Tivax SS 602 User manual

Model SS 602

Instruction Manual

For correct usageread these instructionscarefully and

keep in asafe place forfuture reference.

Please note thatthis sewing machineis only suitable

for domestic use.

Sew &Sew ElectronicSewing MachineSS 602

Michley/Tivax Limited Warranty ToOriginal Purchaser

Michley/Tivax warrantsthis product purchased in the USAagainst defects inmaterial

and workmanship undernormal use andservice for aperiod of oneyear from thedate

of retail purchaseby the originalend-user purchaser.Products will notbe warranted

if the serialnumber is removedor defaced.

This warranty shallbe void upontransfer of ownershipof this productand is

effective only when used in the United States.

Michley/Tivax agreesto repair or replace this unit at no charge, within thewarranty

period, providing thatthe product isdelivered to Michley/Tivax in itsoriginal

package or equivalent,fully insured, withall shipping charges prepaid anda return

authorization number listedon the outsideof the packaging.Ahandling charge of $25

will be appliedto any returnedproduct found notto be defective.To honor this

warranty and toensure the bestservice to ourcustomer, Michley/Tivax requires the

following information tobe included withthe returned unit:

•A copyof the originalsales invoice fromyour vendor.

•Model number &serial number ofthe unit.

•A detaileddescription of theproblem, associate electricalconnection and hardware.

A ReturnAuthorization numbercan be obtainedby faxing to650 963-3585 or

This warranty contemplatesthe owner willreasonably maintain thisinstrument or

product without alteration,negligent use, misuse,or abuse. Furthermore,any

unauthorized alteration ofthis device withoutwritten approval byMichley/Tivax

will void anywarranty and theowner's right tooperate this device.

This warranty presentedabove is exclusiveand in lieuof all otherexpressed or

implied warranties.Any warranty applicableto this productis limited tothe period

described above. Inno event willMichley/Tivax be liable for any special, incidental,

or consequential damage,loss of revenue,or cost ofreplacement goods resulting

from the useof malfunction ofthis product tothe equipment systemon which itis

used. This warranty gives specific legal rights and you may haveother rights that

vary from stateto state.

Caution:

1 This appliance is not intended for use by persons (including children) with reduced

physical, sensory ormental capabilities, orlack of experienceand knowledge, unless

they have beengiven supervision orinstruction concerning useof the applianceby a

person responsible fortheir safety.

2 Children shouldbe supervised toensure that theydo not playwith the appliance.

Correct Disposal of this product:

This marking indicatesthat this productshould not bedisposed with otherhousehold

wastes throughout theEU. To prevent possibleharm to theenvironment or human

health from uncontrolledwaste disposal, recycleit responsibly topromote the

sustainable reuse ofmaterial resources. To return your used device, please use the

return and collectionsystems or contactthe retailer wherethe product waspurchased.

They can takethis product forenvironmental safe recycling.

We reserve theright to improve appearance ofproduct. Please check product byreal one, picture in themanual is just for yourreference.

When using an electrical appliance, basic safety precautions should always be followed,

including the following:

Read all instructions before using this appliance.

DANGER---To reduce the risk of electric shock:

1. An appliance should never be left unattached when plugged in. Always unplug this sewing

machine from the electric outlet immediately after using and before cleaning.

2. Always unplug before replacing a sewing machine bulb. Replace bulb with same type

rated 15 Watts.

WARNING---To reduce the risk of burns, fire, electric shock or injury to persons:

1. Do not allow to be used as a toy. Close attention is necessary when using this sewing

machine by or near children.

2. Use this appliance only for its intended use as described in this owner's manual. Use only

attachments recommended by the manufacturer as contained in this owner's manual.

3.

4. Never operate the appliance with any air opening blocked. Keep ventilation openings of

this sewing machine and foot controller free from accumulation of lint, dust and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being

administered.

8. To disconnect, turn all controls to the off ( “O” ) position, then remove plug from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10. Keep fingers away from all moving parts. Special care is required around the sewing

machine needle.

11. Always use the proper needle plate. The wrong plate can cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

14. Switch this sewing machine off (“O”) when making any adjustment in the needle area,

such as threading the needle, changing the needle, threading the bobbin, changing the

presser foot, and the like.

15. Always unplug this sewing machine from the electrical outlet when removing covers,

lubricating, or when making any other adjustments mentioned in this owner's manual.

SAVE THESE INSTRUCTIONS

NOTE: Sewing machine design and specifications are subject to change without prior notice

Never operate this sewing machine if it has a damaged cord or plug, if it is not working

properly, if it has been dropped or damaged, or dropped into water. Return this sewing

machine to the nearest service center for examination, repair, electrical or mechanical

adjustment.

