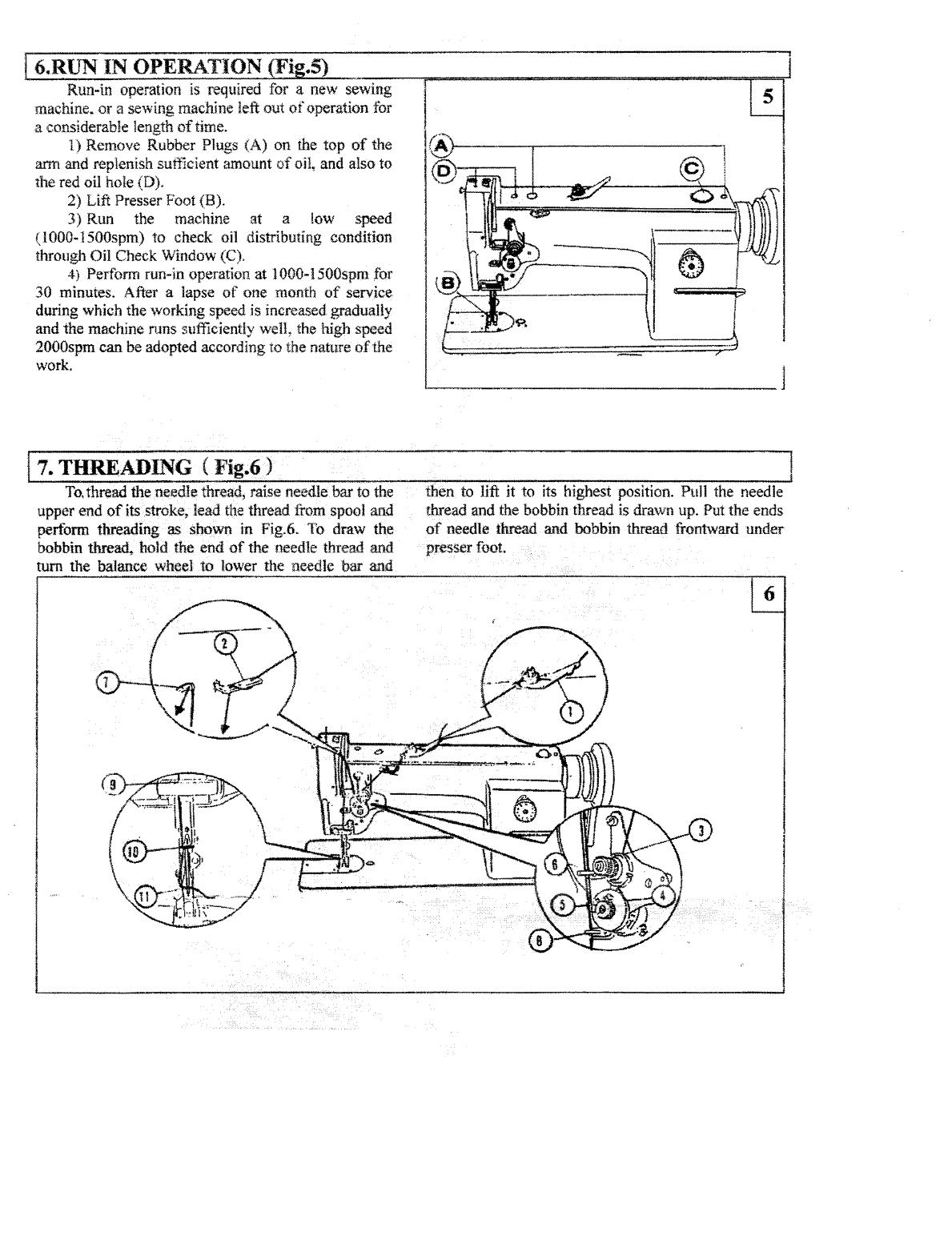

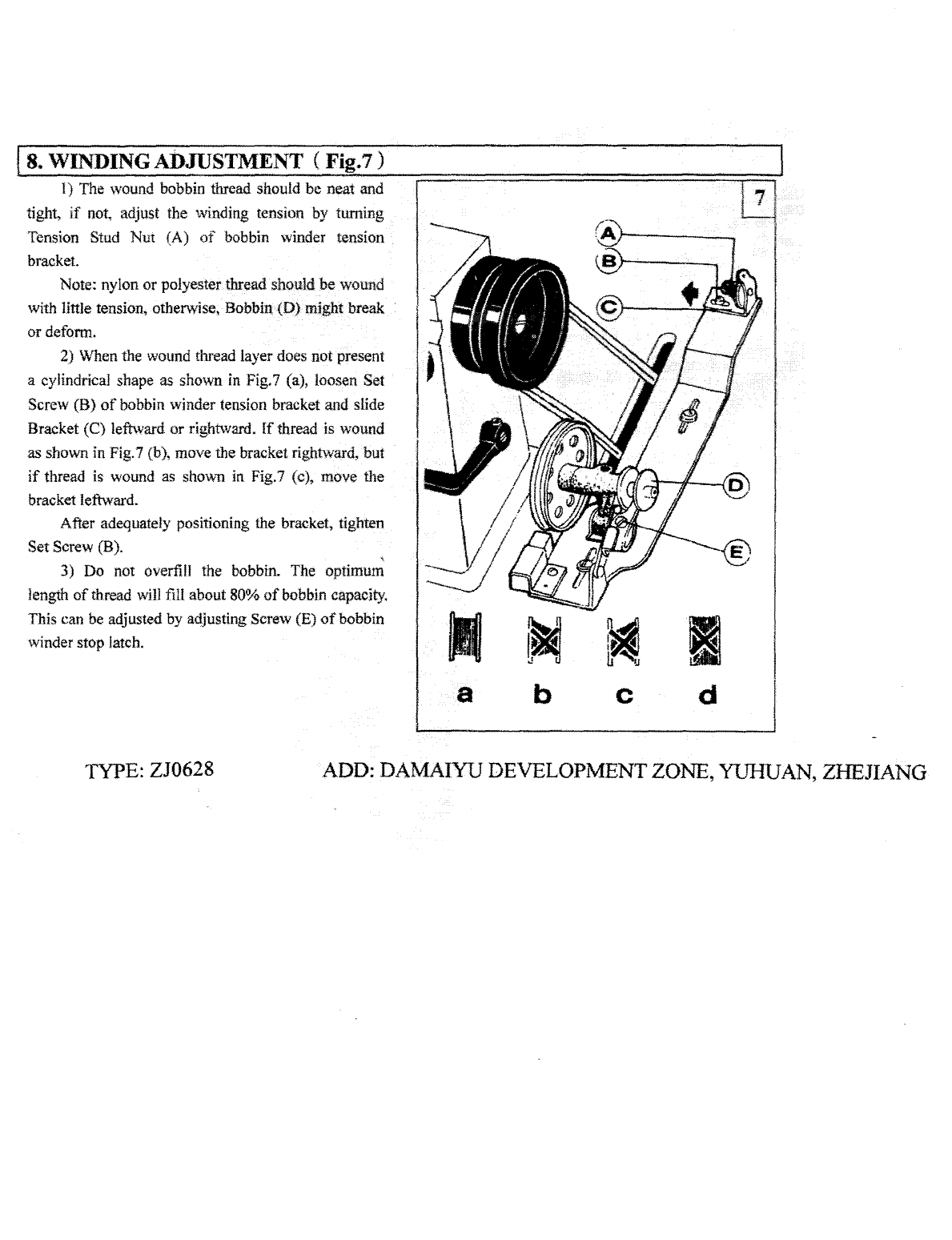

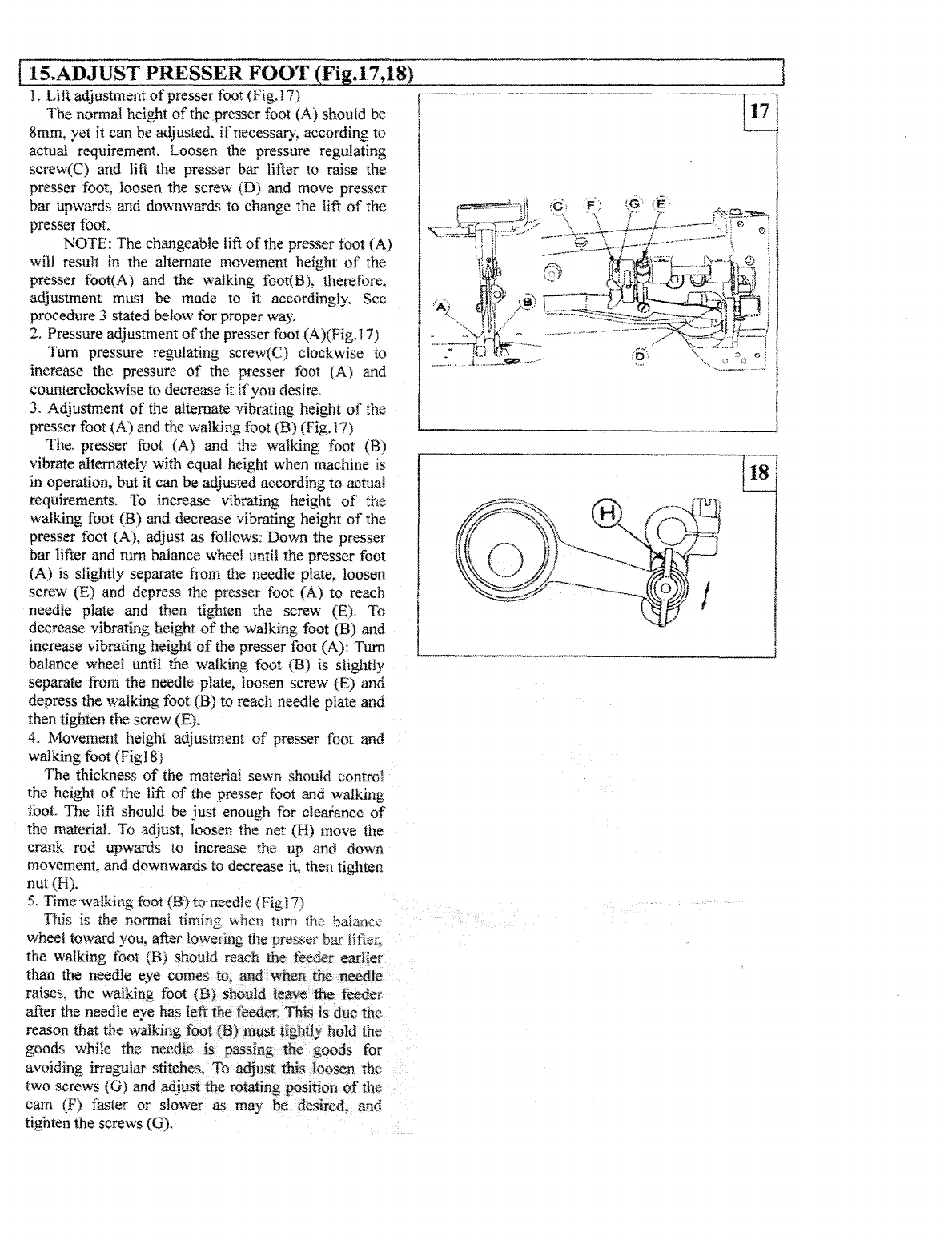

[t5.ADJUST

PRESSER FOOT (Fig.17,18)

1.

Lift adjustment

of

presser foot (Fig.17)

The

normal height

of

the presser foot (A) should be

8mm, yet

it

can be adjusted.

if

necessary. according to

actual requirement. Loosen the pressure regulating

screw(C) and lift the presser bar lifter

to

raise the

presser foot, loosen the screw

(D)

and move presser

bar upwards and downwards to change the lift

of

the

presser foot.

NOTE: The changeable lift

of

the presser foot (A)

will result

in

the alternate movement height

of

the

