tirak XA 300 Series User manual

1

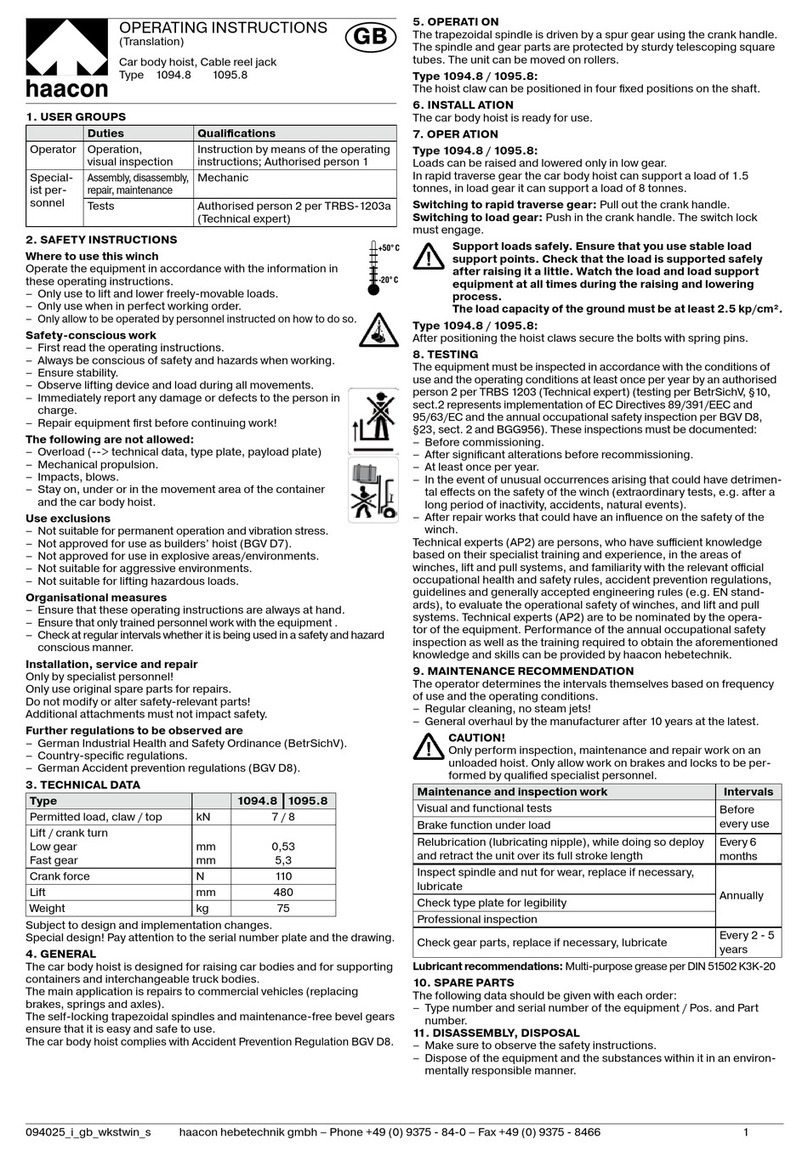

tirak®

Scaffolding Hoist

Instruction Manual

Inc.

XA 300/500/700 series

including BLOCSTOP®

BS/BSO on

2 wire rope

system

TA 1000 P

including

BLOCSTOP®BSO

XA 300 P

including

BLOCSTOP®BSO

XA 500 P

XA 700 P

XA 1020 P

including

BLOCSTOP®BSO

Griphoist

®

Division

www.tractel.com

®

2

Explanation of Symbols used in this manual

INTRODUCTION

...............................................................

3

1. GENERAL WARNING

.............................................

4

2. DESCRIPTION

2.1 Motor and Primary Brake........................................6

2.2 Gear Reducer .......................................................... 6

2.3 Secondary Brake .....................................................6

2.4 Emergency Descent without power .......................6

2.5 Wire Rope Driving Mechanism............................... 6

2.6 Wire Rope ................................................................6

2.7 Technical Data.........................................................7

3. RIGGING INSTRUCTIONS

3.1 General

3.1.1 Scope ............................................................8

3.1.2 Checks before rigging..................................8

3.2 Air supply and hoist control

3.2.1 Air supply ......................................................9

3.2.2 Air preparation unit ......................................9

3.2.3 Air hoses.......................................................9

3.2.4 Hoist Control...............................................10

3.3 Hoist Mounting

3.3.1 TIRAK

®

X-Series ........................................11

3.3.2 TIRAK

®

T-Series.........................................11

3.3.3 Connection to the air supply .....................12

4. WIRE ROPE

4.1 Wire Rope Specification .......................................13

4.2 Wire Rope Rigging Instructions............................13

4.3 Wire Rope Reeving ...............................................15

4.4 De-Rigging .............................................................16

5. OPERATING INSTRUCTIONS

5.1 General ...................................................................16

5.2 Normal Operation ................................................... 17

5.3 Emergency descent................................................18

5.4 BSO Secondary Brake Action................................18

6. TROUBLE SHOOTING

6.1 Mechanical .............................................................19

6.2 Motor troubles ........................................................19

6.3 BLOCSTOP BSO secondary Brake.......................20

7. INSPECTIONS and MAINTENANCE

7.1 Inspections

7.1.1 Daily Inspections.........................................21

7.1.2 Monthly Inspections ....................................22

7.1.3 1/2-Year Inspection.....................................23

7.2 Maintenance

7.2.1 TIRAK

®

Hoist ............................................... 22

7.2.2 Wire Ropes .................................................22

7.2.3 BLOCSTOP BSO Secondary Brake...........22

ADDITIONAL INSTRUCTIONS for

TIRAK®including BLOCSTOP BS/BSO

.........21 to 43

8. NAMEPLATES & LABELS

.................................38

9. WARRANTY INFORMATION

.............................

40

10. ADDITIONAL SOURCES AND TRAINING

...

41

SCAFFOLD SAFE PRACTICE GUIDELINES

.....42

TABLE OF CONTENTS

Safety advice

Symbol Code word Meaning Possible consequence of non-compliance

IMMEDIATE or

WARNING possibly imminant Fatal or serious injuries!

danger:

CAUTION possibly dangerous Injuries to persons

situation: or damage to property

Other advice

NOTE possibly dangerous Damage to equipment

situation: or its surroundings

Instruction to execution/

(none) documentation in writing (none)

(i.e. record keeping)

3

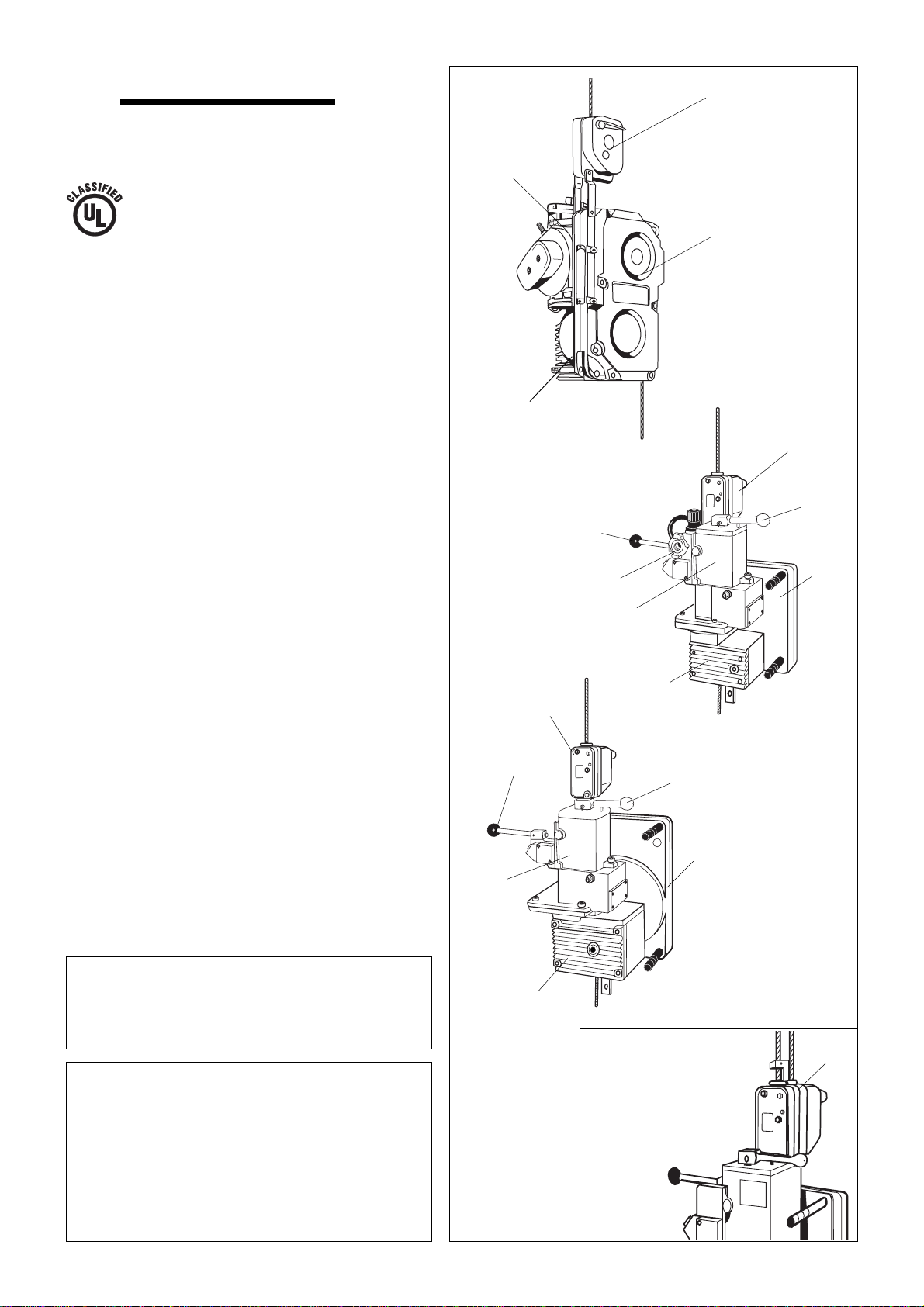

INTRODUCTION

Based on an original design, TIRAK

®

wire rope scaf-

fold hoists are specially manufactured for lifting

personnel in a suspended platform system.

For that purpose they are UL classified.