IMPORTANT SAFETY INSTRUCTIONS

TROUBLESHOOTING

Problem Problem cause Amendment

No power orthe machine

runs slowly

Skipping stitches

Bobbin thread cannot be

drawn up

Thread keeps breaking

Stitches too looseor

uneven

Needle breaks

·Adaptor power inadequate ·Use compatible adaptor

·Needle eye not in the

middle

·Remove and re-insertthe

needle with theflat side of

the needle tothe back

·Needle bent ·Remove and re-inserta

new needle

·Presser foot tooloose ·Tighten thepresser foot

·Lower thread hasbeen

used up

·Replace with newfull

bobbin

·Needle threaded incorrectly

·Re-thread the needle,

making sure itis threaded

from the frontto the back

·Needle bent ·Remove and re-inserta

new needle

·Needle shank notproperly

seated

·Remove and re-inserta

new needle

·Thread tension dial,thread

guide or threadpulling bar

too tight

·Loosen the threadtension

between 3-5 number

·Thread blocked byupper

bobbin

·Upper thread tooloose

·Pull out thespool pin and

make the bobbinor thread

run smoothly

·Needle bent ordeformed ·Remove and re-inserta

new needle

SECTION . CARE OFYOUR MACHINE

20

MACHINE SPECIFICATIONS

Item Specification

Sewing speed (Maximum):

Stitch length:

Stitch width:

Stitch package (Stitch function):

(Built-in stitches):

Machine dimensions:

Weight (Net):

Over 350 s.p.m

3.5 mm (Maximum)

6.5 mm (Maximum)

kg

60

12

345 L 275 W 157 H mm

2.9

TABLE OF CONTENTS

Name of Parts....................................................................................................1

Accessories.......................................................................................................2

Connecting Machine to Power Supply..................................................................3

Before Using Your Sewing Machine.....................................................................3

For Your Safety..................................................................................................3

Presser Foot Lifter..............................................................................................4

Thread Cutter.....................................................................................................4

Extension Table..................................................................................................4

•Detaching the table..................................................................................................4

•Attaching the table...................................................................................................4

•Accessory box.......................................................................................................4

Changing Needle................................................................................................5

To Remove and Attach the Foot Holder.................................................................6

•To remove.............................................................................................................6

•To attach..............................................................................................................6

Changing Presser foot

Bobbin winding..................................................................................................7

•Horizontal spool pin

•Bobbin winding

•Removing the hock cover plate

•Insert the bobbin

Thread the machine...........................................................................................10

•Needle thread

•Drawing up bobbin thread

Adjusting the Needle Thread Tension for aStraight Stitch....................................12

•Correct tension

•Tension is too tight

•Tension is too loose

Stitch Selector..................................................................................................14

Stitch...............................................................................................................15

•Starting to sew

•Finishing sewing

Button sewing...................................................................................................17

Manual buttonhole

.........................................................................................6

•To remove.............................................................................................................6

•To attach..............................................................................................................6

.................................................................................................7

..................................................................................................7 8

....................................................................................9

.....................................................................................................9

.......................................................................................................11

.........................................................................................11

.....................................................................................................12

.................................................................................................12

................................................................................................12

Adjusting the Needle Thread Tension for a Zigzag Stitch.....................................13

•Correct tension.....................................................................................................13

•Tension is too tight.................................................................................................13

•Tension is too loose................................................................................................13

......................................................................................................15

...................................................................................................15

......................................................................................18 19

Troubleshooting...............................................................................................20

Stitch choosing button.......................................................................................16

SECTION . NAME OF PARTS

SECTION . GETTING READY TO SEW

SECTION . SEWING

SECTION . CARE OF YOUR MACHINE

8. Raise thepresser foot, turnthe cloth head

back( because clothis sewed forward,if

you want tosew buttonhole, youneed to

turn the directionof sewing.)

9. Choose stitch2 and stitchadjusting E, push

dialing button tothe right tomake presser

th

foot can feedcloth. ( sameas 4 procedure)

10. Turnon switch andsew till buttonholeis

oversewed fully, then stopsewing.

11. Raisepresser foot, turn the handwheel

with one hand,pull the clothlightly with

another hand.

12. Afterpulling the cloth,cut the threadwith

thread cutter onthe machine.

Notice:

When you pushdialing button, youmust turn thehandwheel into 1-2circles.

SECTION .SEWING

19

NAME OF PARTS

23

24

25

26

27

1 Stitch choosing button

2 Power switch & speed

adjusting button

3 Reverse stitch control

4 Reset

5 Stitch panel

6 Thread tension lever

7 Thread winding bobbin

8 Thread pressing circle

9 Bobbin thread

10 Spool pin

11 Thread clamp

12 Bracket of thread clamp

13 Thread take-up lever

14 Thread tension dial

15 Thread cutter

16 Needle clamp screw

17 Needle

18 Presser foot

19 Drawer

20 Hook cover plate

21 Hook cover release button

22 Handle

23 Bobbin winder spindle

24 Handwheel

25 Foot pedal jack

26 Power jack

27 Presser foot lifter

SECTION . NAME OFPARTS

1

Manual Buttonhole

6. Choose stitch 3and stitch adjustingE, push

1. Pull outthe drawer onyour left side

and push dialingbutton to theleft so

that presser footis not incloth feed

status.

2. Put clothunder presser footand press down

the presser footon the clothwhere you need

to sew buttonhole,then choose stitchand

stitch adjusting E.

3. Turnon switch andsew 3-4 stitchin low

speed, then turnoff switch.

4. Choose stitch2 and keepstitch adjusting in

E place, pushthe dialing buttonto the right

side to makepresser foot incloth feed status.

5. Turnon switch andsew on thecloth in

suitable length, thenturn off switch. Note

that try tokeep sewed stitchin straight line.

dialing button backto the leftso that presser

foot is notin cloth feedstatus.

7. Turnon switch andsew 3-4 stitchin low

speed, then turnoff switch.

