TJERNLUND AIRESHARE ASLL User manual

TJERNLUND PRODUCTS, INC.

1601 Ninth Street • White Bear Lake, MN 55110-6794

PHONE (800) 255-4208 • (651) 426-2993 • FAX (651) 426-9547

Visit our web site • www.tjernlund.com

READ OWNERS INSTRUCTIONS CARE-

FULLY PRIOR TO INSTALLATION.

THESE INSTRUCTIONS MUST REMAIN

WITH EQUIPMENT. DO NOT DESTROY.

AIRESHARETM LEVEL TO LEVEL VENTILATOR

MODEL ASLL

©2009 TJERNLUND PRODUCTS, INC. ALL RIGHTS RESERVED P/N: 8504156

DESCRIPTION

The AireShare™ Level to Level Ventilators distribute air from one conditioned space to another. Virtually every home has temperature

differentials on different levels of the house. The AireShare™ moves air from one level of the house to a room on another level of the

house that is uncomfortably hot or cold. This air movement helps to destratify stagnant air in homes, improve ventilation rates and make

both rooms more comfortable.

ASLL SPECIFICATIONS & COMPONENTS

GENERAL INFORMATION

Every Tjernlund AireShare™ Level to Level Ventilator is electrically factory line tested before shipment.

After opening carton, inspect thoroughly for shipping damage. Impeller should rotate freely and all electrical wires and connections

should be secured. If any damage is found, notify freight carrier and your distributor immediately and file a concealed damage claim.

INSTALLATION RESTRICTIONS

The AireShare™ Ventilator must be installed by a qualified installer in accordance with these instructions and all local codes or in their

absence in accordance with the latest editions of the International Residential Code and International Electrical Code. Improper installa-

tion can create a hazardous condition such as fire, electric shock or personal injury. To reduce these risks significantly, use this device

only in the manner intended by the manufacturer. If you have questions about proper usage of this device, call Tjernlund Products.

Always disconnect the AireShare™ Ventilator from its power source before installation and servicing.

IMPORTANT: An in depth investigation of the floor joist/truss layout is required prior to installation. Avoid a floor/ceiling cavity that is a

path for plumbing supply lines, drains, vents or ductwork. Also confirm foundation block and upstairs walls do not obstruct installation.

SPECIFICATIONS

Blower: 75 cfm

Motor: 115 Volts ~ 60 Hz

25 Watts ~ 0.50 amps maximum

Impeller: Transtangental, cross-flow

Sound: 42 db (1.15 Sones)

DIMENSIONS:

White Ceiling Grille: 5 1/2” x 13 1/2” (flush)

Brown Floor Grille: 5 3/4” x 13 3/4” (flush)

Blower Housing Rough-in: 4 1/16” x 12 5/16”

Outer Sleeve Rough-In: 4 5/16” x 12 5/16”

Expansion Depth* 8 3/4” to 16 1/2”

(*top of floor to bottom of ceiling)

CEILING GRILLE

FLOOR GRILLE

EXPANSION DEPTH

• The AireShare™ may not be used to exhaust hazardous or explosive materials or vapors.

• The AireShare™ may not be used in kitchens or move moisture-laden air from sources such as bathrooms and kitchens.

• The AireShare™ may not be used to move air from from a utility room containing gas or oil fuel heating equipment.

WARNING: Disconnect power to the ASLL before servicing. To reduce the risk of fire, electrical shock and injury to persons, the

AireShare™ must be installed with the ASLL Floor grille that was provided with the ASLL.

WARNING: To reduce the risk of fire or electrical shock, do not use this fan with any solid state speed control devices.

WARNING: To reduce the risk of fire, electric shock, or injury to persons, observe the following:

a. Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer.

b. Before servicing or cleaning unit, switch power off at service panel and lock the service disconnecting means to prevent power

from being switched on accidentally. When the service disconnecting means cannot be locked, securely fasten a prominent

warning device, such as a tag, to the service panel.

c. Installation work and electrical wiring must be done by qualified person(s) in accordance with all applicable codes and standards,

including fire-rated construction.

d. When cutting or drilling into floor, wall or ceiling areas, do not damage electrical wiring and other hidden utilities.

Disrupt power at circuit breaker to outlets near the joist/truss area you will be working in.

When sawing through sheetrock or floor, immediately stop if you detect the saw blade coming in contact

with any wiring or plumbing. Investigate further to determine if it is possible to safely continue to use this

joist/truss cavity. Switch to another joist/truss cavity if necessary.

