the pop as it engages in the machine. See

gure 39

We suggest using a soft bristle brush to wipe out the

bobbin case and the bobbin area. Canned air only blows

the lint around. By using the soft bristle brush you collect

the dust on the brush. Use a business or index card to

clean under the tension spring on the bobbin case. See

gure 40

Each day before you start quilting, unthread your machine

past the take up lever and remove the bobbin case. Place

a small drop of oil in the bobbin hook area before you

begin quilting. This will clean out the fuzz and lint. Place a

drop of oil in the bobbin hook area. Turn your machine on

to run at the slowest setting.

TIP: Lint has a tendency to build up in the bobbin case, especially with cotton threads. A tiny

amount of lint can cause a huge headache! Check the bobbin case each time you change a

bobbin to keep it clean.

Figure 40

Figure 39

Figure 38Figure 37

Threading Overview

This is a diagram of the front side of your Apprentice Plus.

This is the side that faces the fabric. The back of your

machine has the electrical outlet and stitch regulator

connectors.

The numbers have been assigned in threading order.

See gure 41

1. Upper Thread Guide

2. Three Hole Thread Guide

3. Tension Assembly Disc

4. Check Spring

5. Silver Angle Bracket

6. Thread Guide

7. Take Up Lever

Threading Your Apprentice Plus

Your Apprentice Plus is capable of sewing with many types of threads. One thing to keep in mind is

this machine is an industrial machine, so very light threads will be harder to use than more traditional

machine quilting threads. Use of the other threads is alright, as long as you adjust the tension and

slow down. These machines are tested with Superior King Tut thread, which has a long staple and is a

machine quilting thread. When we are at quilt shows we use King Tut on top with Sone on the bottom.

The reason for this is two threads of equal size will ride on top of each other and ght to interlock.

When using a smaller thread in the bobbin, you can get more thread on the bobbin and the threads will

interlock faster and with less ghting since the smaller thread will nestle right down into the twist of the

larger thread, creating a better locking of the stitches.

Lets get started threading the machine:

Step 1: Place a cone of thread on the thread

holder.

Step 2: Pull the thread through the eyelet above

the cone of thread. Make sure to use the eyelet

directly above the cone of thread. See gure 42

8. Thread Guide

9. Thread Guide

10. Thread Eyelet Above the Needle

11. Needle

Figure 41

Figure 42

20 | Apprentice Plus User Guide Apprentice Plus User Guide | 21

Step 3: Thread the upper thread guide as show in gure

43 (if you use all three holes, it will add drag/tension to the

thread).

Step 4: Weave the thread as shown on the three hole

thread guide. (if you use all three holes it will add drag/

tension to the thread). See gure 44

Step 5: Take the thread between the two tension discs from

back to front all the way around. See gure 45 (Release

the tension on the tension disc using the tension release

lever. This will help to ensure your thread gets between the

disc easier.)

Step 6: While holding the thread up over the top of the

tension, hook the check spring. The tension spring should

come down as you pull thread.

Step 7: Thread now needs to run under the silver angle

bracket. See gure 46

Step 8: Now bring the thread up to the thread guide 6

above the tension assembly. You will be able to slide the

thread into this thread guide. See gure 47

Step 9: The thread will now be threaded through the take

up lever from the back towards the front. See gure 48

Step 10: Now bring the thread down the front of the

machine, snapping the thread into thread guide 8 and

thread guide 9 on the way down to the needle. See gures

49 and 50

Step 11: The thread will now go into the thread eyelet

above the needle. See gure 51 This is a hole, and

you will need to thread this spot. (TIP: Use a dental oss

threader to thread the guide above the needle. The

threader will also help thread the needle.)

Step 12: Thread the needle from the front to the back of

the needle. See gure 52

Figure 50Figure 49

Figure 48

Figure 47

Figure 46

Figure 45

Figure 44

Figure 43

Figure 52

Figure 51

How Do I Change the Needle?

