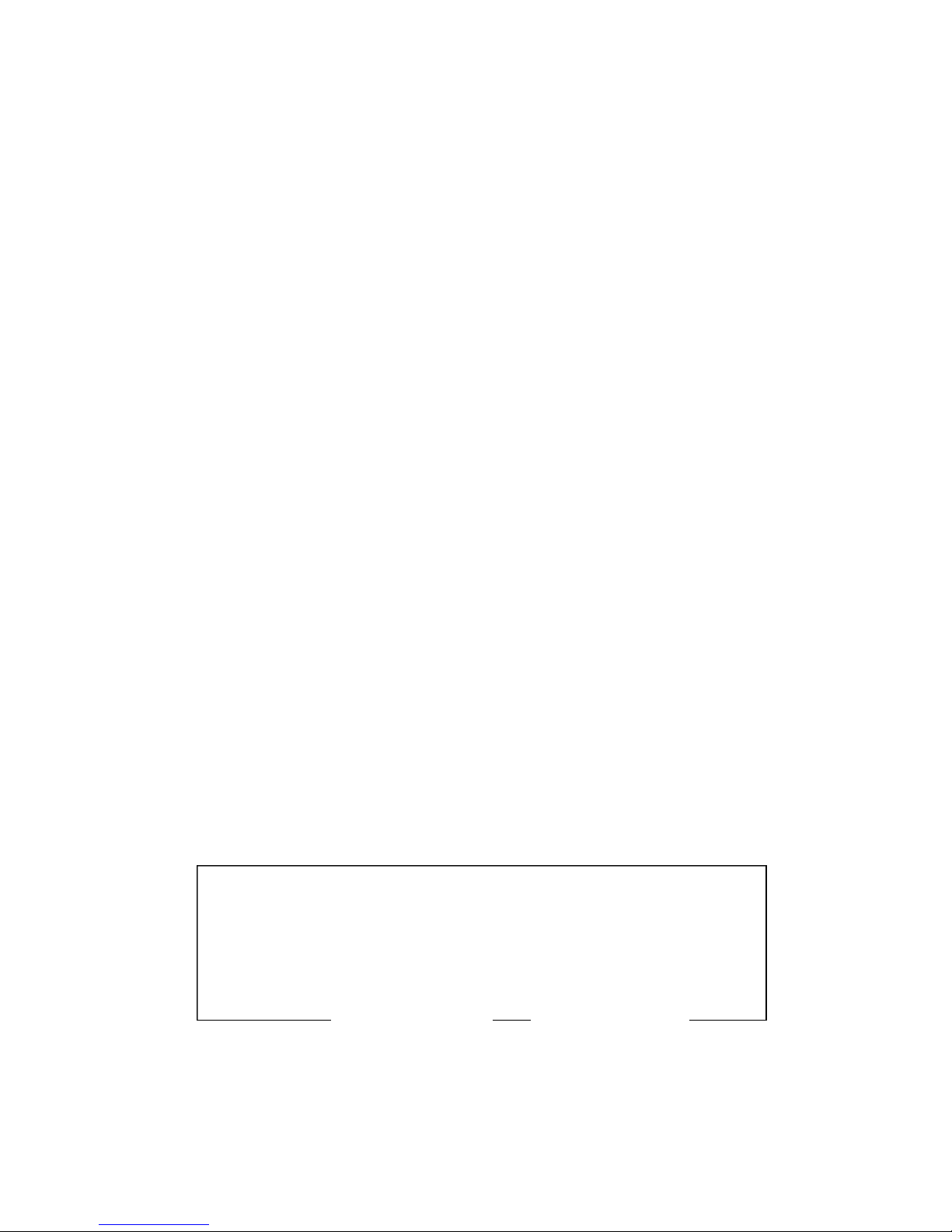

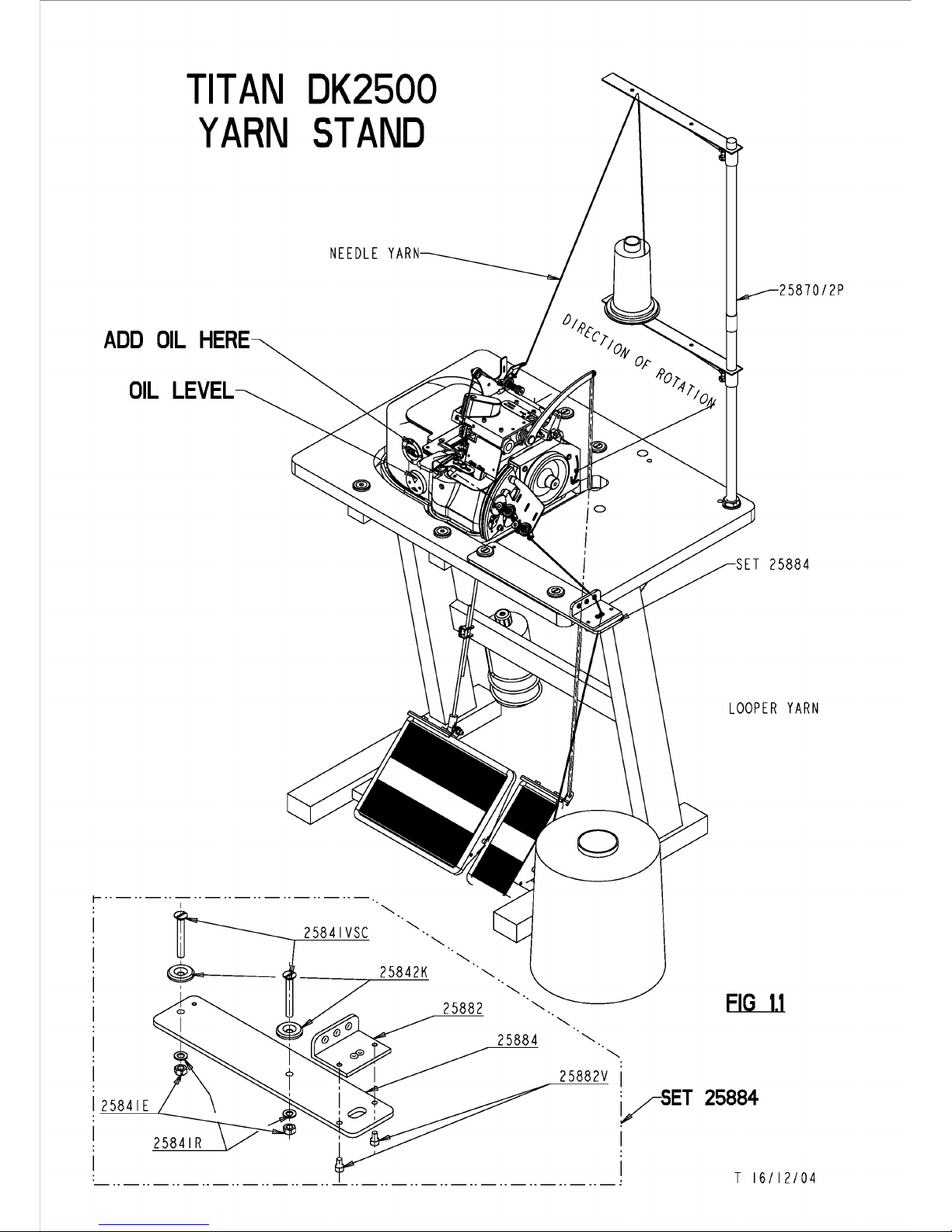

Chapter 1: Installation and lubrication

1. INSTALLATION ................................................................................................................................3

a. Complete machine - with motor and table.................................................................................3

b. Sewing head only .......................................................................................................................5

2. LUBRICATING THE SEWING HEAD....................................................................................................5

