Instruction Manual TITAN DK3700C

CHAPTER 1 : INSTALLATION & OILING

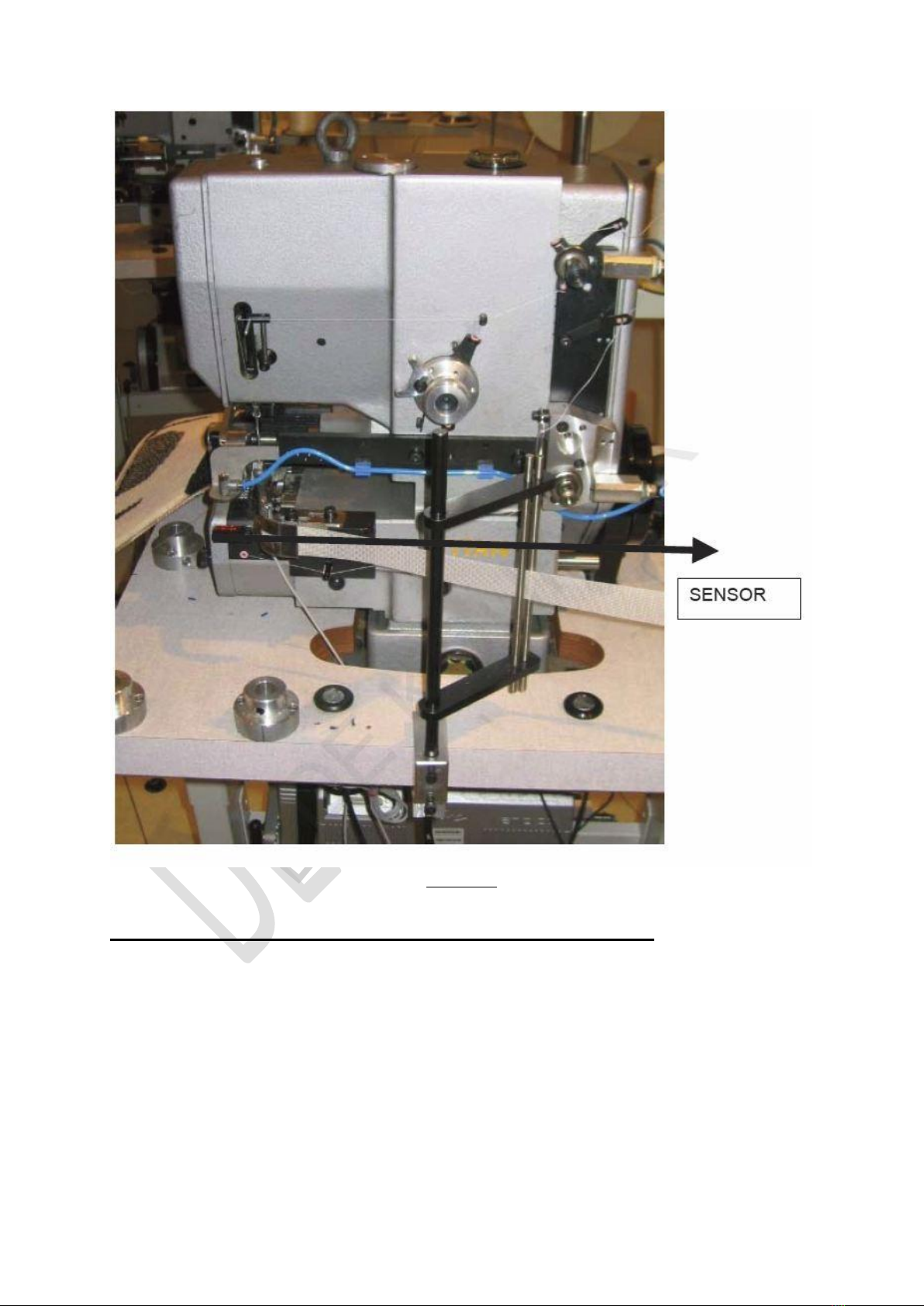

A.The complete machine (with motor and table)

When the machine is delivered completely with table and motor follow the

instructions on the pictures in the manual to assemble the table and the motor. The

package contains all the fasteners (screws, bolts etc.) necessary for the installation.

1. Take the sewing machine out of the package.

2. Place the anti-vibration isolator blocks in the recesses arranged to this effect in

the frame of the table.