TIRAK

®

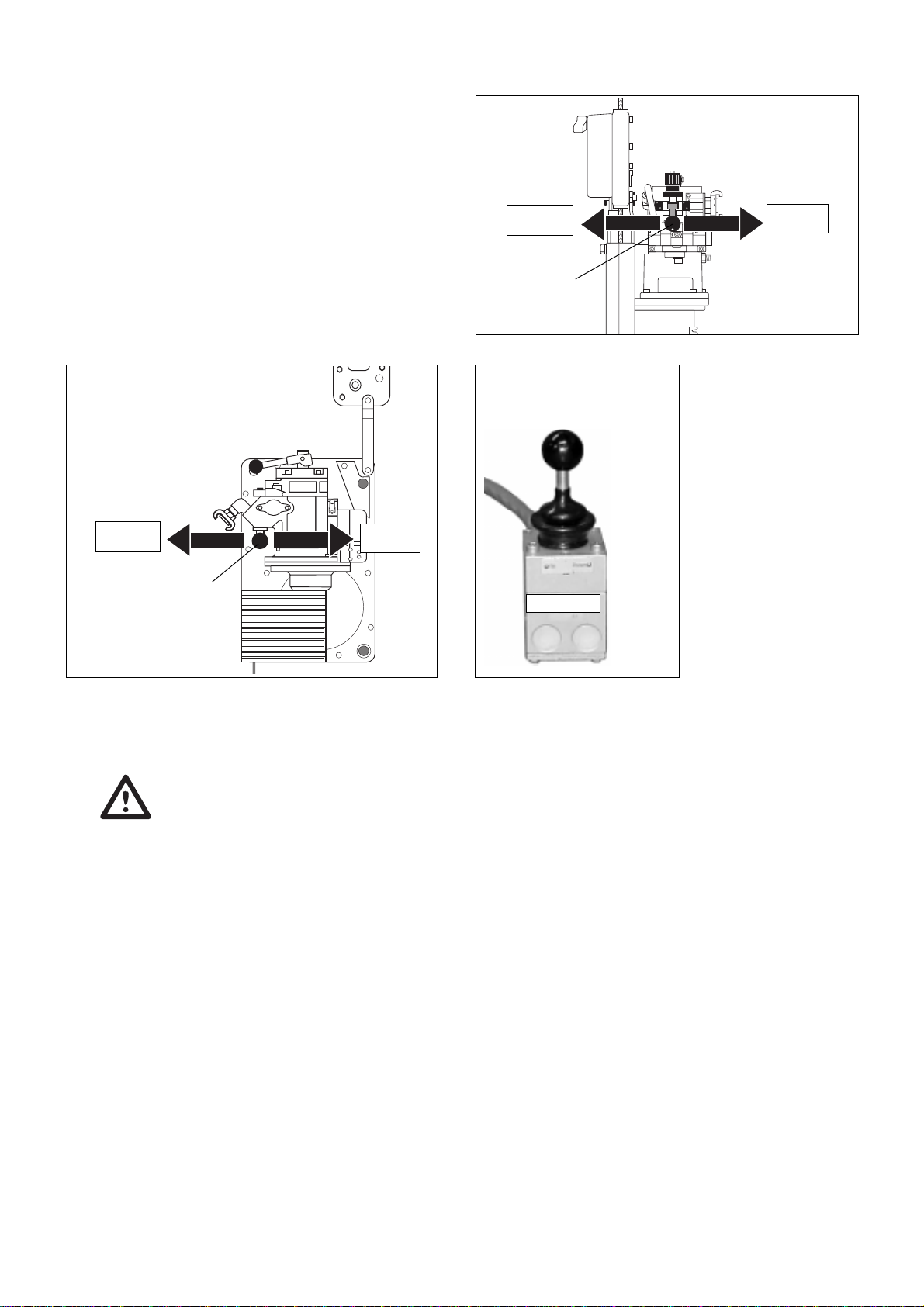

hoists are composed of the fol-

lowing main assemblies (Fig. 1):

A Wire rope driving mechanism

B Gearbox

C Air motor with primary brake

D BLOCSTOP

®

BSO secondary brake, or

E BLOCSTOP BS/BSO secondary brake

F Air hose coupling

G Control lever

H Brake release lever

The main advantages of TIRAK

®

hoists are:

– PowerfuI, fast, and lightweight.

– Simple, rugged, and reliable.

– Unlimited lifting height.

– Constant speed on any height.

– Gentle for its wire rope.

– Mechanical emergency descent device.

The secondary brake (D) or (E), marked

BLOCSTOP

®

BSO or BS/BSO MUST ALWAYS BE

ATTACHED AND USED.

The original design requires, for safety and

efficiency, that it be used with a special TIRAK

®

wire rope specified by the Manufacturer

1)

.

TIRAK

®

hoists are intended to be used for work

going up and down a vertical hanging wire rope.

TIRAK

®

hoists are designed to be rigged to a

compatible platform, workcage or bosun’s chair.

This manual gives the required information for

rigging, operating and maintaining the TIRAK

®

hoists. Responsibility for the complete suspended

platform system lies upon the rigger of that system.

1) “Manufacturer” definition:

Greifzug Hebezeugbau GmbH

Postfach 20 04 40

51434 Bergisch Gladbach Germany

Fig. 1

TA 1000 P

A

XA … series

incl. BLOCSTOP®

BS/BSO on

2 wire rope

system

D

C

A

BD

B

C

A

C

B

E

XA 500 P

XA 700 P

XA 1020 P

XA 300 P

F

GH

H

G

D

“Supplier” definition regarding contact advice in this manual:

TRACTEL Inc. Griphoist® Division

110 Shawmut Rd. P.O. Box 68 • Canton, MA 02021

Tel.: (800) 421-0246 • Fax: (781) 828-3642

Email: [email protected]

Branch office:

315 Cloverleaf Dr., Unit E • Baldwin Park, CA. 91706

Tel.: (800) 675-6727 • Fax: (626) 937-6730

4

1. General Warning

READ THIS GENERAL WARNING FIRST

IN SUSPENDED SCAFFOLD OPERATIONS, SAFETY IS A MATTER OF LIFE OR DEATH

FOR RIGGERS, OPERATORS AND BY-STANDERS.

THIS WARNING IS YOUR SHARE OF DUTIES FOR ACHIEVING SAFETY.

1. It is the rigger’s and the operator’s responsibil-

ity, and their employer’s responsibility, if they

operate under an employer’s control, to strictly

conform to the following warnings.

2. It is imperative for safety and efficiency of the

operations that this manual be read and fully

understood by the rigger and the operator

before rigging or operating the TIRAK

®

. ALL

instructions contained herein must be carefully

and strictly followed, including applicable S.I.A.

guidelines for safe practice (see pages 41 and

42).

3. Should you hand over a TIRAK

®

, under what-

ever conditions, to any party operating out of

your control, you must join a clean copy of this

manual and draw other party’s attention that

strictly following all the instructions therein is

a matter of life or death.

4. Before rigging and operating this TIRAK

®

hoist, the rigger and the operator must

become aware of all the requirements of

federal, state, provincial and local safety

regulations not only applicable to the TIRAK

®

hoist but also to the entire suspended scaffold

system and any component of it.

5. Never use the TIRAK

®

hoist for any job other

than lifting personnel on suspended scaffold

according to the instructions of this manual

6. Never load the TIRAK

®

hoist above its rated

load.

YOUR DUTY TO UNDERSTAND AND COMPLY

7. Keep this manual available at all times for easy

reference whenever required. Extra copies are

available from the supplier.

8. Carefully take notice of all the labels affixed to

the TIRAK

®

. Never rig or operate the hoist if any

label, normally fixed on the hoist is obscured or

missing (see page 38 and 39). The supplier will

supply extra labels on customer’s request.

9. Every time the hoist is to be rigged or used,

check that the hoist, wire rope and other

components of the suspended scaffold system

are complete and in good working condition,

prior to proceeding.

10. A careful and regular inspection of the TIRAK

®

hoist, its wire rope and other components of

the installation is part of the safety

requirements. If you have any questions, call

the supplier.

11. After each de-rigging and before re-rigging,

the TIRAK

®

must be inspected by a competent

person familiar with the TIRAK

®

hoist and

professionally trained for the purpose.

YOUR DUTY TO INSPECT AND MAINTAIN

12. An operator must not be assigned to a sus-

pended job or to rigging for a suspended job, or

to de-rigging after the job, if that person is not:

a) mentally and physically fit for the purpose,

specially at heights,

b) competent for the job to be performed,

c) familiar with all applicable safety rules and

requirements,

d) familiar with the scaffold equipment as rigged,

e) provisionally trained for working under the

above requirements.

13. Never disassemble the TIRAK

®

by yourself or

by your staff. People’s life may be at risk.

Except for the operations described in this

manual, the maintenance of the TIRAK

®

hoists, as well as disassembly and repair,

must be exclusively done by qualified repair-

ers authorized in writing by the supplier.

TIRAK

®

spare parts in accordance with the

serial number of each machine must be ex-

clusively utilized. No substitutions are allowed.

14. Never let the TIRAK

®

hoist and other equip-

ment of a suspended scaffold system be

managed or operated by a person other than

authorized and assigned to the job. Keep the

equipment, either rigged or unrigged, out of

reach of unauthorized persons, while out of

operation.

YOUR DUTY TO TRAIN AND CONTROL PEOPLE

5

23. The BLOCSTOP

®

BSO or BS/BSO secondary

brake located at the upper part of the unit is an

integral piece of the TIRAK

®

hoist. It is strictly

forbidden to detach it from the main body of the

hoist for whatever reason. Doing so would be a

misuse creating an extreme hazard and placing

operators and by-standers in danger of death

resulting from the possible fall of the suspended

equipment: scaffold, workcage, bosun’s chair or

any other items or components.

24. Once the suspended scaffold, work-cage or

bosun’s chair has been lifted off its initial support

(ground or any other level), it is imperative not to

release, remove, alter or obstruct any part of the

equipment under load.

25. NEVER allow any condition which would result

in a suspension wire rope becoming SLACK

during the operation, unless …:

YOUR DUTY TO AVOID TAKING CHANCES

a) … the suspended scaffold, work-cage or

bosun’s chair is supported on a safe surface

giving a safe access to the operator in

compliance with safety regulations, or

unless …

b) … another suspension wire rope has been

safely rigged to the suspended scaffold,

workcage or bosun’s chair.

26. For any job to be performed on the suspended

equipment, consider and control the specific

risks related to the nature of the job.

27. Should you decide that the TIRAK

®

hoist is no

longer to be used, take precautions in

disposing of it so that it cannot be used any

more.

AN ULTIMATE RECOMMENDATION

Never neglect means to improve safety. Due to the risks inherent in the use of suspended scaffold

systems, the supplier strongly recommends that every installation be equipped with secondary wire

rope(s) fitted with a separate fall arrest system. Details about TIRAK

®

with BLOCSTOP

®

BS/BSO

secondary brake on 2 wire rope systems at pages 24 to 37.

This manual is neither a regulations compliance manual nor a general training guide on suspended

scaffold operations. You must refer to proper instructions delivered by manufacturers of the other

pieces of equipment included in your suspended scaffold installation. Whenever calculations and

specific rigging and handling are involved, the operator should be professionally trained to that end and

secure relevant information prior to commencing such work.

15. Training operators and riggers includes setting

up rescue procedure should a scaffold be brought

to a standstill during a job. Such procedure must

be set up by a competent person of the user, or

of its technical consultant, according to the work-

ing conditions, prior to putting the equipment

into operation.

16. Every suspended job must be placed under

the control of a person having the required

competence and the authority for checking

that all the instructions prescribed by this

manual be regularly and efficiently carried out.

YOUR DUTY OF SAFETY BEYOND THE TIRAK

20. … supporting structure and tie-back provide

the requested resistance to every load to be

applied, either static or dynamic, during rigging

or operating the scaffold equipment;

21. … all the requirements in strength and

resistance are obtained with the necessary

safety factor (see regulations and professional

standards);

22. … all the calculations, design and subsequent

work necessary to the above requirements

have been made by a competent person on

the basis of proper technical information

regarding the site.

As being only one piece of the scaffold system,

the TIRAK®hoist can contribute to the required

safety only, if ...:

17. … it is fitted on compatible scaffold equipment,

including the wire rope used in the TIRAK

®

hoist.

18. … other components meet the requirements of

the applicable safety regulations and are of the

proper quality, and assembled to form a safe

suspended scaffold system.

19. … every upper support of the scaffold is stable,

sufficiently strong and properly tied back to the

structure, according to the load either static or

dynamic.

6

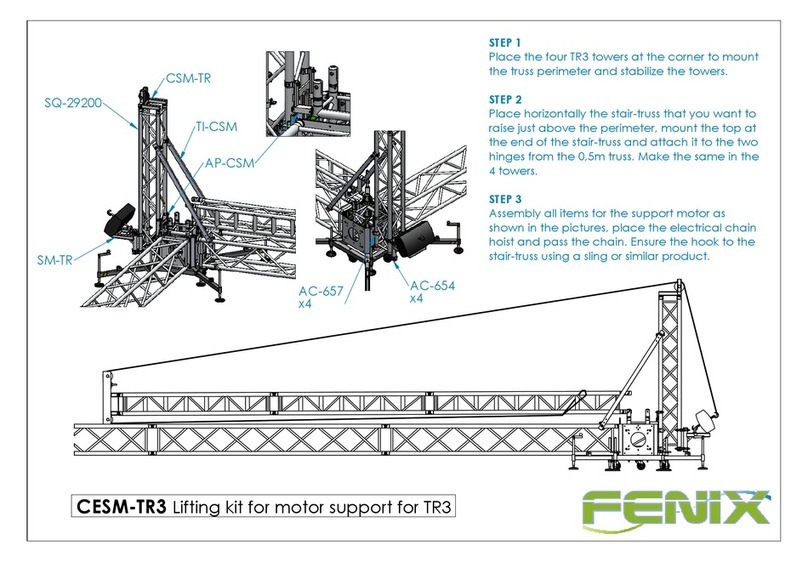

2. DESCRIPTION

2.1 Motor and Primary Brake

TIRAK

®

hoists are driven by a air motor with

a mechanically actuated brake. Electric

TIRAK

®

are available also.