BEFORE YOU START:

Determine the joist/truss cavity mounting location. If you are wiring to an existing outlet it is best to select a

joist/truss section that contains an electrical outlet for wiring. IMPORTANT: Direction of joist/truss might

determine which direction the ASLL can be installed. Review ASLL dimensions and minimum and

maximum expansion of sleeve before installing, (See Diagram A). Use a stud finder to verify joist/truss

location and direction.

TOOLS REQUIRED

Sheetrock Saw • Phillips Screwdriver • Drill • Tape Measure • Utility Knife • Wire Stripper • Stud Finder (required if ceiling is finished)

3/8” drill bit & 1/4” drill bit 2” longer than joist/truss thickness (long bit not required if ceiling is unfinished) • Jig Saw / Reciprocating Saw

INSTALLATION

PRE-INSTALLATION INSPECTION

IMPORTANT: An in depth investigation of the floor joist/truss layout is required prior to installa-

tion. Avoid a section that is a path for plumbing supply lines, drains, vents or ductwork. Also con-

firm foundation block or upstairs walls do not obstruct installation. If wiring to an existing outlet

using surface wiring, it is best to select a joist/truss section that contains an electrical outlet to

wire into.

Determine if the installation is a downflow or upflow application. If ASLL will discharge air up to

the level above it is upflow. If ASLL will discharge air down to a lower level it is downflow.

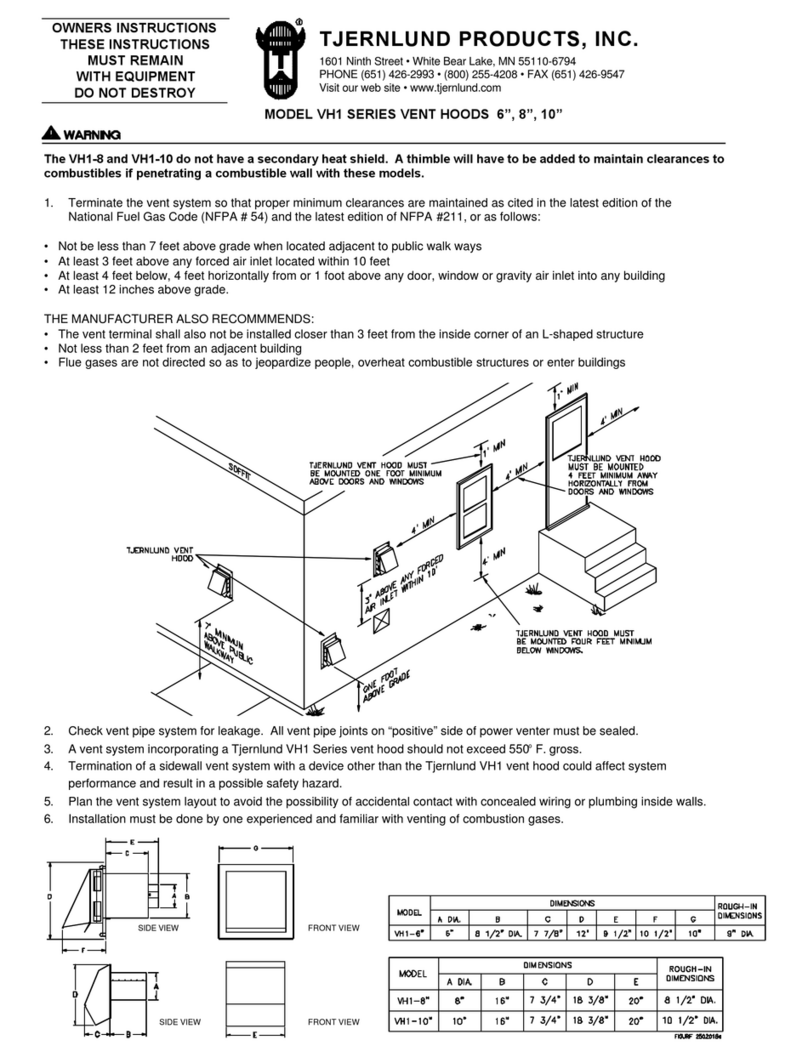

1. Proceed to step 2 if ceiling is unfinished. If ceiling is finished use a stud finder to locate the inside edges of the joist/truss ASLL will

be installed between. Apply masking tape on ceiling along joist/trusses in the desired location ASLL will be installed in. Make sure a

proper analysis as noted above has taken place before cutting hole in ceiling. In the center of the tape cut a 3” x 3” inspection hole

to review the intended installation area using a flashlight and small mirror if necessary, (See Diagram B).