Dialing

button

SECTION .SEWING

18

5

2

1

3

4

6

7

8

9

11

10

12

13

14

15

16

17

20

19

22

21

18

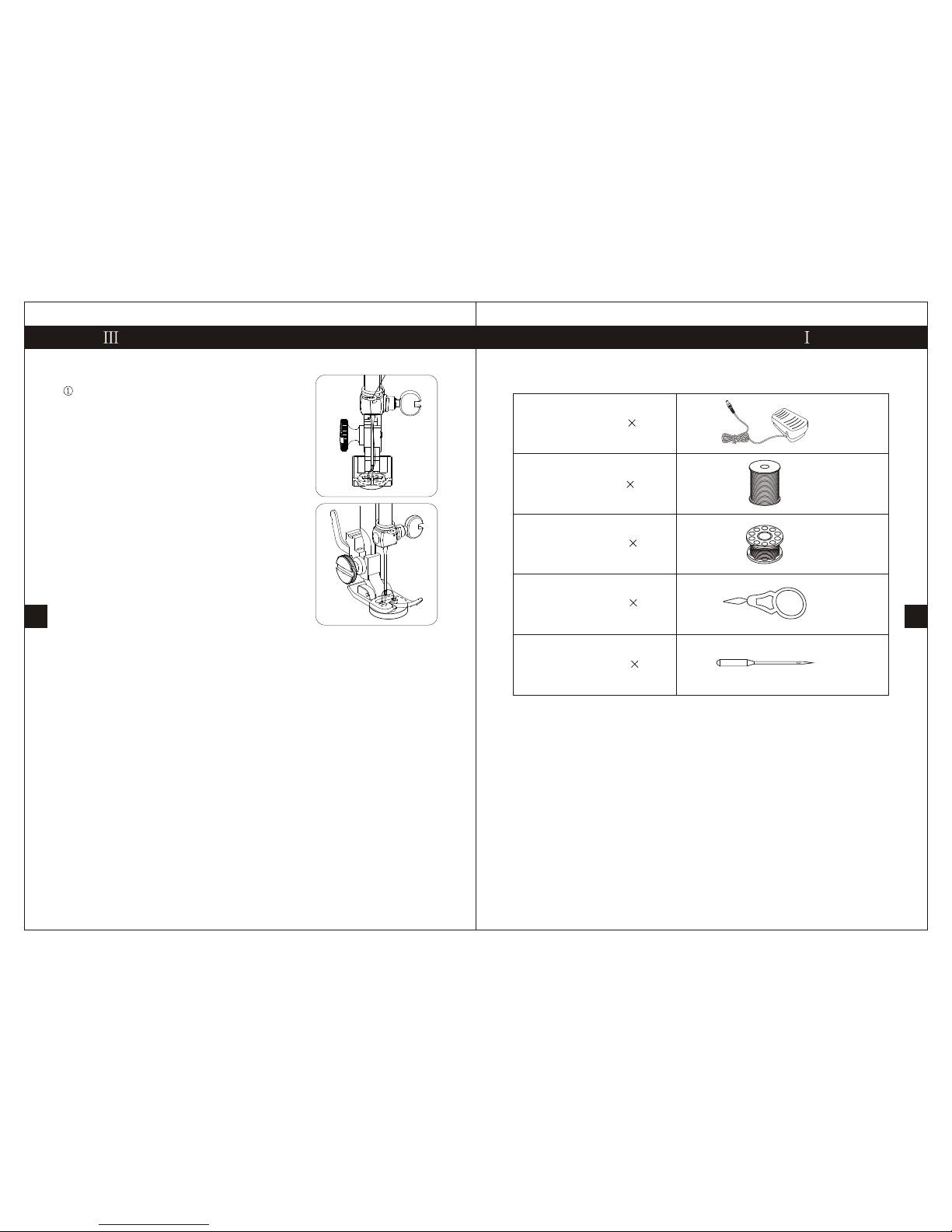

Foot pedal 1

Thread spool 2

Bobbin 2

Needle threader 1

Needle 1

Accessories

SECTION . NAME OFPARTS

2

Button Sewing

Stitch selector: 2to 3

1.Draw theaccessory table and you will see an

adjusting button forbutton sewing. Push the

button to theleft, thus, machine is in the state

of button sewing.Place the button you want

to sew belowthe zigzag foot, making sure to

align the holeswith the horizontal slot in the

foot. Lower thepresser foot to hold the button

in place.

2.Determine whichstitch width setting matches

the distance betweenthe button holes. The

needle must gosafely through each hole when

sewing. Unthread theneedle to help you

determine the zigzagwidth.

3.Thread theneedle. Turn the handwheel, so that

the needle isin its leftmost position, and then

drop the needlethrough the left buttonhole.

4.Press thefoot control and sew about 10 stitches.

5.Sew theother row of holes ( if applicable) using

the steps above.Trim excess threads from both sides of the fabric.