3. Carefully lower the machine to rest on these anti-vibration isolators.

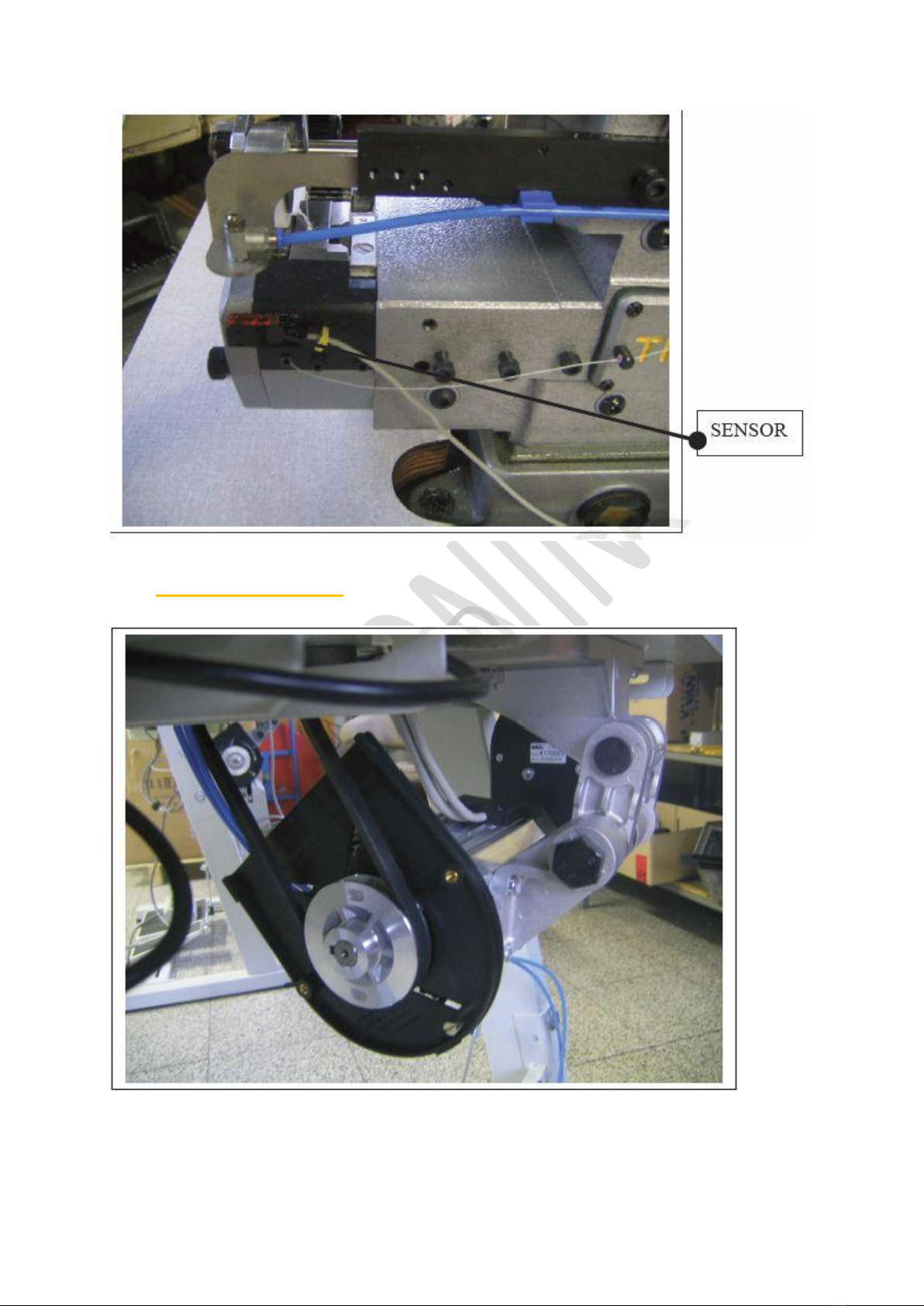

4. Take the 1 litre oil bottle out of the package container.

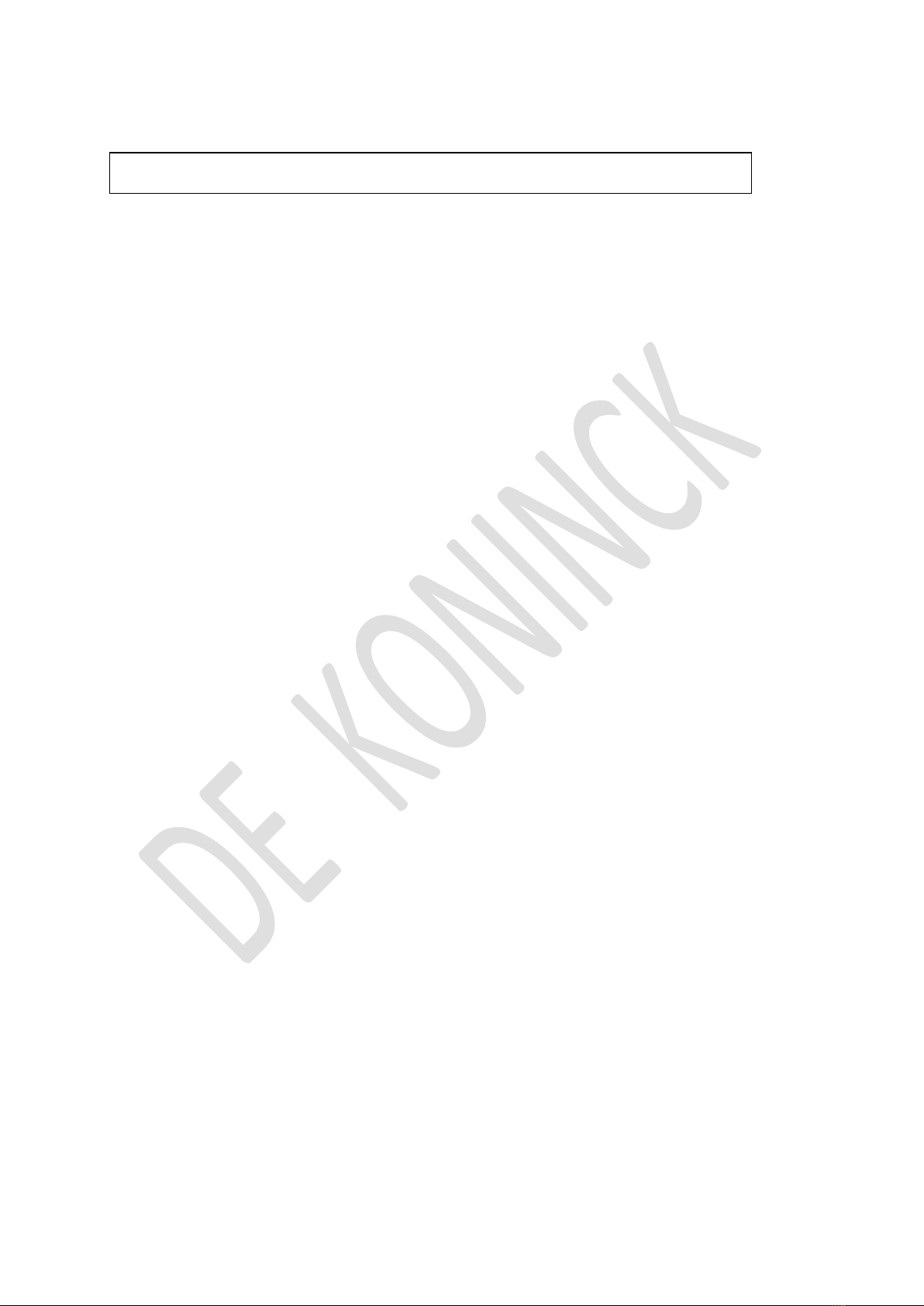

5. Unscrew the filler plug located in the upper part of the machine and poor 1 l of

oil into the machine.

6. Check the oil-level on the sight-glass at the base of the machine.

7. Do NOT run the machine with the oil level lower than the minimum level line.

8. Screw the filler plug back on.

9. The electronic motors are leaving the factory ready to run on

220V/monophase.

10.Use the belt to connect the motor with the sewing machine. Take care not to

tighten the pulley too strong between the two axes. This could bent the axes

and damage some internal parts in the machine or the motor.

11.Verify that the direction of rotation of the sewing machine is correct.

12.Connect the electrical cables.

