STAR INDUSTRIES 660 Series User manual

4101 Garland Dr., Fort Worth, TX 76117

Phone 817.485.6073 Fax 817.428.6008

www.starindustries.com

Installation, Use & Safety Precautions

Manual for Models

660, 660-01 & 660-02

If you need clarication or any additional

information call your Star dealer or call

Star Industries @ 1-800-541-1797

during normal business hours.

BEFORE USE, READ AND UNDERSTAND

THE COMPLETE OPERATOR’S MANUAL.

LIMITATION OF DAMAGES: Star’s obligation

under this warranty shall not include costs of

installation, duty, taxes or any other charges

whatsoever or any liability for direct, indirect,

incidental or consequential damages or delay.

Star’s liability for any and all losses and damage

to purchaser resulting from any cause whatso-

ever, including negligence or breach of form of

warranty, express or implied. by Star, alleged

damage for defective goods, irrespective of

whether such defects are discoverable or latent,

shall in no event exceed the purchase price of

the particular goods. Products repaired or

replaced under

this warranty are warranted only for the

remainder of the original warranty. Any

improper use including operation after discov-

ery of defective or worn parts not approved by

Star or any alteration or repair by others in such

manner as in Star’s judgment aects the prod-

uct materially and adversely shall void this

warranty.

THE FOREGOING WARRANTIES ARE EXCLUSIVE

AND ARE IN LIEU OF ALL OTHER WARRANTIES

(WHETHER WRITTEN, ORAL OR IMPLIED)

INCLUDING WARRANTIES OF ERCHANTABILITY

AND WARRANTY OF FITNESS FOR A PARTICU-

LAR PURPOSE.

Customers Who Bought this product also bought

Safety Work Platforms

Turn your forklift into an aerial

Work Platform

Lift Hooks

Lift uo to 22,000 lbs.