2.2 Gear Reducer

The gear reducer consists of a worm gear

drive in connection with a spur gear, oil bath

lubricated in a sealed aluminum casing.

2.3 Secondary Brakes

The BLOCSTOP

®

BSO overspeed locking

device (D) – hereafter called BSO second-

ary brake – stops the descent immediately

in case of accelerating overspeed.

The BLOCSTOP

®

BS/BSO overspeed and

slack wire rope locking device (E) – here-

after called BS/BSO secondary brake –

additionally provides protection against slack

wire rope or primary wire rope failure, when

using secondary wire ropes.

SECONDARY BRAKES MUST ALWAYS BE

ATTACHED AND USED.

2.4 Emergency Descent

In case of emergency manual descent is

possible at moderate speed, which is con-

trolled by the braking effect of the motor

itself. No handcranking is needed.

2.5 Wire Rope Driving Mechanism

The wire rope enters the hoist from the top,

is led through by the patented driving sys-

tem, and exits opposite its entry. As the wire

rope is not stored inside the hoist, its length

(i. e. the possible rope travel) is unlimited on

principle. The driving system is independent

of the load applied to the wire rope. The

whole mechanism is housed in an aluminum

casing.

2.6 Wire Rope

TIRAK

®

hoists use a Special TIRAK

®

Wire

Rope (see chapter 4). Unless specificly speci-

fied in writing by the manufacturer, only this

special TIRAK

®

wire rope may be used.

NOTE: The manufacturer declines all re-

sponsibility for machines used

with a wire rope other than speci-

fied by them.

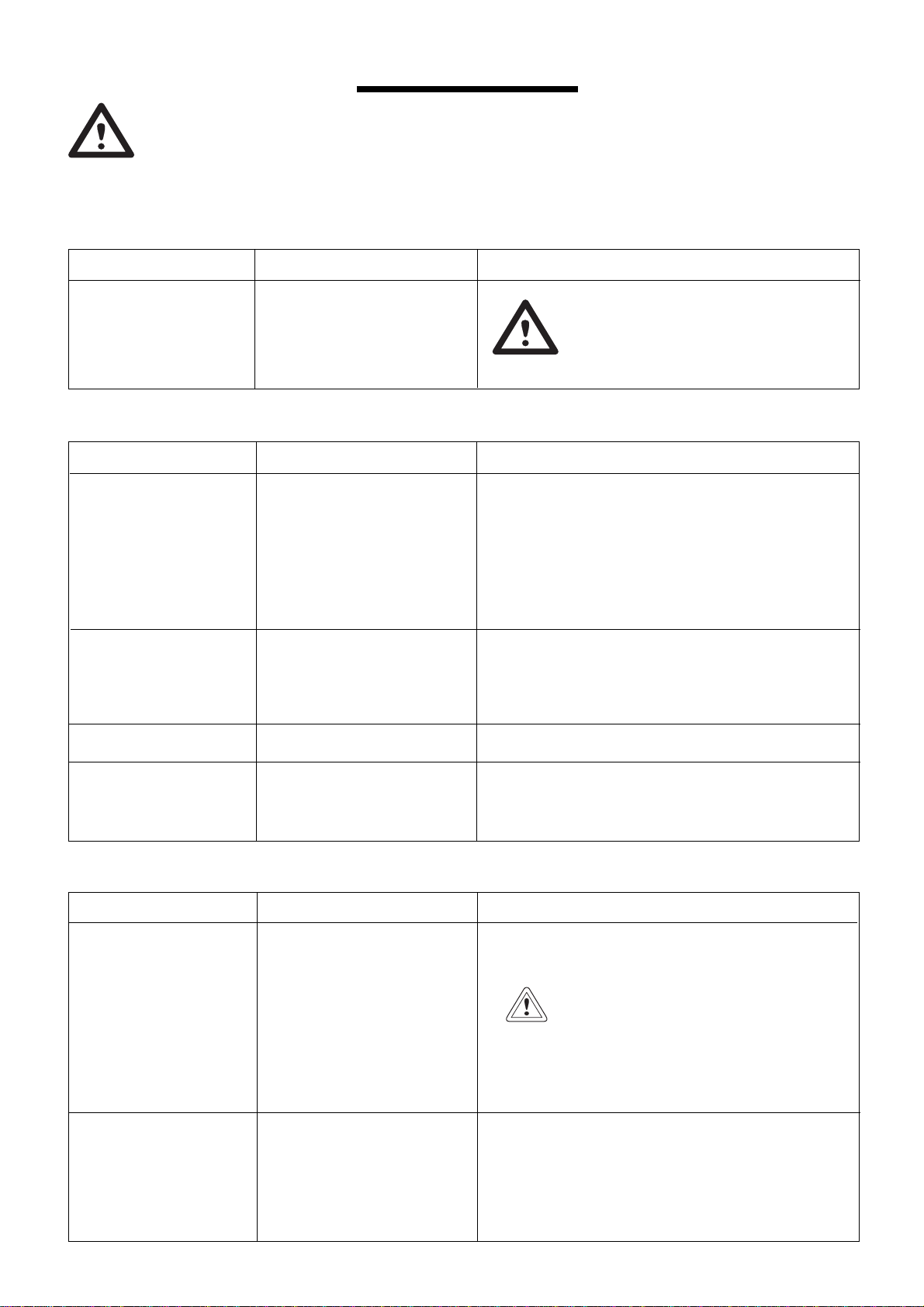

a1

A

c2

C

TA 1000 P

XA … series

for 2 wire rope

system

E

D

XA 300 P

B

C

A

B

a1

D

C

Dd2

d1

A

B

XA 500 P

XA 700 P

XA 1020 P

AWire rope driving mechanism

a1 Stirrup adapter (X-Series)