NOTE: The following installation illustrations show the upper level floor with carpeting.

2. If floor above has carpeting it may be desirable to pull carpeting back if possible. If it is a good installation area, slowly drill a small

pilot hole with a 1/4” drill bit through the 3” x 3” inspection hole or center of joist/truss area up through subfloor. Drill bit might cause

carpet to unravel so be cautious. Once you go through subfloor reverse out of the hole. Use an extended screw driver or scratch awl

to push through the carpet above.

DIAGRAM A

UPFLOW

INSTALLATION

DOWNFLOW

INSTALLATION

THE FOLLOWING STEPS ARE FOR AN UPFLOW INSTALLATION

3. Place ASLL Outer Sleeve template center alignment hole over drill bit or screw driver. Align template cutout lines parallel with

baseboard and tape template to floor, (See Diagram C). Use a utility knife and cut out carpeting and pad along Outer Sleeve

template lines denoted, (See Diagram D).

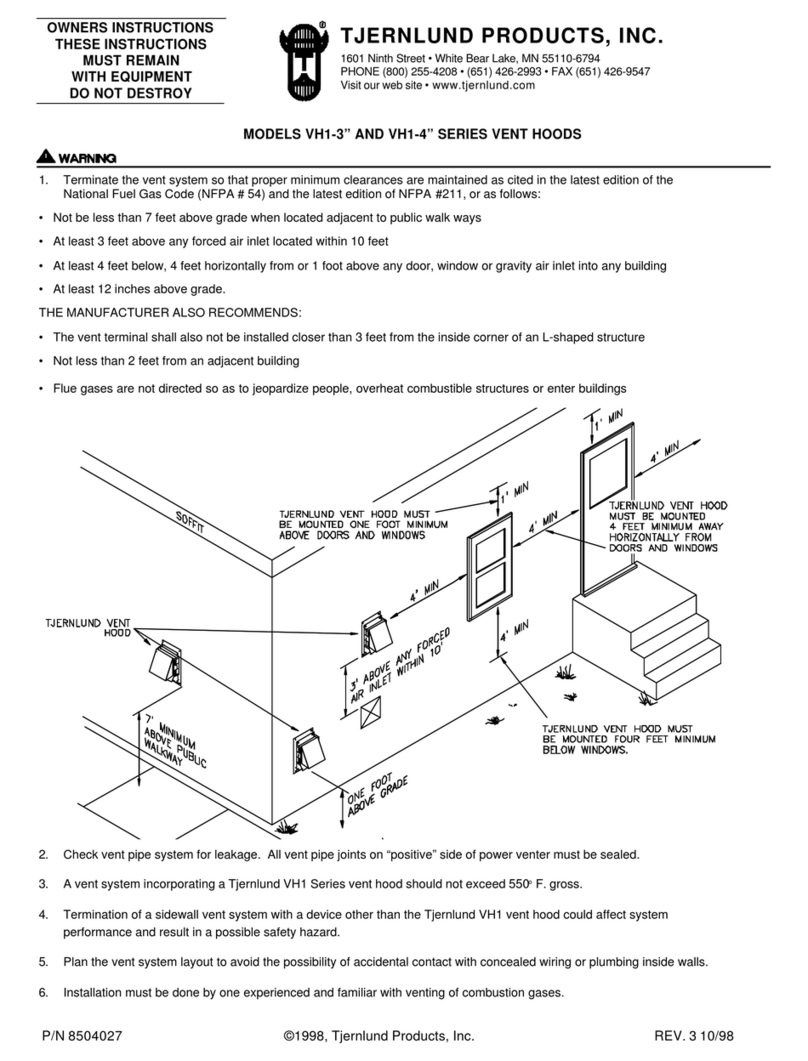

4. Drill the 4 corners out on floor with a 3/8” drill bit and saw opening out using a jig saw or reciprocating saw. The final rough-in opening in

the floor for an Upflow application must measure 4 5/16” x 12 5/16” for Outer Sleeve. IMPORTANT: Rough-in openings must

not exceed dimensions provided or Outer Sleeve flange may fall through opening, (See Diagram E).