safely and securely

Visit www,starindustries.com or call us at 800-541-1797 for more information

on these and other great products

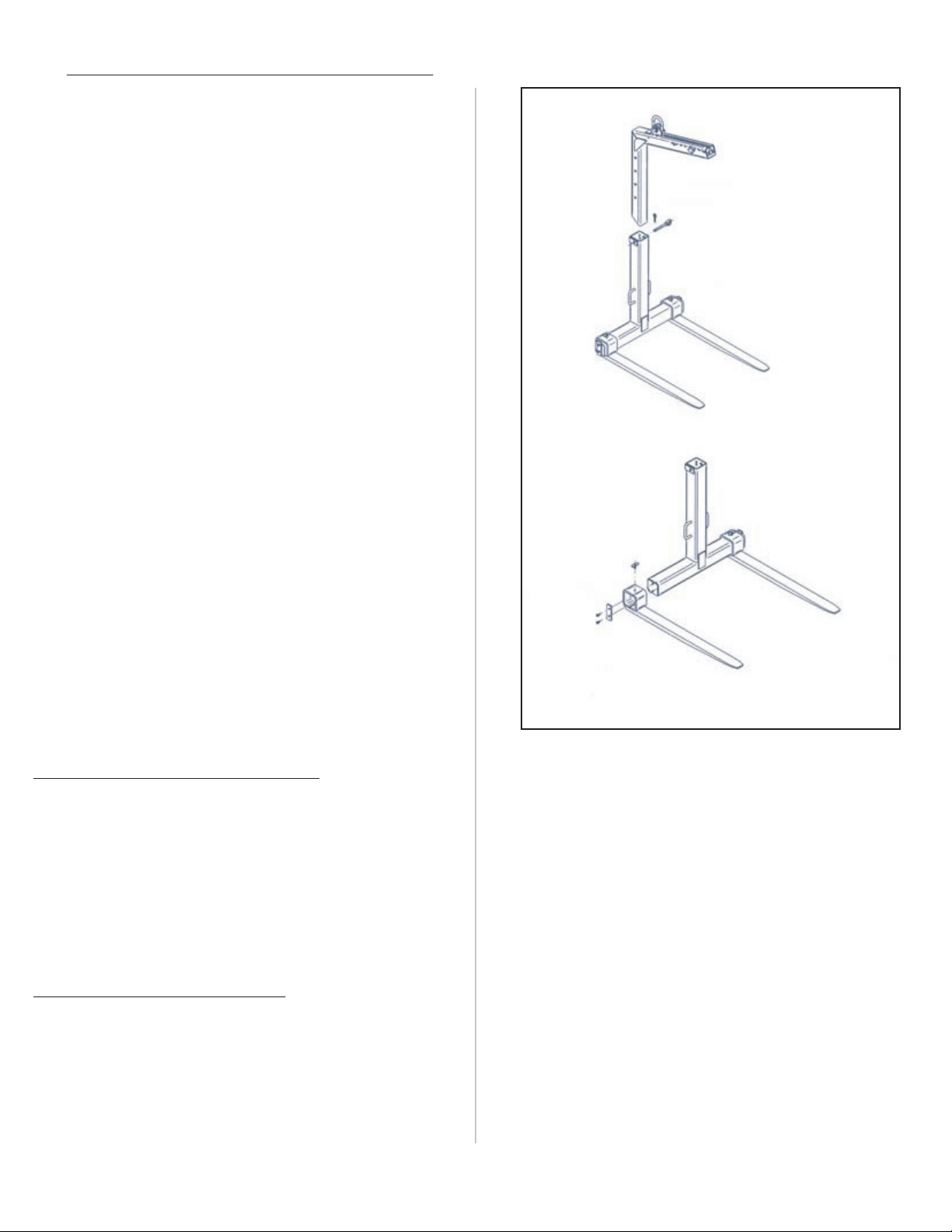

CRANE FORKS ATTACHMENT

OPERATOR’SMANUAL

MODEL 660

WITH 660-02 BLOCK FORKS

MODEL 660

WITH 660-01 GENERAL PURPOSE FORKS

(660-03 BRICK FORKS SIMILAR)

General Safety Precautions

Under no circumstances should personnel be

elevated with Crane Forks.

Users should review the Operator’s Manual &

Safety Information and understand all operations

of the crane forks before using it.

Materials to be elevated with the crane fork must

be adequately secured to prevent material from

falling from pallets or packages.

Never allow personnel to stand under the load.

Use the handles on the king post to guide the

crane fork into the pallet/package to prevent

injury to ngers or other parts of the hand.

Make sure the lifting equipment is capable of

handling the weight of the loaded crane fork.

Certication

Star Crane forks have been engineered and tested in

accordance with A.N.S.I. Standards and the model 660

is rated at 6000 lbs capacity at a 23.6" load center

with an equally balanced load, however with the

smaller 660-03 Brick Tines the capacity is reduced to

4500 lbs.

WARRANTY PROCEDURE: Upon notication, Star

Industries will determine if the product will need to

be returned to Star Industries for inspection or

repair or if the Star dealer or other entity can be

authorized to make the repair at his location or if

circumstances dictate other solutions. Dealer or

other entity repairs must have prior written autho-

rization. Reimbursement will be at the current“Star

Warranty Labor Rate” and will not include reim-

bursement for osite travel. A Warranty Claim Form

must be submitted within 45 days of warranty

repair authorization to receive credit for repair.

A return authorization number must be obtained

from Star Industries before a product can be

returned for inspection and/or warranty and that

number must appear on the return shipping label.

Upon inspection, Star Industries will determine if

the product is defective and if so, whether it will be

repaired or replaced. Repair or replacement is at

the discretion of Star Industries. Transportation

charges to Star Industries are not covered under

the warranty and must be prepaid by dealer or

customer unless it is within the rst two years of

warranty. In which case, if evidence acceptable to

Star Industries, is provided

that the product is defective and the return is from

within the continental United States or Canada,

Star will arrange for return shipment at Star Indus-

tries’expense. Products found to be defective

within the initial two year period and returned to

Star Industries for repair or replacement will be

returned to the dealer or customer freight prepaid

providing it is within the continental United States

or Canada. Warranted products to be shipped

outside the United States or Canada and those

warranted after the initial 2 years will be shipped

freight collect. Unwarrantable products will be

returned freight collect at the

request of the dealer or customer, otherwise they

will be destroyed.

2 11

Dimension

A B C D E F G

48” to 68 62” to 80” 68” to 86” 7” 39” 6.5” 23.6”

Assembly and Adjustment

The King post can be adjusted for greater load height

from 48" to 68" by removing the locking pin and

raising the upper arm section for load heights - Make

sure personnel raising the post have sucient

strength to handle the weight.

Tines are installed on the bottom square horizontal

tube and are secured with the end plates and locked

into position with the TBolts. Adjust the tines to allow

for even load distribution.

Fitting to crane

The crane fork should be connected to the crane by

means of a universal joint type suspending element

via the crane hook or rotator.

< < < Star Industries Limited Warranty > > >

Star Products are warranted to the original pur-

chaser against defective workmanship and/or

materials (when properly installed, used, and main-

tained) for a period as specied below from date of

delivery to the customer by an authorized Star

Dealer or direct from Star Industries. This warranty

does not cover misuse, abuse, normal wear and

tear, or accidental damage.