SECTION .SEWING

17

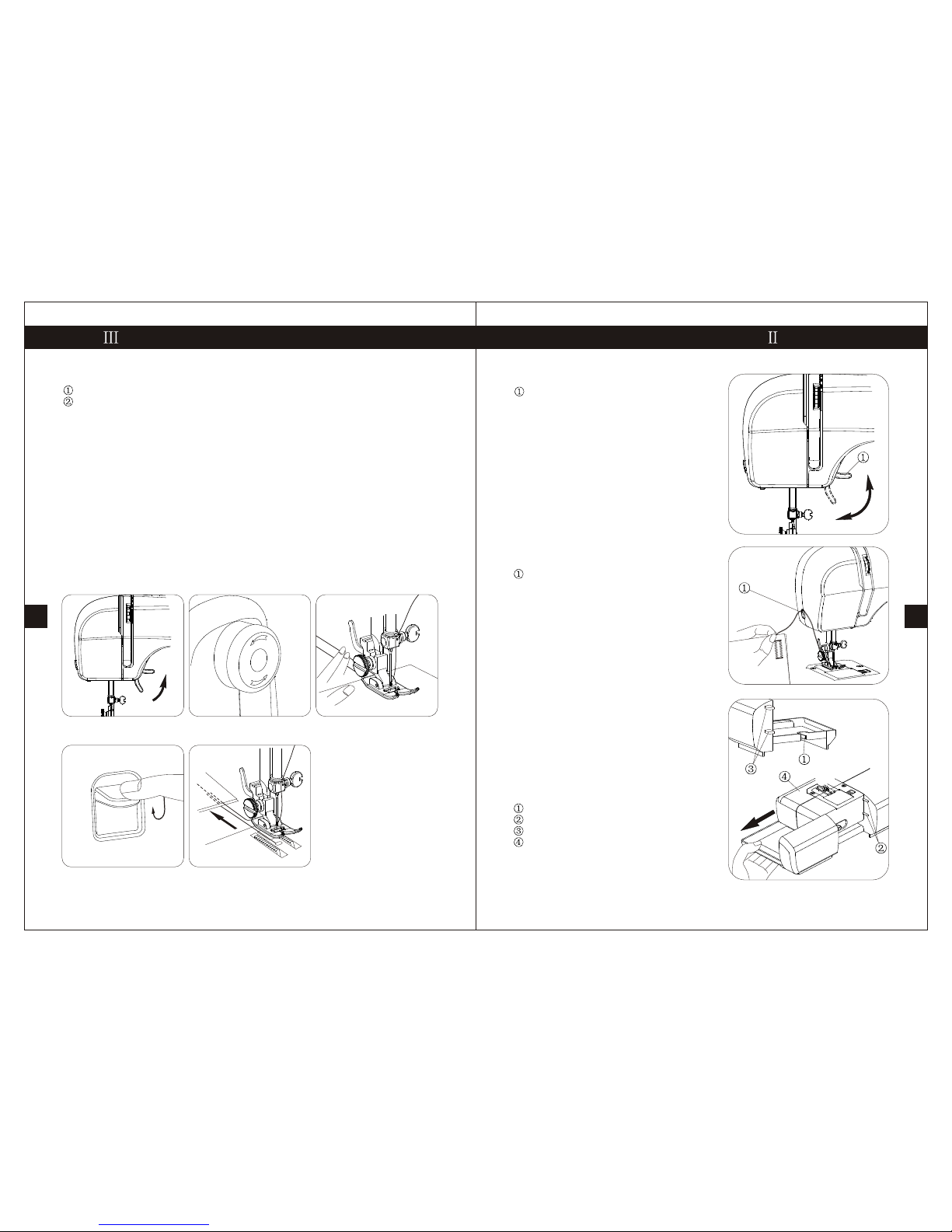

Connecting Machine toPower Supply

Power supply plug

Outlet

Machine socket

Machine plug

Power switch

1.Turnoff the power switch .

2.Insert themachine plug

3.Insert thepower supply plug into the outlet .

4.Turnthe power switch to the leftor right toturn on the power.

Before Using Your Sewing Machine

Before using yoursewing machine forthe first time,place a wastefabric under the

presser foot andrun the machinewith thread fora few minutes.Wipe awayany oil

which may appear.

For Your Safety

While in operation,always keep youreyes on thesewing area. Donot touch any

moving parts suchas the threadtake-up lever,handwheel or needle.

Always turn off the powerswitch and unplug from the power supply:

nWhen leaving themachine unattended.

nWhen attaching orremoving any parts.

nWhen cleaning themachine.

Do not placeanything on thefoot control, whennot sewing.