5. Proceed to step 8 if ceiling below is unfinished. Slide the Outer Sleeve through the floor. Using a 1/4” long drill bit, follow the corners of

the Outer Sleeve straight down and drill 4 holes through the ceiling material below, (See Diagram F). Connect the 4 holes on the ceiling

below with a straight edge and compare the dimensions on the ceiling to Blower Housing template dimensions which measure 4 1/16” x

12 5/16”, See Diagram G).

6. If ceiling is sheetrock use a sheetrock saw and follow the lines from step 5 and cut out ceiling opening, (See Diagram G). If ceiling is

not sheetrock, use a jig saw or reciprocating saw. IMPORTANT: Both openings should be directly centered above one another.

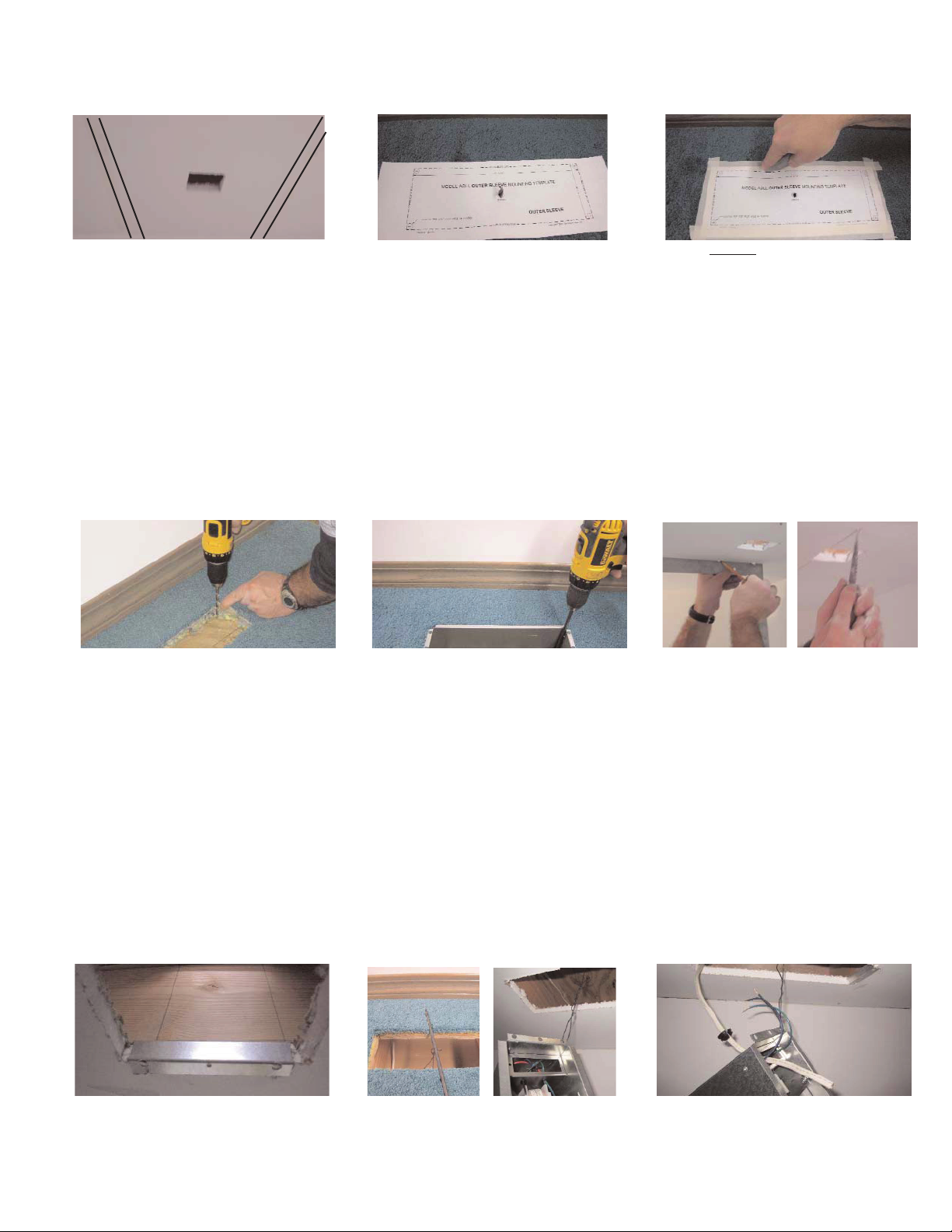

7. If ceiling is sheetrock or ceiling tile, slide sheetrock mounting brackets over sheet rock ends. The 2 large holes in brackets must face

down, (See Diagram H). IMPORTANT: If using ceiling tile, it must be able to support 8 pounds to support the ASLL blower. If ceiling

tile is not adequate enough to support the ASLL then the ASLL must be framed in and properly supported by ceiling track.

