2 TN-1341 INSTRUCTION MANUAL

FOR SAFE OPERATION

1.

Keep your hands away from needle, belt and any other moving parts when you

turn ON the power switch or while the machine is in operation.

2. Do not put your fingers into the thread take-up cover while the machine is

operating.

3. Turn OFF the power switch when tilting the machine head or removing t

cover or the V belts.

4. During operation, be careful not to allow your or any other person’s head,

hands, or clothes to come close to the handwheel, V belt and motor. Also, do not

place anything close to them.

5. Do not operate your machine with the belt cover and finger guard removed.

6. When tilting the machine head, be sure to confirm that the head rest is

properly attached to your machine head and be careful not to allow your fingers or

the like to be pinched in the machine head.

1.

To ensure safety, never operate the machine with the ground wire for the

power supply removed.

2. When inserting/removing the power plug, the power switch should be turned

OFF in advance.

3. In time of thunder and lightening, stop your work and disconnect the power

plug from the receptacle to ensure safety.

4. If the machine is suddenly moved from a cold place to a warm place, dew

condensation may be observed. In this case, do NOT turn ON the power to the

machine until after you have confirmed that there is no danger of water drops in the

machine.

5. The hook rotates at a high speed while the machine is in operation. To

prevent possible injury to hands, be sure to keep your hands away from the vicinity

of the hook during operation. In addition, be sure to turn OFF the power to the

machine when replacing the bobbin.

6. To avoid possible accidents due to abrupt start of the machine, be sure to turn

OFF the power to the machine.

7. Be careful of handling this product so as not to pour water or oil, shock by

dropping, and the like since this product is a precision instrument.

8. When tilting or returning the sewing machine to the home position, hold the

upper side of the machine head wi

th both hands and perform the work quietly so that

fingers or the like are not caught in the machine.

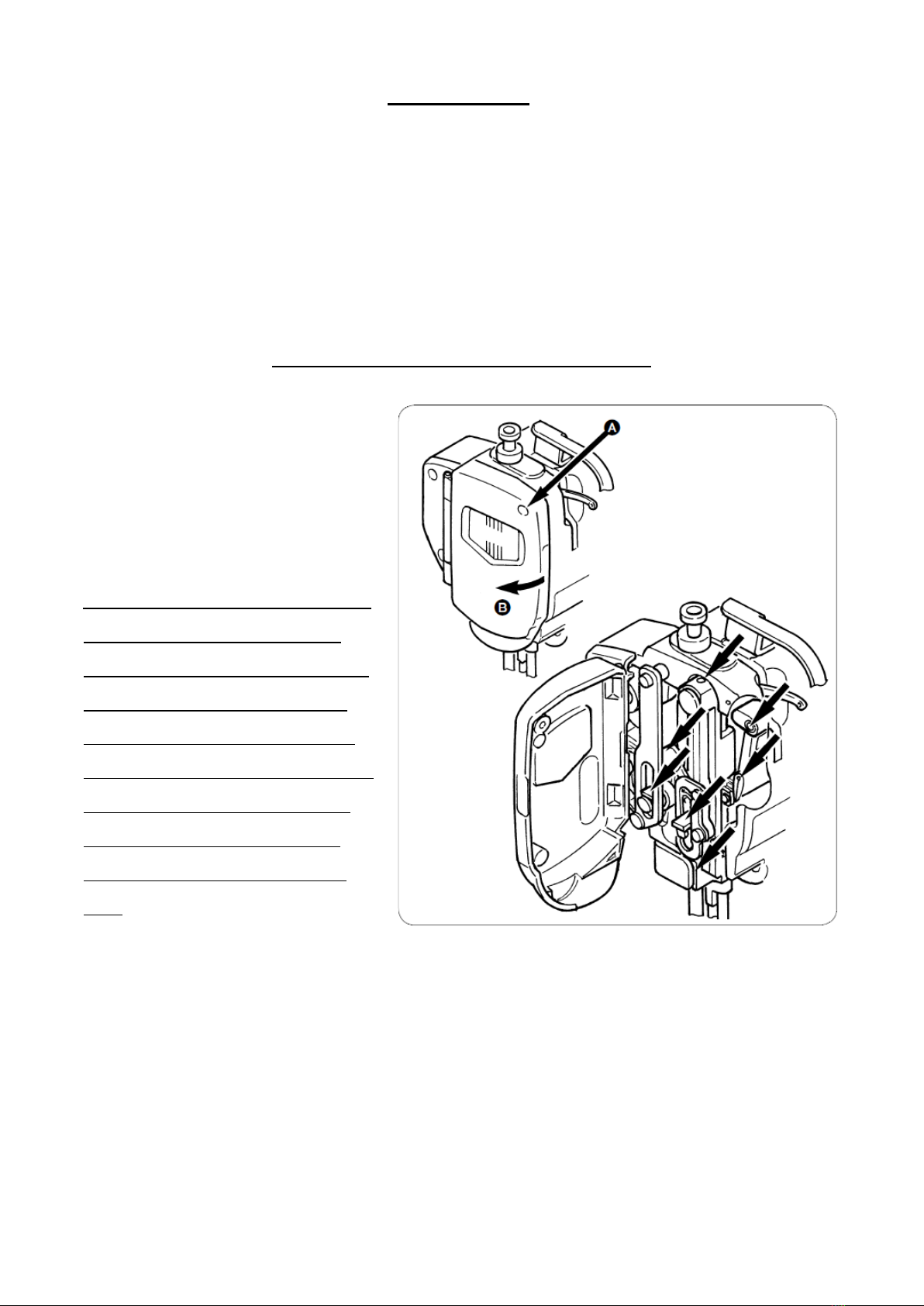

CAUTION

Note that safety devices such as “eye guard”, “finger guard”, etc. may be omitted from

the illustrations in this Instruction Manual for easy explanation.

When operating the machine, be sure not to remove these safety devices.