SECTION . GETTING READYTO SEW

3

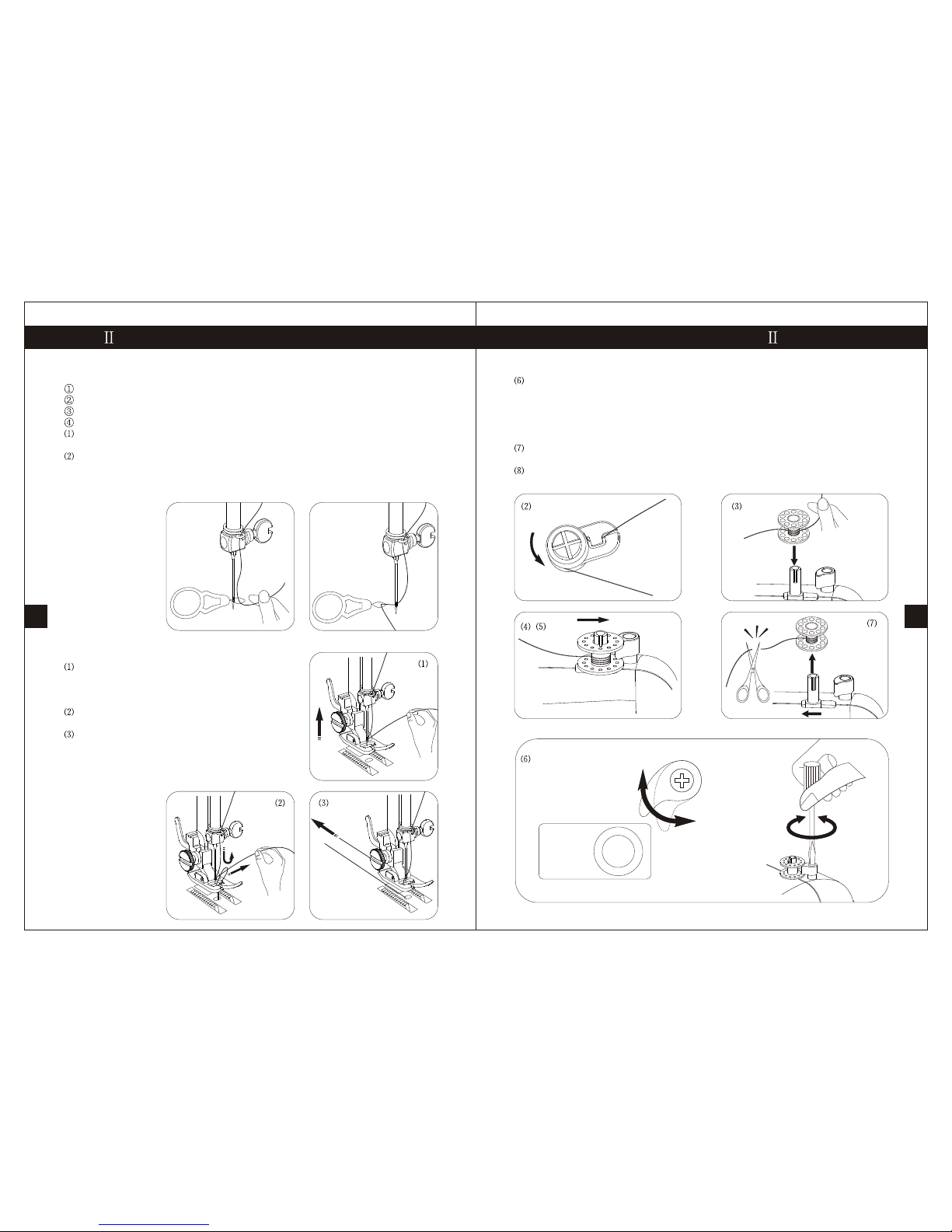

Stitch choosing button

Sewing straight stitch

Sewing other stitches

Left position

Middle position

Right position

Left & rightneedle positions:3 to 6

Middle position: 2

Three needle positions:7 to 12

When you pushbutton to theright, green indicator of stitch pattern is on default

stitch 1.All stitches can be chosen as you like by pressing stitch pattern button.

When you pushbutton to theleft, straight stitch is chosen. Moreover, there are

three needle positions.

Needle position adjusting.If you need another needle position to sew fabric with

a straight stitch, draw fabric and needle thread out, push button to the right and

choose stitches otherthan straight stitch, then needle position is changed as you

like. Stitches canbe adjusted into different needle positions below.

SECTION .SEWING

16

Presser Foot Lifter

Presser foot lifter

The presser footlifter raises andlowers the

presser foot.

Thread Cutter

Thread cutter

Youdo not needa pair ofscissors to cutthe

thread after sewing.Simply use thebuilt-in

thread cutter.

Extension Table

Detaching the table

Pull the tableaway from themachine for

“free-arm” sewing ofcuffs and sleeves.

Attaching the table

Push the extensiontable until itsnaps into

the machine.

Pin

Holes

Tab

Free-arm

Accessory box

Open the coverof the accessorybox toward

you. The sewing accessories are conveniently located in the box.

•

•

•

SECTION . GETTING READYTO SEW

4

Stitch

Straight stitch: 1

Zigzag stitch: 2to 12

Starting to sew

Raise the presserfoot and positionthe fabric onthe needle plate.Turn thehandwheel

and lower theneedle to thepoint where youwant to start.Lower the presserfoot and

pull the threadstoward the back.Depress the footcontrol. Gently guidethe fabric

along a seamguide line lettingthe fabric feednaturally.

CAUTION: Do notplace fingers nearthe presser footwhen guiding fabric,or the

needle clamp screwmay strike andinjure your fingers.

Finishing sewing

To fasten the ends of a seam, press the reverse stitch control and sew several reverse

stitches. Raise thepresser foot. Removethe fabric, drawthe threads tothe back and

cut them withthe thread cutter. The threads are now the proper length to begin

sewing the nextseam.