8. Use a rod with wire attached to ASLL Blower Housing mounting bracket to suspend ASLL blower from floor above while

wiring, (See Diagram I).

9. Supply electrical power through ceiling opening on the side of ASLL where power will enter unit. See “Wiring” section for wiring

specifics. Use provided strain relief bushing for standard 14-2 w/ground NM-B nonmetallic sheathed cable (Romex) and snap into

place in 7/8” knockout on ASLL electrical box with about 6-8” of wire pushed into ASLL electrical box, (See Diagram J). Push wire up

tight against ASLL Blower Housing and slide the ASLL up through the hole in the ceiling until the flange of the ASLL blower section

meets the ceiling, (See Diagram K).

DIAGRAM B DIAGRAM C DIAGRAM D

IF CEILING IS FINISHED, PLACE TAPE ALONG

JOIST/TRUSS. CUT A 3” INSPECTION HOLE TO

VERIFY IT IS A GOOD INSTALLATION LOCATION.

PLACE ASLL OUTER SLEEVE TEMPLATE CEN-

TER ALIGNMENT HOLE OVER DRILL BIT OR

SCREW DRIVER.

FOR AN UPFLOW APPLICATION CUT OUT CAR-

PET & ROUGH-IN OPENING USING OUTER

SLEEVE TEMPLATE (4 5/16” X 12 5/16”).

DIAGRAM E

DRILL OUT CORNERS WITH 3/8” DRILL BIT.

IMPORTANT: ROUGH-IN OPENING FOR OUTER

SLEEVE MUST NOT EXCEED 4 5/16” X 12 5/16”.

DIAGRAM F DIAGRAM G

CONNECT (4) HOLES WITH A STRAIGHT EDGE

AND MAKE SURE BLOWER HOUSING DIMEN-

SIONS MEASURE 4 1/16” X 12 5/16”. CUT OUT

OPENING WITH SHEETROCK OR JIG SAW.

DIAGRAM I

SUPPORT ASLL BLOWER FROM ABOVE BY

USING ASLL MOUNTING FLANGE AND MECHAN-

ICS WIRE OR OTHER SUITABLE METHOD.

SNAP PROVIDED STRAIN RELIEF BUSHING INTO

ASLL ELECTRICAL BOX WITH 6-8” OF WIRE IN

ELECTRICAL BOX.

DIAGRAM J

IF CEILING BELOW IS FINISHED, DRILL (4) 1/4”

HOLES THROUGH CEILING USING EACH OF

THE 4 CORNERS OF OUTER SLEEVE AS A

GUIDE.

DIAGRAM H

INSTALL SHEETROCK BRACKETS ON BOTH

ENDS OF OPENING WITH LARGER HOLES IN

BRACKETS FACING DOWN.

10. Using the (4) provided black screws, align holes on ASLL Blower Housing mounting bracket with holes in sheetrock mounting brack-

et (utilized if ceiling is sheetrock or ceiling tile). Install the (4) screws straight up. The screws must grip the sheetrock mounting

bracket small grip hole. Do not over tighten screws, (See Diagram L). If ceiling is unfinished cut (2) pieces from floor cutout

material and secure each piece to the joist/truss and install (4) screws in ASLL Blower Housing mounting bracket, (See Diagram L).

11. Wire the ASLL as illustrated in the “Wiring” section. Push the wires into the ASLL electrical box and install electrical box cover

and ceiling grille with the provided screws, (See Diagram M). Ceiling grille may be painted if desired.

12. IMPORTANT: If the combined width of the Joist/Truss thickness, ceiling and subfloor is over 13”, adhere both air flow leakage stickers

over electrical relief slot opening in Outer Sleeve to prevent air leakage into joist/truss cavity, (See Diagram N).

13. Install the Outer Sleeve in floor. CAUTION: When installing Outer Sleeve make sure electrical relief opening is on the side electrical

enters ASLL, (See Diagram O).