presser foot(A) and

the

walking foot(B), therefore,

adjustment must be made

to

it accordingly. See

procedure 3 stated below for proper way.

2. Pressure adjustment

of

the presser foot (A)(Fig.17)

Tum

pressure regulating screw(C) clockwise to

increase the pressure

of

the presser foot

{A)

and

counterclockwise

to

decrease it

lfyou

desire.

3.

Adjustment

of

the aliemate vibrating height

of

the

presser foot

(A)

and the walking foot

(B)

(Fig.17)

The. presser foot {A) and

the

walking foot

(B)

vibrate altemateiy with equal height when machine is

in operation. but it can

be

adjusted according

to

actual

requirements.

To

increase vibrating height

of

the

walking foot (B) and decrease vibrating height

of

the

presser foot (A), adjust as follows:

Down

the presser

bar lifter and turn balance wheel until the presser foot

(A)

is

slightly separate from the needle plate, loosen

screw (E) and depress the presser foot (A)

to

reach

needle plate and then tighten the screw (E). To

decrease vibrating height

of

the walking foot (B) and

increase vibrating height

of

the presser foot (A):

Tum

balance wheel until the walking foot (B) is slightly

separate from the needle plate, loosen screw (E)

and

depress the walking foot (B)

to

reach needle plate

and

then tighten the screw (E).