•

•

SECTION .SEWING

15

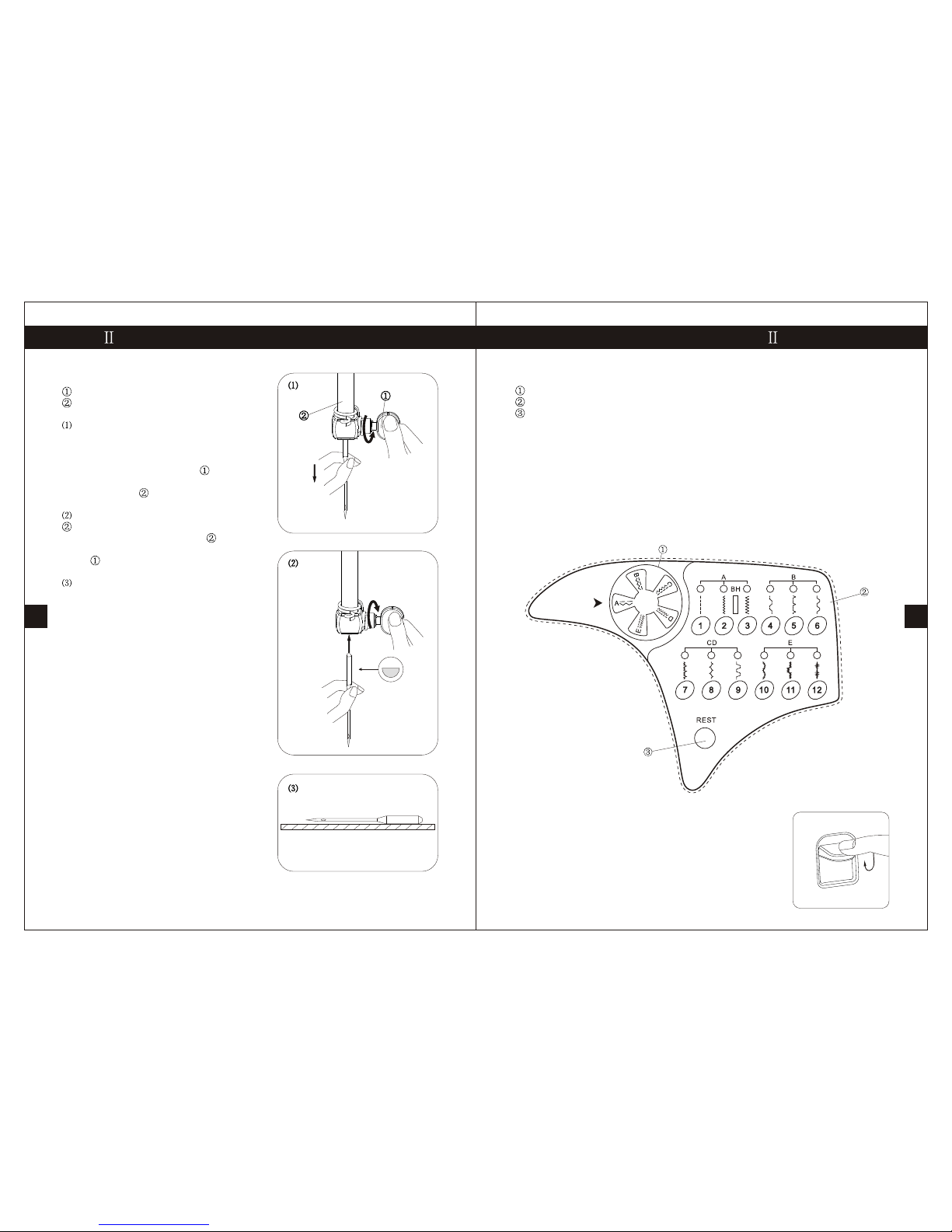

Changing Needle

Needle clamp screw

Needle clamp

Turn off the powerswitch.

Raise the needleto its highestposition by

turning the handwheelcounterclockwise,

toward you, andlowering the presserfoot.

Loosen the needleclamp screw by turning

it counterclockwise. Removethe needle from

the needle clamp .

Insert a newneedle into theneedle clamp

with the flatside to therear. When inserting

the needle intothe needle clamp , push itup

as far asit goes. Tighten the needle clamp

screw firmly by turningit clockwise.

Tosee if theneedle is good,place the flat

side of theneedle onto somethingflat (needle

plate, glass, etc.).Thegap between theneedle

and the flatsurface should beconsistent. Never

use a bentor blunt needle.Adamaged needle

can cause permanentsnags or runsin knits,

fine silks andsilk-like fabrics.

SECTION . GETTING READYTO SEW

5

Stitch Selector (how to selectstitches)

Sewing guide display

Stitch pattern ingreen indicator

Reset key

Choose the stitchyou need and press stitch patternbutton, green indicator will show

the desired stitch.

If you wantto choose anotherstitch pattern, firstpress the reset key and green

indicator returns todefault stitch ( stitch 1), then press your desired stitch pattern.

Stitch width andstitch length can be changed by turning sewing guide display. Each

stitch pattern canbe adjusted into 5 different widths and lengths.

NOTE:

To avoid needle or fabric damage, make sure the needle is up and out of the fabric

while selecting astitch.

Reverse Stitch Control

Press the stitchcontrol to sewin reverse.

SECTION . GETTING READYTO SEW

14

ToRemove andAttach the FootHolder

Thumb screw

Foot holder

Presser foot lifter

To remove

Remove the thumbscrew by turning it

counterclockwise with ascrewdriver.

To attach

Match the holein the footholder with the threaded

hole in thepresser foot lifter Fit the thumbscrew

into the hole.Tighten thescrew by turning it

clockwise with ascrewdriver.

•

•

SECTION . GETTING READYTO SEW

6

Adjust the NeedleThread Tension fora

Zigzag Stitch

•

•

•

For an idealzigzag stitch, the bobbin thread

does not showon the rightside (Top side) of

the fabric, andthe needle thread shows slightly

on the wrongside (Bottom side)of the fabric.