BGearbox

CMotor with brake

c1 Control lever UP / DOWN

c2 Brake release lever

DBLOCSTOP BSO

secondary brake

d1 Control lever

d2 EMERGENCY STOP

on the BLOCSTOP

E BLOCSTOP®BS/BSO

secondary brake

Fig. 2

c1

c1 c2

7

wire rope classification/ 5 x 19, 4 x 26, 5 x 26, with fiber core,

construction or 6 x 19 (min. 17 wires per strand),

galvanized or black, lubricated,

preformed, IPS or XIPS

nominal diameter in./mm 5/16 in. / 8.4 mm 3/8 in. / 9.5 mm

allowable diam. range in. 0.319 to 0.331 0.362 to 0.374

of new wire rope mm 8.1 to 8.4 9.2 to 9.5

minimum actual lbs 10,000 15,000

breaking strength kN 44.5 66.8

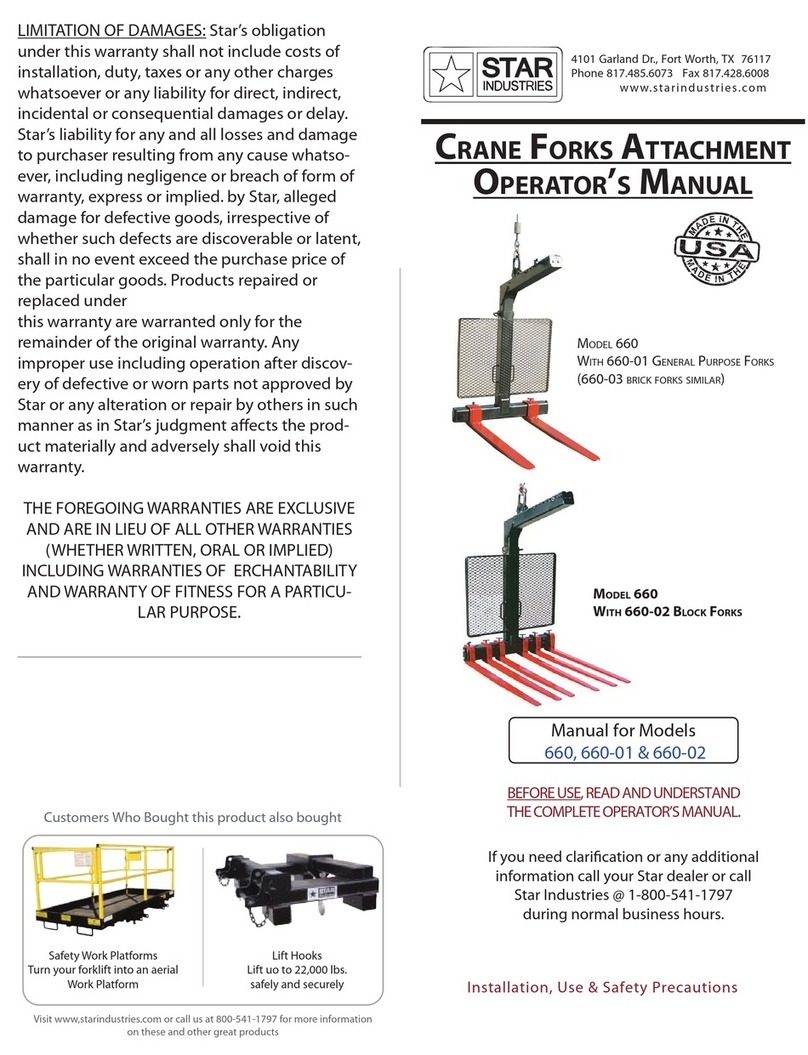

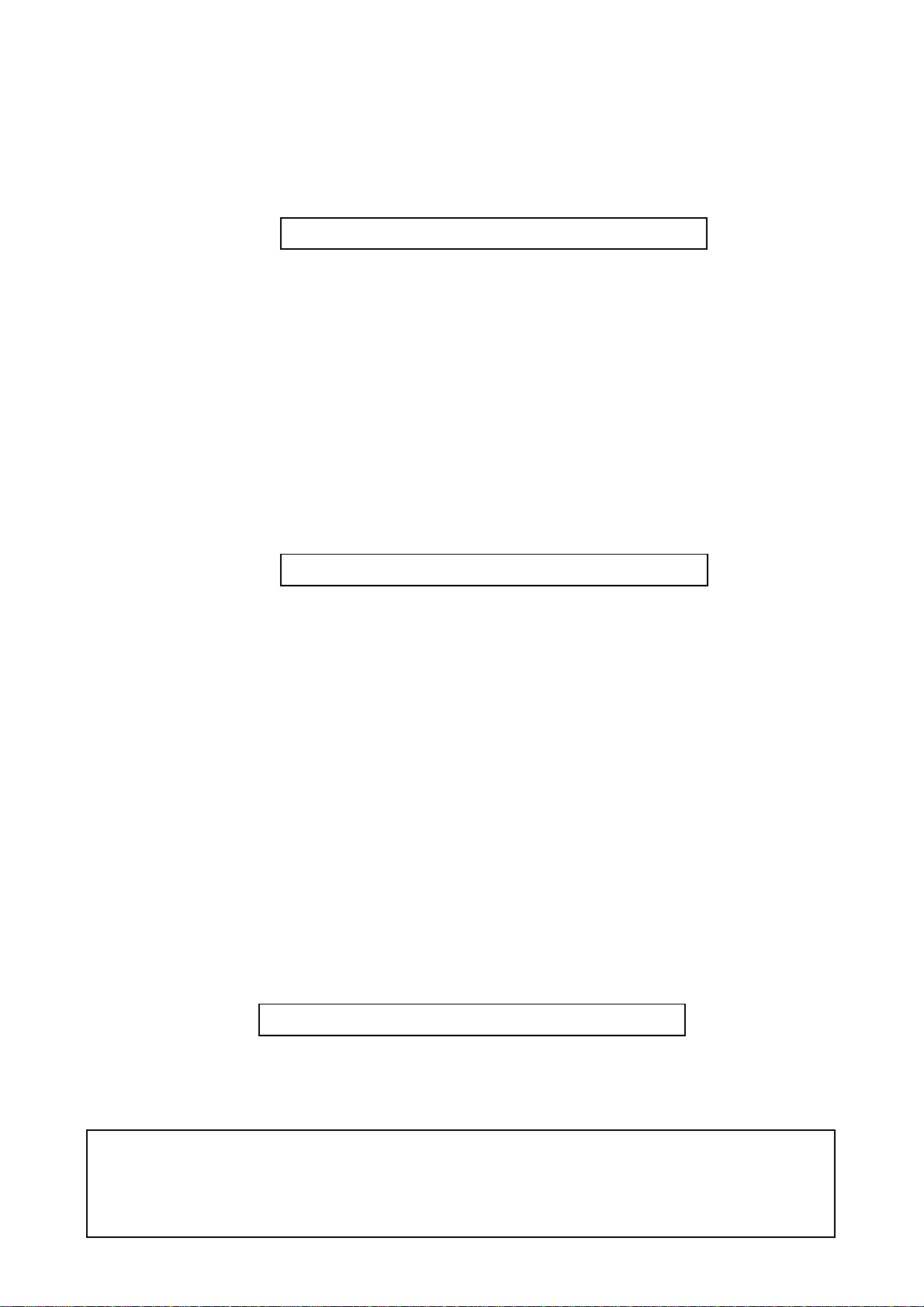

2.7 Technical Data

Fig. 3 Dimensions

XA 300 P

including

BLOCSTOP®

BSO

TA 1000 P

TA 1020 P

incl. BLOCSTOP®BSO

XA 500 P

XA 700 P

XA 1020 P

incl. BLOCSTOP®BSO

b

a

c

b

a

c

c

b

a

TIRAK®Model direct control

XA 300 P XA 500 P XA 700 P XA 1020 P TA 1020 P

remote control

XA 300 PB XA 500 PB XA 700 PB XA 1020 PB TA 1020 PB

including BLOCSTOP

®

Model BSO 500 BSO 1000 BSO 1020

Rated load lbs 700 1,000 1,500 2,000 2,000

kg 315 450 680 900 900

Lifting speed ft/min 33 35 30 23 35

m/min 10 11 9 7 11

Weight (with BSO) lbs 67 91 91 91 172

kg 30 41 41 41 78

Dimensions over all a in. 30.7 33.5 33.5 33.5 34.9

mm 779 858 858 858 886

b in. 15.9 16.9 16.9 16.9 16.5

mm 403 430 430 430 420

c in. 13 14 14 14 14.3

mm 330 354 354 354 362

Motor specifications air motor

Maximum rated

inlet pressure psi 85

Minimum quantity cfm 46 64 100

wire rope in. 5/16 3/8

diameter mm 8.4 9,5

Table 2

Table 1

Note: DO NOT alter the preset

adjusting screw marked

with red sealing wax

(see Fig. 4 and 5).

Fig. 4

XA 300

Fig. 5

XA 500

XA 700

XA 1020

CAUTION:

Correct wire rope diameter within the allowable

diameter range is very important for the TIRAK

®

function!

UNDERSIZED

wire rope may cause slippage in

the hoisting mechanism and in the BSO second-

ary brake.

OVERSIZED

wire rope may cause dam-

age to the guide band and other internal

parts or jam in the hoist causing dam-

age to the wire rope itself!

It also may cause the BSO secondary

brake to malfunction.

8

3. RIGGING INSTRUCTIONS

3.1 GENERAL

3.1.1 Scope

Instructions and advice in this manual exclusively

refer to the following items (Fig. 4):

–TIRAK scaffold hoist

with BLOCSTOP

®

BSO secondary brake

or BS/BSO

1)

secondary brake;

–Special TIRAK wire rope;

–Air supply hose.

1) Instructions and advice for TIRAK

®

including BLOCSTOP

®

BS/BSO

secondary brake for 2-wire-rope-systems

see seperate instructions

on pages 24 to 37.

3.1.2 Checks before rigging

It is a qualified person’s responsibility to check the

whole installation to meet all safety requirements of:

– OSHA regulations and federal, state, provincial

or local safety regulations,

– the proper instructions delivered by the manufac-

turers of the other pieces of equipment included

in your suspended scaffold installation.

Some pieces are:

– Support equipment including tie-back;

– platform system, work-cage, or bosun’s chair;

– safety equipments (personal fall arrest system);

– barricade below the drop of the platform/work-

cage/bosun’s chair.

NOTE: This information is NOT to be considered as

a complete checklist for your specific installa-

tion. It is only a sample list of some general

components, which make part of a typical sus-

pended scaffold installation (Fig. 5).

Fig. 6 Relevant Items (principle sketch)

Air Power

supply hose

Special

TIRAK

®

wire rope

Fixing the

wire rope to the

support equipment

Connecting

TIRAK

®

and

platform system

TIRAK

®

with

BLOCSTOP

®

BSO

secondary brake

Lifeline

Tie-back Support

equipment

Special

TIRAK

®

wire rope

TIRAK

®

with

BLOCSTOP

®

BSO

Suspended

platform

system

Air

supply

hose

Barricade

Fig. 7 Typical suspended scaffold installation

Personal

Fall Arrest

System

9

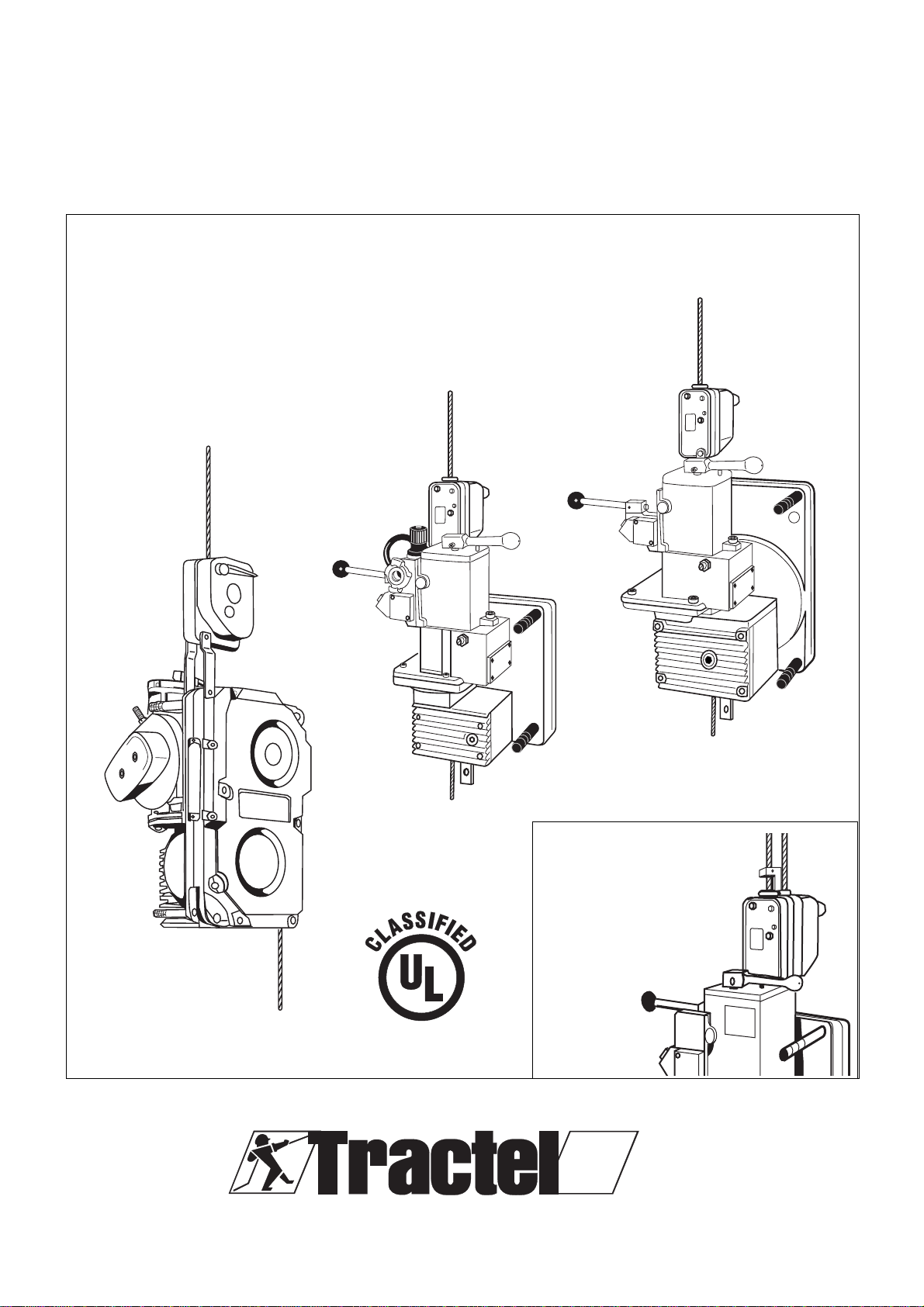

3.2 Air supply and hoist control

3.2.1 Air Supply

Check that the compressed air supply meets

the following requirements :

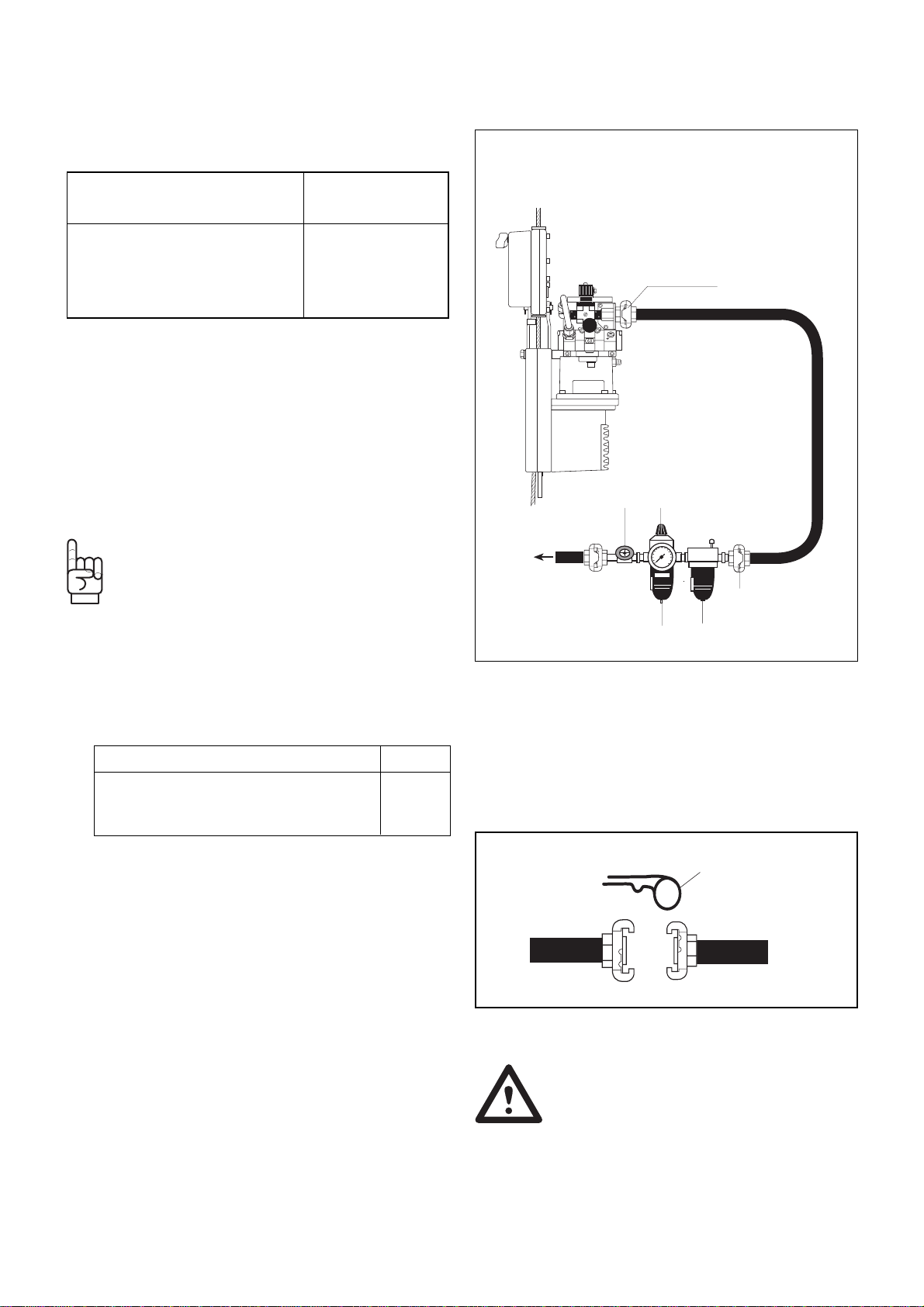

Fig. 8

Maximum rated

inlet pressure 85 psi *)

Minimum quantity

XA 300 P 46 cfm

XA 500 to 1020 P 64 cfm

TA 1000 P 100 cfm

WARNING

Never disconnect the air supply

unless :

1) The air compressor has been shut off or the

connection to the supply system has been in-

terrupted with a shut-off valve.