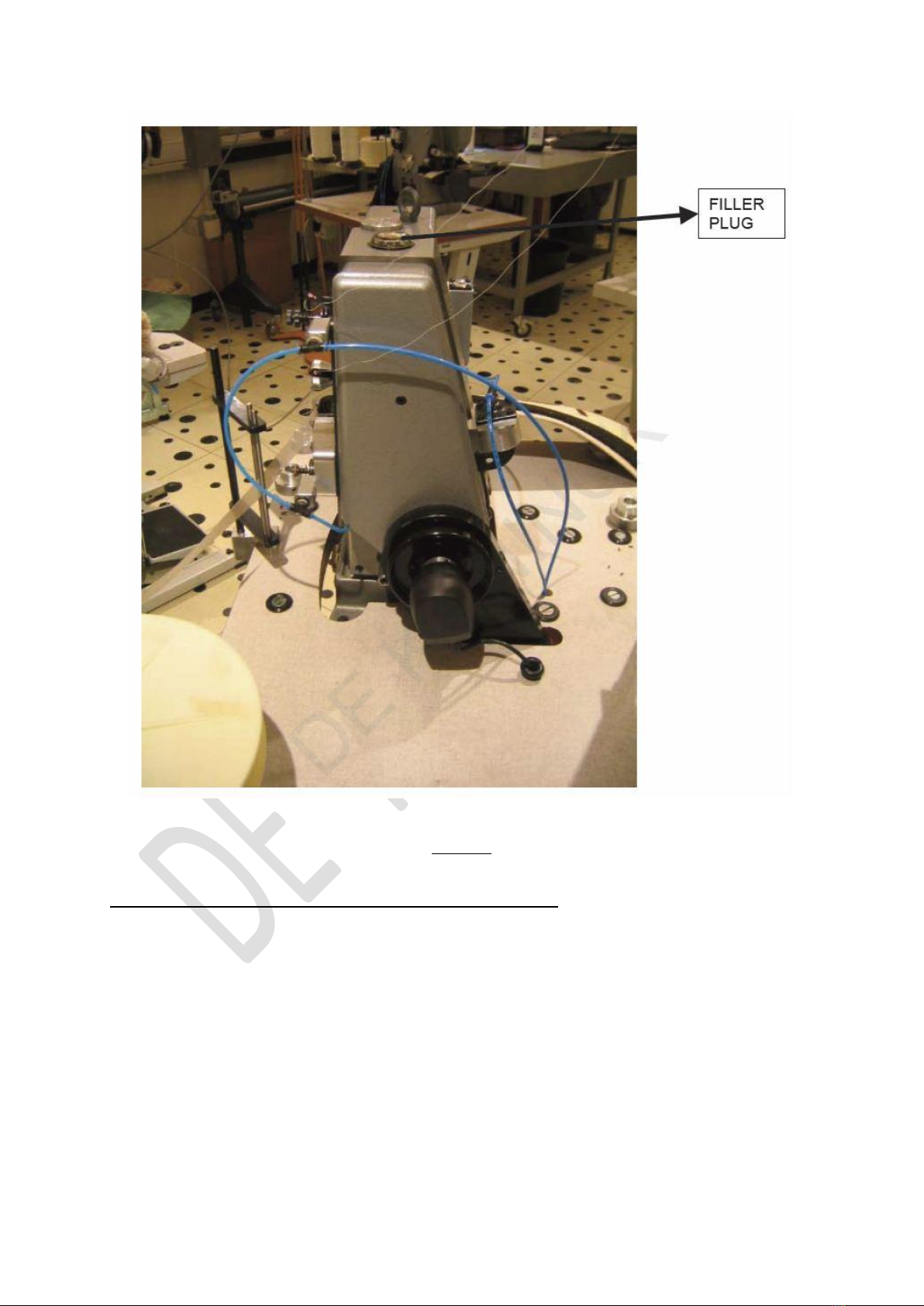

13.Connect the pneumatic cables.

14.After having put the machine into operation, it is advised to run the machine at

very low speed (200-300 rpm) for a few minutes in order to allow the oil to

reach the needle bar.

B. Head only

The TITAN sewing head requires a drive motor with following specifications :

Motor rating : ¾ HP (Horse Power)

Motor speed : 2800 rpm

The V-belt (delivered with the sewing head) should be connected with a

pulley of 70 mm in diameter to the motor.