See the illustrationsfor the correct appearance.

To match this appearance, adjust the needle

tension.

Correct tension

Right side (Top side) offabric

Wrong side(Bottom side) of fabric

Minimize the amountof needle thread visible

on the wrongside (Bottom side)of the fabric

without causing excessivepuckering, or

causing the bobbinthread to show on the right

side (Top side) ofthe fabric.

Results vary withfabric, thread andsewing

conditions.

Tension is too tight

Right side (Top side) offabric

Wrong side(Bottom side) of fabric

The corner ofeach zigzag pullstogether on the

right side ofthe fabric.

Tension is too loose

Right side (Top side) offabric

Wrong side(Bottom side) of fabric

The corner ofeach zigzag pullstogether on the

wrong side ofthe fabric.

SECTION . GETTING READYTO SEW

13

Changing Presser Foot

Snap-on button

Groove

Pin

To remove

Raise the needleto its highest position by turning the

handwheel counterclockwise. Raisethe presser foot,

and press thesnap-on button on the backof the foot

holder.

To attach

Place the selectedpresser foot, so that the pin on the

foot lies justunder the groove on the footholder.

Lower the presserbar to lockthe foot intoplace.

•

•

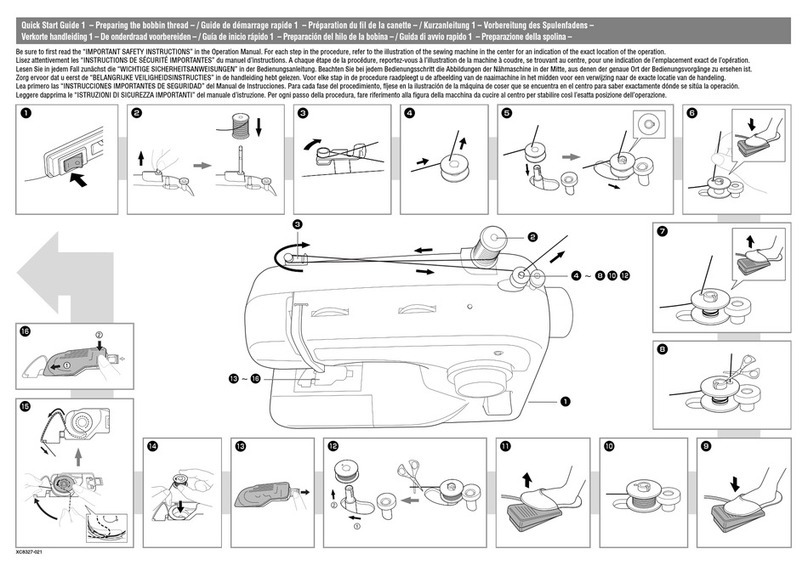

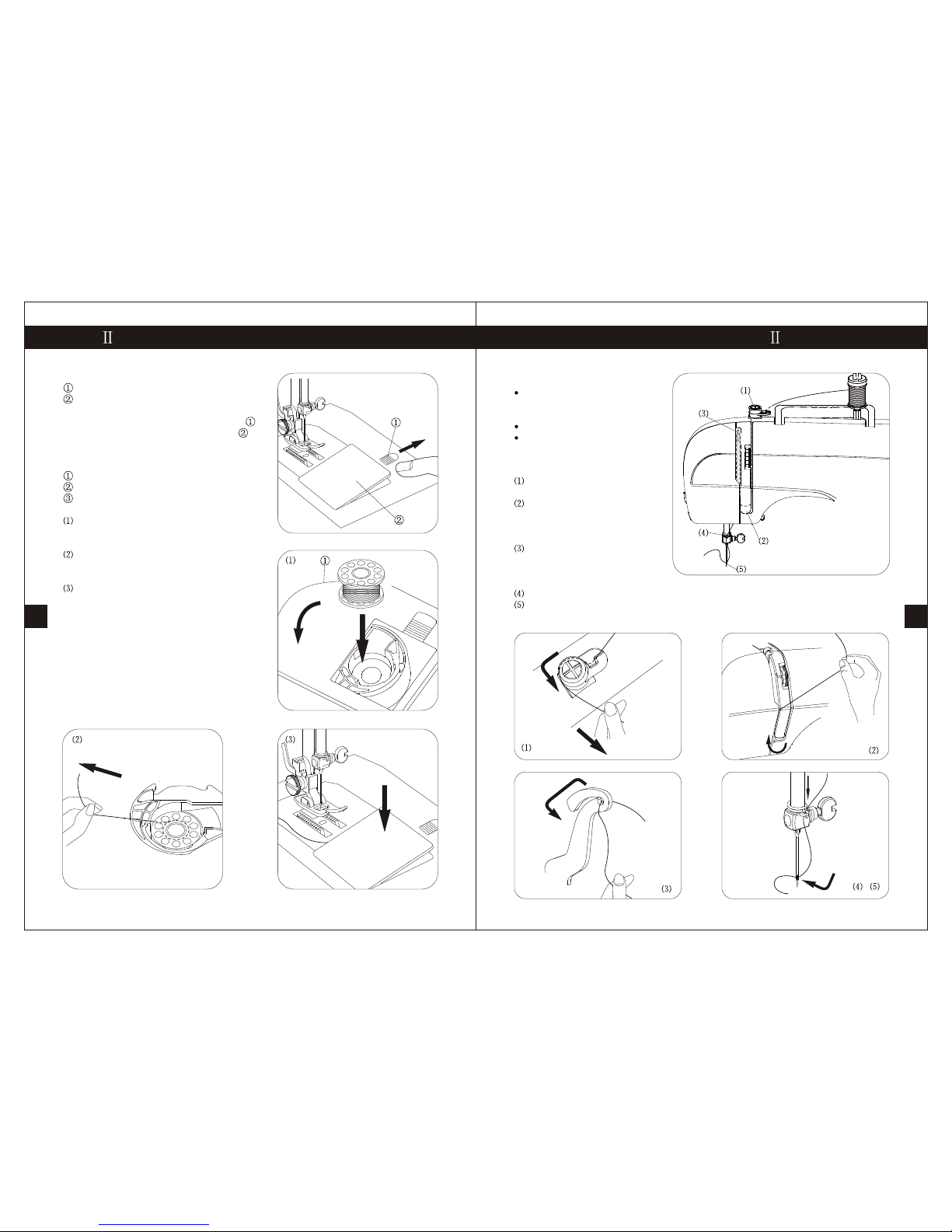

Bobbin Winding

Horizontal spool pin

Spool pin

Spool holder

Lift up thespool pin . Place a spool of thread on the spoolpin with thethread

coming off the spool as shown. Attach the spool holder , and pressit firmly

against the spoolof thread.

•

Bobbin winding

Draw the threadfrom the spool

Guide the threadaround the thread guide.

For the horizontalspool pin

Put the bobbinon the bobbin winder spindle.

Push the bobbinto the right.

With thefree end ofthe thread heldin your

hand, turn onswitch or depress the foot

control. Bobbin willmake turns and wind

thread. Touch bobbin winder stopper tightly,

it stops automatically.

•

SECTION . GETTING READYTO SEW

7

Adjust the NeedleThread Tension fora

Straight Stitch

•

•

•

Correct tension

Needle thread (Top thread)

Bobbin thread (Bobbinthread)

To loosen

To tighten

The ideal straightstitch has threads locked

between two layersof fabric, as illustrated

(magnified to showdetail).If you look at the

top and bottomof a seam, notice that the

stitches are evenlybalanced.

When adjusting theneedle thread tension,

the higher thenumber, the tighter the top

thread tension.

Results depend on:

-stiffness and thickness of the fabric

-number offabric layers

-type ofstitch

Tension is too tight

Needle thread (Top thread)

Bobbin thread (Bottomthread)

Toloosen tension

Right side (Top side) offabric

Wrong side(Bottom side) of fabric

The bobbin threadshows through on the