14. Unit can be operated by switching the on/off switch below floor grille, (See Diagram P). ASLL can also be wired into a 120 VAC wall

switch or thermostat if desired, see “Wiring” for details. Insert the floor grille.

IMPORTANT: An in depth investigation of the floor joist/truss layout is required prior to installation. Avoid a joist/truss cavity that is a

path for plumbing supply lines, drains, vents or ductwork. Also confirm foundation block and upstairs walls do not obstruct installation. If

wiring to an existing outlet, it is best to select a joist/truss section that contains an electrical outlet for wiring.

DIAGRAM P

ASLL CAN BE OPERATED BY ON/OFF

SWITCH THROUGH FLOOR GRILLE OR IT

CAN BE WIRED INTO A 120 VAC WALL

SWITCH OR THERMOSTAT.

IMPORTANT: IF ASLL OUTER SLEEVE WILL BE

EXPANDED OVER 13”, AIR FLOW LEAKAGE

STICKERS MUST BE APPLIED OVER ELECTRI-

CAL RELIEF SLOT TO PREVENT AIR LEAKAGE.

DIAGRAM N

The following steps must be completed to convert the ASLL from an upflow to a downflow installation.

Remove (1) screw from On/Off switch coverplate. Pull On/Off cover assembly out and remove Blue & Red wires connected to

switch. Turn ASLL over and remove electrical access coverplate from opposite side. Pull Blue & Red wires through and

connect to On/Off switch terminals - Red to center, Blue to other, (See Diagram A1). Reinstall On/Off assembly with (1) screw,

(See Diagram A2). Reinstall electrical access coverplate on opposite side.

Remove (3) screws from blower guard screen, turn ASLL over and and reinstall blower guard screen flush against both outer

edges of ASLL blower housing to prevent contact with moving blower wheel, (See Diagram A3).

FEED ON/OFF SWITCH WIRES THROUGH FROM

OTHER SIDE AND PUSH ON MALE SWITCH TER-

MINALS - RED TO CENTER, BLUE TO OTHER.

INSTALL ON/OFF ASSEMBLY WITH (1) SCREW

REMOVED FROM OTHER SIDE. REINSTALL

ELECTRICAL ACCESS COVERPLATE ON OPPO-

SITE SIDE.

DIAGRAM A1 DIAGRAM A2

INSTALL BLOWER GUARD SCREEN WITH (3)

SCREWS REMOVED FROM OTHER SIDE.

DIAGRAM A3

DIAGRAM O

INSTALL OUTER SLEEVE THROUGH FLOOR.

CAUTION: ELECTRICAL RELIEF SLOT MUST BE

ON SIDE ELECTRICAL ENTERS ASLL OR DAM-

AGE MAY RESULT.

OUTER SLEEVE

ELECTRICAL RELIEF SLOT

THE FOLLOWING STEPS ARE FOR A DOWNFLOW INSTALLATION

APPLY

STICKERS

OVER

RELIEF

SLOT IF

EXPAND

OVER 13”

RELIEF

SLOT

DIAGRAM L

INSTALL (4) SCREWS

IN BLOWER HOUSING

MOUNTING FLANGE

INTO SHEETROCK

MOUNTING BRACKET.

FOR UNFINISHED CEIL-

INGS, SCREW PIECES

OF WOOD CUT FROM

FLOOR OPENING TO

JOIST/TRUSS TO SUP-

PORT ASLL BLOWER.

INSTALL CEILING GRILLE

INTO SHEETROCK

MOUNTING BRACKET

WITH PROVIDED SCREWS.

DIAGRAM M

WIRE PER WIRING

DIAGRAM. INSTALL

ASLL ELECTRICAL

BOX COVER.

DIAGRAM K

PUSH WIRE UP TIGHT AGAINST ASLL BLOWER

HOUSING AND SLIDE UP UNTIL FLUSH WITH

CEILING.

1. Proceed to step 2 if ceiling is unfinished. If ceiling is finished use a stud finder to locate the inside edges of the joist/truss cavity the

ASLL will be installed between. Apply masking tape on ceiling along joist/trusses in the desired location ASLL will be installed in.

Make sure a proper analysis as noted above has taken place before cutting hole in ceiling. In the center of the tape cut a 3” x 3”

inspection hole to review the intended installation area using a flashlight and small mirror if necessary, (See Diagram B1).

NOTE: The following installation illustrations show the upper level floor with carpeting.

