3

CONTENTS

PREFACE..................................................................................................................................................................2

SAFETY RULES .........................................................................................................................................................4

GENERAL SAFETY ....................................................................................................................................................5

IMPORTANT SAFETY INSTRUCTIONS ......................................................................................................................6

APPLICATION OF THIS INSTRUCTION MANUAL......................................................................................................6

STYLES OF MACHINES.............................................................................................................................................7

TN-737D..................................................................................................................................................................7

TN-747D..................................................................................................................................................................7

TN-757D..................................................................................................................................................................7

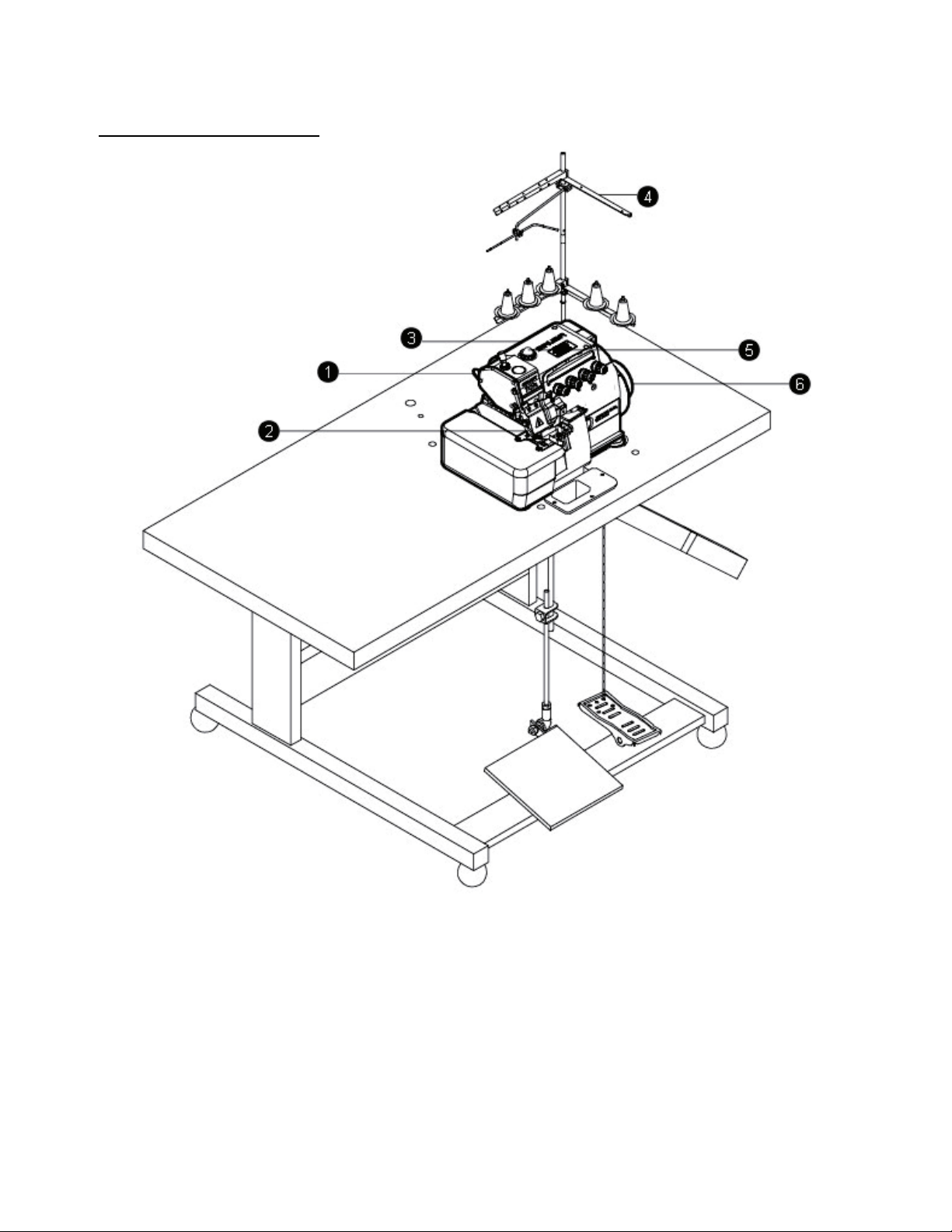

PARTS OF THE MACHINE ........................................................................................................................................8