A 134RSAN needle (size 18) will be installed on your Apprentice Plus from the factory. When it is time to

replace the needle, you can easily install one. Be sure the power switch is o. Remove the bobbin case.

To remove the needle, use the smaller screwdriver

included with your machine.

Step 1: Loosen the screw just above the thread

guide on the needle bar; the needle should fall out as

you loosen the screw.

Look closely at the needle. Your home sewing

machine needle shank (top of the needle) has a

at side. The top of the long arm machine needle

is round. On the point end of the needle there is a

scarf, or notch, in one side. The scarf must face

the back of your machine. The long groove at

the eye of the needle faces you as you insert the

needle.

Why does the scarf go to the back of the machine?

When the needle goes down through the fabric into the bobbin case, the hook comes around behind the

needle to pick up the thread. The scarf has to be there to provide a way for the hook to get between the

needle and the thread in order to pick up the thread.

Step 2: Place the new needle up in the slot, making sure the needle is up in the needle bar as far up as

it will go. Make sure the scarf is facing the back of your machine. Tighten the screw on the needle bar

while holding the needle up.

TIP: Use the old needle to hold the new needle in place while you tighten the screw. By placing

the point of the old needle into the eye of the new needle, you can see how straight you are

placing the scarf of the needle.

Before you turn your machine on, go to the back of the machine and turn the hand wheel a complete

turn, making sure the needle goes down in the center of the throat plate and the hook in the bobbin

area rotates with the needle smoothly. Put the needle down as far as possible. In the bobbin area, you

should be able to see the eye of the needle. When the hook rotates, it picks up the thread at the back

of the needle, then the top thread pulls the bobbin thread up to create a stitch. The scarf must face the

back of your machine.

Top of needle is

round, not at like on

your home sewing

maching needles.

Long groove goes to

the front. This is a path

for the thread to follow.

Back of needle has a

scarf. This is where the

hook passes and picks

up the top thread to

create the stitch.

Figure 53

22 | Apprentice Plus User Guide Apprentice Plus User Guide | 23

How Do I Make Adjustments to Make the Perfect Stitch?

Understanding how your long arm machine makes a stitch will help you make the proper adjustments to

make the perfect stitch. The technique all long arm machines use to make a stitch is basically opposite

of the home sewing machine. The home sewing machine is designed to press together two layers of

fabric and sew while the fabric is held in place by the presser foot. Long arm machines are designed

to press and sew multiple layers together while the machine head is moving. The dierence is, there is

practically no needle deection on a standard sewing machine, and a large amount of needle deection

on the long arm. The higher the tension, the more the needle will deect. Another cause for the needle

to deect on a standard machine is the type of fabric being sewn. A tightly woven fabric tends to force

the needle in dierent directions as it penetrates the fabric. This type of deection depends greatly on

the type of needle and type of point you use, such as a ball point or sharp point.

What is needle deection? What causes it? And how is needle deection related to the

stitches on my quilt?

On a long arm quilting machine, a stitch is mechanically created the same way as a home sewing

machine, except the quilter is the feeddog moving the machine head over the fabric. The hopping foot

presses the fabric together tighter and more quickly than a home sewing machine presser foot because

the fabric must be able to slide between the foot and the needle plate as the machine is sewing. This

means that the machine is moving while the needle is in the fabric. The worst thing for a needle is to be

in the fabric while the machine is moving which bends the needle, creating needle deection.

Good stitches will interlock in the batting between the quilt top and backing. In real life, this goal is rarely

achieved. For this reason, you need to be aware that you will have “pokies” if you use dierent colors of

thread on top and in the bobbin. Pokies are where you can see tiny dots of the contrasting thread where

the bobbin catches the top thread. If there is slightly more tension on the top than on the bottom, you

will see the pokies on the top side of the quilt. If the greater tension is on the bobbin, you will see the

pokies on the back of the quilt. If the pokies are objectionable to you, use the same color thread on both

top and bottom.