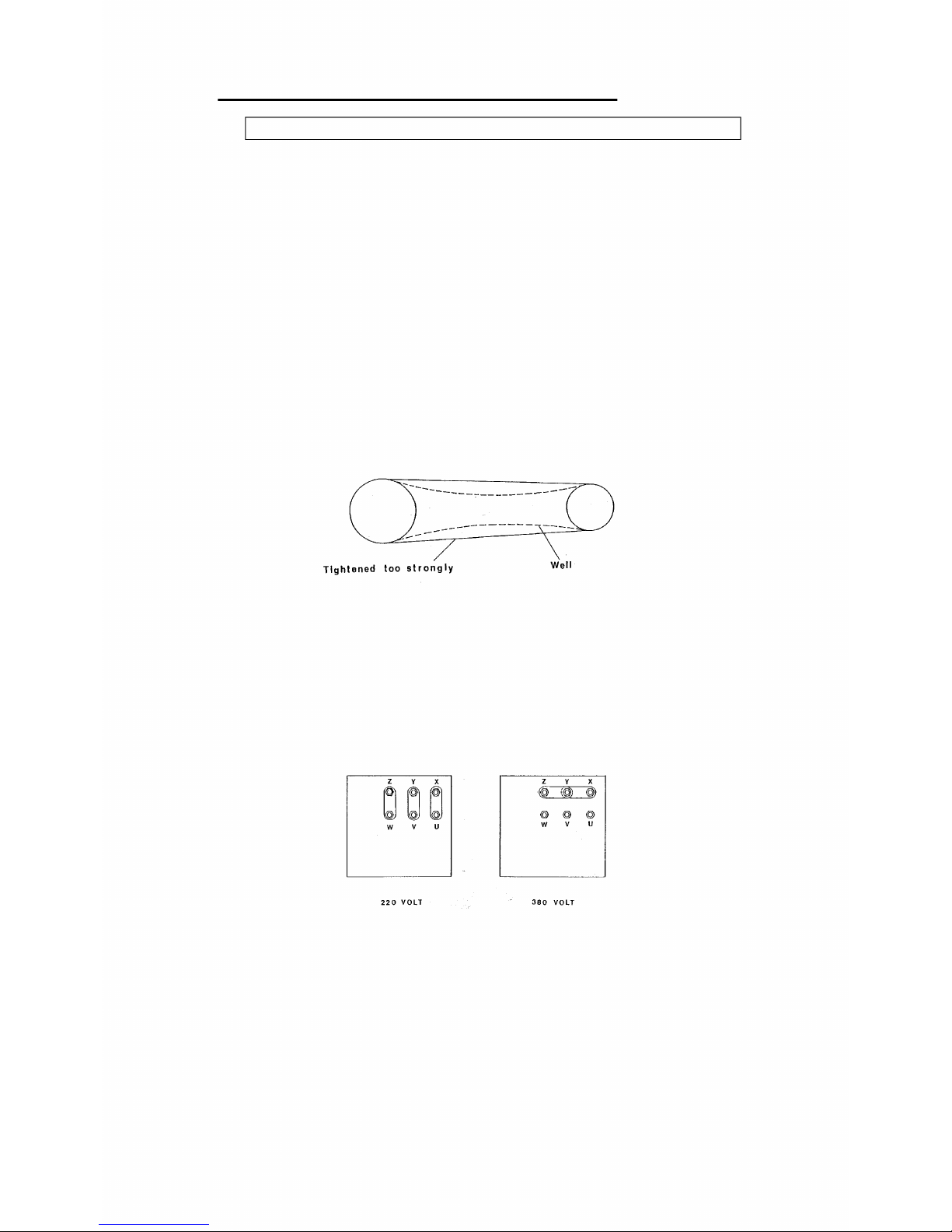

Chapter 2: Threading

1. TYPES OF YARNS.............................................................................................................................7

a. Needle yarn................................................................................................................................7

b. Chain yarn .................................................................................................................................7

2. THREADING ....................................................................................................................................7

a. Needle thread.............................................................................................................................7

b. Chain yarn .................................................................................................................................7

Chapter 3: Stitch formation

1. CHAIN YARN FEED ..........................................................................................................................9

2. Stitch density setting......................................................................................................................11

a. On standard equipment............................................................................................................11

b With the stitch density regulator...............................................................................................11

Chapter 4: Mechanic adjustment of the sewing head

1. TYPES OF NEEDLES .......................................................................................................................13

a. How often are the needles to be replaced?..............................................................................13

b. Needle replacement..................................................................................................................13

c Needle height adjustment ..........................................................................................................15

d. Replacing the needle bar and adjusting the needle height ......................................................15

2. UPPER LOOPER..............................................................................................................................17

a. Preparatory work.....................................................................................................................17

b. Replacing the upper looper .....................................................................................................17

c. Upper looper fine adjustment...................................................................................................17

3. THE LOWER LOOPER .....................................................................................................................19

a. Preparatory work.....................................................................................................................19

b. Replacing the lower looper......................................................................................................19

c. Adjusting the upper looper to the lower looper .......................................................................21

d. Adjusting the distance between needle and lower looper........................................................21

4. THE CUTTING MOTION...................................................................................................................23

a. Renewing the upper knife.........................................................................................................23

b. Renewing the lower knife.........................................................................................................23

c. Knife fine adjustment ...............................................................................................................23

d. Aligning the lower blade with the needle plate........................................................................23

5. THE PRESSER FOOT ................................................................................................................. 23-25

6. FEED-DOG.....................................................................................................................................26

7. CHAIN GUIDE ................................................................................................................................27

8. STITCH PLATE FINGER ...................................................................................................................27

Chapter 5: Maintenance schedule

Maintenance schedule........................................................................................................28