2) All air pressure has been bled from the supply

lines.

Table 3

Hose connection

between hoist and

air preparation unit

as short as possible

Water Separator

and Oiler

Air Preparation Unit

to

air

supply

Manometer

3/4 " coupling

Filter and

Regulator

Shut-off valve

3/4 " coupling

3.2.2 Air preparation unit

The compressed air must be dry and well oiled. To

guarantee this install an air preparation unit with water

separator/filter, pressure regulator and oiler directly

before the TIRAK

®

(Fig. 8).

This precaution ensures the longevity of the air motor.

NOTE: Higher pressure from the supply system

(max. 230 psi) must be reduced to the required

85 psi by means of the pressure regulator.

3.2.3 Air Hoses

1) Before starting the operation blow through the air

supply hose leading from the air preparation unit

to the TIRAK

®

to avoid impurities entering motor.

For trouble free working, the supply hoses must

have the minimum rated cross sections:

From air preparation unit to TIRAK

®

3/4 "

When running two TIRAK

®

from one

compressed air supply, between 1 "

air supply and air preparation unit

The TIRAK

®

is outfitted with a 3/4 " coupling .

Be sure that all connectors, hoses and inline valves

are rated for a minimum pressure of 200 psi.

Couplings must be secured with hairpins (Fig. 9).

2) Connect and lock all air lines from the air supply to

the air preparation unit using a locking pin. Install

relief devices across them.

a) Start the compressor and slowly apply air pres-

sure to the hoses.

b) Blow through the air supply hose leading from

the air preparation unit to the hoist to avoid im-

purities entering the motor.

c) Inspect all air hoses to ensure that they are in

good conditions and that connections are not

leaking.

d) By means of the regulator, adjust the supply

system to the required 85 psi.

*) The TIRAK

®

will lift capacity at a reduced

speed with a minimum pressure of 55 psi.

Table 4

Locking-pin

Fig. 9

10

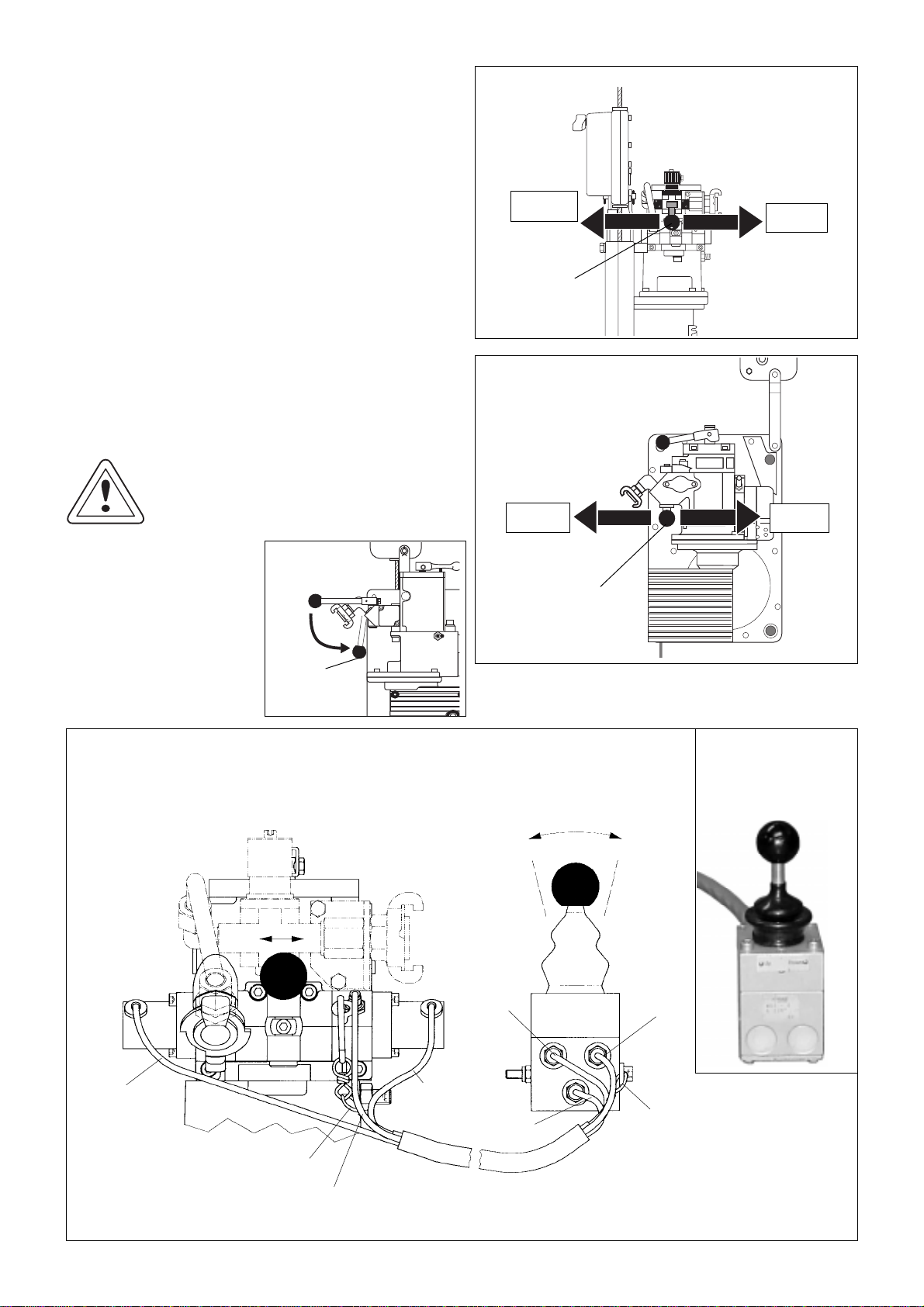

3.2.4 Hoist Control

The TIRAK

®

control is effected

– by means of a "two-way" hand lever on the motor

(Figs. 10 to 12), or

– by means of a remote control valve (Fig. 13), con-

nected to the motor with three flexible hoses inside

a covering hose with steel wire rope for strain relief.

Connection to the motor by self-gripping couplings;

transparent hose = air inlet,

blue hose = UP control,

red hose = DOWN control.

To reeve or climb the TIRAK

®

move and hold the control

lever/valve to the UP-position. To descend or unreeve

move and hold the control lever/valve to the DOWN-

position.

The control lever/valve is spring actuated so that, when

released, it will return to the neutral position and the

mechanical brake automatically stops travel

CAUTION!

DO NOT fix any hoi8st control lever

in the UP or DOWN position.

To avoid damage during

transport the Control lever

of all TIRAK

®

Hoists can

be turned into a storage

position.

See the example for the

XA 500 P in (Fig. 12).