5 year Warranty: All Star products except as

noted below (Includes HD

Auger Drives and most non-

hydraulic products)

2 year Warranty: Medium Duty Auger Drives

1 year Warranty: Auger Bits and Auger Accesso

ries (excludes auger drives),

Crane Forks, Grapples, 4 in 1

Buckets, Angle Broom,

Mad Beaver Brush Cutters, Self

Dumping Hoppers, Replace

ment Forks, and Over the

Bucket Forks.

6 months Warranty: Concrete Mixers

WARRANTY CLAIM NOTIFICATION: Product defects

should be reported to the Star dealer from whom

the product was purchased or to Star Industries in

writing promptly after discovery. Preferably photo-

graphs showing the defect should also be provided

along with a written report of circumstances

involved. Warranty claims not made within 30 days

after discovery of the defect shall be null and void.

WARRANTY DETERMINATION: If a warranty claim is

found worthy and made within the warranty

period we reserve the right at our discretion to

repair existing defects or to replace it with the

same or current model free of charge or to issue a

credit for the reasonable cost of repair or take

possession of the equipment and issue reimburse-

ment for the calculated value.

10 3

4 9

How it works

The crane fork is equipped with a spring loaded

trolley that keeps the forks level with or without a

load. The trolley is designed so that when tension is

relieved on the hoist line, the spring returns the

trolley to the empty fork position. When the load is

lifted and tension is applied, the trolley travels out

to a predetermined stop set at the load center of the

loaded crane fork. A trolley end stop pin is provided

to adjust the travel of the trolley for various

pallet/package sizes.

Operation

When picking a new load check to see that the load

is being carried with the forks level or slightly tipped

up. If not, immediately lower the load to the ground

and relieve the tension on the hoist line. Then

reposition the Trolley End Stop Pin in the top arm to

adjust the travel of the trolley so that it stops at the

crane fork’s loaded vertical load center. You may

have to move the pin several times to nd the

position where the forks hang level or slightly

tipped up with the load.

For proper operation of the trolley, the load must be

greater than 1,100 lbs otherwise the trolley will not

travel properly. When lifting the load, the hoist line

should lead the load slightly to ensure that the

trolley moves out to the loaded stop position. The

maximum load capacity of the Crane Fork must not

be exceeded. The maximum load capacities are

based on a 23.6" load center on the forks. Use

handles to guide the crane fork into the

pallet/package. Keep hands o other parts of the

crane fork during use to prevent getting ngers

mashed between the crane fork and the load.

Never stand under the load.

Parts List

Item

No. Qty Description Part Number

1 1 Lower Section Assy. 660-B

1 Set of 2 Pallet tines 1.5"x4"x46" 660-01

2 1 Set of 6 block tines 1.5"x2"x47" 660-02

1 Set of 2 brick tines 1.5"x3"x39" 660-03

3 2/6 Tine T-Bolt 660-33

4 2 End Plate 660-34

4.1 4 End plate screw 660-341

5 1 King post pin w/ locking ring 660-35

5.1 1 King post pin only 660-351

5.2 1 locking ring only 660-352

Parts Manual

Crane Fork Lower Section

8 5

Transporting the pallet fork

When in transit, the pallet fork must be properly

secured and if it is carried on a boom truck make sure

the boom and crane fork cannot swing out in an

uncontrolled manner. In addition make sure the

boom does not exert any extreme compression force

on the crane fork.

Maintenance and Repair

General notes

Thorough regular maintenance of the crane fork is

essential to prevent downtime and prolong its life.

Strict cleanliness must be observed in all mainte-

nance operations.

Grease

Chevron Delo #2 or

Any multi-purpose high-melting-point lithium-based

grease of consistency

category 2

Maintenance every 50 hours of operation

(Depending on conditions more frequent mainte-

nance may be required)

Check screw connections, tighten if necessary

Apply grease thru Zerk ttings on top of top arm

Remove any rust or corrosion and Lubricate tine

adjustment T-bolts

Annual Maintenance

Check for cracks, wear, corrosion and functional

safety (to be carried out by qualied specialist).

Parts List

Crane Fork – Upper Section

Item

No. Qty Description Part Number

1 1 upper section complete 660-A

2 1 trolley slide 660-12

3 2 trolley slide wear pads 660-13

4 2 Grease Zerks 660-14

5 1 trolley pin assy. 660-15

5.1 1 Trolley pin 660-151

5.2 2 Cotter pins 660-152

5.3 2 trolley pin washers 660-153

6 1 Trolley pick ring 660-16

7 1 Spring guide tube 660-17

8 2 Compression springs 660-18

9 1 Upper arm cover plate 660-19

10 4 Hex head screw – m10x25 660-20

11 2 Hex head screw – m10x35 660-21

12 1 Left slide rail 660-22

13 1 right slide rail 660-23

14 6 Locking screw – m8x16 660-24

15 1 Trolley stop pin 660-25

15.1 1 Hairpin for trolley stop pin 660-251

6 7

Upper part - Changing springs, spring guide, slide, cover plate and sliding rails

Remove four hexagon screws (1) and pin (2).

