ENGLISH

ENGLISH

6

INDEXINDEX

INDEXINDEX

INDEX

Page

POSITION OF SERIAL NUMBERS..................................................... 7

Frame number.................................................................................... 8

Engine number.................................................................................... 8

OPERATING CONTROLS.....................................................................9

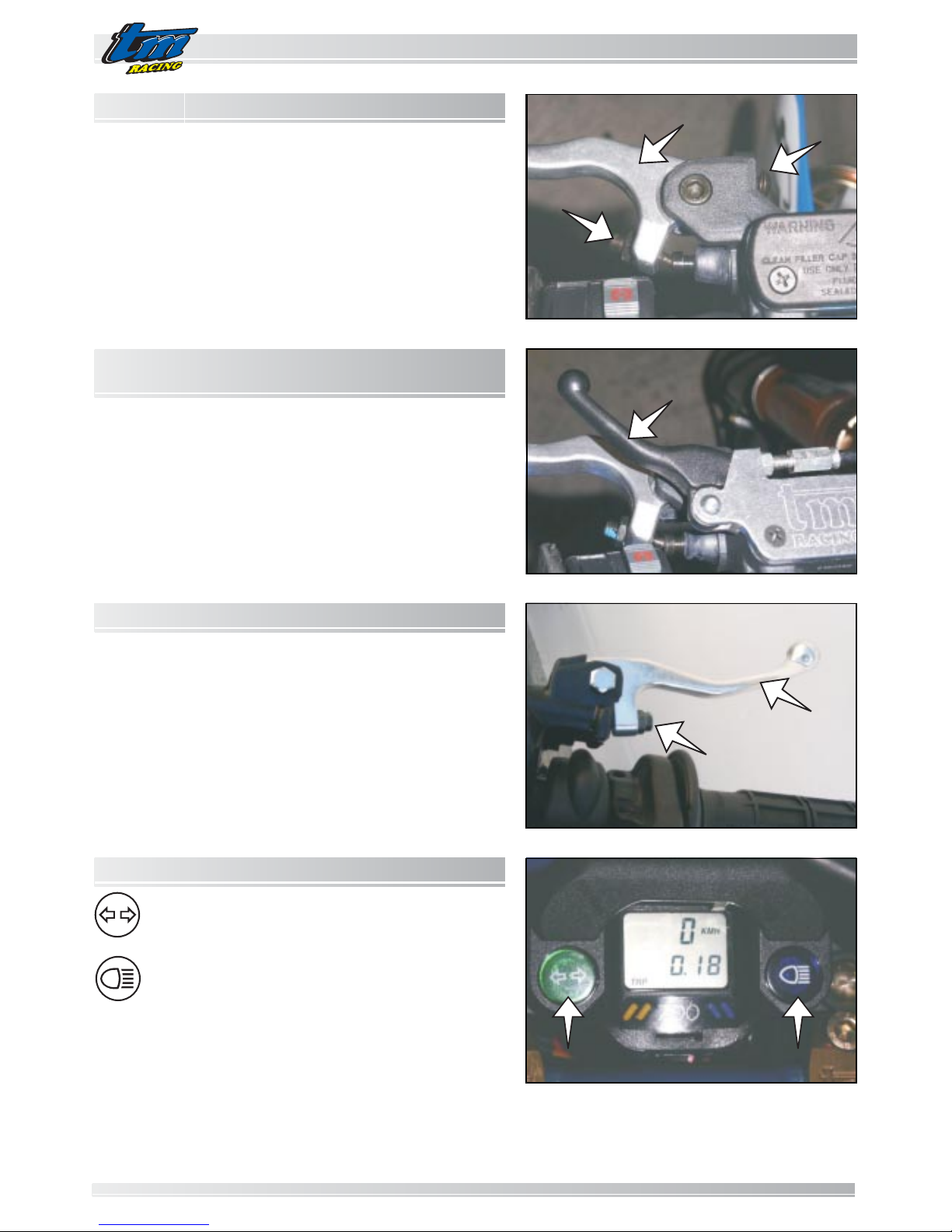

Clutch lever.........................................................................................10

Manual decompressor lever............................................................... 10

Front brake lever................................................................................ 10

Control lights.......................................................................................10

Electronic tachometer ....................................................................... 11

Function selection and reset.............................................................. 11

Programming the electronic tachometer............................................. 11

Programming the clock....................................................................... 12

Setting the distance travelled............................................................. 12

Engine stop switch (MX/SMX).............................................................12

Combinationswitch (END/SMR/SMM)................................................ 12

Start command and emergency stop

(END/MXE.S./SMXE.S./SMR/SMM) ..................................................... 13

Fuel fill cap......................................................................................... 13

Fuel tap.............................................................................................. 13

Throttle command (cold starter)......................................................... 14

“By-Pass” command (warm starter)...................................................14

Idle speed adjustment command.........................................................14