Fig. 10

XA series

down up

Control

lever

Fig. 11

Control

lever

TA Series

down up

Fig. 12

Control

lever

Fig. 13

Remote control

XA Series

red

red

blue

blue

transparent

transparent

Strain relief

Strain relief

down up

Fig. 13a

Remote control

reverse siede view with

“UP / DOWN” marking

11

Fig. 14

Hoist

mounting

TIRAK

®

X-series

Fig.15

Hoist

mounting

TIRAK

®

T-series

90

°

Anchor

pin

Stirrup

90

°

Stirrup

adapter

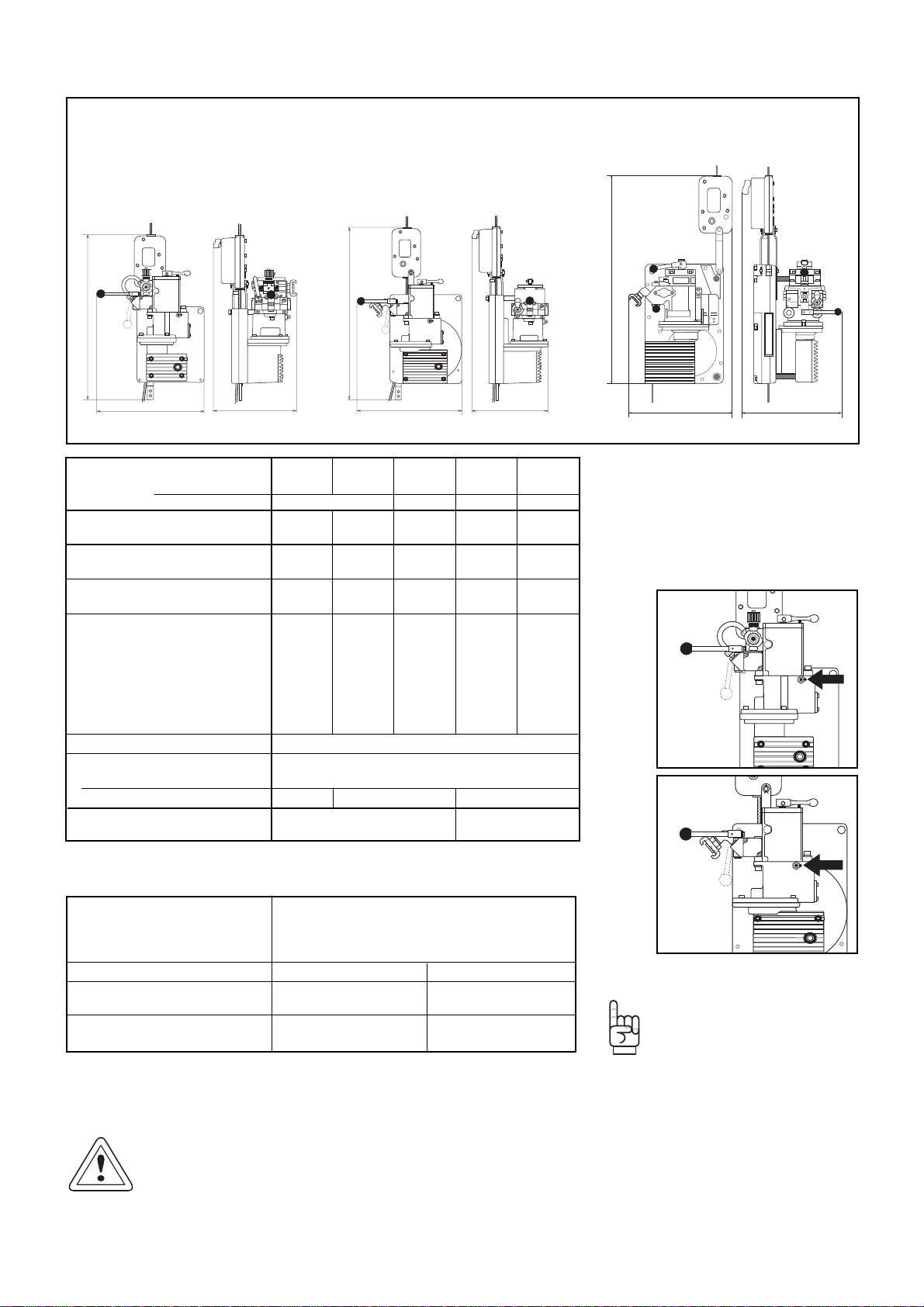

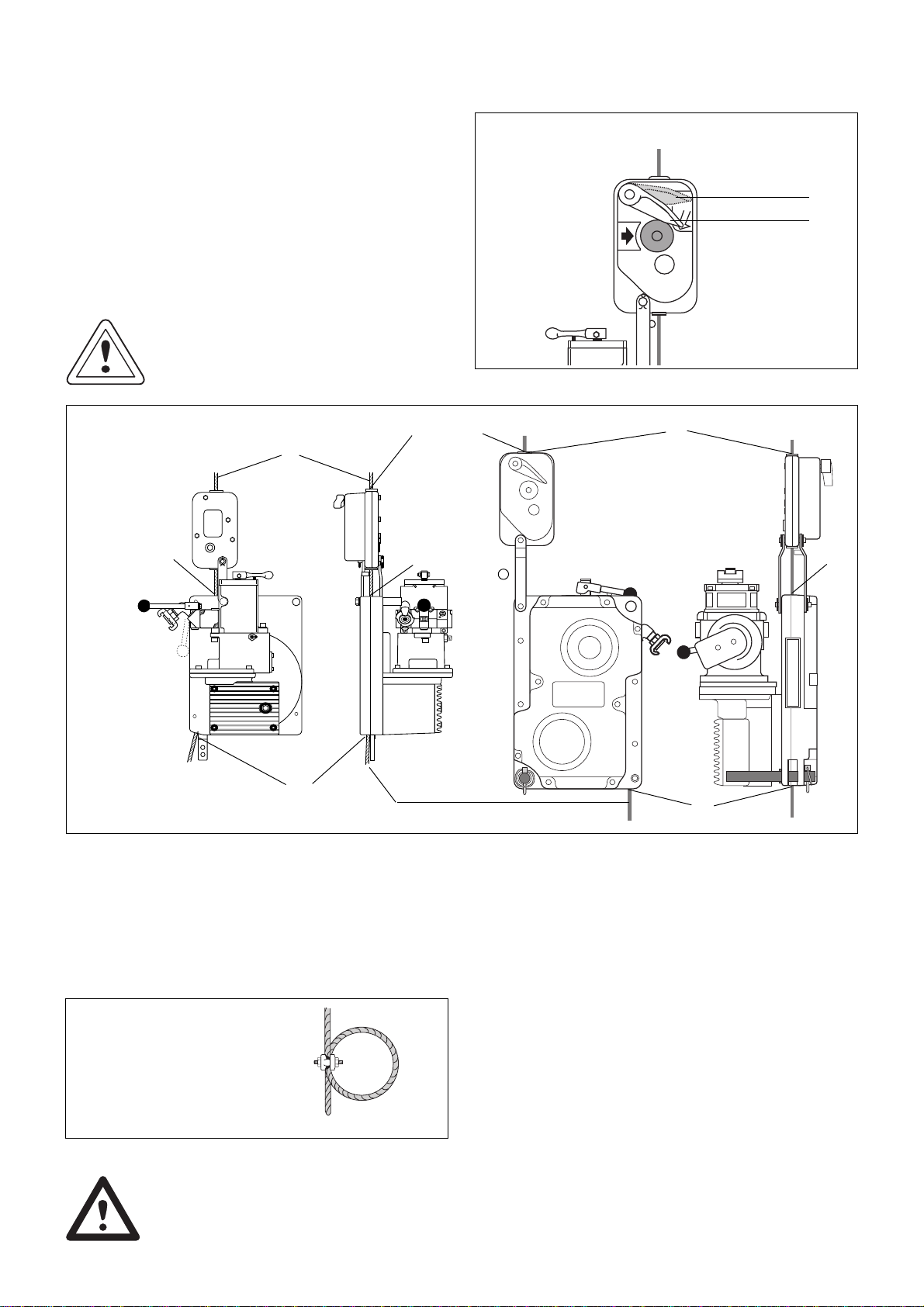

3.3 Hoist Mounting

3.3.1 TIRAK®X-series

Bolt the hoist to platform stirrup us-

ing stirrup adapter, which also

holds the hoist in its upright position

(see Figs. 14 and 16).

Use two 1/2 inch diameter grade 5

or better bolts with locking nuts.

WARNING:

HOIST CONNECTION

BOLTS MUST NOT

BEAR ON THREADS.

Ø d

e

f

a

1

a

3

XA 300 P

a

1

= 4.41 in. / 112 mm

a

2

= 3.94 in. / 100 mm

a

3

= 3.86 in. / 98 mm

b = 1.58 in. / 40 mm

c

b

Fig. 16 Dimensions of connecting parts (stirrup adapter)

TIRAK

®

X-series

Ø d

b

efa

2

a

3

c

XA 500/700

series

c = 0.47 in. / 12 mm

d = 0.51 in. / 13 mm

e = 1.36 in. / 32 mm

f = 1.02 in. / 26 mm

Fig. 17 Dimensions of connecting parts

TIRAK

®

T-series

Anchor pin Ø:

0.63 in. / 16 mm

Anchor hole Ø:

0.65 in. / 16.5 mm a = 1.1 in. / 28 mm

b = 0.55 in. / 14 mm

a

bb

3.3.2 TIRAK®T-series

Fix the hoist using its anchor pin (see Fig. 15 and 17).

Make sure that the hoist is held in its upright position

by means of an appropriate support. The anchoring

device must attach to the pin between the 2 cast ears

“b” of Fig. 19.

WARNING:

THE HOIST MUST BE MOUNTED SUCH

THAT THE WIRE ROPE PERPENDICU-

LARLY ENTERS THE HOIST.

(Figs. 14 and 15)

Fig. 18 Special rigging arrangement

NOTE: Any rigging ar-

rangment other than

described in this manu-

al is entirely under the

rigger’s responsibility.

For special projects like

shown in Fig. 20 contact the

supplier for additional in-

formation.

12

3.3.3 Connection to the air supply

1) Attach air hoses and air preparation unit to the

work platform. It is important that all air line con-

nections are locked and supported by a strain

relief device. The weight of the air line must not be

carried by the TIRAK

®

hoist power inlet connec-

tion.

2) Before connecting the hoist :

a) Start the compressor and slowly apply air pres-

sure to the hoses.

b) Blow through the air supply hose leading from

the air preparation unit to the hoist to avoid

impurities entering the motor.

c) Shut off the compressor and let all air pressure

be bled from the supply lines.

d) Pour a small amount of oil into the air hose.

e) Connect air hoses to the hoist.

3) After all connections are made :

a) Start the compressor and slowly apply air pres-

sure to the hoses.

b) Inspect all air hoses to ensure that they are in

good condition and that connections are not

leaking.

c) By means of regulator, adjust the supply sys-

tem to the required 85 psi

d) Run the motor for approx. 2 seconds to let the

oil completely distribute in the air motor. This

means higher performance and an increase in

service life.

4. Wire Rope

4.1 Wire rope specification

Use only wire ropes specified by the manufacturer:

(1) Classification/Construction:

5x19, 4x26, 5x26, with fiber core, or 6x19 (min.

17 wires/strand), galvanized or black, lubricated,

preformed IPS or XIPS.

Figure 19 Checking Wire Rope Diameter “d”

Incorrect

CORRECT

Figure 20 Wire Rope Handling

d

(2) Diameter:

CAUTION: Correct wire rope diameter within the

allowable diameter range is very impor-

tant for the TIRAK

®

function!

UNDERSIZED

wire rope may cause slip-

page in the hoisting mechanism and in

the BSO secondary brake.

OVERSIZED

wire rope may cause dam-

age to the guide band and other internal

parts or jam in the hoist causing damage

to the wire rope itself!

It also may cause the BSO secondary

brake to malfunction.

NOTE: How to measure wire rope diameter:

The correct diameter of the wire rope is

the largest cross-sectional measurement

across the strands (and not the valleys).

The measurement should be made care-

fully with calipers as shown in Fig. 19.

1) Allowable diameter range of NEW wire rope:

5/16 in. (8.4 mm) = 0.319 to 0.331 in. (8.1 to 8.4 mm)

3/8 in. (9.5 mm) = 0.362 to 0.374 in. (9.2 to 9.5 mm)

Table 5: Wire Rope Diameter and min. actual Breaking Strength

wire min. actual for TIRAK

®

hoists

rope breaking with

diameter

1)

strength rated load up to

5/16 in. 10,000 lbs 1,500 lbs

8.4 mm 44.5 kN 680 kg

3/8 in. 15,000 lbs 2,000 lbs

9.5 mm 66.8 kN 900 kg

4.2 Wire rope rigging instructions

WARNING :

Be sure to use a wire rope with the

diameter marked on the TIRAK®

nameplate.

CAUTION:

Always unreel and reel the wire rope

in a straight line (Fig. 20) to prevent

kinks, which make it unusable for

the hoist.

(1) RIG FROM TOP.

You should have enough wire rope to reach to the

ground or other safe level with about five feet

(1.5 m) extra for ensuring safety.

13

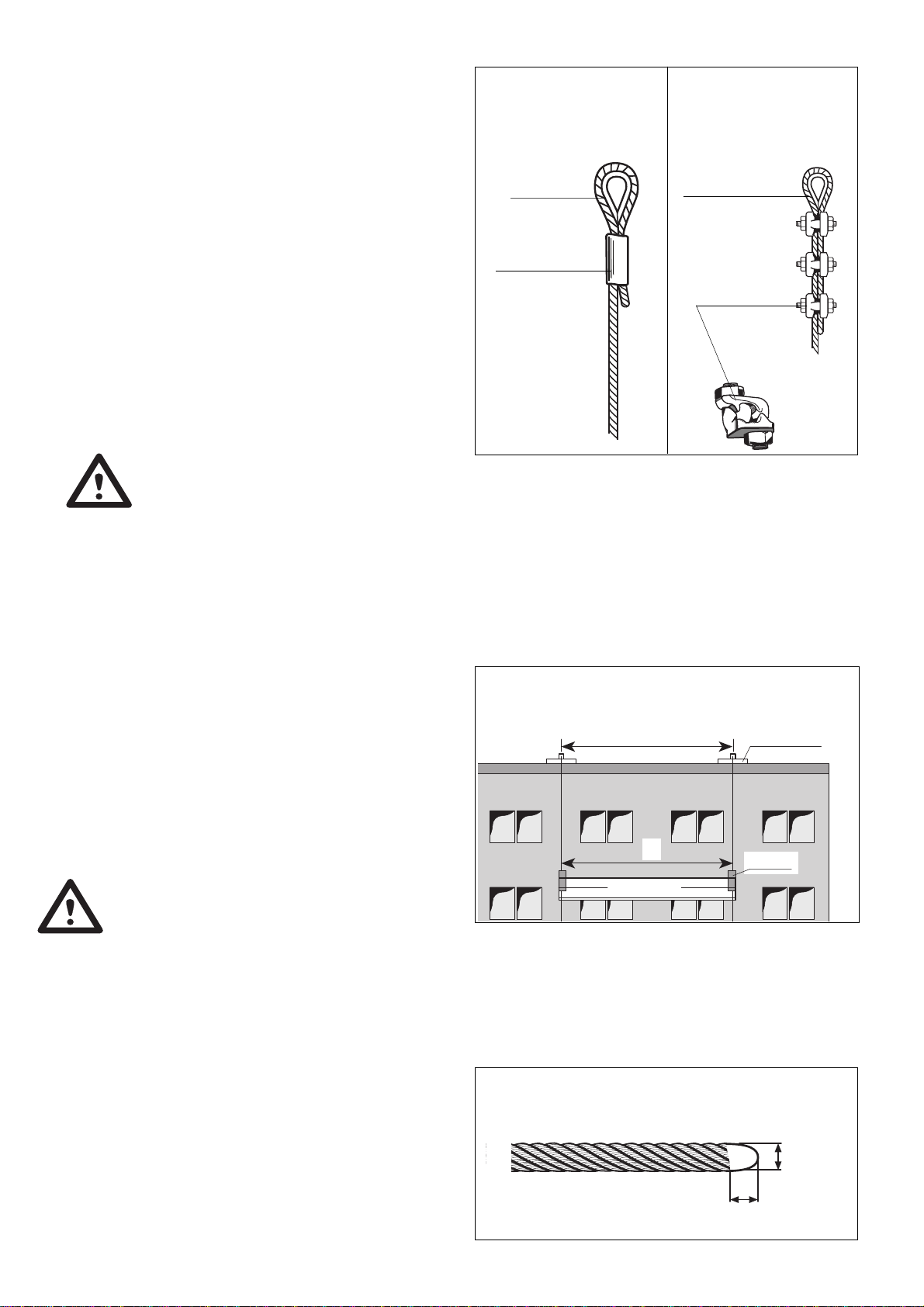

4.2 Wire rope rigging instructions

(continued)

(2) If the wire rope is not equipped with a swaged

fitting as shown in Fig. 21, proceed as follows:

– Install heavy duty thimble with a minimum of

three (3) J-Type (Fist Grip) Clamps (Fig. 22).