TIP: A general rule of thumb is...if the stitch looks bad on the top, it is the bottom tension. If the

stitch looks bad on the bottom, it is the upper tension. The upper and lower threads play tug of

war with each other.

Tension, Tension, Tension

This probably causes more problems than anything else. You need correct tension on the top and

bottom threads, but you must also have correct tension on the quilt held between the bars. You should

be able to gently rock the belly bar where the backing fabric is attached. This allows enough movement

of your quilt layers for the needle to penetrate and make good stitches.

Before you start making adjustments to your machine, ask yourself, “What changed?” If your machine

was stitching great and all of a sudden it has loopies on the back or puckers, “What changed?” Did you

just change the bobbin? Did you just lift the take up bar? Did you lower the take up bar after nishing

your last quilt? Did you recently change the needle? Did you just roll the quilt?

If the take up bar with the quilted portion of your quilt is too high, it will result in poor stitch quality. You

need a ngertip space between the quilt and the machine bed. Higher will result in poor stitch quality.

Lower and the quilt will create a drag on your machine’s movement.

Look at your bobbin. A sloppy wound bobbin will not create a good stitch. Make sure that the threads

on the bobbin are snug and evenly wound. Check to see if there is a piece of lint in the bobbin case.

Tension Troubleshooting Checklist

• Is the side tension lever down?

• Have I oiled my machine regularly?

• Is the quilt too tight on the frame?

• Is the thread coming o the cone freely?

• Has your thread jumped out of the tension discs?

• Check your threading. Has anything been missed, or has the thread ipped itself around something,

increasing your tension?

• Is the hopping foot too high or too low?

• Is your take up bar too high? Did you lower the take up bar after your last quilt?

• Do you need to change your needle?

• Is your needle in properly?

Top Thread Breaking

• Check to see that your thread is coming o the spool freely, and the thread guide is centered over the

spool and has not developed any burrs or catches.

• Check to see if the thread has looped itself around the spool pin.

• Check to see if the needle is in correctly, with the scarf facing the back of the machine.

• Have you recently changed the needle? Is it as high as it will go in the needle bar?

The Stitch Regulator does not keep up with me

Just like driving your car, you need to make controlled starts and stops, practice being consistent in your

movements.

Eyelashes

Eyelashes on the back of the quilt can be caused by too little top tension. Turn the thread tension disk

clockwise ¼ turn. Make small adjustments. Repeat until stitch quality is good. Remember the upper

and lower thread play tug of war with each other.

Loose Top Stitch

• Is the tension lever handle down? It lowers the hopping foot and applies the tension disk.

• Is the bobbin thread inserted in the slot of the bobbin case?

• Adjust the tension disk small turns clockwise. Repeat until stitch quality is good.

24 | Apprentice Plus User Guide Apprentice Plus User Guide | 25

Quilt Top Puckers

Is your backing fabric stretched too tight? While the backing fabric needs to lie at and without wrinkles,

stretching it too tight can make the quilt top pucker. After stitching and releasing the backing fabric, the

top will pucker.

The top tension is too tight. Adjust the tension disc small turns counter clockwise. Repeat until stitch

quality is good.

Stitches are Skipped

Skipped stitches leave needle holes without thread while large and small stitches in regulated mode

means the encoders are not picking up the signal of your movements because of lint or thread stopping

or slowing the reading.

First, check to see that your machine is threaded correctly. Look at the check spring. Does the thread

lay in the check spring? When properly threaded, the check spring will move up and down as the

machine is stitching, and the thread is owing freely.

Check the needle. Be sure it is all the way up into the shaft and the scarf is toward the back. If it has

been used for some time, replace the needle. A blunt needle will make a popping sound as it penetrates

the quilt sandwich.

Machine Drags Making it Dicult to Move

Check to make sure the quilt on the take up bar is not dragging on the bed of the machine. A ngertip

distance between the take up bar and the bed of the machine is all that is necessary. Elevating the take

up bar too high can cause loopies on the back. Look for lint or thread that might be snagging as you

move the machine.