2. If floor above has carpeting it may be desirable to pull carpeting back if possible. If it is a good installation area, slowly drill a small

pilot hole with a 1/4” drill bit through the 3” x 3” inspection hole or center of joist/truss up through subfloor. Drill bit might cause car-

pet to unravel so be cautious. Once you go through subfloor reverse out of the hole. Use an extended screw driver or scratch awl

to push through the carpet above.

3. Place ASLL Blower Housing template center alignment hole over drill bit or screw driver. Align template cutout lines parallel with

baseboard and tape template to floor, (See Diagram C1). Use a utility knife and cut out carpeting and pad along Blower Housing

template lines denoted, (See Diagram D1).

4. Drill the 4 corners out on floor with a 3/8” drill bit and saw opening out using a jig saw or reciprocating saw. The final rough-in opening in

the floor for a Downflow application must measure 4 1/16” x 12 5/16” for Blower Housing. IMPORTANT: Rough-in openings must

not exceed dimensions provided or Blower Housing flange may fall through opening, (See Diagram E1).

5. Proceed to step 7 if ceiling below is unfinished. Using a 1/4” long drill bit, follow the corners of the Blower Housing cutout straight down

and drill 4 holes through the ceiling material below, (See Diagram F1). Connect the 4 holes on the ceiling below with a straight edge and

compare the dimensions on the ceiling to Outer Sleeve template dimensions which measure 4 5/16” x 12 5/16”, (See Diagram G1).

6. If ceiling is sheetrock use a sheetrock saw and follow the lines from step 5 and cut out ceiling opening, (See Diagram G1). If ceiling

is not sheetrock, use a jig saw or reciprocating saw. IMPORTANT: Both openings should be directly centered above one another.

7. Supply electrical power to side of ASLL where power will enter unit. See “Wiring” section for wiring specifics. Use provided strain

relief bushing for standard 14-2 w/ground NM-B nonmetallic sheathed cable (Romex) and snap into place in 7/8” knockout on

ASLL electrical box with about 6-8” of wire pushed into ASLL electrical box, (See Diagram H1).

8. Push wire up tight against ASLL Blower Housing and insert the ASLL blower through floor opening until flange meets floor, (See

Diagram I1).

9. If ceiling is sheetrock or ceiling tile, slide sheetrock mounting brackets over sheet rock ends. The 2 large holes in brackets must

face down, (See Diagram J1).

DIAGRAM B1 DIAGRAM C1 DIAGRAM D1

IF CEILING IS FINISHED, PLACE TAPE ALONG

JOIST/TRUSS. CUT A 3” INSPECTION HOLE TO

VERIFY IT IS A GOOD INSTALLATION LOCATION.

FOR A DOWNFLOW APPLICATION CUT OUT

CARPET & ROUGH-IN OPENING USING BLOW-

ER HOUSING TEMPLATE (4 1/16” X 12 5/16”).

DIAGRAM E1

DRILL OUT CORNERS WITH 3/8” DRILL BIT.

IMPORTANT: ROUGH-IN OPENING FOR BLOWER

HOUSING MUST NOT EXCEED 4 1/16” X 12 5/16”.

DIAGRAM F1

IF CEILING BELOW IS FINISHED, DRILL (4) 1/4”

HOLES STRAIGHT DOWN THROUGH CEILING

USING EACH OF THE 4 CORNERS OF BLOWER

HOUSING CUT OUT AS A GUIDE.

PLACE ASLL BLOWER HOUSING TEMPLATE

CENTER ALIGNMENT HOLE OVER DRILL BIT OR

SCREW DRIVER.

DIAGRAM G1

CONNECT (4) HOLES WITH A STRAIGHT EDGE

AND MAKE SURE OUTER SLEEVE DIMENSIONS

MEASURE 4 5/16” X 12 5/16”. CUT OUT OPENING

WITH SHEETROCK OR JIG SAW.

Table of contents

Other TJERNLUND Ventilation Hood manuals

Popular Ventilation Hood manuals by other brands

Gorenje

Gorenje S3 IHGC963S4X manual

KOBE

KOBE ISX2136SQB-1 Installation instructions and operation manual

U.S. Products

U.S. Products ADVANTAGE-100H Information & operating instructions

Kuppersberg

Kuppersberg DUDL 4 LX Technical Passport

Framtid

Framtid HW280 manual

Thermador

Thermador HGEW 36 FS installation manual