wrong side ofthe fabric, andthe stitch

feels bumpy. Turnthe dial to a lower

tension setting numberto loosen the

needle thread tension.

Tension is too loose

Needle thread (Top thread)

Bobbin thread (Bottomthread)

Totighten tension

Right side (Top side) offabric

Wrong side(Bottom side) of fabric

SECTION . GETTING READYTO SEW

12

The position ofthe bobbin winderstopper is adjustabledepending on therequired

amount of threadon the bobbin. Using a screwdriver, loosen thescrew one turn or

less ,so thatyou can adjust the position of the bobbin winder stopper. Do not take

the screw allthe way out. Retighten the screw to fix the stopper at the desired

position.

When the bobbin is wound, turn off switch. Return the bobbin winder to its

original position bymoving the spindle to left, and cut the thread as shown.

The machine willnot sew untilthe clutch isengaged.

SECTION . GETTING READYTO SEW

8

•Needle threader

Needle threader

Ring

Needle eye

Thread end

Raise the needleto its highestposition. Paying attentionto the needlepoint,

put ring ofneedle threader togo through needleeye.

Draw thread intoring and pullring back fromneedle eye. Releasethe needle

threader and thethread has beenthreaded through needleeye.

NOTE:

Thread length leaves for 5-10 cm is recommended when sewing.

•Drawing up bobbinthread

Raise the presserfoot. Hold theneedle thread

lightly with yourleft hand and rotate the

handwheel counterclockwise forone complete

turn.

Bring the bobbinthread up bypulling the needle

thread up.

Pull both threads10 to 15cm under andbehind

the presser foot.

SECTION . GETTING READYTO SEW

11

•

•

Removing the hookcover plate

Hook cover platerelease button

Hook cover plate

Slide the hookcover plate releasebutton

to the right,and remove thecover plate

Inserting the bobbin

End of thread

Notch

Notch

Place a bobbinin the bobbinholder with

the thread runningoff counterclockwise.

Draw the threadto the left,Pull out about

15.0 cm ofthread.

Attach thehook cover plate.

SECTION . GETTING READYTO SEW

9

Threading the machine

Raise the threadtake-up lever to

its highest positionby turning the

handwheel counterclockwise.

Raise the presserfoot lifter.

Place a spoolon the spool pin,

with the threadcoming off as

shown.

Draw the endof the thread

around the upperthread guide.

While holding the thread near

the spool, drawthe end of the

thread down aroundthe check

spring holder.

Firmly draw thethread up from

right to leftover the take-up

lever, anddown into the take-up

lever eye.

Slide the threadbehind the needle bar thread guide on the left.

Thread the needle from front to back, or use a needle threader.

SECTION . GETTING READYTO SEW

10

Table of contents

Other Tivax Sewing Machine manuals