Dicult to Control the Movement of the Machine

Check for lint or other debris on the track and bars. Sometimes the smallest pieces of thread create the

biggest headaches.

Check Spring Replacement/Tension Knob

From time to time you may need to replace the check spring. We will use a series of photos to help you.

Tension Assembly with broken

spring. (old tension knob) Screw on inside of machine. Loosen

only. DO NOT REMOVE

Remove assembly from machine.

Be careful of release pin.

Machine with tension assembly

removed.

Tension assembly out of machine.

DO NOT LOSE PIN

PIN

Broken

Spring

Loosen screw only.

DO NOT REMOVE

Remove tension assembly from

barrel.

Tension assembly and barrel.

Remove spring. Spring removal. Spring removed.

Tension Assembly with good

spring. (new tension knob)

Figure 54 Figure 56

Figure 55

Figure 59Figure 58Figure 57

Figure 63 Figure 64 Figure 65

Figure 62Figure 61Figure 60

26 | Apprentice Plus User Guide Apprentice Plus User Guide | 27

New spring, This tail is what was

broken.

Insert the new spring. Twist while inserting the new spring.

New spring in place. Insert the tension assembly back into

the barrel. REMEMBER DO NOT

LOSE THE PIN

Insure that you are all the way in.

Give the tension assembly a twist

until you feel resistance on the check

spring.

Tighten screw. Make sure the pin is

still there.

Place the assembly back into your

machine.

Once in, ensure that your check

spring is at 11:00.

Press in and notice the tension disk

opens.

Release and the disk will close; this

is the proper place for your tension

assembly.

Figure 74Figure 73

Figure 72

Figure 71Figure 70Figure 69

Figure 68Figure 67Figure 66

Figure 77Figure 76Figure 75

Tighten screw on your machine. Tension assembly back in

place with new check spring

at 11:00.

For ne adjustment of check spring

insert screwdriver. Turn clockwise for

more tension.

Machine will not sew. I cannot turn the hand wheel.

No matter how hard you try to keep the bobbin area free of loose threads

and lint, we will sometimes get a jam. Most jams start with the needle

down as the jam is due to something getting into the bobbin race. The

bobbin race is a part of the bobbin hook which keep the hook rotat-

ing smoothly with no wandering as it rotates. Don’t panic. This can be

cleared. It just takes a little work.

Step 1: Turn the power o.

Step 2: Remove the belt guard so you can get a good grip on

the hand wheel. See page 11 for instructions.

Normal sew rotation if you are standing at the back of the

machine looking at the hand wheel is counter clockwise. If you

turn the machine counter clockwise you will force whatever is

jamming the machine deeper into the bobbin race.

Step 3: Rotate the hand wheel clockwise to back the jam out

of the bobbin race. (This may take some eort to get it worked

free.)

Step 4: Normally when you get it backed up, it will fall out and

you will be able to make a full rotation with the hand wheel.

Once it feels free, take the needle plate o the machine and give

the bobbin area a good cleaning. Prior to putting the needle

plate back on, rotate the hand wheel counter clockwise (normal

machine rotation).

While rotating the hand wheel by hand, ensure that you have

free movement of the machine. If everything is working well, you

can put the needle plate back on and put the belt guard back

on. You will be ready to start quilting again.

Figure 81 shows thread caught.

Figure 82 show the race.

The Race

is this

small

space

here on

the hook

assembly.

Figure 79 Figure 80Figure 78

Figure 82

Figure 81

28 | Apprentice Plus User Guide Apprentice Plus User Guide | 29

Timing Between Needle and Rotating Hook

Follow these steps to help get the proper timing on your machine.

Step 1: Remove the two needle plate screws from

your machine and set the needle plate to the side.

Step 2: Remove the two screws on the protection

cover at attach it to the face plate of the machine.

See gure 83

Step 3: Remove the three screws holding the face

plate to the machine. Remove the face plate and set

this part aside.