Pull complete spring guide (4) forwards out of upper part (3).

Slacken o the two hexagon screws (6) on the cover plate (5).

Squeeze together the rst spring (7) on the cover plate (5) (maintain preload)

Remove corresponding hexagon screw (6).

Swing cover plate (5) to one side. Relieve pressure on spring.

Remove second spring (8) in the same way.

WARNING !!

Always relieve pressure on springs slowly and one ata time to avoide risk of injury !!

Remove sliding rails (9 and 10)

Install in the reverse order.

For load capacities above 2000 kg / 4400 lbs, a second person is needed to relieve the load on the

spring slowly.

This manual suits for next models

3

Table of contents

Popular Lifting System manuals by other brands

Upright

Upright AB-46 Bi-Energy Operator's manual

WOOD'S POWR-GRIP

WOOD'S POWR-GRIP P110L02DC3 operating instructions

Challenger Lifts

Challenger Lifts 44060 Installation, operation & maintenance manual

AUTOLIFT

AUTOLIFT I-Swim2 instruction manual

SCANCLIMBER

SCANCLIMBER SC4000 instruction manual

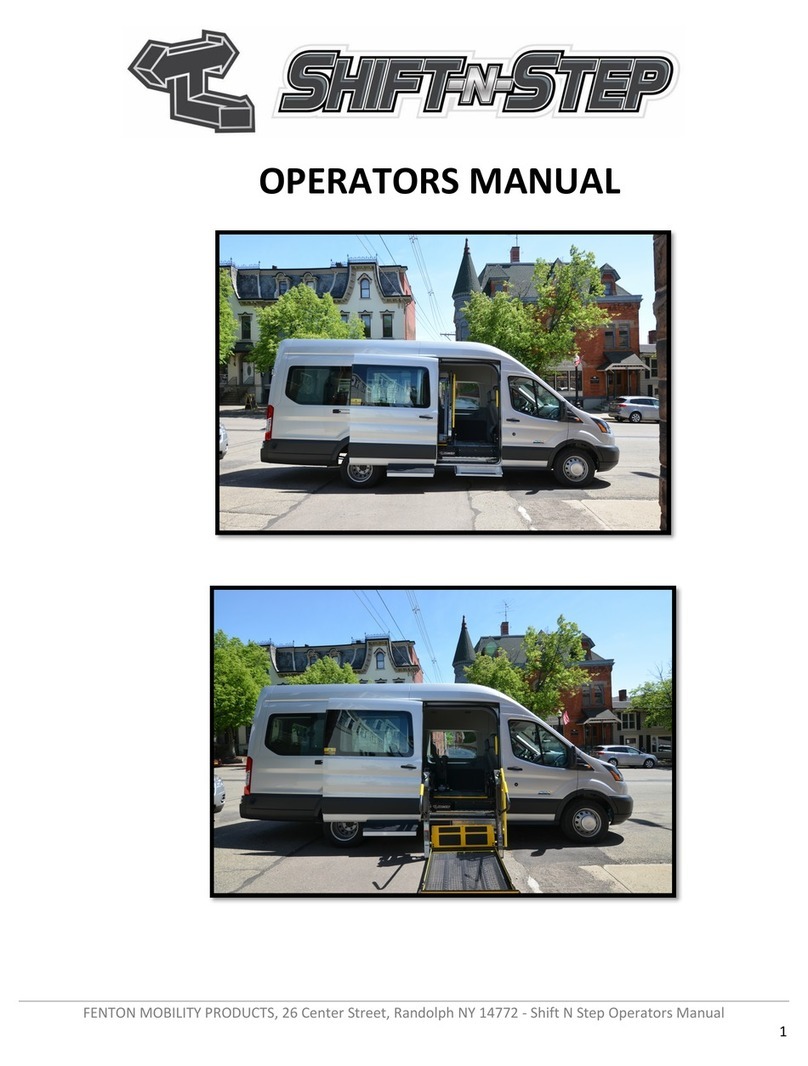

Fenton

Fenton Shift N Step Operator's manual

Ergoswiss

Ergoswiss SL 14 Compact Series Operating instruction

Genie

Genie Lift Guard GR-12 Service manual

Terex

Terex Genie GR -12 Service manual

WM System

WM System WM LIGHT Installation, use and maintenance manual

Stockmaster

Stockmaster Mezzalift Assembly instructions

Scaleo medical

Scaleo medical Poweo 140 Quick Up user manual