Gear shift pedal .............................................................................. 15

Kickstart pedal................................................................................... 15

Brake pedal ...................................................................................... 15

Side stand.......................................................................................... 15

Fixing for off-the-road journeys.........................................................16

Ignition switch.................................................................................... 16

Fork adjustment in compression........................................................ 16

Fork adjustment in extension..............................................................17

Damper adjustment in compression................................................... 17

Damper adjustment in extension........................................................ 18

Steering lock ..................................................................................... 19

ADVICEANDGENERALRECOMMENDATIONSFOR

COMMISSIONING THE MOTORCYCLE .......................................... 21

Indications for the first start-up..........................................................22

Running in instructions....................................................................... 22

INSTRUCTIONSFORUSE...................................................................23

Pre-ride control.................................................................................. 24

Engine ignition when cold...................................................................25

Engine ignition when warm ............................................................... 25

If engine is “flooded”.......................................................................... 26

Departure............................................................................................26

Changing gear, accelerating, slowing down.......................................26

Braking................................................................................................28

Stoping and parking ........................................................................ 28

Petrol.................................................................................................. 29

LUBRICATIONAND MAINTENANCE PROGRAMME ...................... 31

FRAMEANDENGINE MAINTENANCE ............................................. 37

Control of steering bearings and play adjustment...............................38

Telescopic fork vent screws............................................................. 39

Cleaning of telescopic fork dust scraper........................................... 39

Basic calibration of the chassis on the basis of pilot weight .......... 39

Damper calibration and spring control................................................40

Establishment of damper static lowering........................................... 40

Establishment of damper lowering in running order........................... 40

Control of telescopic fork basic calibration........................................ 41

Variation of telescopic fork pre-load.................................................. 41

Replacement of fork springs...............................................................41

Variation of damper spring pre-load ..................................................42

Rear suspension mechanical linkage................................................. 42

Page

Control chain tension......................................................................... 43

Correction of chain tension (all except SMM) ................................. 43

Correction of chain tension (SMM) ................................................... 44

Chain maintenance............................................................................. 44

Chain wear.........................................................................................45

Basic indications for TM disc brakes................................................. 45

Free play adjustment of the front brake lever......... ...................... 46

Control front brake fluid......................................................................47

Top-up front brake fluid...................................................................... 47

Control front brake pads.....................................................................47

Replacement of front brake pads.......................................................48

Modification of rear brake pedal basic position..................................49

Control rear brake fluid level.............................................................. 49

Top-up rear brake fluid....................................................................... 49

Control rear brake pads......................................................................50

Replacement of rear brake pads........................................................50

Disassembly and assembly of front wheel........................................50

Disassembly and assembly of rear wheel (all except SMM) ......... 51

Disassembly and assembly of rear wheel (SMM)..............................52

Control of spoke tension.....................................................................52

Tyres, tyre pressure.......................................................................... 53

Control/adjustment of magnetic sensor distance................................53

Battery(all models with E.S.) .......................................................... 53

Battery charger...................................................................................54

Recharge fuse (all models with E.S.) ............................................. 55

Services fuse (all models with lights)............................................... 55

Replacement of headlight / position light bulb.................................... 55

Replacement of headlight / position light bulb (with cyclops).............56

Replacement of rear light bulb

positionlight/stop light/numberplate light(END/SMR/SMM) ................56

Replacement of indicator bulb............................................................ 56

Cooling................................................................................................57

Control coolant level........................................................................... 58

Unloading, filling and bleeding of cooling system................................58

Replacement of exhaust silencer filling material.................................58

Cleaning the air filter........................................................................... 59

Control of hand decompressor adjustment........................................ 59

Adjustment of throttle cable command............................................... 60

Adjustment of clutch lever basic position.......................................... 60

Control hydraulic clutch oil level......................................................... 60

Bleeding of hydraulic clutch................................................................60

Carburetor - Adjustment of idle speed............................................... 61

Basic indications regarding wear of the carburetor...........................61

Control fuel level (float height)........................................................... 62

Emptying of carburetor tank............................................................... 62

Oil circuit .................................................................................. 62

Control engine oil level........................................................................63

Engineoil ........................................................................................ 63

Change engine oil ............................................................................ 63

TROUBLESHOOTING......................................................................... 66

CLEANING..........................................................................................68

PRECAUTIONSFOR WINTER USE.................................................... 68

PRESERVATION................................................................................. 68

Start-up after seasonal pause........................................................... 68

TECHNICAL DATA - ENGINE........................................................ 69/70

CARBURETORSETTINGS..................................................................71

ENGINECOUPLINGTORQUES.......................................................... 72

CYCLE PART TECHNICAL DATA .................................................73-74

ALPHABETICAL INDEX......................................................................75

WIRING DIAGRAM................................................................ appendix

INDEXINDEX

INDEXINDEX

INDEX