Step 4: Check the protection ange of the position

bracket (A). This should be engaged in the notch (B)

of the bobbin case holder. (D) in the drawing shows

the set screw to adjust hook timing. See gure 84

Step 5: Turn the hand wheel to locate the needle to

its lowest position. Note: Correct needle position is

when you can see a small portion of the eye of the

needle. See gure 85

Step 6: If the needle is not stopping in the correct

position, you will need to proceed to the next step. If

it is in the correct position, move to step 9.

Step 7: Loosen needle bar connecting screw (A).

This will allow you to raise and lower the needle bar

for correct location. Note: Check all photos before

making any adjustments See gure 86

Step 8: Once you have the needle in the correct

location, tighten needle bar connecting screw (A) to

prevent the needle bar from moving out of position.

Adjusting rotating hook point timing with needle.

Step 9: Turn the hand wheel counter clockwise to

locate needle to its lowest position.

Step 10: At lowest position, turn the hand wheel to

raise the needle 2.5 mm (1/8”) See gure 86

Step 11: Hook point should be just above eye of the

needle. See gure 88

Figure 86

Figure 85

Figure 84

Figure 83

Step 12: If the hook point is in the correct

position then move to step 18. If the hook point

is past this point or not yet reached this position

then you will need to follow the next few steps

to adjust the hook so that when the hook point

reaches this position it is just above the eye of the

needle. Proceed to the next step.

Step 13: See gure 84 for position of the three

screws (D). Loosen the three screws holding the

hook assembly to the shaft. (Note you will have to

rotate the hand wheel to get to all three screws.)

Step 14: With the hook loose, reposition the

needle to the lowest position. Rotate the hand

wheel counter clockwise to bring the needle up

2.5mm (1/8”) See gure 87

Step 15: Now rotate the hook so that the point

of the hook is just at the edge of the needle. See

gure 88

Step 16: Lock one screw holding the hook into

this position.

Step 17: Rock the hand wheel back and forth to

ensure that you have the hook in the right position

to pass the back of the needle just above the eye

of the needle.

Step 18: When adjusting the rotating hook point

timing also note that clearance between notch

bottom of needle (D) and hook point (C) must be

maintained. HOOK CAN NOT RUB AGAINST

NEEDLE.

Step 19: Once you feel like everything is in the

right place tighten all screws you loosened.

Step 20: Return all covers and screws back into

place on your machine.

Figure 87

Figure 88

Figure 89

30 | Apprentice Plus User Guide Apprentice Plus User Guide | 31

Adjusting the Bobbin Winder Lever

(amount of ll on the bobbin)

Step 1: Using your allen wrench, loosen the set screw (A)

holding the bobbin winder lever (B) in place. See gures 90

and 91 Note: You do not need to pull the bobbin winder out

to adjust this setting.

Step 2: Move the bobbin winder lever in for less ll and out

for more ll.

Step 3: Tighten set screw (A) to prevent bobbin winder lever

(B) from moving.

Adjusting the Tension Assembly Thread Guides for Proper Fill

Step 1: Loosen the set screw (D) so that you can adjust the

tension assembly thread guides (E). Adjust tension assembly

thread guides (E) up and down until bobbin lls evenly top to

bottom. See gure 92

Step 2: Tighten the set screw.

Figure 92

Figure 91

Figure 90

D

E

Adjusting Bobbin Winder and Contact with the Shaft

Step 1: Loosen the three (3) screws (A) holding the bobbin winder in place but do not remove them.

See gure 93

Step 2: Twist the bobbin winder (B) to the right for more contact with the inner shaft or move left for less

contact.

Note: When twisting the bobbin winder (B) you need to stand on the side of the machine with the access panel.

Step 3: The bobbin winder disk with the friction ring needs to contact the disk on the upper shaft when

engaged. See gure 94

Step 4: Once done moving the bobbin winder, retighten the screws to hold the bobbin winder in place.

Turning the bobbin winder to the right

will move the friction wheel closer.

Turning the bobbin winder to the left

will move the friction wheel away.

Friction Ring

Figure 94

Figure 93

Table of contents