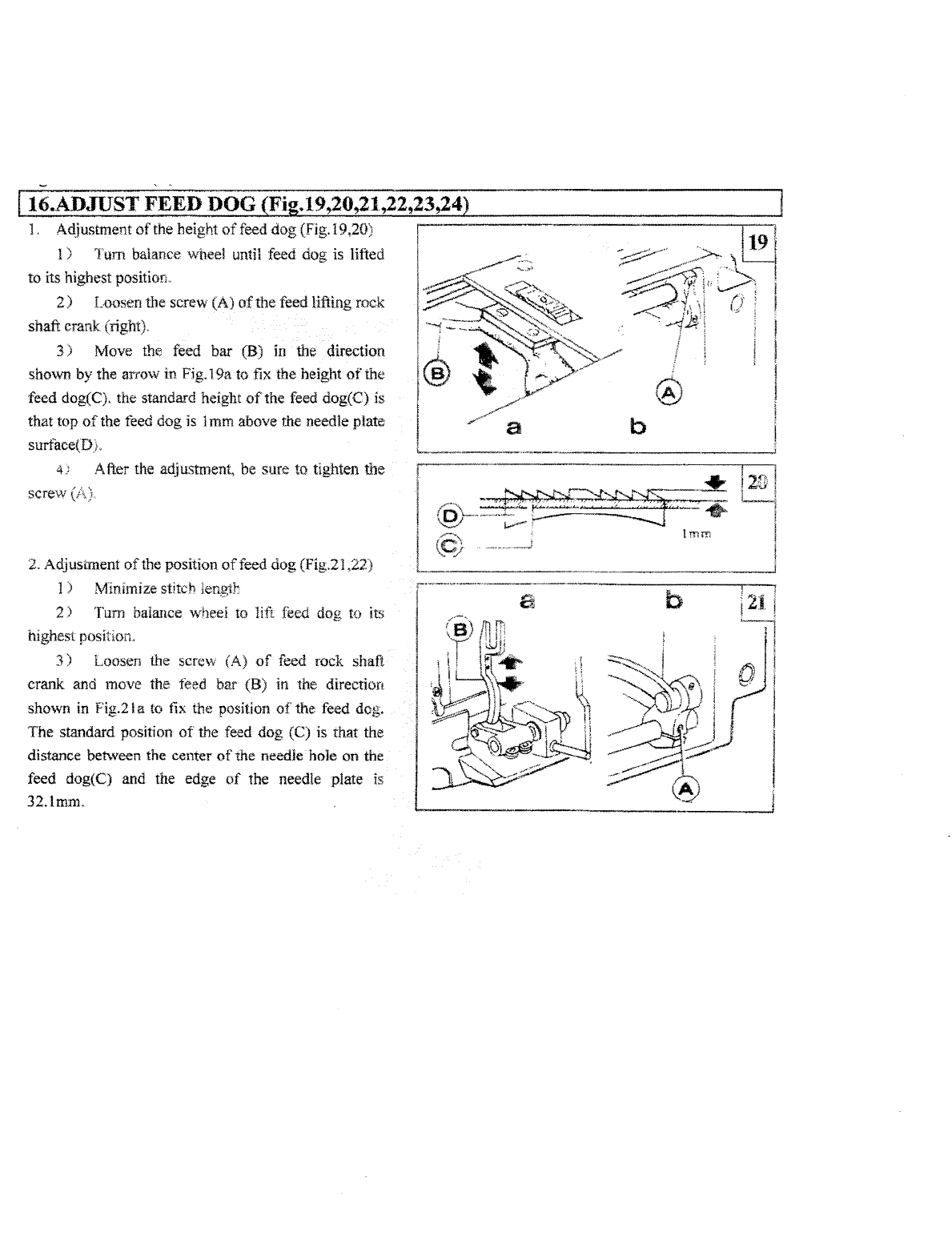

4. Movement height

adjusm1ent

of

presser foot and

walking foot (Fig

18)

The

thickness

of

the materia! sewn should control

the height

of

the lift

of

the presser toot and walking

toot

The

lift should be

just

enough for clearance

of

the materiaL To adjust, loosen the net (H) move

the

crank rod upwards to increase the up and down

movement, and downwards to decrease it, then tighten

nut (H).

5. Time walking foot

(B}toneedle

{Fig17)

This is the normal timing when turn the balance

wheel toward you, after lowering the presser bar

the walking

toot

(B) should reach the earlier

than the needle eye comes to,

and

when me needle

raises, the walking toot

(B)

should

me

feeder

after the needle eye has left the feeder. This is

due

the

reason that the walking foot

(B)

must tightly hold

the

goods while the needle

is

passing the·. goods for

avoiding irregular stitches. To adjust this loosen the

two screws

(G)

and adjust

the

rotating position

of

the

cam (F) faster

or

slower

as

may

be

desired,

and

tighten the screws (G).

From the library of: Superior Sewing Machine & Supply LLC