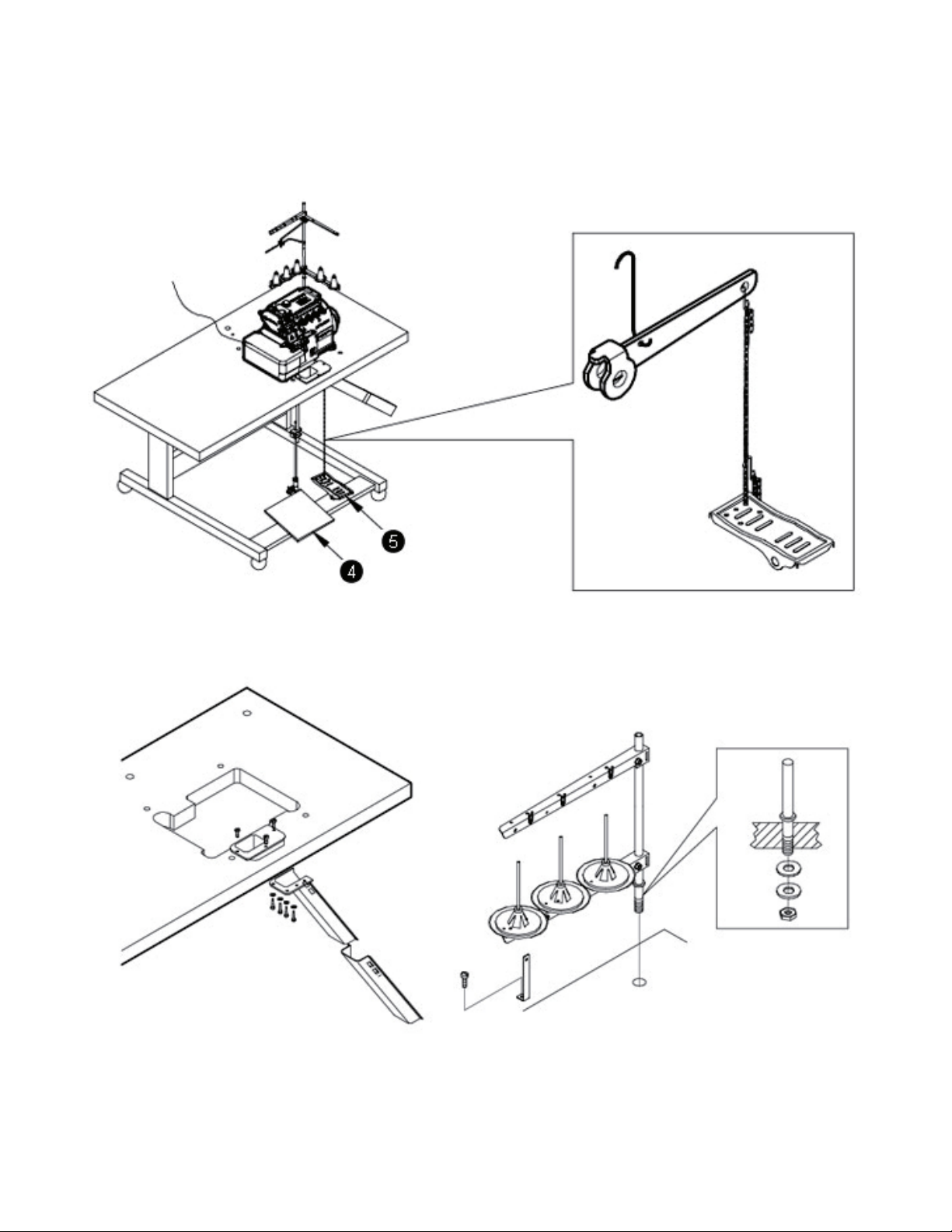

INSTALLATION.........................................................................................................................................................9

HANDLING YOUR MACHINE .................................................................................................................................11

BREAK IN PERIOD..................................................................................................................................................12

LUBRICATION........................................................................................................................................................12

THREADING...........................................................................................................................................................14

TENSIONS..............................................................................................................................................................17

NEEDLES................................................................................................................................................................18

CHANGING THE STITCH LENGTH ..........................................................................................................................19

CHANGING THE DIFFERENTIAL FEED ....................................................................................................................20

ADJUSTING / REPLACING BLADES.........................................................................................................................21

REPLACE THE UPPER BLADE .................................................................................................................................21

REPLACE THE LOWER BLADE ................................................................................................................................21

ADJUST THE HEM / CUTTING WIDTH ...................................................................................................................22