– Apply first clamp approximately 7" (18 cm) from

thimble. Tighten nuts moderately.

– Attach second clamp as close to thimble as pos-

sible. Leave nuts loose.

– Attach the third clamp half-way between first

and second clamp, leaving the nuts loose. Take

up wire rope slack.

– Tighten nuts evenly on all clamps (approx.

30 ft-lbs. torque) as specified by the clamp manu-

facturer.

WARNINGS:

a) Retighten after the wire rope is loaded for

the first time

b) Inspect fastening periodically. In use, wire

ropes will stretch and reduce in diameter.

Retighten all “Fist Grip” nuts periodically.

(3) Anchor the wire rope end to a rigging device,

which complies with all relevant safety require-

ments.

Be sure to use compatible connecting devices,

e.g. a 1/2 in. anchor shackle or similar with ad-

equate strength and safety factor. Secure it.

(4) Insure that the anchor points of the wire ropes

are directly above the position of the hoists

(Fig. 23).

WARNING:

Improper spacing is dangerous, and

could cause failure of the support system.

Fig. 24 Wire Rope Tip

Same distance

X

Platform

Support

system

Hoist

X

Fig. 23 Suspension Distance

Fig. 22

Wire Rope Termination

by Fist Grip Clamps

Fig. 21

Wire Rope Termination

by Swaged Fitting

Fist Grip Clamp

Heavy duty

thimble

Heavy duty thimble

Ferrule

(Sleeve)

4 in. (10 cm) Straight

max. 1

1

/

2

dia.

dia.

(5) Check that wire rope tip is welded round.

(Fig. 24)

IF NOT:

a) Prepare ends by brazing or welding – make

sure all end wires are captured.

b) Grind end to approximately 1/4" diameter.

DO NOT grind end flat or to a cone shape. End

must be rounded (Fig. 24).

c) The last 4 in (10 cm) of the wire rope must be

straight for proper reeving.

14

4.4 De-Rigging

(1) Before de-rigging each TIRAK

®

hoist must be

unloaded by bringing down the platform to a safe

and stable support.

(2) Remove the loop at the free wire rope end.

(3) Push Control lever into DOWN-position to let the

wire rope run out.

(4) With gloved hands slowly pull the wire rope through

BSO secondary brake.

(5) Clean the wire rope, reel it (see Fig. 22, page 12),

and store it in a clean and dry place.

Fig. 25 Opening of BSO Secondary Brake

(d1) Closed

(d1) Open

4.3 Wire rope reeving

(1) Open the BSO secondary brake by pushing down

the control lever (d1) until it locks (Fig. 25).

(2) With gloved hands push the rope through the BSO

secondary brake at (A) into the hoist rope inlet (B).

Push it inside, and push control lever/valve in UP-

position, until the wire rope reeves itself

automatically and exits at (C) on the other side

(Fig. 26).

CAUTION: Check that wire rope exit (C) is not

blocked in any manner.

Never load the wire rope exiting

from (C), by applying a load to it

or tensioning.

(3) After reeving through the hoist, be sure to loop

and clamp the free end of the wire rope, to prevent

the rope from, inadvertently unreeving through the

hoist.

Always tie this loop, using a fist grip clamp, when

the platform is at ground level or other safe sur-

face (Fig.27).

B

Fig. 26 Wire rope reeving

A

B

C

TIRAK

X-Series

A

C

B

TIRAK

T-Series

R

Entrance wire rope

Exit wire rope

Must not be loaded!

Fig. 27 Loop at free wire rope end

Bottom free end of wire rope

Fist grip clamp

WARNING: AT EVERY SET-UP OR RERIGGING

check the wire rope length to ensure

that it reaches the ground or other

safe level with about five feet

(1.5 m) extra for safety.

15

5. Operating Instructions

5.1 GENERAL

(1) BE FAMILIAR with the equipment and its proper

care.

DO NOT operate hoist, if adjustment or repairs are

necessary, if any warning, operating or capacity

label normally attached to the hoist is obscured,

damaged, or missing.

(See labels’ list on page 37).

REPORT same promptly to your supervisor and

also notify next operator, when changing shifts.

(2) WARNING:

SAFETY DEMANDS THAT YOU

TEST THE SYSTEM

BEFORE GOING ALOFT:

a) CHECK PLATFORM fully rigged and loaded by

cycling UP and DOWN several times near

ground level or safe surface.

b) CHECK PRIMARY BRAKE for mechanical func-

tion: When stopping the hoist the load must be

held immediately.

c) CHECK BSO SECONDARY BRAKE:

IAt ground level first close the BSO secondary

brake by pushing EMERGENCY STOP button

(d2). Then push the control lever/valve in

DOWN-position and make the wire rope form a

loop between TIRAK

®

casing and BSO second-

ary brake (Fig. 28). Open BSO secondary brake

by pulling down control lever (d1) until it locks

in the open position.

With gloved hands sharply pull wire rope in

arrow direction (Fig. 28) – the BSO secondary

brake should close immediately. Reset BSO

secondary brake by pulling down control lever

(d1) until it locks in the open position.

II Lift platform 3 ft. (1 m) above ground or safe

surface, and push EMERGENCY STOP button

(d2) of the BSO secondary brake (Fig. 29).

Try to lower the platform to check that the BSO

secondary brake holds the load.

A loop should form as shown in Fig. 28, which

means the BSO secondary brake is supporting

the load.

Raise platform until the hoist supports the load

Reset (d1) to the open position.

III During operation regularly check through the

window (d3) that the centrifugal weights are

rotating (Fig. 30).

Fig. 29

BSO Secondary Brake

Checks II + III

Fig. 28

BSO Secondary Brake

Check I

Wire rope loop

EMERGENCY

STOP (d2)

(d1) OPEN

(d1) Closed

(d1) Open

(d1) CLOSED

(d3) Window

EMERGENCY

STOP (d2)

WARNING: IF DURING ONE OF THE CHECKS

THE BSO SECONDARY BRAKE MAL-

FUNCTIONS, IT MUST BE RE-

PLACED.

d) Check that the Control lever return to the normal

position when released. It should move freely with-

out sticking.

Check that the Brake release lever also returns

back in normal position after pulling up.

WARNING: IF DURING ONE OF THE CHECKS

THE CONTROL LEVER OR THE

BRAKE RELEASE LEVER MAL-

FUNCTIONS, THE TIRAK®HOIST

MUST BE REPLACED.

e) CONTINUOUSLY CHECK rigging, lines, clear-

ances, and all other elements throughout the entire

time on the job.

16

5.2 Normal operation

(1) For UP and DOWNWARD MOTION of the plat-

form just push the control lever or control valve

lever in the corresponding direction.

(Figs. 30 to 32)

(2) When operating platform, take care to operate

hoists so that the platform stays level without tilt-

ing one end more than the other.

(3) When using the reomte control valve:

– Alway check the connections before using the

control valve.

– Take care of the connected air hoses, when

moving the remote control on the platform.

Fig. 30

XA series

down up

Control

lever

(3) WARNINGS

a) DO NOT fix Control lever in run position.

b) DO NOT operate the hoist, if it is functioning

improperly, or damage is noted.

c) NEVER pick up a load beyond the rated ca-

pacity appearing on the hoist.

d) STOP OPERATIONS IMMEDIATELY, if at any

time, when the hoist operates, the wire rope

does not move (i.e. no UP or DOWN travel).

It is likely that damaged wire rope is jam-

ming the hoist. Continued operation might

cause wire rope failure or damage to the

hoist.

CONTACT the SUPPLIER!

e) IN CASE OF AN INCIDENT involving injury,

or property damage, contact the supplier im-

mediately.

DO NOT disturb, alter, or move any equip-

ment at the scene of the incident.

Fig. 31

Control

lever

TA Series

down up

Fig. 32

Remote control

UP DOWN

4) Special Operating Notes for Welding or

Arc scarfing

– ALWAYS PROTECT your equipment and your-

self from the danger of arcing.

– BE SURE supporting equipment is grounded to

prevent arcing across wire rope to the struc-

ture.

– DO NOT use wire rope as a ground for welding.

– DO NOT allow your welding gun to contact wire

rope, hoist, or any other metal equipment or

structure.

– PROTECT work area above and below hoist

with insulation.

Split a section of air rubber hose, and wrap

around wire ropes.

– Use an insulated thimble assembly to attach all

wire rope(s) to the suspension system.

17

5.3 Emergency Descent

Should a failure in the air supply occur, you can

de-

scend with the platform proceeding as follows:

Pull brake release lever upwards in arrow direction

(Fig. 33). The hoist will descend at moderate speed,

which is controlled by the braking effect of the motor

itself. TO STOP release lever .

IMPORTANT: A minimum load of approximately

550 lbs/250 kg per hoist is required

to initiate descent in that described

way.

Brake

release

lever

Fig. 33

5.4 BSO Secondary Brake Action

(1) EMERGENCY STOP

Push EMERGENCY STOP button of the BSO Sec-

ondary brake, if – for whatever reason – you

want to absolutely stop downward travel of the

platform.

(2) To reset BSO secondary brake:

Raise the platform until the hoist supports the load.

Push the control lever in the OPEN position (d1)

(Fig. 34). DO NOT force it open.

(3) If the BSO secondary brake has automatically

closed:

WARNING: STOP DOWNWARD TRAVEL! YOU

MAY HAVE RUN OFF THE WIRE

ROPE CAUSING OVERSPEED.

WITH EXTREME CAUTION TRY TO

GO UP.

IF YOU CANNOT GO UP, A RESCUE IS RE-

QUIRED.

When the hoist supports the load, reset the BSO

secondary brake as described above.

CAUTION:If the BSO secondary brake repeat-

edly stops downward travel, contact the

supplier for advice. Check wire rope

diameter (see Table 5, page 12).

EMERGENCY

STOP (d2)

Fig. 34 BSO Secondary Brake

(d1) Closed

(d1) OPEN

If the BSO secondary brake is closed, raise the plat-

form until the hoist supports the load. Push the control

lever in the OPEN position (d1) (Fig. 34).

DO NOT force it open.

NOTE : If during emergency descent the BSO

Secondary brake will close, you have to

wait for air power. With a minimum pres-

sure the hoist must move up to get the

BSO free. Reset BSO by pushing down

control lever (e1) in open position.

DO NOT force it open!

If air power is not available, you have to re-

quire help or a rescue!

WARNING: If the BSO secondary brake stops

downward travel during emer-

gency descent, DO NOT DETACH

BSO secondary brake FROM

HOIST!

WARNING:

DURING USE OF THE HOIST NEVER

DETACH BSO SECONDARY BRAKE!

18

WARNINGS!

Avoid injuries:

1. Checks and repair of the pneu-

matic equipment must only be

carried out by QUALIFIED per-

sons!

2. Any other repair should only be car-

ried out by TRACTEL Group Company

or by a qualified person, and only

original spare parts shall be used.

6. TROUBLE SHOOTING

Problem Cause Remedy

1. Unit operates but a) Secondary brake is closed a) Depress secondary brake control lever to be

rope will not reeve. sure it is open.

b) Wire rope improperly b) Be sure wire rope has been passed through the

inserted. secondary brake, into the traction box and is in

full contact with the sheave.

c) Wire rope improperly c) Ensure wire rope end is properly prepared, and

prepared has no weld berries on side and is straight for

at least 4 inches.

2. Unit operates and a) Overload a) Check and reduce load, if necessary.

wire rope reeves but

will not climb. b) Pressure/flow drop b) Check for adequate air supply.

c) Wire rope c) Check wire rope and replace if worn, or damaged.

3. Unit will climb but Closed BSO secondary brake Power up approximately 6 inches while depressing

will not descend. BLOCSTOP

®

control lever to open it.

4. Excessive wire rope a) Worn guide bushing. a) Replace inlet and outlet bushings if worn.

wear. b) Rigging b) Rigging alignement - wire rope must pass

straight through hoist, not at an angle.

6.2 Mechanical Troubles

6.1 Wire Rope Drive Mechanism Troubles

WARNING: STOP

OPERATIONS

IMMEDIATELY!

Continued operation might cause

wire rope failure.

Contact the supplier.

Problem Cause Remedy

1. Motor does not run. No air power. a) Check to ensure proper flow and air pressure

are available at the compressor and the hoist.

CAUTION ! Always turn off air supply before

tightening, loosening, or removing air

fittings or connections.

b) Check to ensure that the compressor outlet

valves are fully opened.

c) Check for air pressure at the hoist machine.

All hoses will be firm when under pressure.

2. Motor will not run, a) Binding vanes a) Clean and lubricate the motor (see 7.2.3 on page 22).

despite correct,

power supply. b) Frozen vanes b) Thaw the unit by blowing ducted dry heat on it.

DO NOT USE OPEN FLAME!

Use anti-freeze-lubricant (see 7.2.3 on page 22)

c) Brake not released c) Operate motor with brake released manually.

If motor then starts: Return the unit for repair.

6.3 Motor Troubles

Problem Cause Remedy

Wire rope does not move It is likely that damaged wire

through, i. e. no UP nor rope is jamming the hoist.

DOWN movement.

19

Problem Cause Remedy

1. Hoist goes up BSO secondary brake is closed WARNING ! STOP DOWNWARD TRAVEL!

but not down primary wire rope has run out or Proceed according para. 5.4 (3) page 17

has failed.

2. BSO secondary brake a) Mechanical defect. a) Contact supplier.

automatically closes

without apparent reason. b) Oversized or damaged b) Check wire rope and replace, if necessary.

wire rope.

Problem Cause Remedy

3. Unit will not lift the load a) Overload a) Check load and reduce if necessary.

b) Low pressure or flow b1) Check air pressure and flow at the hoist and

the compressor.

b2) Use a seperate air line for each unit.

c) Excessive amount of hoses c) Use larger diameter hose.

being used with a “Y” connector

d) Vanes sticking d) Lower a short distance, then try to lift.

4. Low power or low speed a) Low pressure or flow a1) Check air pressure and flow at the hoist

and the compressor.

CAUTION ! Always turn off air supply

before tightening, loosening, or

removing air fittings or connections.

a2) Check for leaks at all hose connections and

replace seals wherever necessary.

a3) Check for tight kinks in air lines.

Bends and tight kinks will restrict air flow.

b) Excessive amount of hoses b1) Use larger diameter hose.

being used with a “Y” connector b2) Use a seperate air line for each unit.

c) Oil shortage c) Check oiler on air preparation unit.

5. Unit stops while in oper- Power failure Check according to No. 1.

ation and will not restart.

6. Motor runs but unit is a) Oil shortage a) Check lubrication.

noisy. b) Debris in traction b) Return the unit for repair to the supplier.

7. Lubricator will not a) Oil shortage a) Check oil level in reservoir bowl.

function b) Incorrect oil b) Replace oil with Amoco Industrial No. 32 or equal.

8. Exhaust ices up Damp compressed air Use an antifreezing lubricant (see 7.2.3 on page 22).

and motor looses power.

9. Motor ices up and will a) Damp compressed air a1) Thaw muffler with ducted heat.

not run DO NOT USE OPEN FLAME!

a2) Thaw entire unit with ducted heat.

6.4 BSO Secondary Brake Troubles

If you cannot find a trouble’s cause, contact the supplier.

7. INSPECTIONS and MAINTENANCE

NOTE: A maintenance program should start for

each hoist immediately after it is entered

into service.

This maintenance program should comply

with recommendations in the applicable parts and

Instruction Manual, and all pertinant Federal, State,

Provincial and Local regulations.

Unauthorized replacement parts

:

Use only TRACTEL INC. replacement parts. The

replacement of any part with anything other than a

TRACTEL INC. authorized replacement part may

adversely affect the fundtion and safety of this

hoist and voids the warranty. TRACTEL INC. dis-

claims liability for any claims of damages, whether

warranty, property damage, personal injury or death

arising from the use of unauthorized parts.

Regular inspections should be followed for

the life of the hoist and written inspection

records kept as specified.

20

7.1.2 MONTHLY INSPECTIONS

(1) All items under daily inspection.

(2) Wire Rope Inspection

All wire rope should be inspected once a month,

and a signed and dated inspection record

maintained.

WIRE ROPE SHOULD BE REPLACED, IF ANY OF

THE FOLLOWING CONDITIONS ARE NOTED:

Conditions for replacing wire rope:

– Broken wires or strands.

– Excessive corrosion.

– Heat damage, evident through discolored wires.

– Reduction from nominal diameter of more than

5%.

– Kinking, crushing, birdcaging, or any other distor-

tion of the wire rope structure (Fig. 37).

7.1 Inspections

7.1.1 DAILY INSPECTIONS

EACH DAY PRIOR TO USE AND DURING OPERA-

TION CHECK:

(1)Pneumatic :

a) Check oil level in air preparation unit.

b) Check condition of all air hoses and connectors,

if damaged DO NOT USE THEM.

c) Check all air line connections for locking pins

and strain relief. Be sure all relief devices are

properly connected and air line is supported by

work platform and not the hoist.

d) Check motor function. If it makes unusual noises,

starts sluggishly or will not start, before using

refer to TROUBLESHOUTING page 19/20.

(2) Primary brake function: Lift platform 3 ft (1 m)

above ground or safe surface. Start and stop down-

wards travel – the platform be held immediately.

If not, STOP working and replace the hoist.

(3) BLOCSTOP

®

BSO secondary brake function.

IAt ground level first close the BSO secondary

brake by pushing EMERGENCY STOP button

(d2). Then push control lever/valve in DOWN-

position and make the wire rope form a loop

between TIRAK

®

casing and BSO secondary

brake (Fig. 35). Open BSO secondary brake by

pulling down control lever (d1) until it locks in

the open position.

With gloved hands sharply pull wire rope in

arrow direction (Fig. 35) – the BSO secondary

brake should close immediately. Reset BSO

secondary brake by pulling down control lever

(d1) until it locks in the open position.

II Lift platform 3 ft. (1 m) above ground or safe

surface, and push EMERGENCY STOP button

(d2) of the BSO secondary brake (Fig. 36). Try

to lower the platform to check that the BSO

secondary brake holds the load. A loop should

form as shown in Fig. 35, which means the

BSO secondary brake is supporting the load.

Raise platform until the hoist supports the load

Reset (d1) to the open position.

III During operation regularly check through the

window (d3) that the centrifugal weights are

rotating (Fig. 36).

(4) Wire rope: free of kinks, cuts, broken wires, bird-

cages, heat damage, contamination etc.

(5) Wire rope corrosion due to acid or caustics.

Replace wire rope if exposed to these contami-

nants.

(6) Wire rope lubrication: The wire rope has to be

clean and lightly lubricated.

(7) Rigging

Wire rope termination, connection to the suspen-

sion system. It must be aligned and secure.

Fig. 36

BSO Secondary Brake

Check II + III

(d1) Open

EMERGENCY

STOP (d2)

(d1)CLOSED

(d3) Window

Fig. 35

BSO Secondary Brake

Check I

Wire rope loop

(d1)Closed

(d1) OPEN

EMERGENCY

STOP (d2)

(8) Check for parts damage.

WARNING: If there is any:

STOP working, unless the damaged

part(s) is (are) replaced.

(9) Safety harness(es), lifeline(s), fall arrester(s)

and lanyard(s) must be used at all times in

accordance with the requirements of OSHA regu-

lations and state, provincial or local codes.

This manual suits for next models

7

Table of contents

Popular Lifting System manuals by other brands

Bishamon

Bishamon KGL20NH Operation and service manual

AMGO

AMGO PRO-18 Installation and service manual

JLG

JLG 1930ES Service maintenance manual

Fieldmann

Fieldmann FDAD 6571 instruction manual

APlusLift

APlusLift HW-10KBP Installation & operation manual

Cooper Tools

Cooper Tools Campbell GXL Operator's manual

RBF Industries

RBF Industries Bathmate Instruction book

Lift Tech Marine

Lift Tech Marine AC AUTO STOP GEN 2 owner's manual

DÖRR

DÖRR B-4WE 2.4G instruction manual

Walker Magnetics

Walker Magnetics BUX BM2 Owners/operators manual and safety instructions

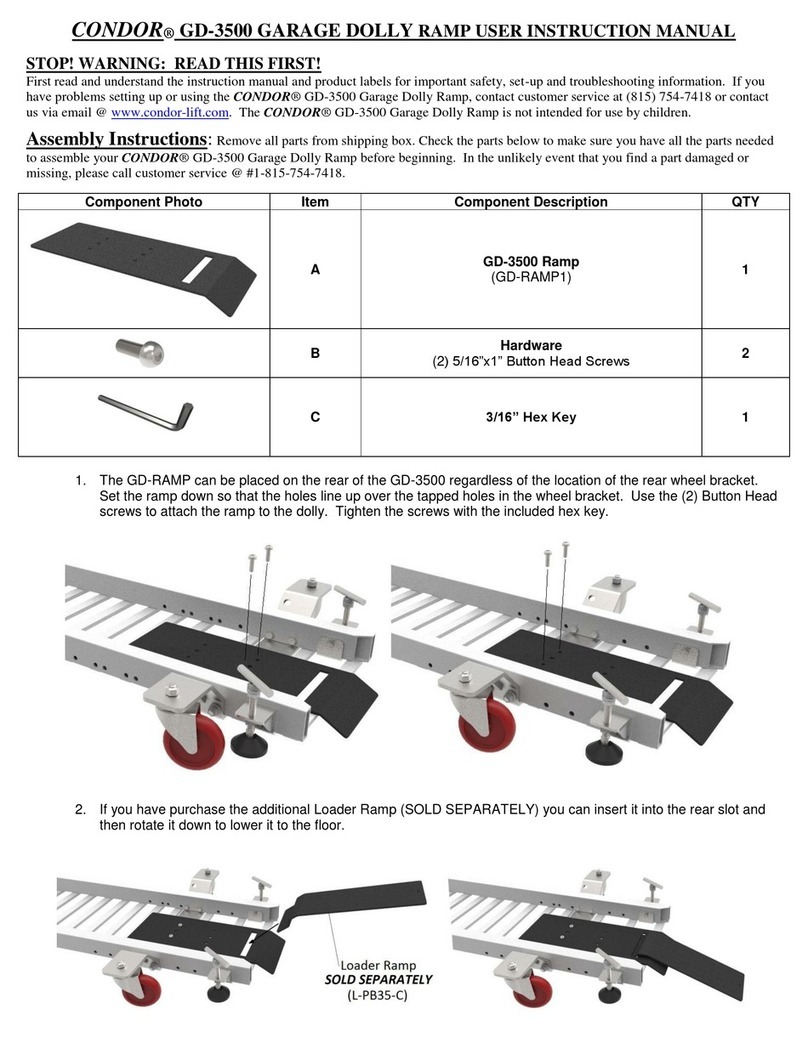

Condor

Condor GD-3500 User instruction manual

TMG

TMG TMG-ALS03 product manual